Patents

Literature

73 results about "Methylhexahydrophthalic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methylhexahydrophthalic anhydride is a cyclic dicarboxylic anhydride that is the cyclic anhydride of methylhexahydrophthalic acid. It has a role as an allergen and a curing agent.

Electric-insulation epoxy resin castable for outdoor mutual inductor

ActiveCN103709608AExcellent physical and chemical propertiesHeat resistantPlastic/resin/waxes insulatorsPolymer scienceFirming agent

The invention relates to an electric-insulation epoxy resin castable for an outdoor mutual inductor. The epoxy resin castable comprises the following materials by weight percent: 21-26% of resin, 45-55% of filling, 15-25% of a curing agent and 2-6% of other auxiliary agents, wherein the resin is formed by mixing organic silicon modified epoxy resin, phenolic aldehyde epoxy resin, brominated epoxy resin and bisphenol F-type epoxy resin; the filling is silane-processed silica powder; the curing agent is modified methylhexahydrophthalic anhydride; the other auxiliary agents include a curing catalyst, a plasticizer, a reactive diluent, a silane coupling agent, a coloring agent and an antioxidant. The electric-insulation epoxy resin castable has excellent physical and chemical properties and has the performance of heat resistance, low temperature resistance, ultraviolet irradiation resistance, ageing resistance and the like. The electric-insulation epoxy resin castable is applicable to the electric insulation of the outdoor mutual inductor and other electrical equipment.

