Conductive silver paste and preparation method and application thereof

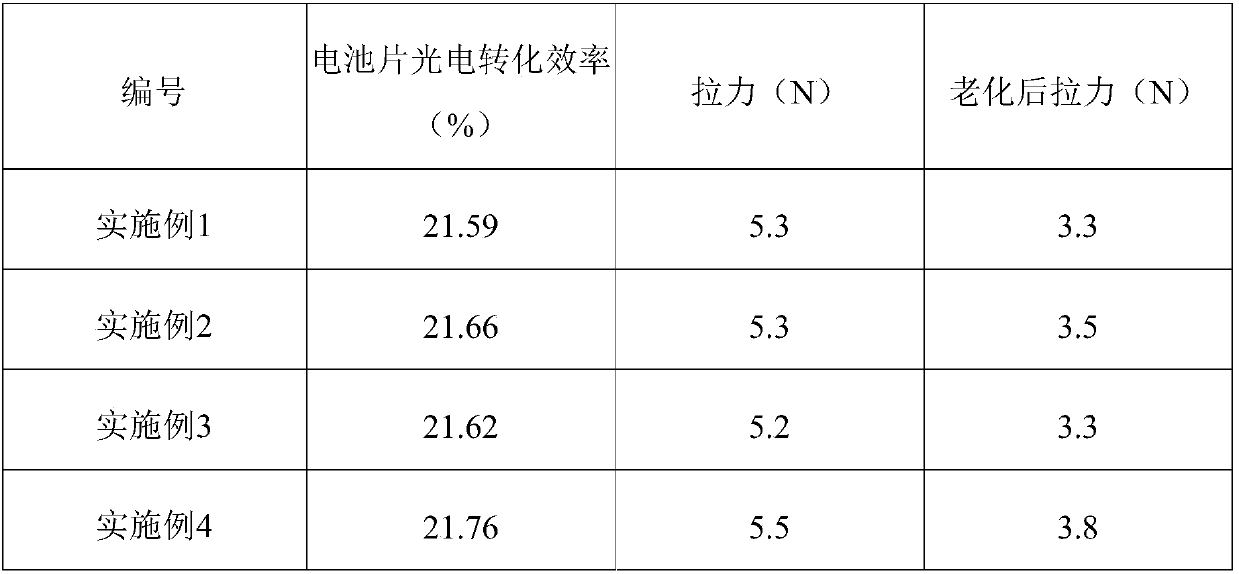

A technology of conductive silver paste and silver powder, which is applied in the field of solar cells, can solve problems such as difficult control, adverse effects of bonding tension, and reduce corrosion in the sintering process, so as to achieve high photoelectric conversion efficiency, good welding tension and aging performance, and adhesion good binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0066] This embodiment provides a conductive silver paste, which is prepared through the following steps.

[0067] Preparation of glass powder composition: raw materials are mixed (45 parts of bismuth oxide, 18 parts of silicon oxide, 20 parts of aluminum oxide, 15 parts of boron oxide, 2 parts of sodium oxide, potassium oxide, magnesium oxide, barium oxide, zinc oxide), and then Perform melting, quenching, grinding, and water washing processes to obtain a glass powder composition;

[0068] Prepare organic vehicle: mix solvent (75 parts of butyl carbitol acetate), cellulose resin (10 parts of ethyl cellulose), additives (4 parts of oleic acid, 3 parts of polypropylene glycol, 8 parts of polyamide wax), get an organic carrier;

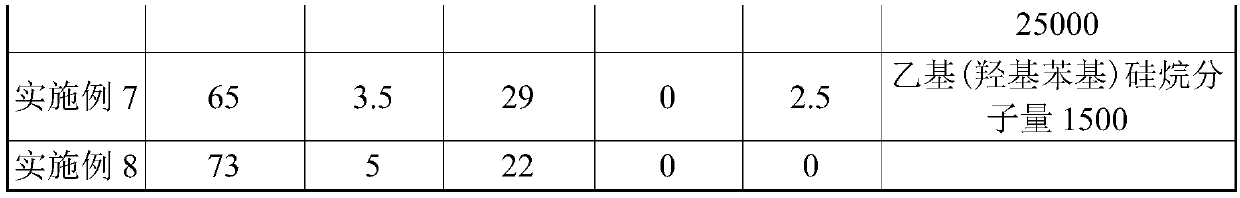

[0069] Prepare conductive silver paste, mix silver powder, glass powder, organic vehicle and organosilicon compound,

[0070] Or, after mixing with the raw materials of the organic carrier when preparing the organic carrier, then mix with other raw ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| tensile load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com