Production process of PVC decorative film

A production process and decorative film technology, applied in the production process of PVC decorative film, can solve the problems of performance degradation, unsuitable for electrical package use, physical and mechanical performance degradation, etc., to achieve enhanced migration resistance and thermal stability, excellent UV resistance Irradiability, effect of increasing UV resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A production process of PVC decorative film, comprising the following steps:

[0028] S1 raw material preparation, including the following components by mass, 100 parts of PVC resin, 5 parts of epoxidized soybean oil, 9 parts of triglyceride trimellitate, and 3 parts of organic tin stabilizer;

[0029] S2 The above-mentioned raw materials are weighed according to the mass fraction, the PVC resin is preheated to 50℃~90℃, epoxidized soybean oil and organic tin stabilizer are added, the temperature is raised to 130℃~160℃ and stirred, and then triglyceride trimellitate is added to react to obtain a polymer melt;

[0030] In S3, the polymer melt prepared in S2 is added to the extruder under the condition of 160 ℃~180 ℃ for extruding, and is calendered by a calender to obtain a PVC sheet;

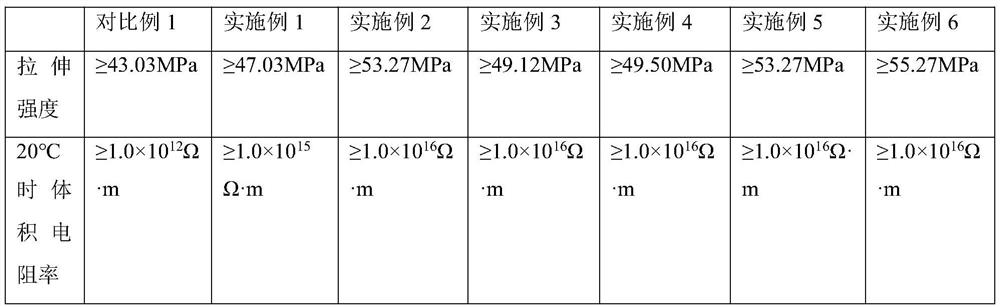

[0031] In S4, the PVC sheet prepared in S3 is injected by an injection molding machine, and then cooled in a pure water pool and then wound up to obtain a PVC decorative film. After testi...

Embodiment 2

[0033] A production process of PVC decorative film, comprising the following steps:

[0034] S1 raw material preparation, including the following components by mass, 100 parts of PVC resin, 5 parts of epoxidized soybean oil, 9 parts of triglyceride trimellitate, 3 parts of organic tin stabilizer, 1 part of barium stearate and hard Zinc fatty acid 0.5 part;

[0035] S2 The above-mentioned raw materials are weighed according to the mass fraction, the PVC resin is preheated to 50℃~90℃, epoxidized soybean oil and organotin stabilizer are added, the temperature is raised to 130℃~160℃ and stirred, and then triglyceride trimellitate is added, Add barium stearate and zinc stearate to react to obtain polymer melt;

[0036] In S3, the polymer melt prepared in S2 is added to the extruder under the condition of 160 ℃~180 ℃ for extruding, and is calendered by a calender to obtain a PVC sheet;

[0037] S4 injects the PVC sheet prepared in S3 with an injection molding machine, and then coo...

Embodiment 3

[0039] A production process of PVC decorative film, comprising the following steps:

[0040] S1 raw material preparation, including the following components by mass, 100 parts of PVC resin, 5 parts of epoxidized soybean oil, 9 parts of triglyceride trimellitate, and 3 parts of organic tin stabilizer;

[0041] S2' The above raw materials are weighed by mass fraction, the PVC resin is preheated to 70°C, epoxidized soybean oil and organotin stabilizer are added, and after stirring for 5 to 10 minutes, the temperature is raised to 130°C to 160°C and stirred, and then three trimellitic acid is added. Glycerides are reacted to obtain polymer melts;

[0042] S3, adding the polymer melt prepared in S2 into the extruder under the condition of 160 ℃~180 ℃ and extruding, and calendering and forming by a calender to obtain a PVC sheet;

[0043] S4 injects the PVC sheet prepared in S3 with an injection molding machine, and then cools it in a pure water pool and then winds it up to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com