Owner:JIANGXI TENGDE IND

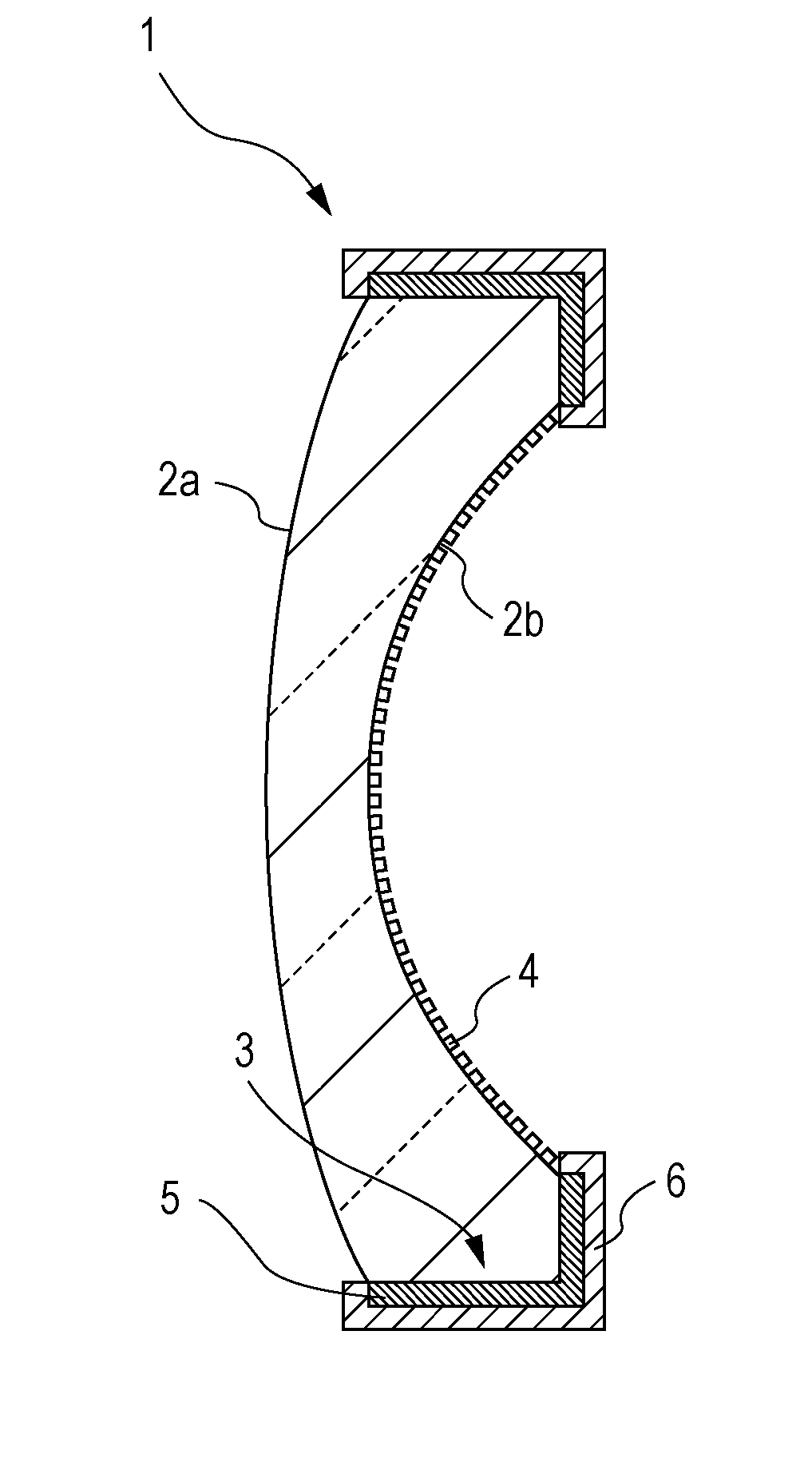

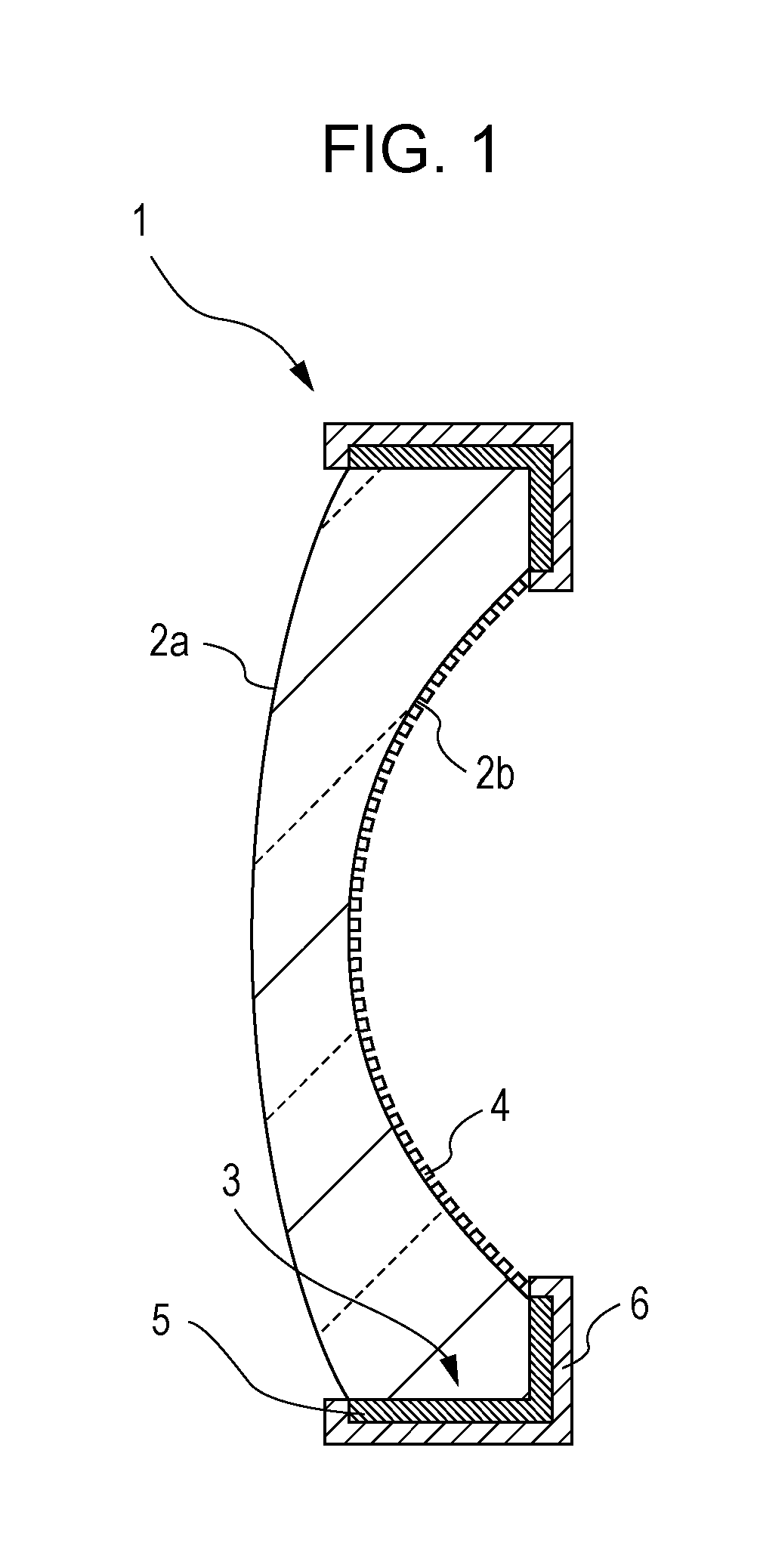

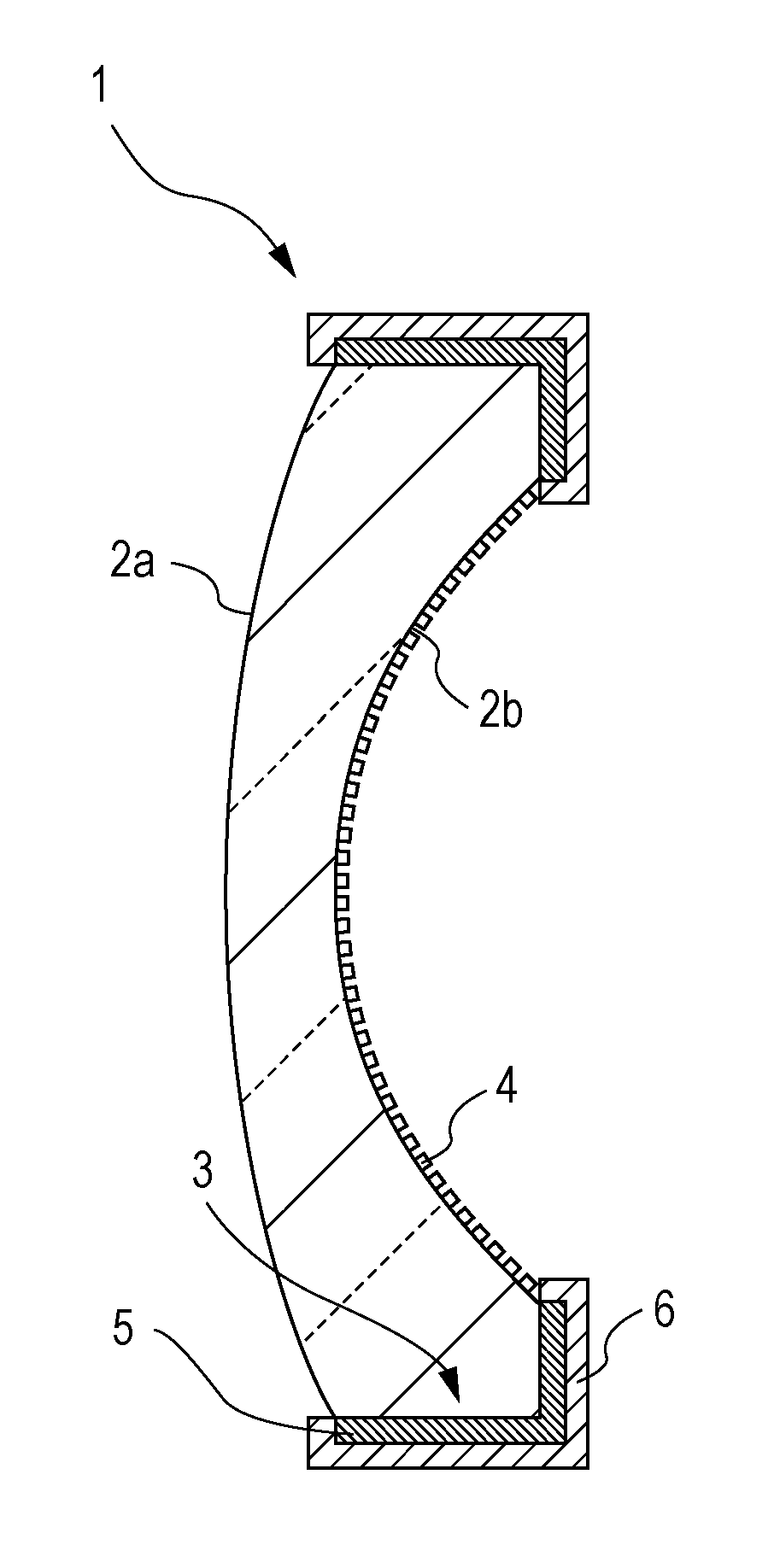

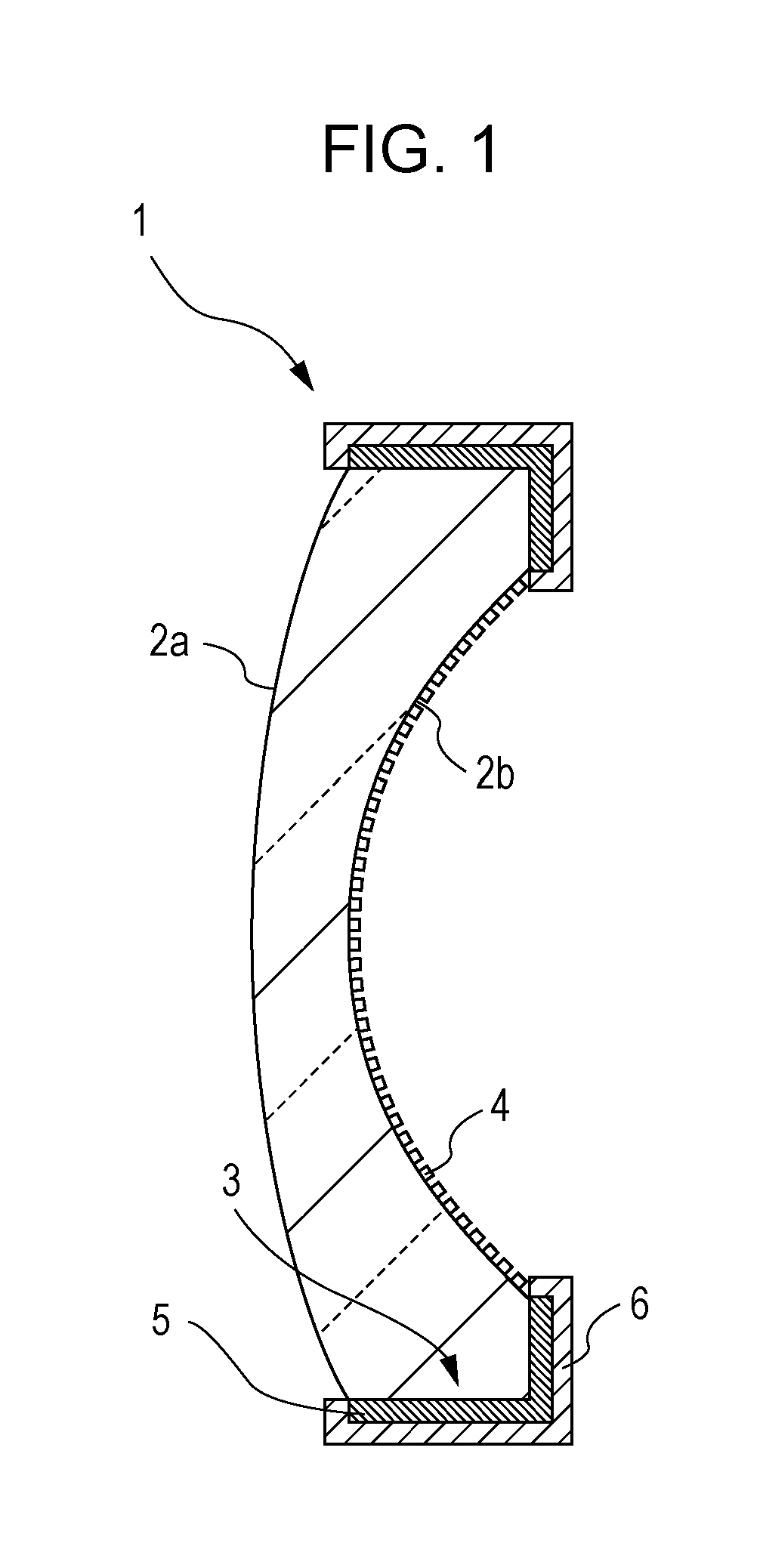

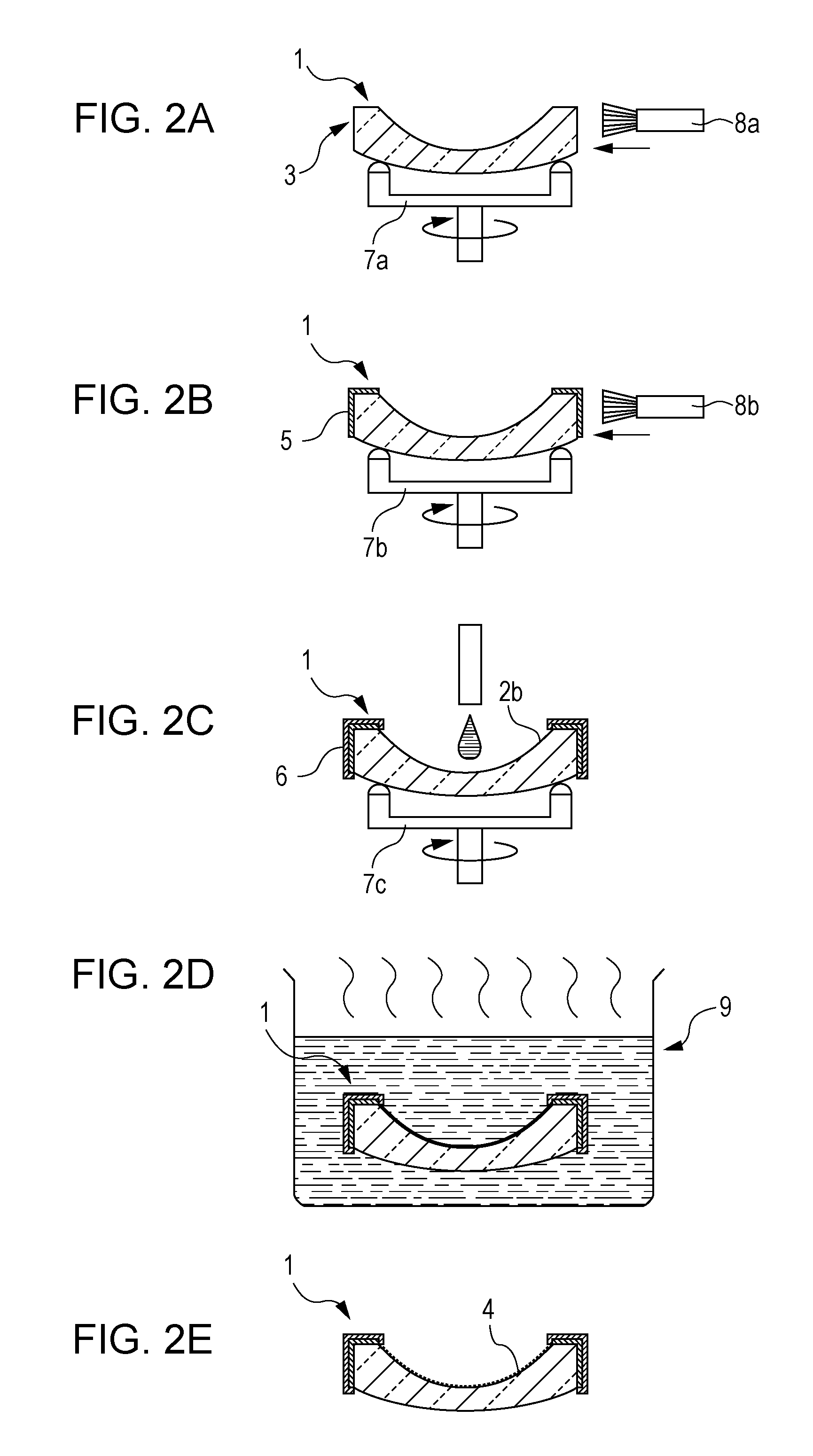

Optical element, method of manufacturing optical element, and imaging optical system

InactiveUS20110176216A1Increase flexibilityIncrease resistanceSpecial surfacesCoatingsHexahydrophthalic anhydrideMethylhexahydrophthalic acid

An optical element includes an optically effective area and an optically ineffective area partly or entirely coated with a coating opaque at wavelengths used. The opaque coating contains a cured product prepared from an epoxy resin and a curing agent containing an alicyclic acid anhydride. The alicyclic acid anhydride is preferably methylhexahydrophthalic anhydride or hexahydrophthalic anhydride.

Owner:CANON KK

Liquid epoxy resin composition for packaging LED (Light Emitting Diode)

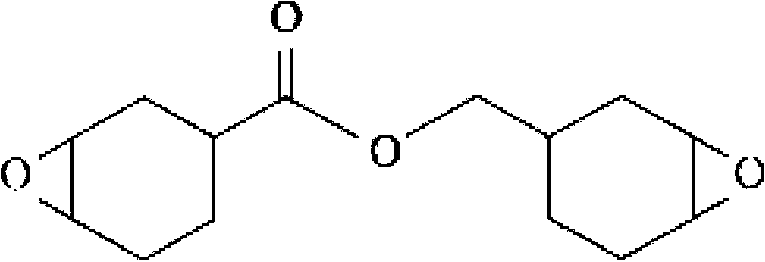

InactiveCN102702682AGood flexibilityImprove crack resistanceSemiconductor devicesCrack resistanceHexahydrophthalic anhydride

