Glass material for high-sheet-resistance shallow crystallized silicon solar cell as well as preparation method and slurry thereof

A solar cell and glass frit technology, applied to conductive materials dispersed in non-conductive inorganic materials, circuits, photovoltaic power generation, etc., can solve the problems of high loss, reduced electrode shading area, and large shading loss, etc., to improve contact resistance , Improve welding tension and good wetting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

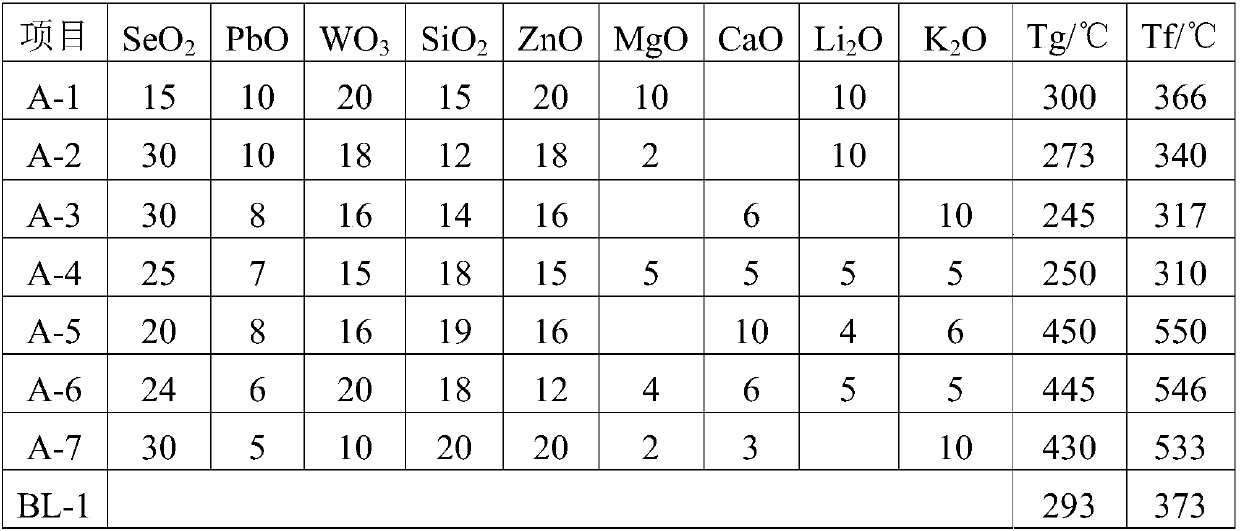

[0021] A glass frit for high square resistance shallow crystalline silicon solar cells, the raw materials of each component are shown in Table 1, using mass percentage, the preparation steps are: use a muffle furnace to melt the glass raw materials at 1300 ° C for 1 hour, fully homogenize After melting, the quenching process of glass is carried out by water quenching method, and the glass is ball-milled with a planetary ball mill to obtain powdered glass frit with a suitable particle size. The particle size distribution of the obtained glass frit is D50≤5μm, wherein, A-1~A -7 is the experimental group, and BL-1 is the control group, which is a commercially available glass powder.

[0022] Table I

[0023]

Embodiment 2

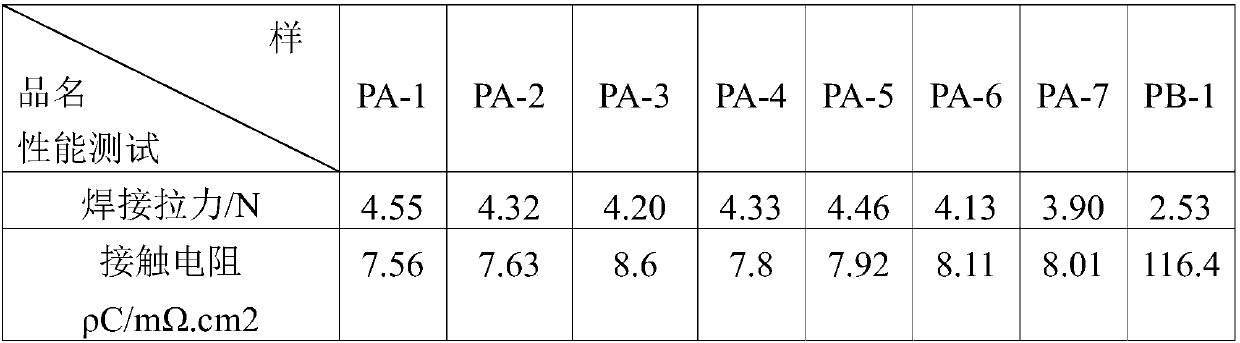

[0025] Prepare PA-1~PA-7 and PB-1 silver paste coatings with the glass frits prepared by the above-mentioned A-1~A-7 experimental groups and the glass frits purchased by the BL-1 control group respectively according to the following methods. The prepared silver paste was subjected to the next performance test.

Embodiment 2-1

[0027] Fully mix 86.5wt% conductive silver powder, 2.5wt% A-1 glass frit, and 11wt% organic medium, use a three-roll mill to grind the slurry, and use a scraper fineness agent to test the grinding fineness, slurry The grinding fineness of the slurry is below 10μm, and the prepared slurry is named PA-1.

[0028] Wherein, the organic medium is a mixture of ethyl cellulose, wood rosin, dibutyl phthalate, and butyl carbitol acetate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com