Method for preparing plasticizer

A technology of plasticizer and end-capping agent, applied in the field of plasticizer preparation, can solve the problems of softening and sticking of polymer, loss of plasticizer effect, reduction of polymer performance, etc., and achieves good plasticizing and toughening effect, Improves extraction resistance and reduces volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a method for preparing a plasticizer, comprising the following steps: A) heating nylon acid, diol and end-capping agent to 120°C to 200°C in a protective atmosphere to react to obtain an intermediate product. B) reacting the intermediate product at 180° C. to 260° C. and 5 Pa to 200 Pa to obtain a plasticizer.

[0024] Wherein, the step A is the esterification reaction of nylon acid and glycol, specifically: in a protective atmosphere, the temperature of nylon acid, glycol and end-capping agent is raised to 120°C~200°C, preferably 140°C~180°C , to obtain intermediate products. The protective atmosphere is a protective gas well known to those skilled in the art, preferably nitrogen, helium or argon, more preferably nitrogen. The reaction temperature of step A is relatively high and needs to be carried out in a protective atmosphere, otherwise side reactions such as oxidation and carbonization will occur, resulting in an increase in impurities in t...

Embodiment 1

[0041] 1.1 Add 2500g of nylon acid with an average molecular weight of 131g / mol, 1653g of 1,2-propanediol and 125g of activated carbon into the reactor. Under the protection of nitrogen, heat up to 100°C, stir for 12 hours, and filter while hot to obtain light-colored first intermediate product.

[0042] 1.2 Add 1523g of the first intermediate product obtained in 1.1, 68g of isooctyl alcohol and 5.3g of n-tetrabutyl titanate into the reaction kettle. Under the protection of nitrogen, raise the temperature to 140°C, stir and react for 4 hours, then raise the temperature to 200°C , Polycondensation reaction was carried out at 60pa, and nylon acid polyester plasticizer was obtained after 2h, which was a light yellow transparent viscous liquid.

[0043] The nylon acid polyester plasticizer obtained in 1.2 was analyzed by gel permeation chromatography, and its weight average molecular weight was 4100, and its molecular weight distribution index was 2.3.