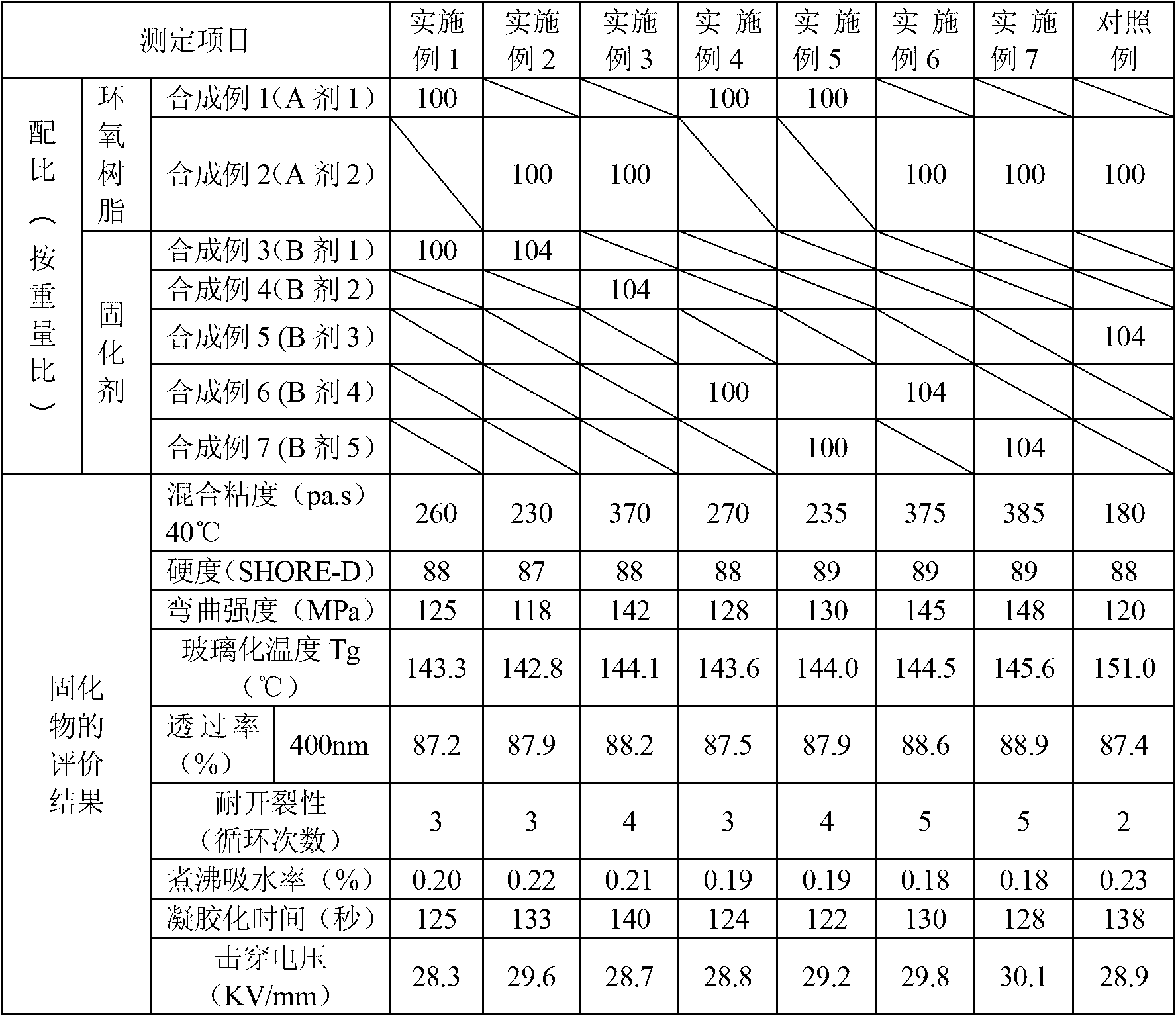

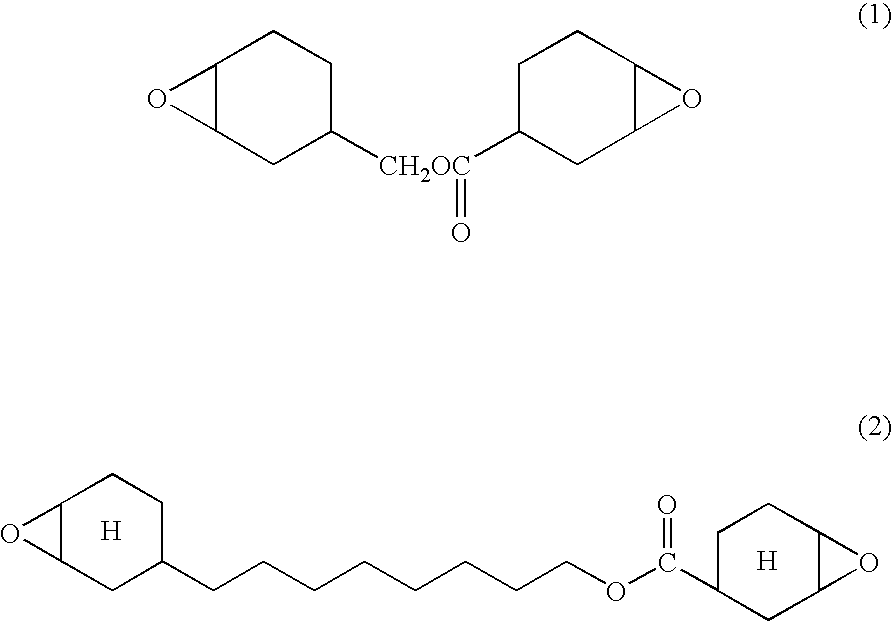

The invention discloses a liquid epoxy resin composition for packaging an LED (Light Emitting Diode). The liquid epoxy resin composition consists of an agent A and an agent B, wherein the agent A comprises 97-99 percent by weight of epoxy resin composition and 1-3 percent by weight of defoaming agent; the agent B comprises 94-97 percent by weight of alicyclic anhydride, 0.02-0.1 percent by weight of antioxidant, 0.02-0.1 percent by weight of ultraviolet absorber, 2-5 percent by weight of toughening modifier and 0.5-1.5 percent by weight of accelerator; and the weight ratio of the agent A to the agent B is 100:(100-105). The epoxy resin composition in the agent A is bisphenol-A epoxy resin and 3,4-epoxy cyclohexylmethyl and 3,4-epoxycyclohexyl carboxylate; and the alicyclic anhydride in the agent B is at least one of methyl tetrahydrophthalic anhydride, methyl hexahydrophthalic anhydride and hexahydrophthalic anhydride; and the toughening modifier is neopentyl glycol. The neopentyl glycol has a structure of a branched chain, so that the flexibility and the cracking resistance of the cured epoxy resin are remarkably improved.

Owner:JIAXING JIAGANG SYNTHETIC MATERIALS

Curable resin composition for encapsulating optical semiconductor and cured product thereof

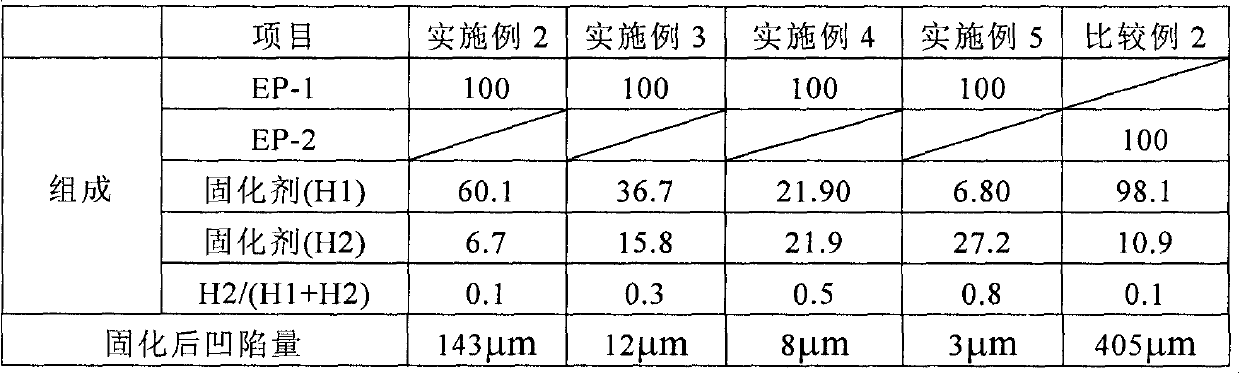

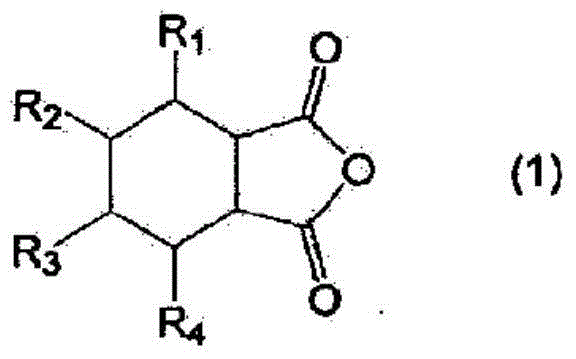

InactiveCN101942073AAvoid dentsExcellent resistance to corrosive gasesSolid-state devicesEpoxy resin adhesivesEpoxyHydrogen atom

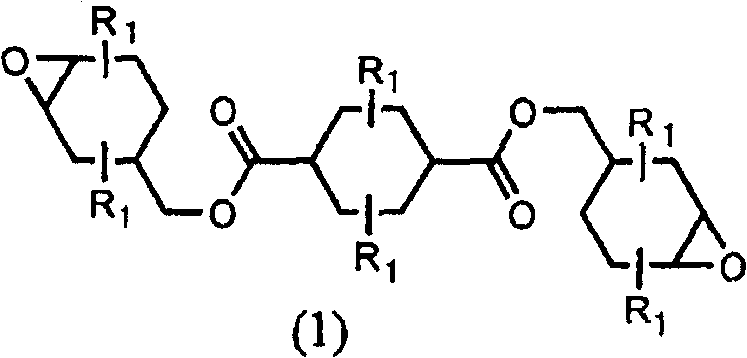

The invention aims to provide a curable resin composition for encapsulating an optical semiconductor and a cured product thereof, which can prevent sinking after curing and have excellent property of etchant gas resistance and excellent dyeing resisting property. The curable resin composition contains epoxy resin, solidifying agent and / or solidifying booster expressed by formula (1) (in the formula, a plurality of R1 can be same or different and can independently present hydrogen atom or methyl). The curable resin composition of the invention, used as the optimized solidifying agent cyclohexane-1, 3, 4-triformic-3, 4-anhydride and methyl hexahydrophthalic anhydride, has particular effect in preventing sinking after curing.

Owner:NIPPON KAYAKU CO LTD

Epoxy resin pouring sealant and usage method

ActiveCN102850988ALow melting pointLow viscosityNon-macromolecular adhesive additivesOther chemical processesEpoxyElectronic controller

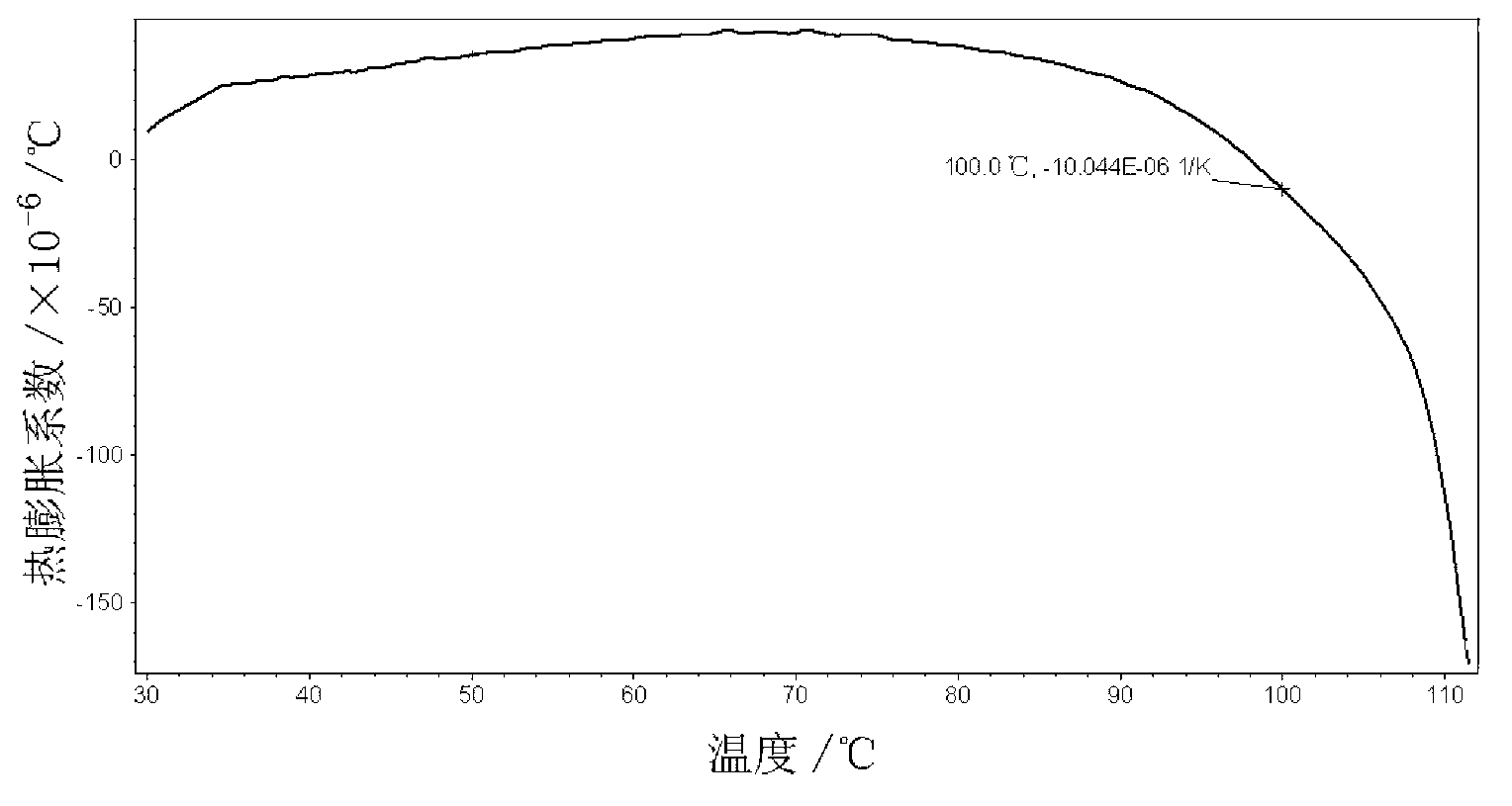

The invention relates to an epoxy resin pouring sealant and a usage method. The epoxy resin pouring sealant is composed of an o-cresol-formaldehude epoxy resin matrix, a methylhexahydrophthalic anhydride curing agent, an electronic grade torispherical silica micro powder filler, a diluent and an antifoaming agent, wherein the composition ratio of the epoxy resin matrix to the curing agent is 1: (0.6-1.4), and the composition ratio of the epoxy resin matrix to the filler is 1: (0.3-2.4). According to the epoxy resin pouring sealant, a curing process is that pre-curing is performed at the temperature of 90 DEG C for 0.5-1 hour, and curing is performed at the temperature of 150 DEG C for 2-3 hours. The epoxy resin pouring sealant has the advantages of being low in toxicity, density, thermal expansivity coefficient and water absorption rate, high in bending strength and compressive strength and good in application prospect and can be widely applied to electronic controllers, sensors, aerospace components and the like.

