High-tension main grid silver paste applied to N-type solar cell and preparation method thereof

A technology of solar cells and high tensile force, which is applied in the direction of cable/conductor manufacturing, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., and can solve the problem of connection strength between over-welding ribbon and main grid, deformation of battery sheets, and increase in series connection Resistance and other problems, to achieve high photoelectric conversion efficiency, strong welding tension, good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

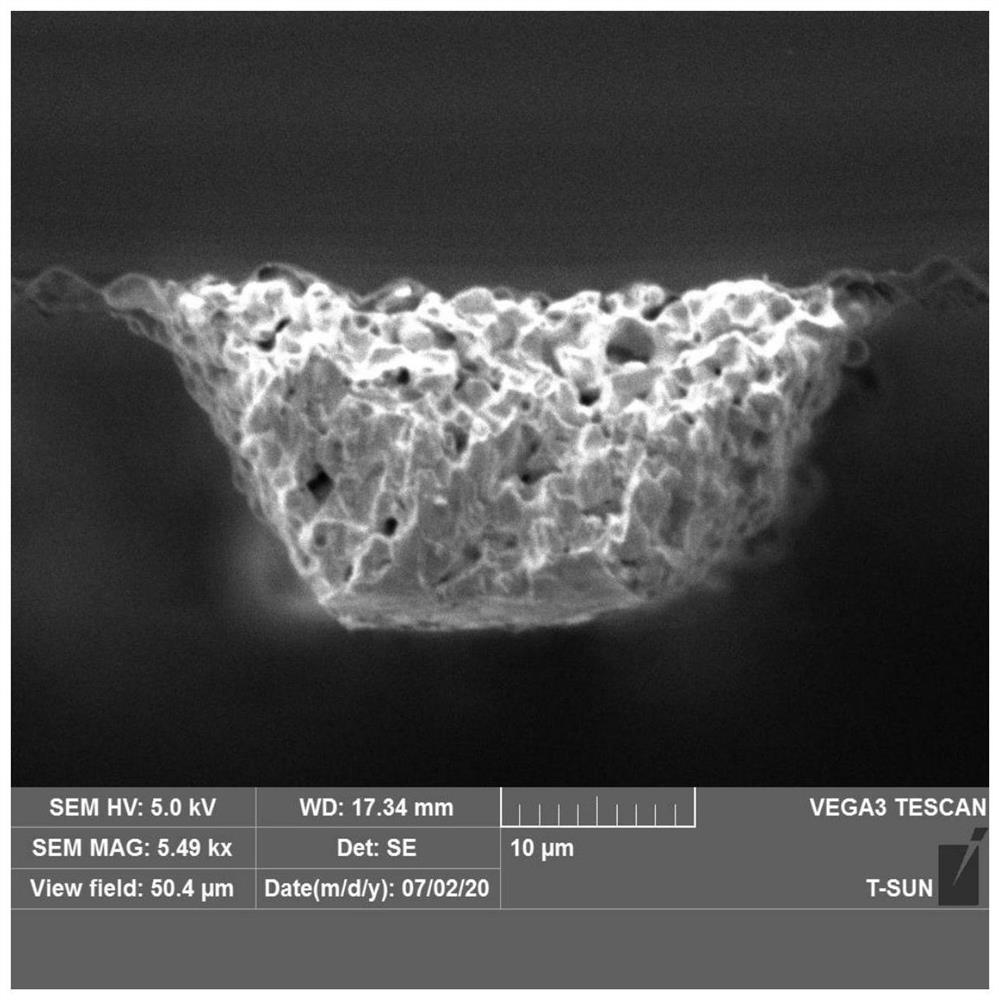

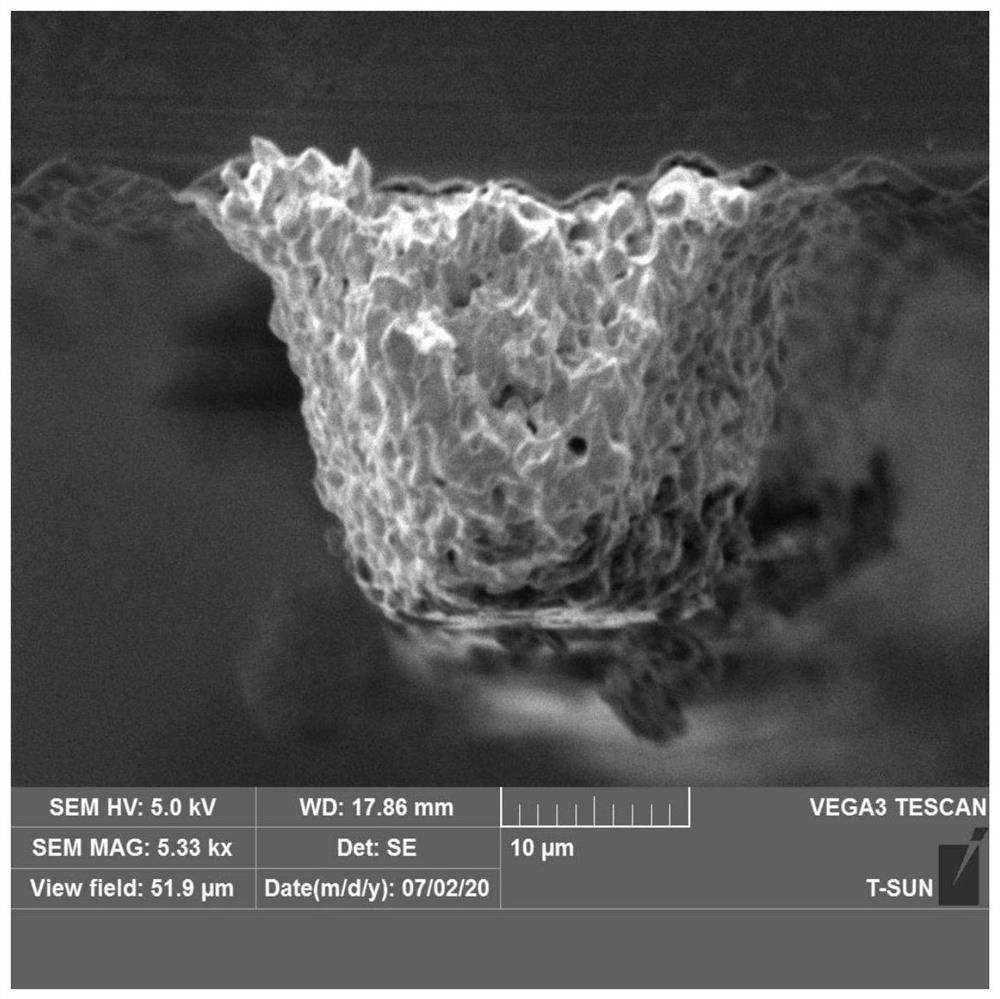

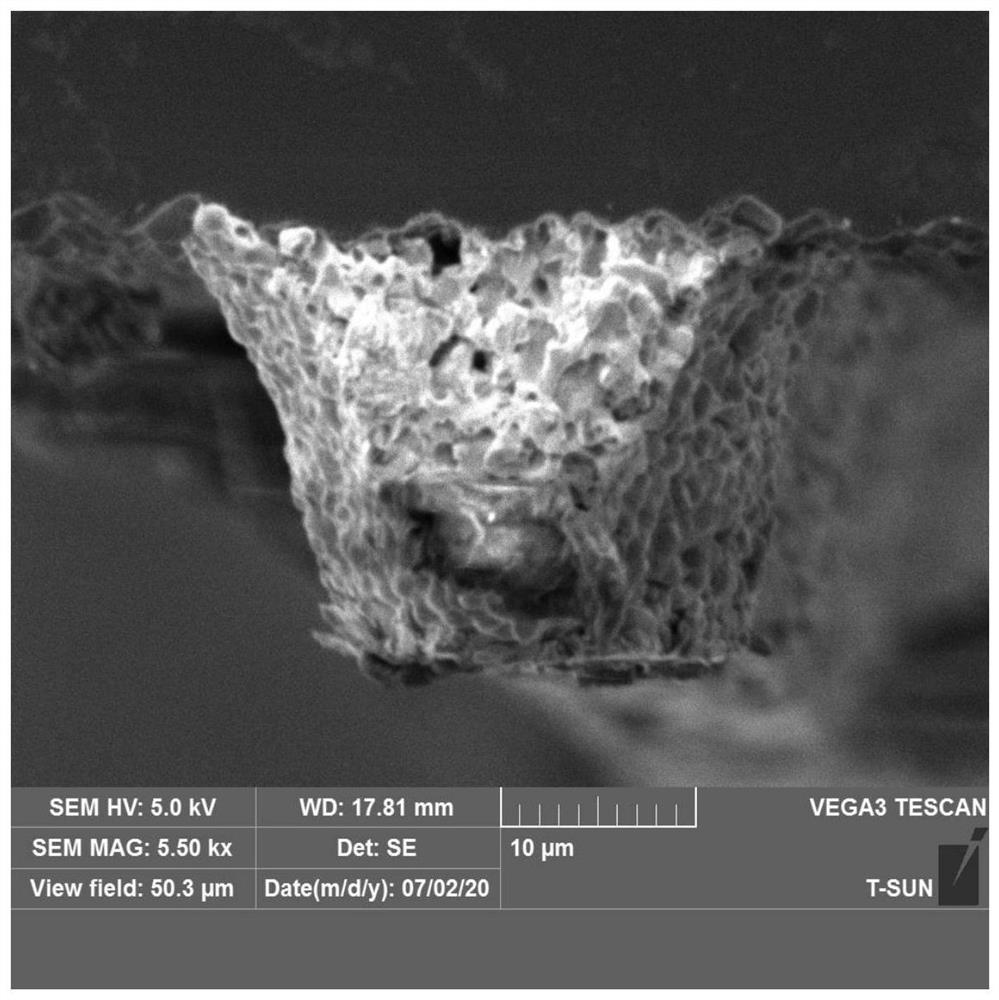

Image

Examples

preparation example Construction

[0048] According to above-mentioned formula, a kind of preparation method of the high tension busbar silver paste that is applied to N-type solar cell of the present invention comprises the following steps:

[0049] Step 1: Accurately weigh the weight of each component with an analytical balance, add the organic carrier and glass powder into a centrifuge tube and mix evenly, then put the centrifuge tube into a centrifuge and centrifuge for 1-3 times to prepare a glass slurry. The rotational speed of the