Monocrystalline silicon wafer with grooves in surface, heterojunction solar cell and preparation method

A technology of monocrystalline silicon wafers and solar cells, applied in circuits, electrical components, photovoltaic power generation, etc., can solve problems such as large series resistance, high light shading, and large silver paste consumption, so as to increase speed, reduce shading area, The effect of reducing the requirements of bonding ability and setting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The present invention also provides a method of preparing a single crystal silicon wafer having a groove as described in any of the above, comprising the steps of:

[0056] S1: According to the preset graphics, the laser etching process is applied to the front side of the single crystal silicon wafer and the back surface, respectively, such as the graphics of the front gate line of the solar cell and the back gate line. The front and back surface of the crystalline silicon wafer erates a groove having a certain depth and width, depending on the width of the groove, the number of grooves and the number of gate lines may or inconsistent, such as if the groove width is narrow, one The gate line can correspond to a groove of two and more, and the number of grooves is larger than the number of gate lines;

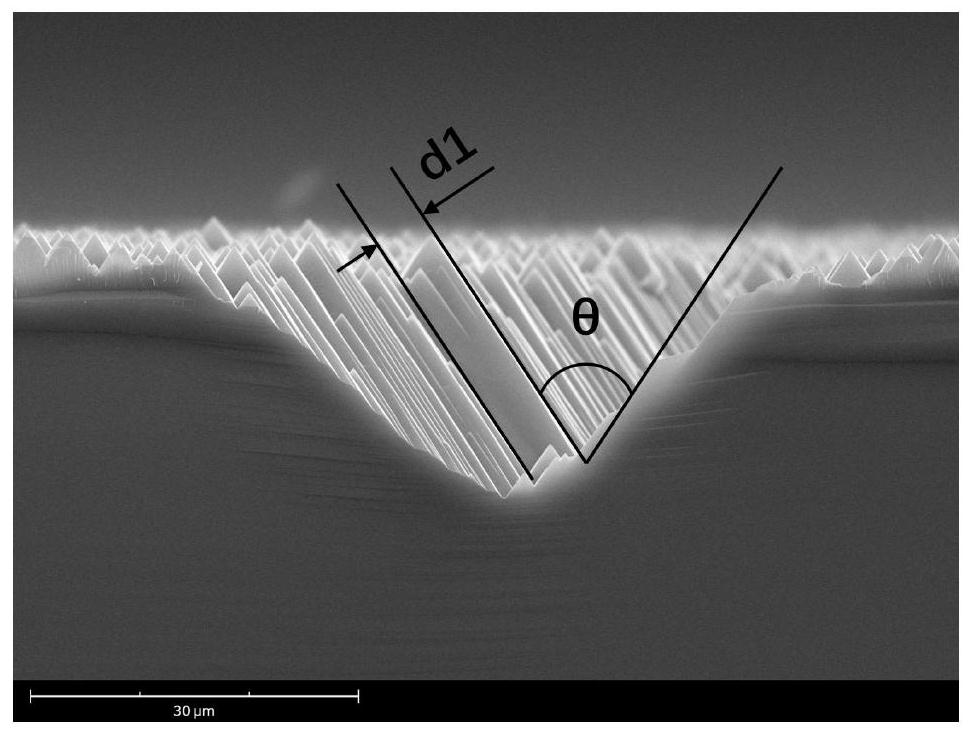

[0057] S2: Corrosion wafer in the alkaline solution, so that the groove width of the laser-etched, the inner surface and the surface of the groove becomes more flat, the alka...