Owner:CENT SOUTH UNIV

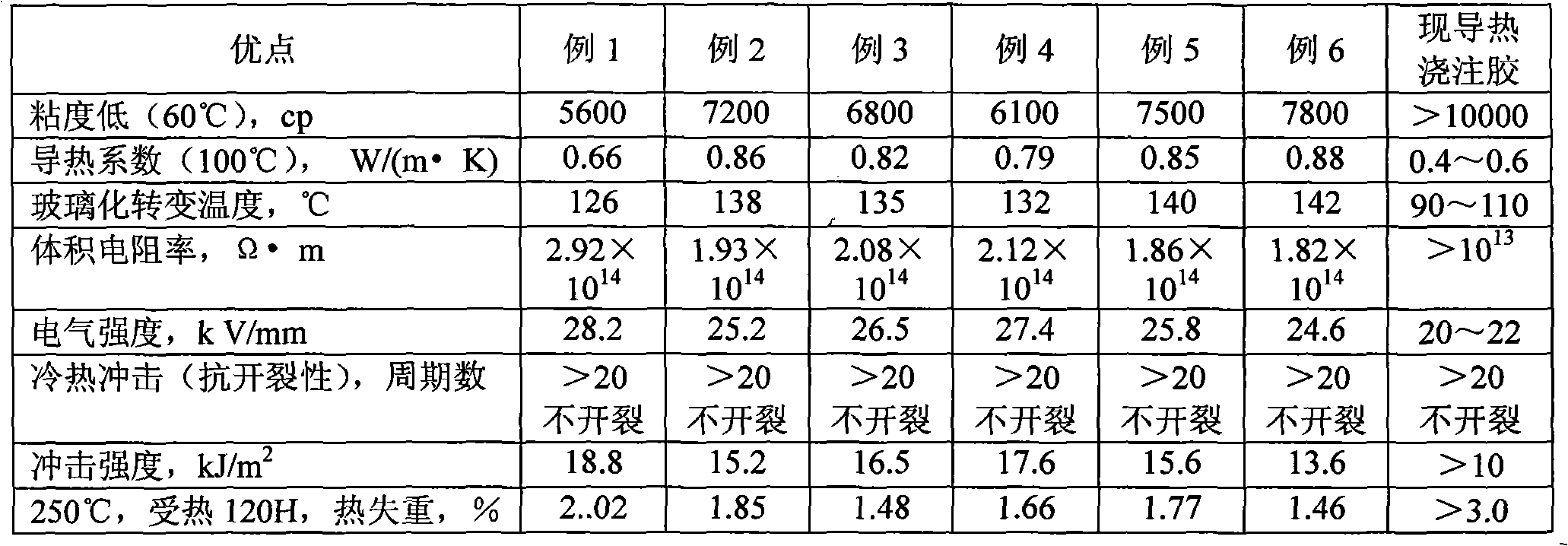

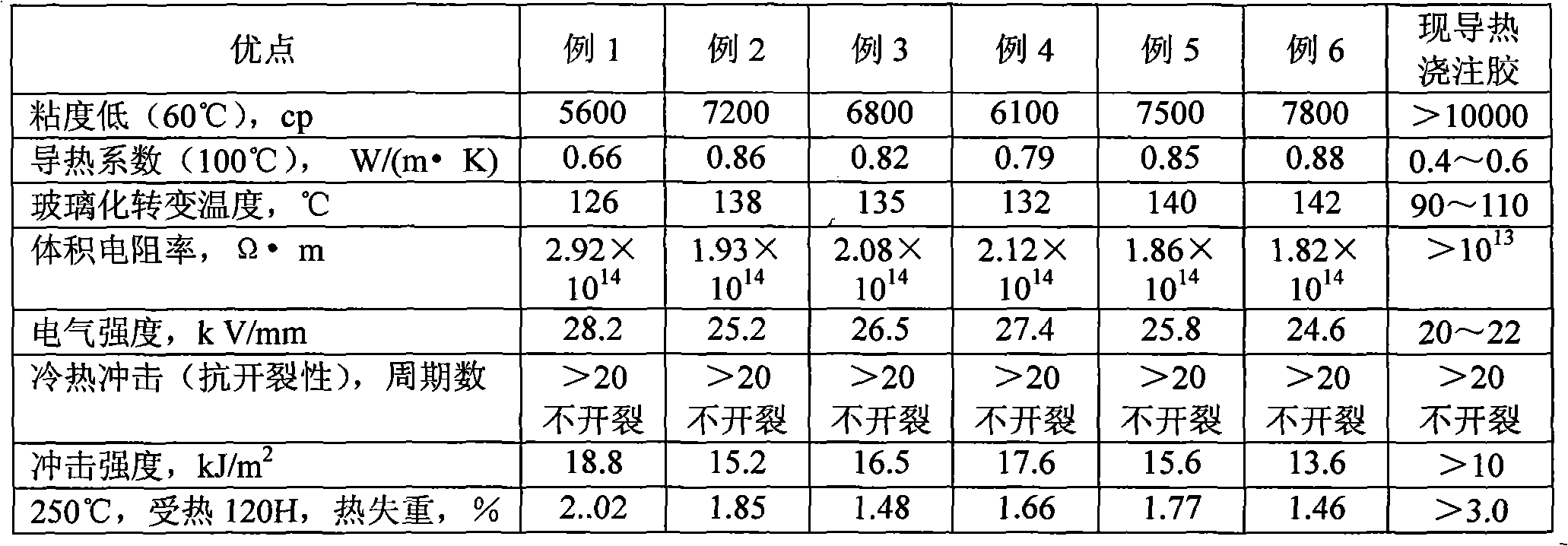

Heat conduction insulating casting glue and preparation method thereof

ActiveCN102093665ALow viscosityGood workmanshipInorganic insulatorsHeat-exchange elementsEpoxyTetrahydrophthalamic acid

The invention relates to a heat conduction insulating casting glue and a preparation method thereof. The casting compound comprises the following main components in parts by weight: (A) 100 parts of hydantoin epoxy resin, (B) 60-120 parts of anhydride curing agent, and (C) 200-400 parts of inorganic heat conductive filler, wherein the component A (per 100 weight parts) contains 10-15 weight partsof alcohol plasticizer; the component B is one or more of hexahydrophthalic anhydride, tetrahydrophthalic anhydride, methyltetrahydrophthalic anhydride, methylhexahydrophthalic anhydride and methylnadic anhydride; and the component C is one or more of silica micropowder, aluminum oxide, aluminum nitride and boron nitride in 300-900 meshes. The preparation method of the casting compound comprises the following steps: mixing A and B proportionally; soaking C in ethanol solution of silane coupling agent, dispersing at a high speed, filtering, and oven-drying; heating the mixture of A and B, adding C, mixing, and debubbling; and casing, and curing. The casting compound provided by the invention has low viscosity, greatly improved heat-conducting property and improved mechanical properties, and is convenient in casting. The preparation method of the casting compound is solvent-free, and has no pollution to the environment.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

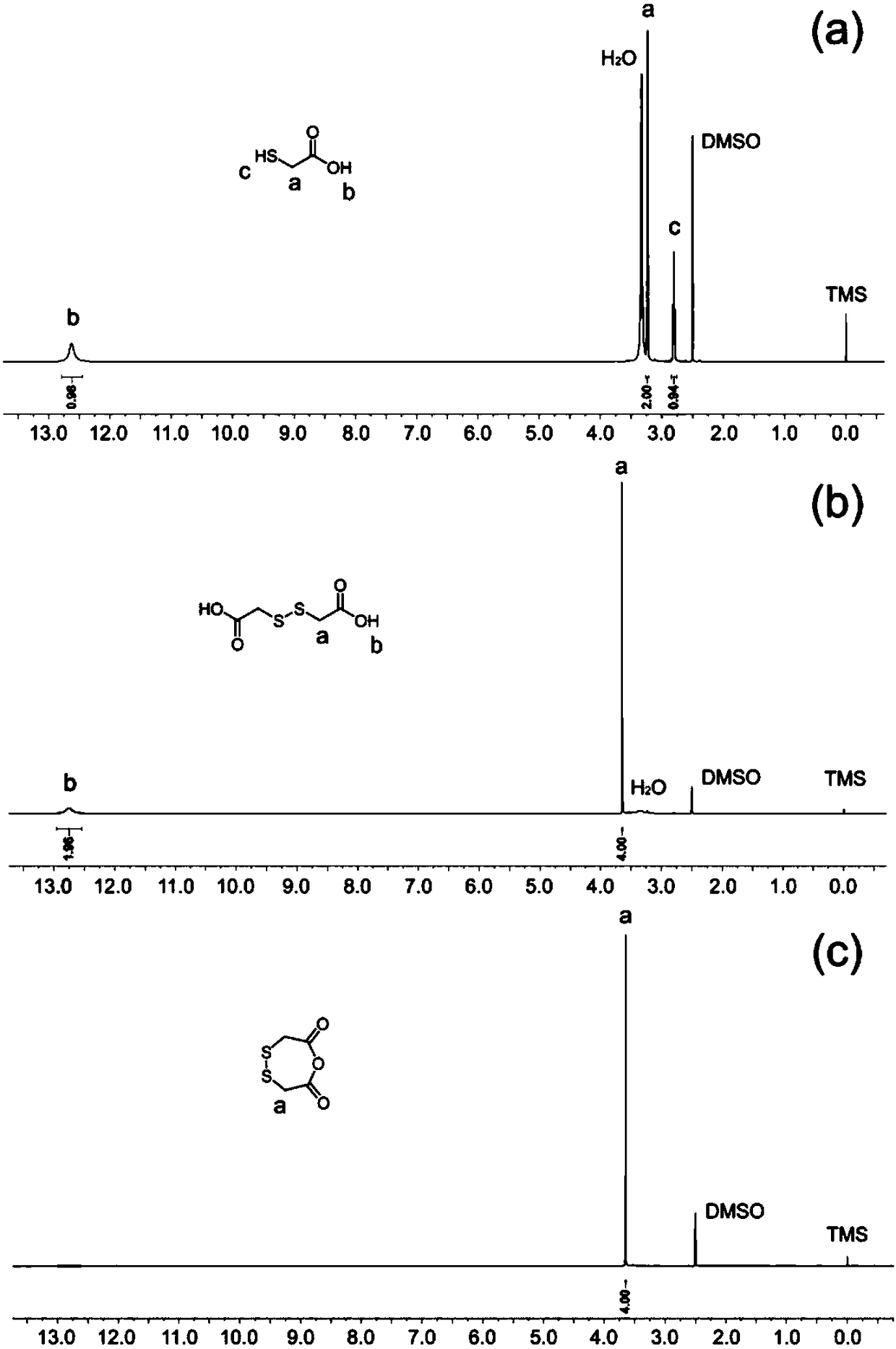

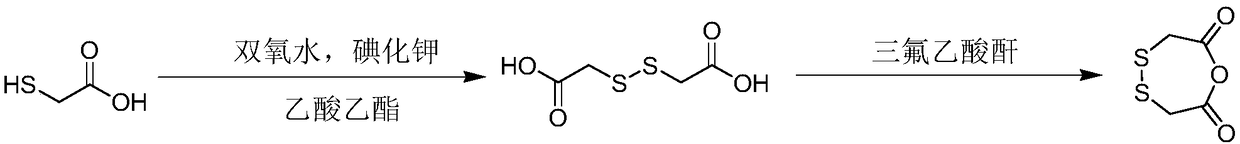

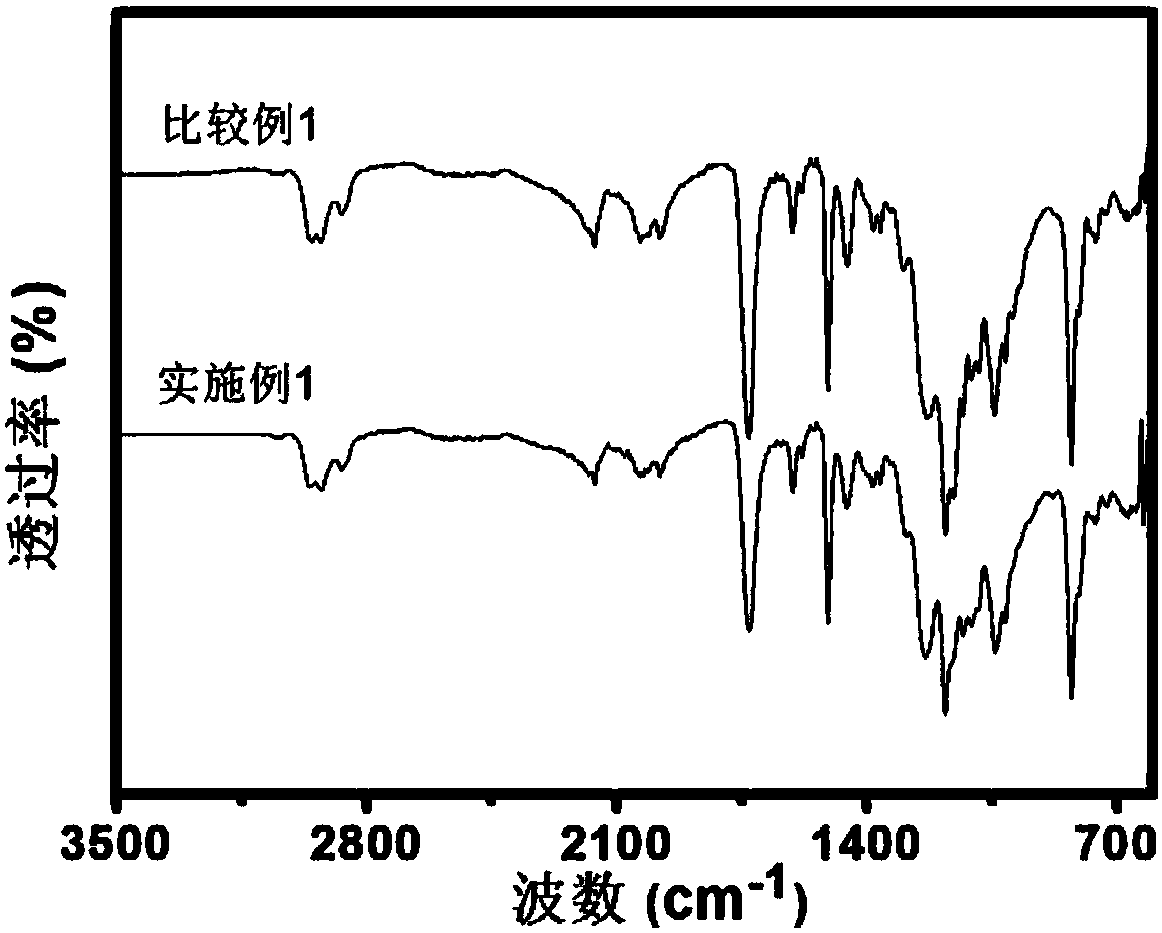

Reversible self-repairing epoxy resin and preparation method and recovery remodeling method thereof