centrifuge is 800-1200rmp, and the centrifugation time is 3-7min. Firstly, the glass slurry is prepared to realize the dispersion of the nanometer system, so that the dispersion of the system is more uniform.

[0050] Step 2: Put the glass paste prepared in Step 1 into a three-roll machine for three-roll grinding treatment. The distance between the rolls of the three-roll machine is 5-40 μm, and the speed of the three-roll machine is 100-200 rpm. There are three rollers in the ...

Embodiment 1

[0055] A kind of high-tensile busbar silver paste applied to N-type solar cells of the present invention comprises the following components:

[0056] 87.5wt% silver powder: the weight ratio of spherical silver powder A to spherical silver powder B is 7:3, the median particle size of spherical silver powder A is 800nm, the tap density is 5.5g / mL, and the median particle size of spherical silver powder B is The diameter is 365nm, and the tap density is 4.5g / mL.

[0057] 10wt% organic vehicle: the quality of the organic vehicle is 100%, and the organic vehicle of the present invention contains 10wt% resin (polyvinyl butyral ester resin: acrylic resin: ethyl cellulose resin=3:6:1 ), 82.5wt% organic solvent (alcohol fat twelve: terpineol: tributyl citrate=20:30:32.5) and 7.5wt% organic auxiliary agent (leveling agent: thixotropic agent: defoamer= 2:2:3.5), wherein the molecular weight of polyvinyl butyral resin of the present invention is 25000, the molecular weight of acrylic res...

Embodiment 2

[0064] A kind of high-tensile busbar silver paste applied to N-type solar cells of the present invention comprises the following components:

[0065] 80wt% silver powder: wherein the weight ratio of spherical silver powder A to spherical silver powder B is 17:3, the median diameter of spherical silver powder A is 900nm, the tap density is 6g / mL, and the median diameter of spherical silver powder B is 450nm, the tap density is 5g / mL.

[0066] 15wt% organic vehicle: the quality of the organic vehicle is 100%, and the organic vehicle of the present invention contains 10wt% resin (polyvinyl butyral ester resin: acrylic resin: rosin resin=4:5:1), 85wt% % organic solvent (alcohol fat twelve: terpineol: tributyl citrate: butyl carbitol acetate=4:4:4:5) and 5wt% organic additive (leveling agent: thixotropic agent : defoamer: drier: dispersant=1:1:1:1:1), wherein the molecular weight of polyvinyl butyral ester resin of the present invention is 40000, the molecular weight of acrylic re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com