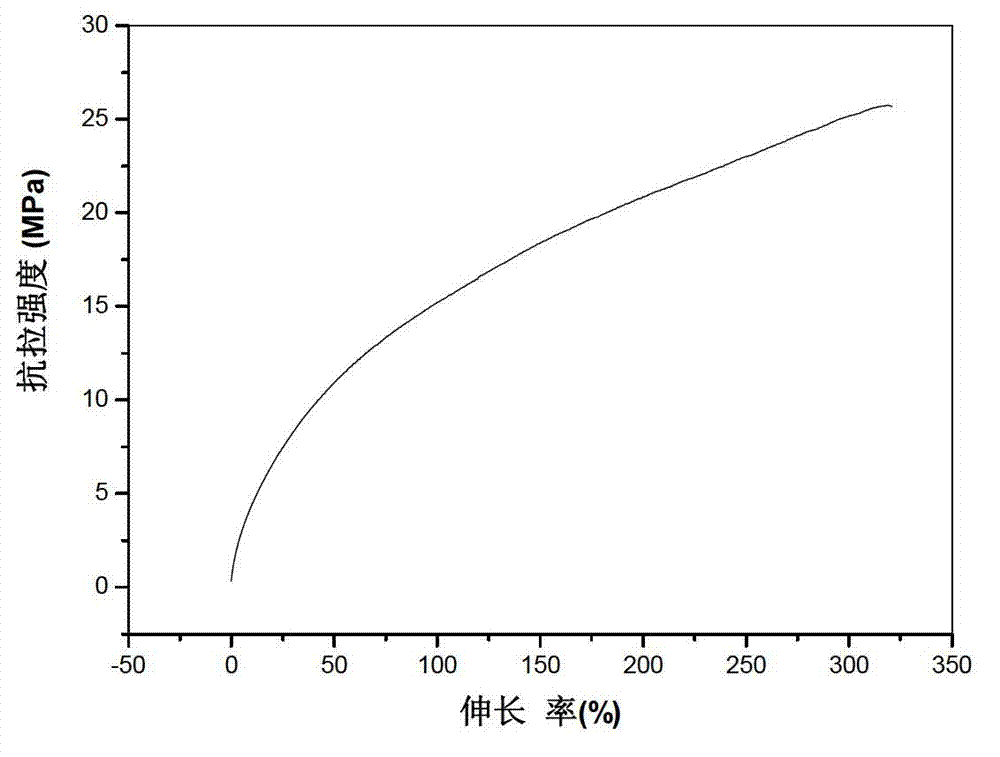

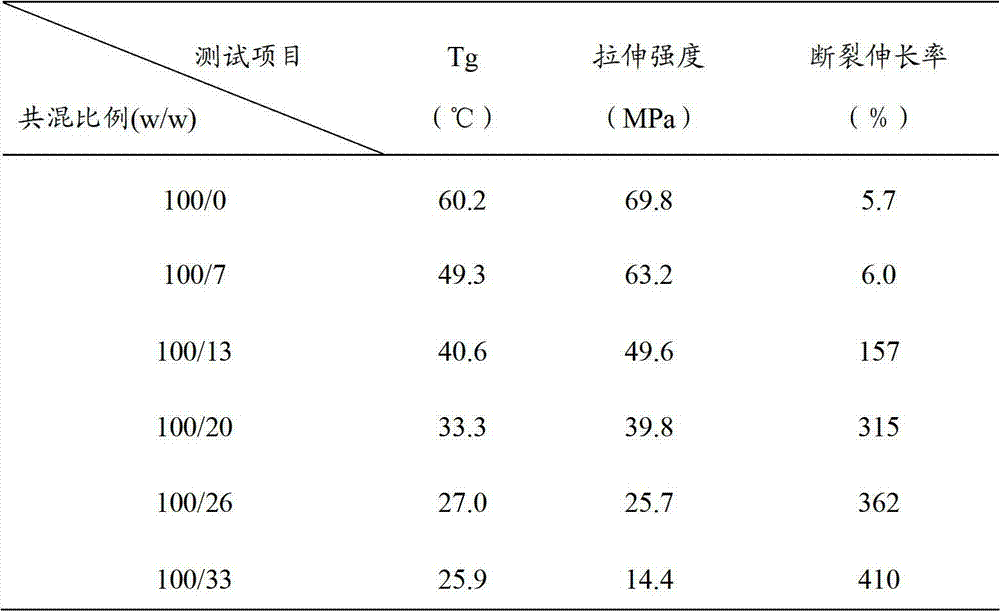

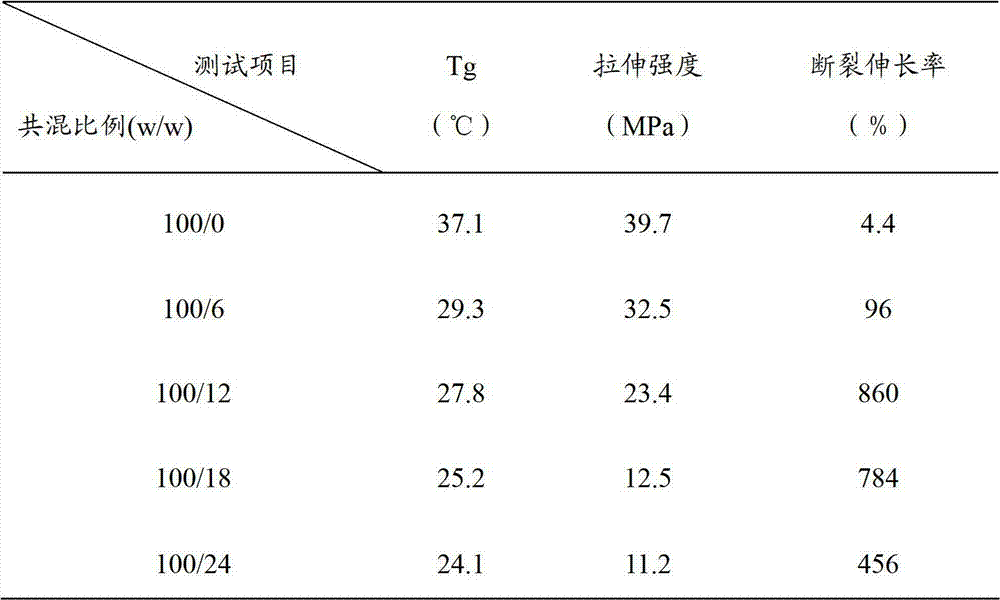

[0044] The nylon acid pol...

Embodiment 2

[0054] 2.1 Add 2500g of nylon acid with an average molecular weight of 131g / mol, 2306g of diethylene glycol and 125g of activated carbon into the reactor. Under the protection of nitrogen, heat up to 120°C, stir for 12 hours, and filter while hot to obtain light-colored No. an intermediate product.

[0055] 2.2 Add 1762g of the first intermediate product obtained in 2.1, 68g of isooctyl alcohol, 3.1g of antimony trioxide and 3.1g of zinc acetate into the reaction kettle, and raise the temperature to 140°C under nitrogen protection, and stir for 4 hours. Raise the temperature to 200°C, carry out the polycondensation reaction at 60 Pa, and obtain the nylon acid polyester plasticizer in the form of light yellow viscous liquid after 6 hours.

[0056] The nylon acid polyester plasticizer obtained in 2.2 was analyzed by gel permeation chromatography, and its weight average molecular weight was 19800, and its molecular weight distribution index was 2.7.

[0057] The nylon acid polye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com