ActiveCN108440740AGuaranteed heat resistanceAchieve reversible self-healingProductsOrganic chemistryCross-linkMethylhexahydrophthalic acid

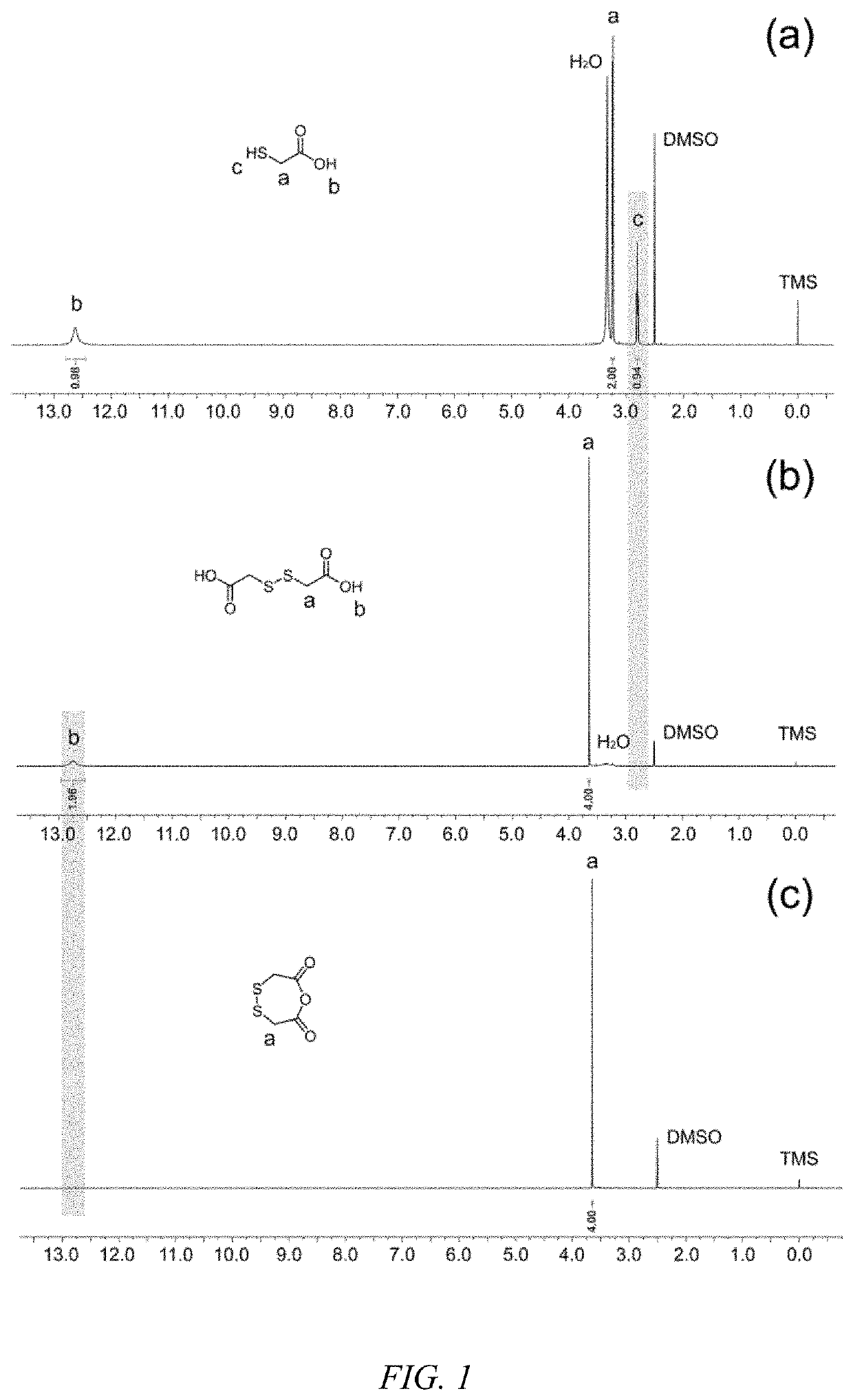

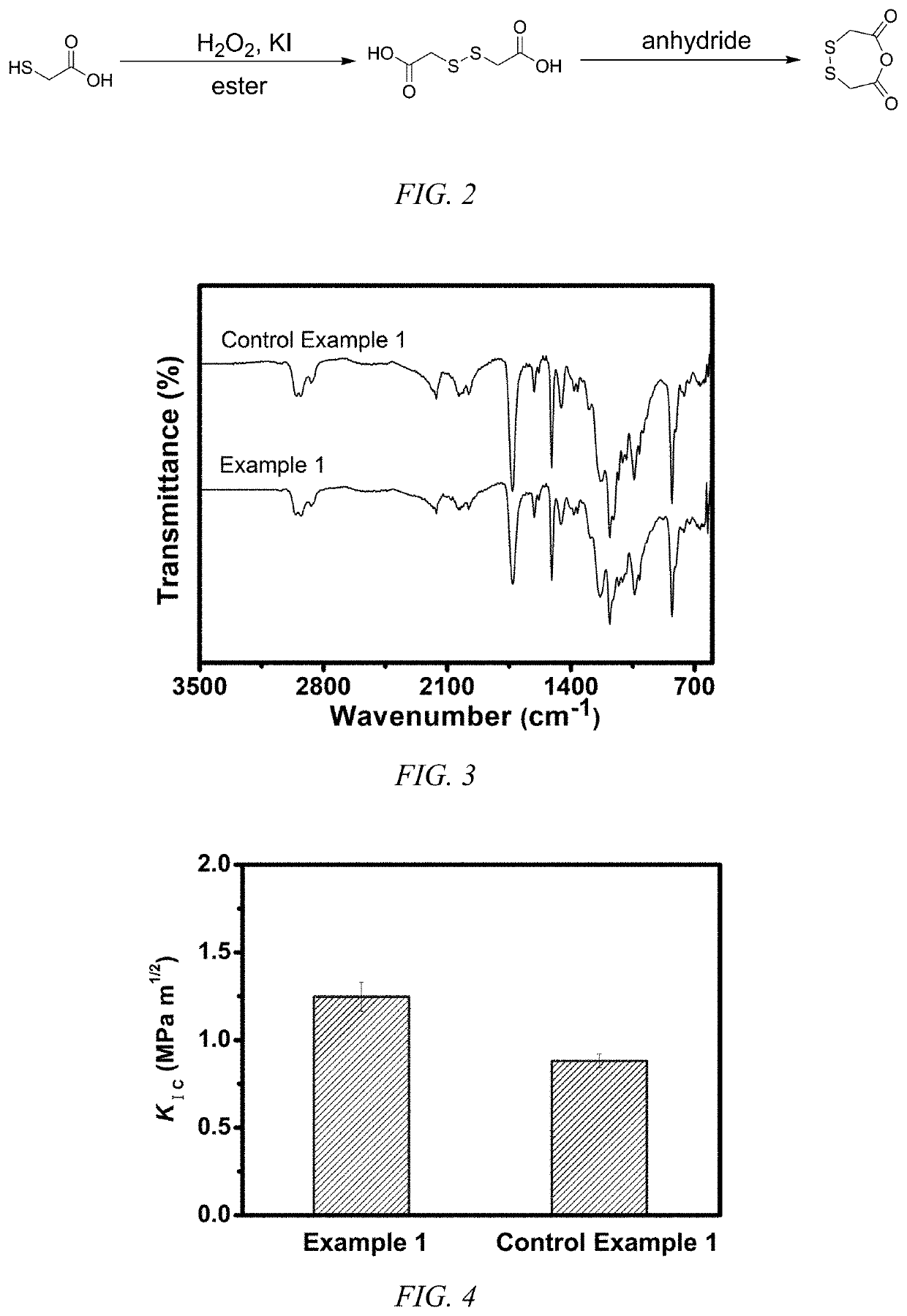

The invention discloses a reversible self-repairing epoxy resin and a preparation method and a recovery remodeling method thereof. Under the catalysis of potassium iodide, an ester solution of 2-thioglycolic acid is oxidized by 30% hydrogen peroxide to obtain 2,2'-dithiooxalic acid. The 2,2'-dithiooxalic acid is subjected to dehydration and cyclization through an anhydride to prepare 2,2'-dithiooxalic anhydride. The 2,2'-dithiooxalic anhydride is mixed with methylhexahydrophthalic anhydride in proportion, an epoxy resin is added, and curing is conducted, so that the reversible self-repairing epoxy resin is obtained. The composition of the dynamic cross-linked network and the permanent cross-linked network in the epoxy resin is changed, the reversible self-repairing and recovery remodelingof the epoxy resin are realized, the excellent heat resistance is obtained, and the mechanical property is improved. The preparation method of the reversible self-repairing epoxy resin provided by theinvention has the advantages of wide raw material source and simple process and the product has the characteristics of being good in applicability and high in practicability.