Embodiment 1

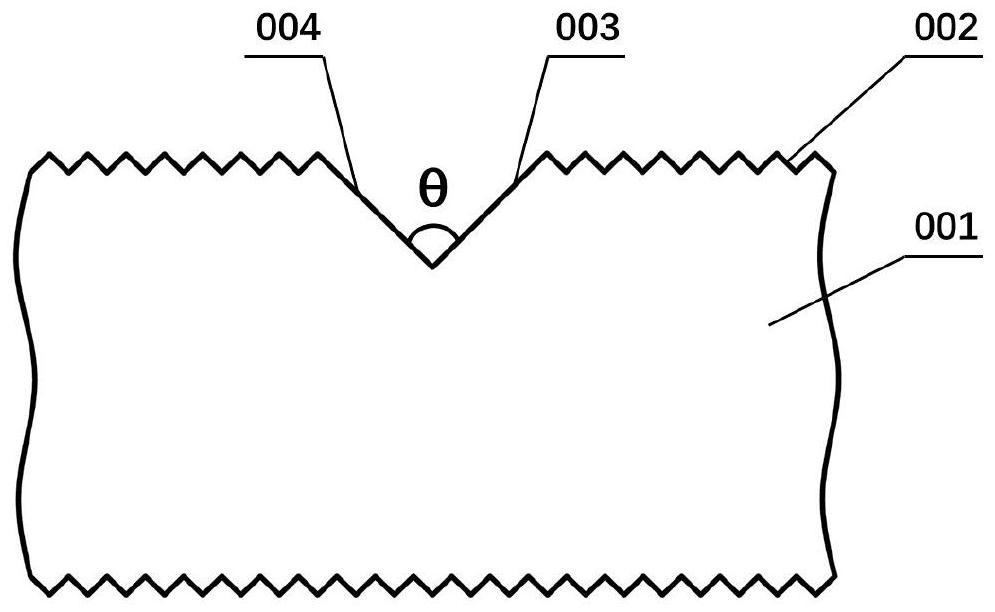

[0070] This example is used to prepare a single crystal silicon wafer having a groove provided by the first surface provided by the present invention (eg figure 1 ),Specific steps are as follows:

[0071] (1) Laser split groove: According to the battery grid line pattern, the front and back surface of the single crystal silicon wafer, respectively, the groove depth is 16 μm, the groove width is 15 μm, and the front gate line pattern is like Figure 13 As shown, the back gate line pattern is like Figure 14 Indicated;

[0072] (2) Ozone cleaning: Wash the silicon sheet in the mixed solution of ozone and hydrofluoric acid, the ozone concentration is 30 ppm, the mass fraction of hydrofluoric acid is 1%, the temperature is 25 ° C, the time is 3 min, then rinsing in pure water Silicon film 2min;

[0073] (3) Alkali polishing: Corrosion wafer in KOH solution, the mass fraction of KOH is 7%, the temperature is 80 ° C, then the time is 3 min, then rinsing the silicon wafer in pure water 2mi...

Embodiment 2

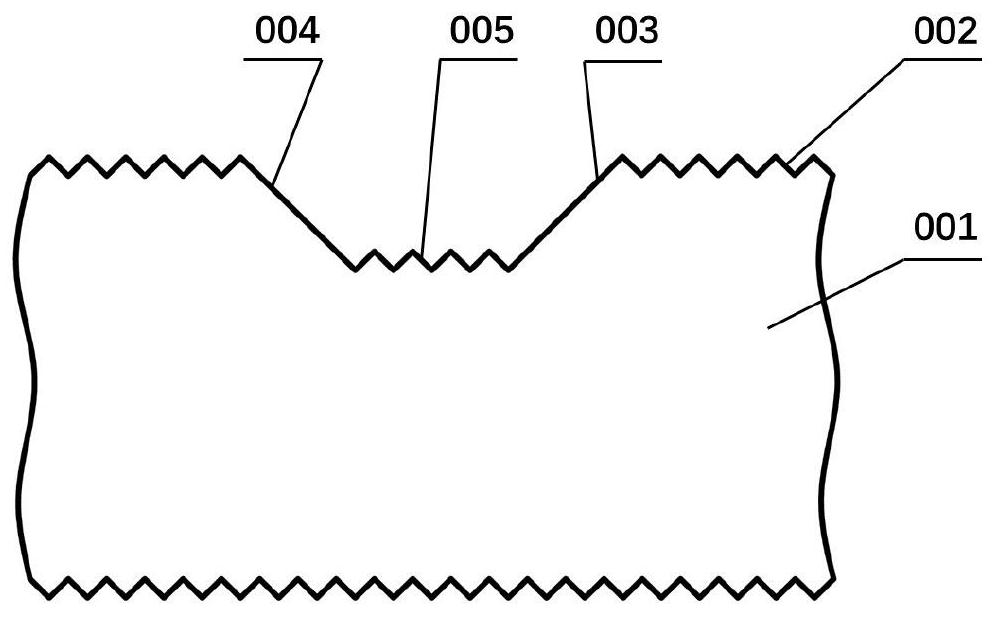

[0090] This example is used to prepare a single crystal silicon wafer having a groove provided by the second surface provided by the present invention, and the specific steps are as follows:

[0091] (1) Laser splitting: according to the battery grid line pattern, the laser etching groove is applied to the back surface, respectively, the groove depth is 16 μm, the groove width is 15 μm; the front gate line pattern is like Figure 13 , Back gate line graphic Figure 14 Indicated;

[0092] (2) Ozone cleaning: Wash the silicon sheet in the mixed solution of ozone and hydrofluoric acid, the ozone concentration is 30 ppm, the mass fraction of hydrofluoric acid is 1%, the temperature is 25 ° C, the time is 3 min, then rinsing in pure water Silicon film 2min;

[0093] (3) Alkali polishing: Corrosion silicon wafers in KOH solution, the mass fraction of KOH is 7%, the temperature is 80 ° C, the time is 6 min, then the wafer is rinsed in pure water 2min; the alkali polished recess Section of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com