Owner:TECHSTORM MATERIAL TECH SHANGHAI CO LTD

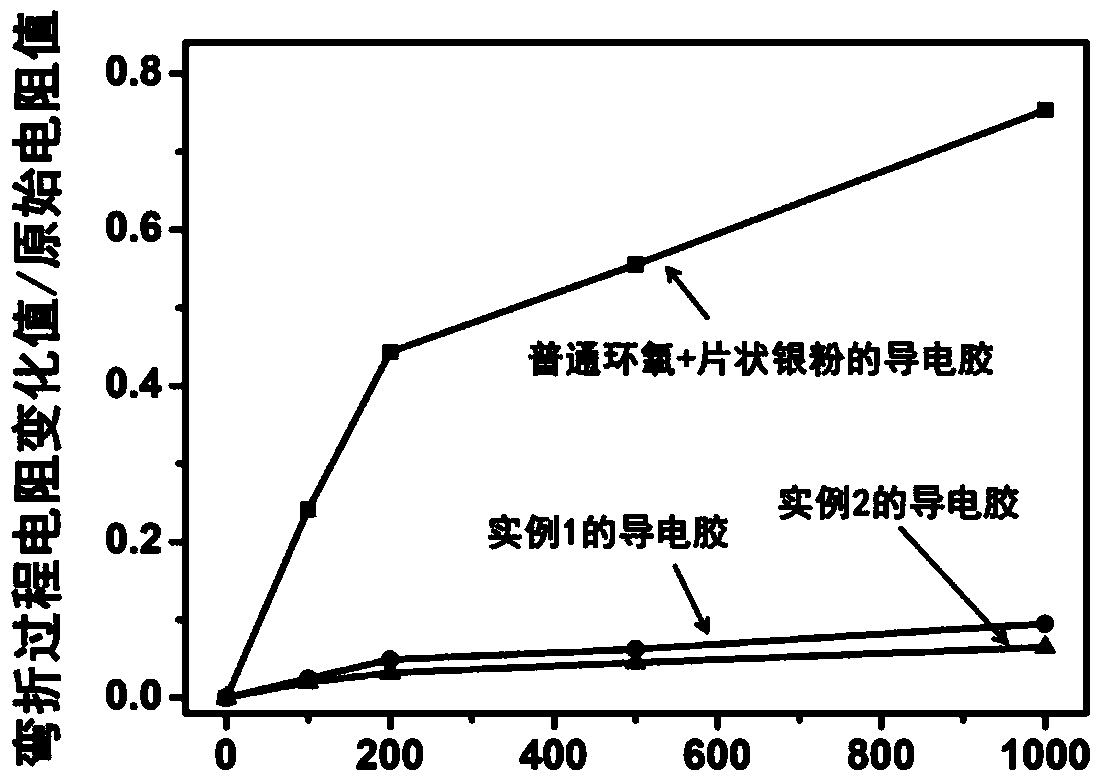

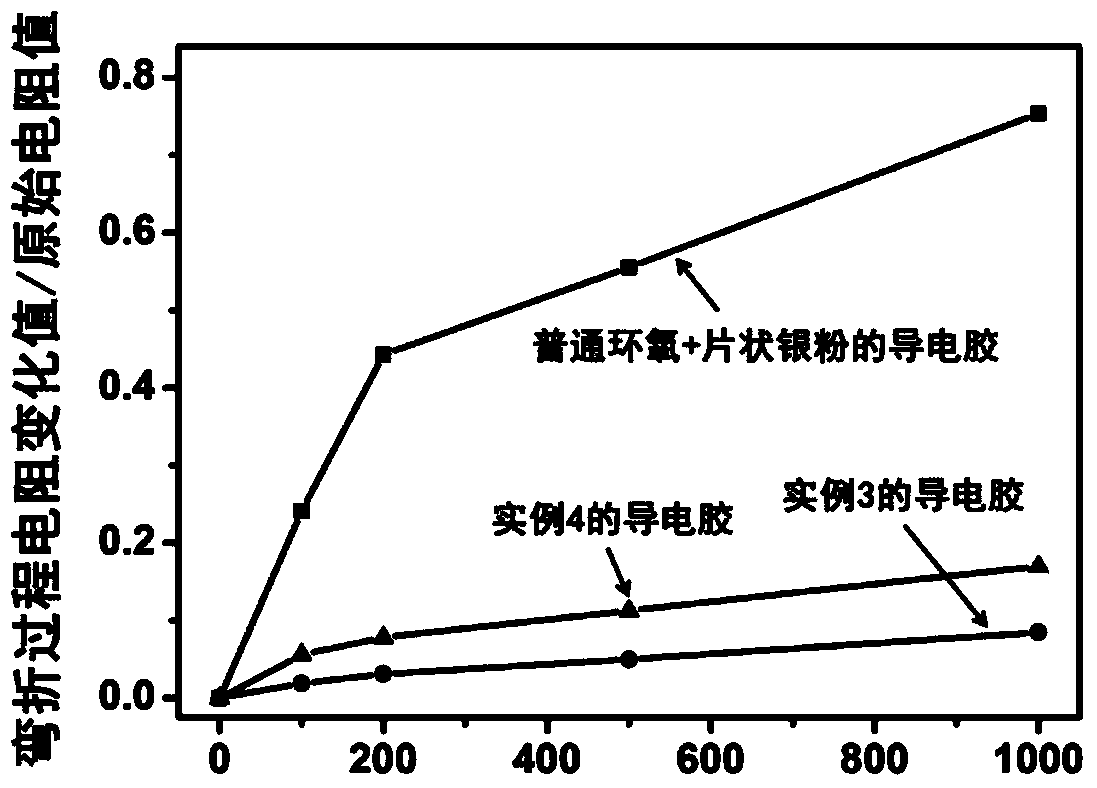

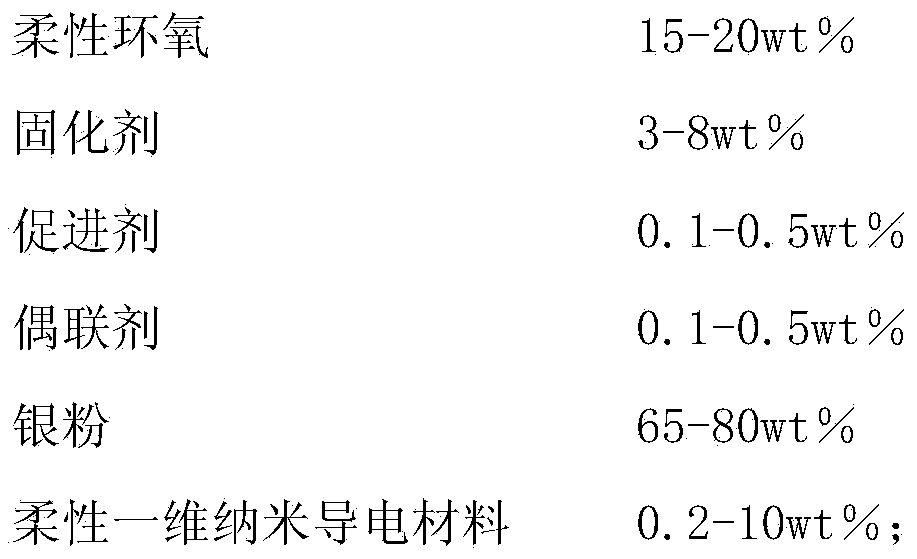

Flexible conductive adhesive capable of being used in direct coating manner and preparation method of flexible conductive adhesive

InactiveCN104263303AImprove conductivityGood flexibilityEpoxy resin adhesivesGraft polymer adhesivesTetrahydrophthalamic acidAdhesive

The invention discloses a flexible conductive adhesive capable of being used in a direct coating manner and a preparation method. The flexible conductive adhesive consists of 15-20wt% of flexible epoxy, 3-8wt% of a curing agent, 0.1-0.5wt% of an accelerant, 0.1-0.5wt% of a coupling agent, 65-80wt% of silver powder and 0.2-10wt% of flexible one-dimensional nano conductive material, wherein the flexible epoxy is a mixture of bisphenol-A epoxy resin with ethylene-vinyl acetate copolymer soft segments grafted and aliphatic glycidyl ether epoxy resin; the curing agent is one or more of methylhexahydrophthalic anhydride, methyl tetrahydrophthalic anhydride and tetrahydrophthalic anhydride; the accelerant is an imidazole compound; the coupling agent is one or more of KH 550, KH560 and KH570; the flexible one-dimensional nano conductive material is a carbon nano tube or a conductive metal nano wire. The flexible conductive adhesive has the excellent conductivity and the good flexibility, the conductivity is almost not changed after being bent repeatedly, and the flexible conductive adhesive can meet requirements of flexible electronic products.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

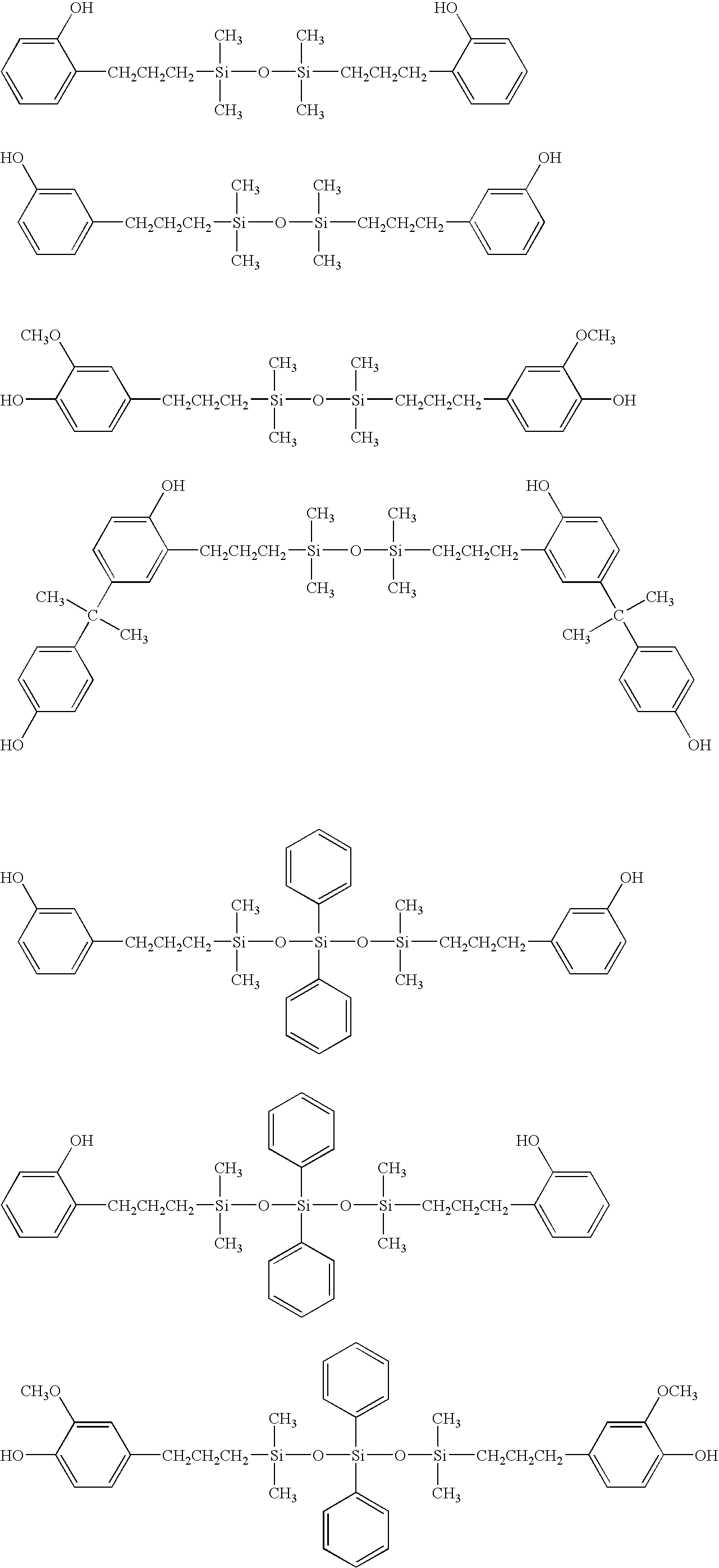

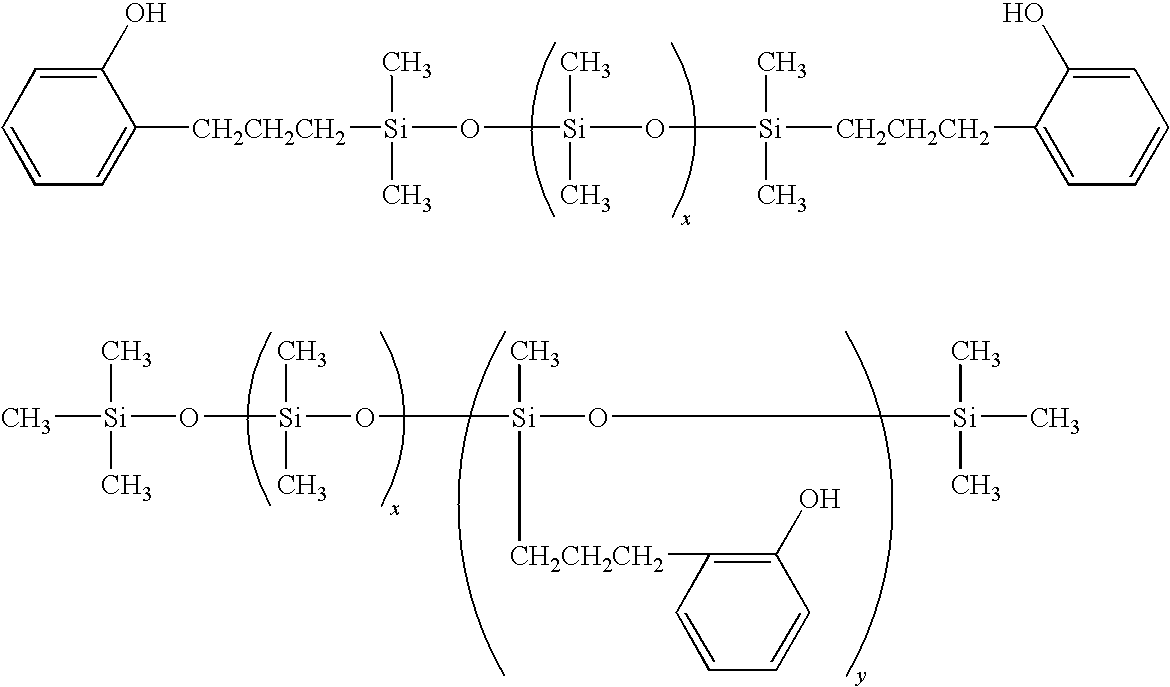

Curable Silicone Composition

InactiveUS20100140537A1Excellent flexibility and adhesionEasy to operateHeat-exchange elementsMethylhexahydrophthalic acidOrganic compound

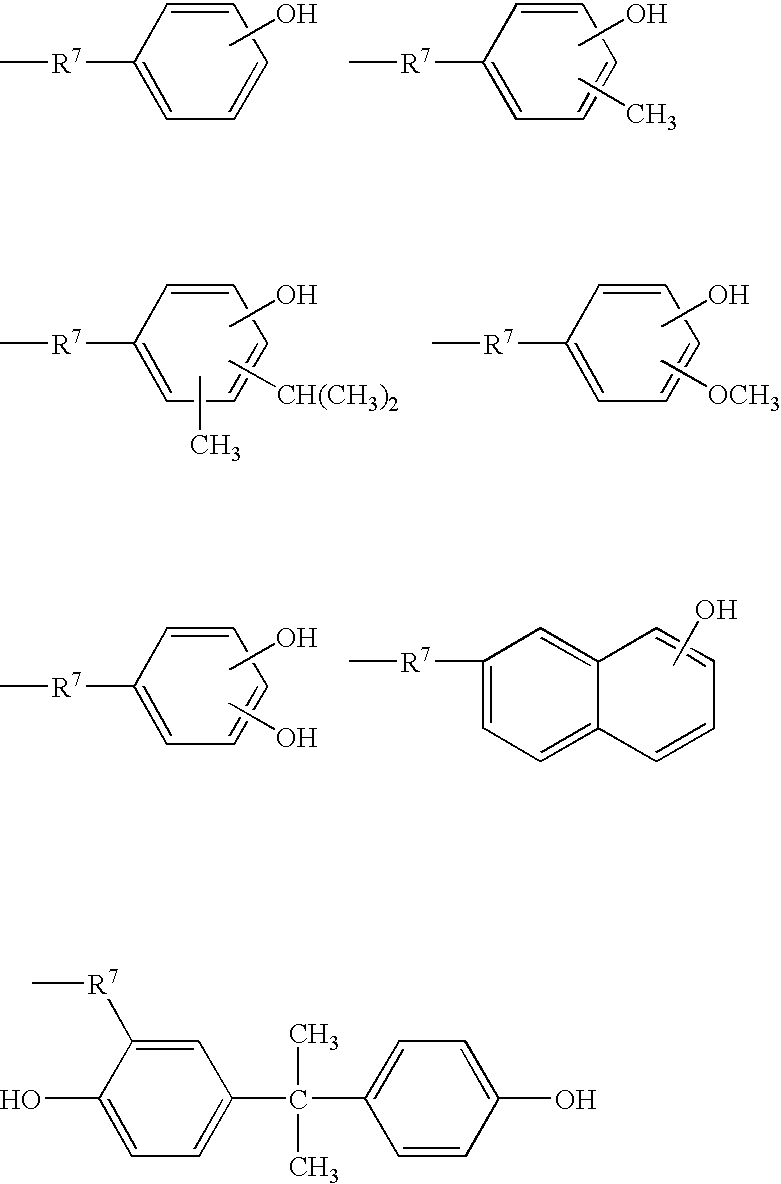

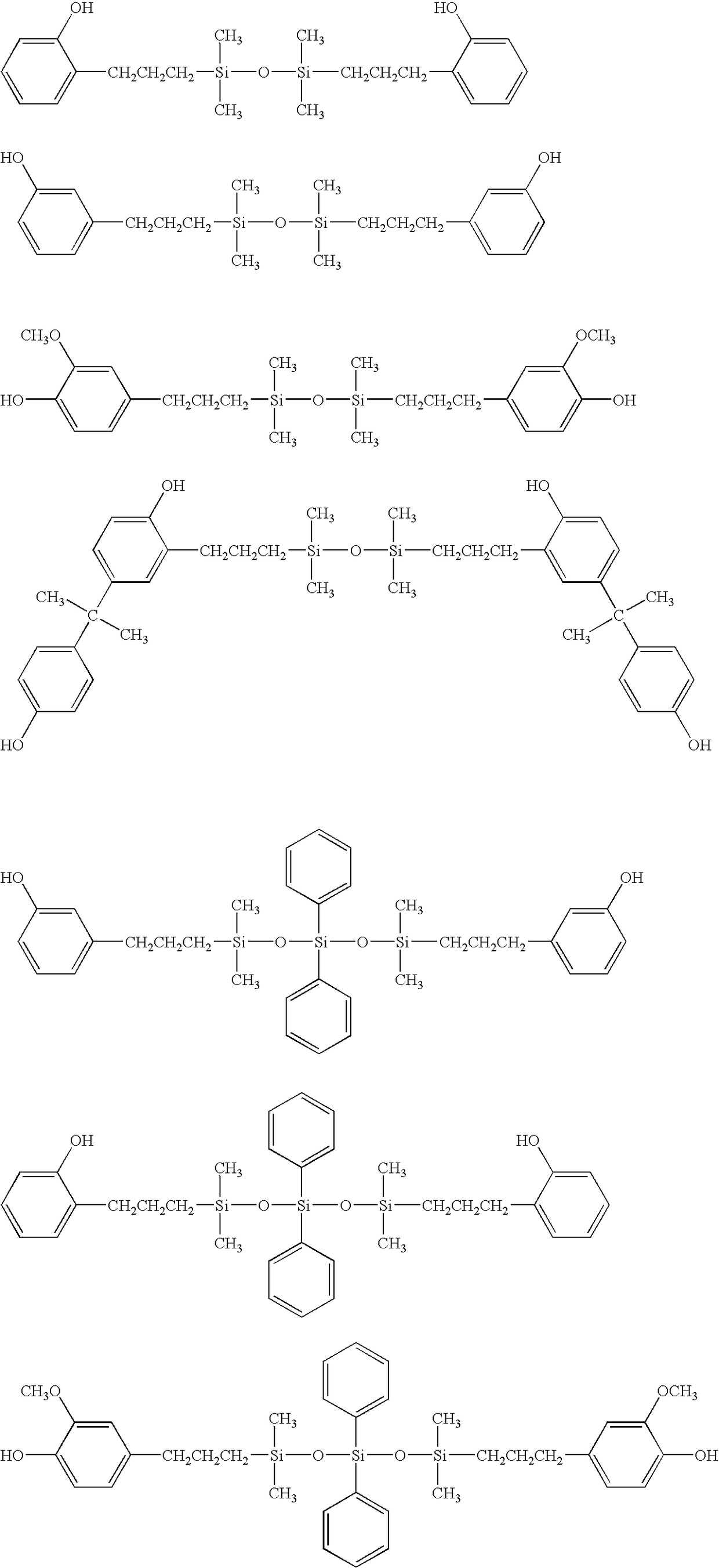

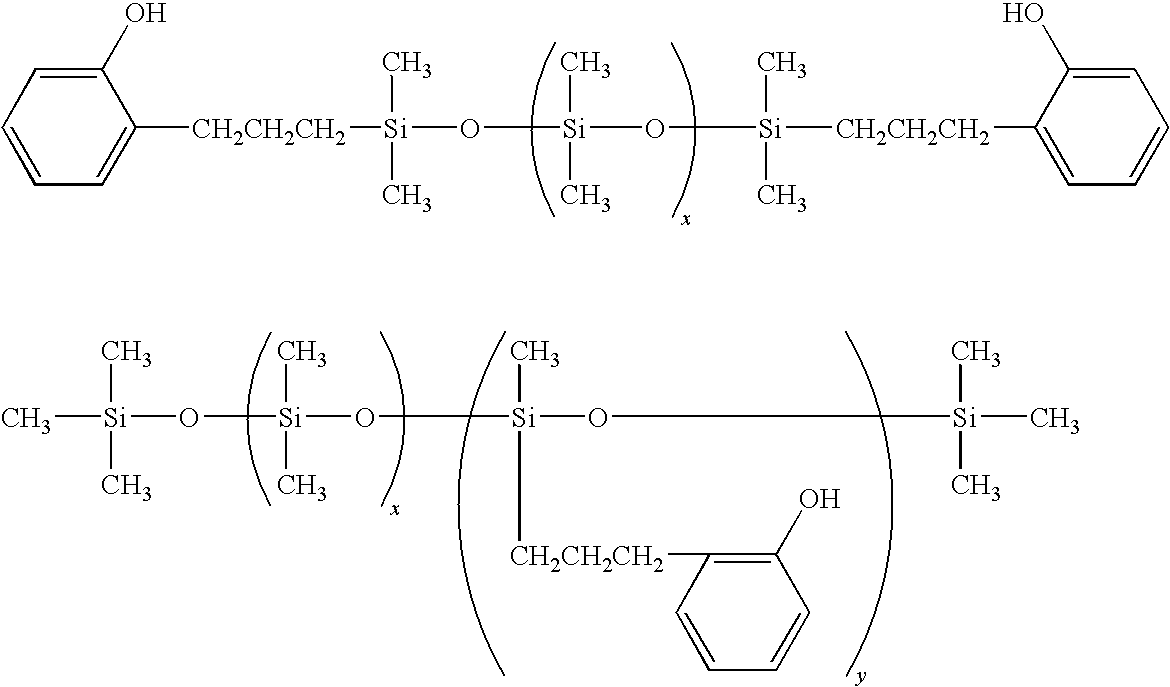

A curable silicone composition comprising at least the following components: (A) an organopolysiloxane that contains epoxy groups and, preferably, has a branched molecular structure; (B) a phenolic-type curing agent such as an organosiloxane having in one molecule at least two phenolic hydroxyl groups; and (C) an acidic-anhydride type curing agent such as a methylhexahydrophthalic anhydride, as well as an arbitrary components such as (D) a curing accelerator, (E) a filler, or (F) an organic epoxy compound; is characterized by excellent handleability and reduced oil-bleeding during curing, and, when cured, forms a cured body of excellent flexibility and adhesion.

Owner:DOW CORNING TORAY CO LTD

Hybrid grafted oxidation-resistant and flame-retardant epoxy material and preparation method thereof

The invention discloses a hybrid grafted oxidation-resistant and flame-retardant epoxy material. The material is prepared from raw materials in parts by weight as follows: 3-4 parts of ammonium polyphosphate, 6-8 parts of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide, 1-2 parts of vinyl trimethoxy silane, 0.1-0.2 parts of azobisisobutyronitrile, 2-3 parts of triglycidyl isocyanurate, a proper amount of dimethylformamide, 0.8-2 parts of 3-amino propyl triethoxysilane, 17-20 parts of a 10%-13% hydrochloric acid solution, 5-8 parts of methyl hexahydrophthalic anhydride, 100-120 parts of epoxy resin E40, 3-4 parts of dioctyl sebacate, 0.8-1 part of diisocyanate, 1-2 parts of diacetone acrylamide, a proper amount of ethanol, 0.4-1 part of tert-butyl hydroquinone, 3-5 parts of diniconazole, 2-3 parts of sodium myrastate and 1-2 parts of calcium borate. The added tert-butyl hydroquinone and the like can effectively improve the oxidation resistance of the finished material and improve the storage stability of the finished product.

Owner:倪群

Optical lens having sub-wavelength structure containing aluminum or aluminum oxide, method of manufacturing optical lens, and imaging optical system including optical lens

InactiveUS8905559B2Increase flexibilityIncrease resistanceOptical articlesCoatingsHexahydrophthalic anhydrideMethylhexahydrophthalic acid

Owner:CANON KK

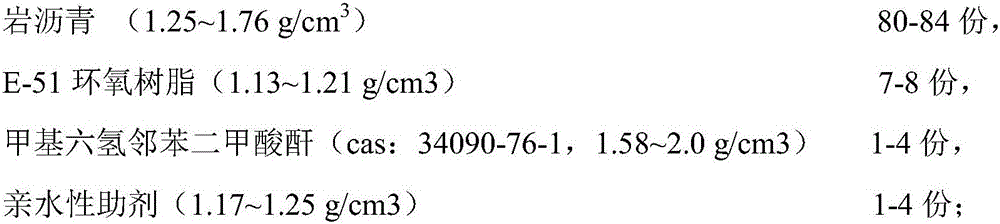

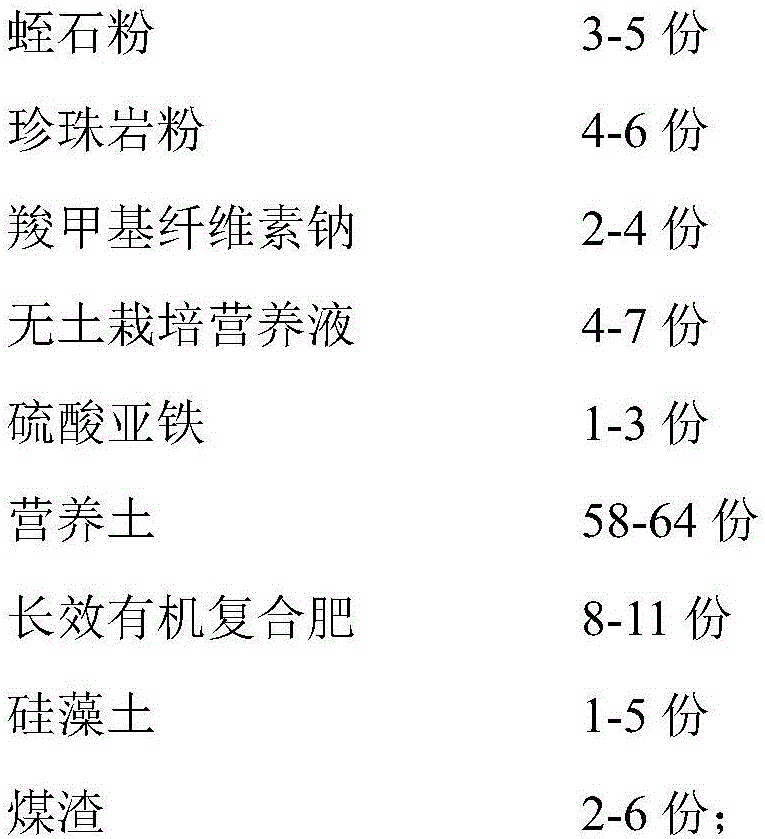

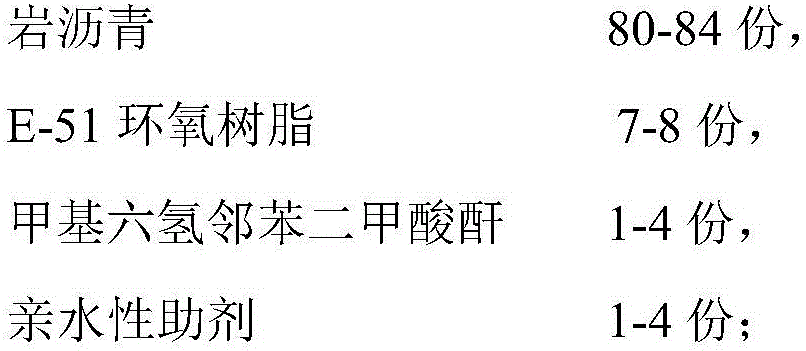

Slope-protective plant-growing type pitch blend containing planting matrix and preparation method and application for same

ActiveCN106212100AAchieve the purpose of growthImprove adhesionGrowth substratesCulture mediaEpoxyNutrient solution

The invention discloses a slope-protective plant-growing type pitch blend containing planting matrix and preparation method and application for the same. The blend comprises pitch material and planting matrix. The pitch is made of the following compositions by parts: 80 to 84 parts of rock pitch, 7 to 8 parts of epoxy resin, 1 to 4 parts of methylhexahydrophthalic anhydride, 1 to 4 parts of hydrophilic assistant; the planting matrix is made of the following compositions by parts: 3 to 5 parts of vermiculite powder, 4 to 6 parts of perlite powder, 2 to 4 parts of Carboxymethylcellulose sodium, 4 to 7 parts of soilless culturing nutrient solution, 1 to 3 parts of ferrous sulfate, 58 to 64 parts of nutrient soil, 8 to 11 parts of long-acting organic composite fertilizer, 1 to 5 parts of kieselguhr and 2 to 6 parts of coal cinder; and the pitch is immersed into the planting matrix or the planting matrix is poured on the pitch. The slope-protective plant-growing type pitch blend containing planting matrix is advantaged by great durableness, vigorous plant production and strong adaptability.

Owner:宁波东兴沥青制品有限公司

Alumina thermal conductive composite material and preparation method thereof

The invention discloses an alumina thermal conductive composite material, which is composed of the following raw materials (by weight): 0.3-0.5 part of dimethyl imidazole, 10-13 parts of nano-alumina, 1-2 parts of 3,5-diaminobenzoic acid, 0.3-0.7 part of pyridine, 2-3 parts of triphenyl phosphate, 0.1-0.2 part of lithium chloride, 0.6-1 part of a silane coupling agent kh560, 0.7-1 part of neodymium acetylacetonate, 1.6-2 parts of methyl hexahydrophthalic anhydride, 80-90 parts of epoxy resin 6101, 0.6-1 part of 1-hydroxyethylidene-1,1-diphosphonic acid, 2-3 parts of ammonium metaborate, 5-7 parts of microcrystalline wax, 0.3-1 part of glyceryl stearate, 0.4-1 part of ethylene bis-stearamide, 2-4 parts of polyvinyl alcohol and 1-2 parts of calcium propionate. By addition of microcrystalline wax, polyvinyl alcohol, etc. in the composite material, dispersity of the filling material in epoxy resin can be effectively raised and stability of the finished product can be enhanced.

Owner:邹小凤

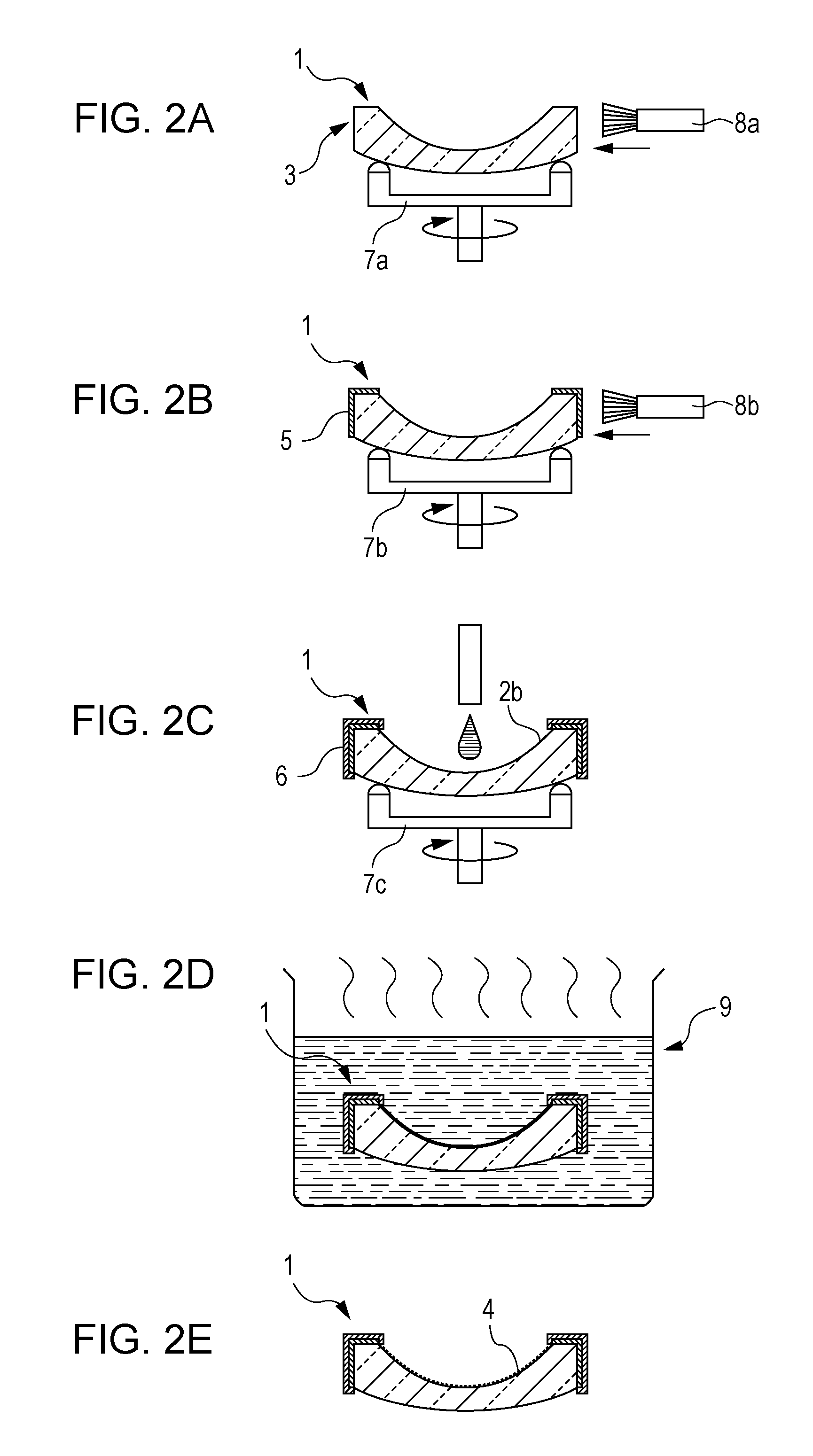

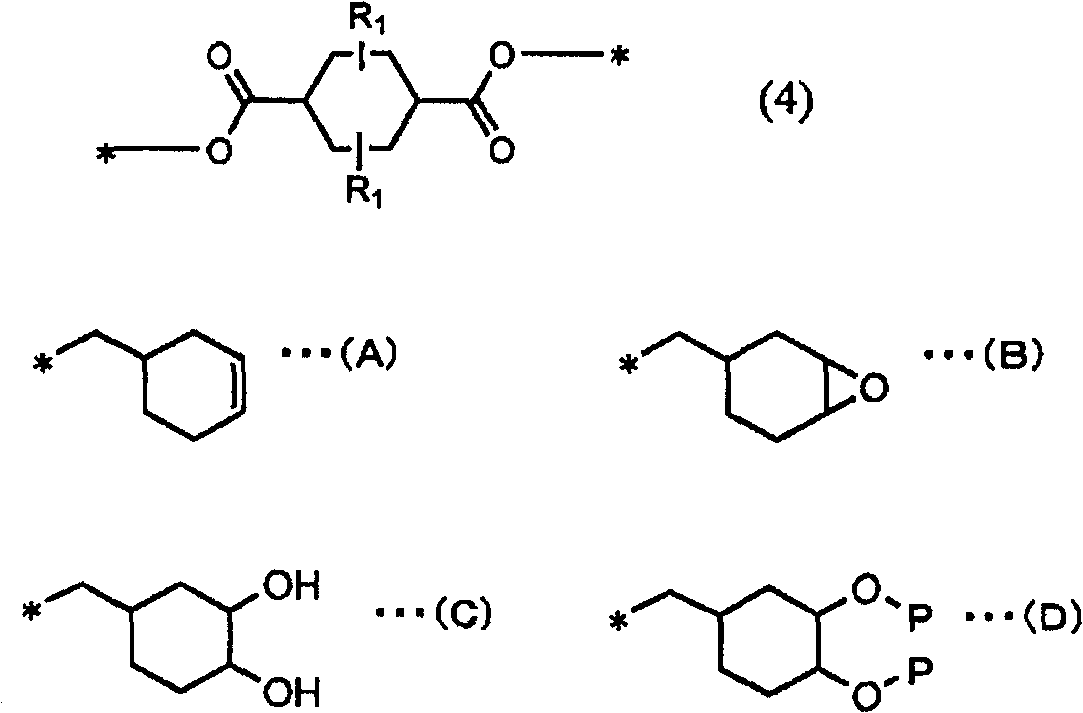

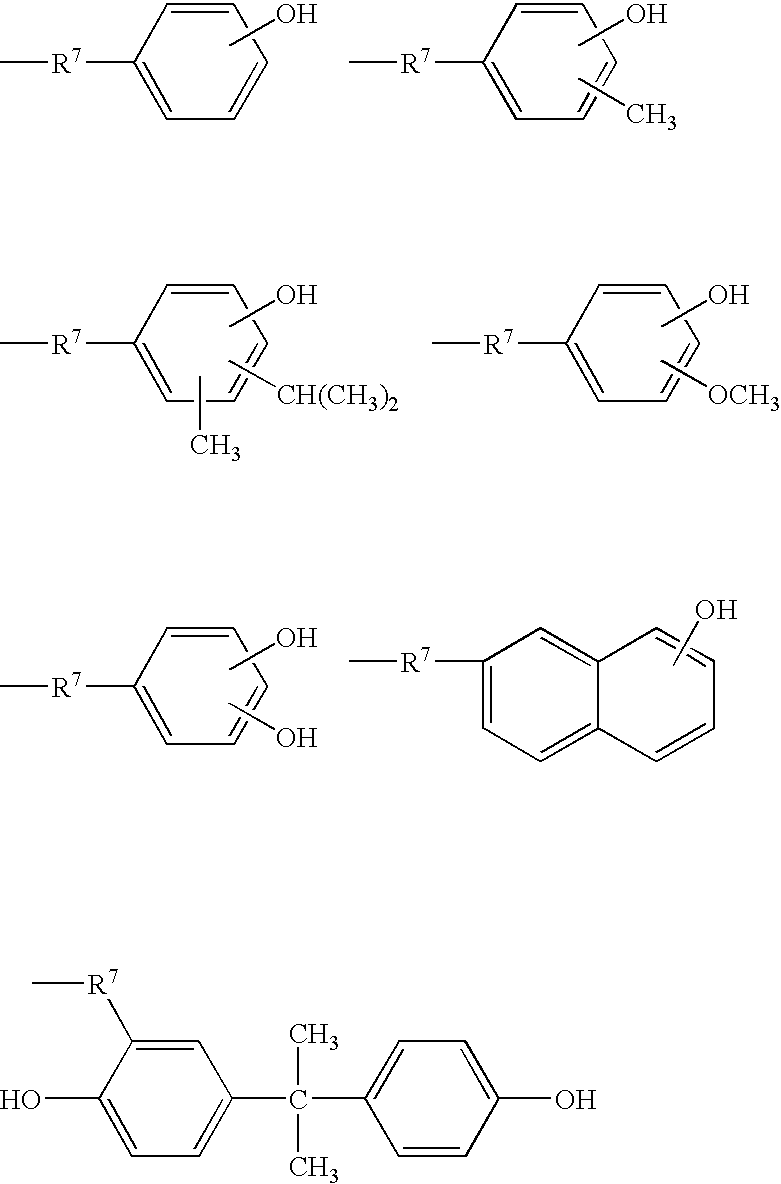

Epoxy resin composition

InactiveUS20090215969A1Improve heat resistanceImprove light resistanceOrganic chemistryDiffusing elementsCyclohexanedimethanolHeat resistance

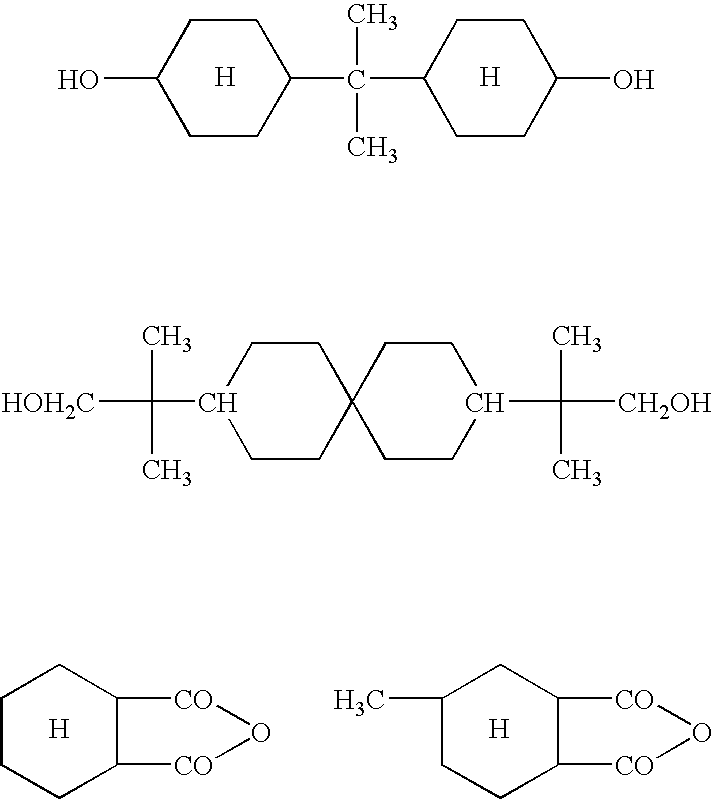

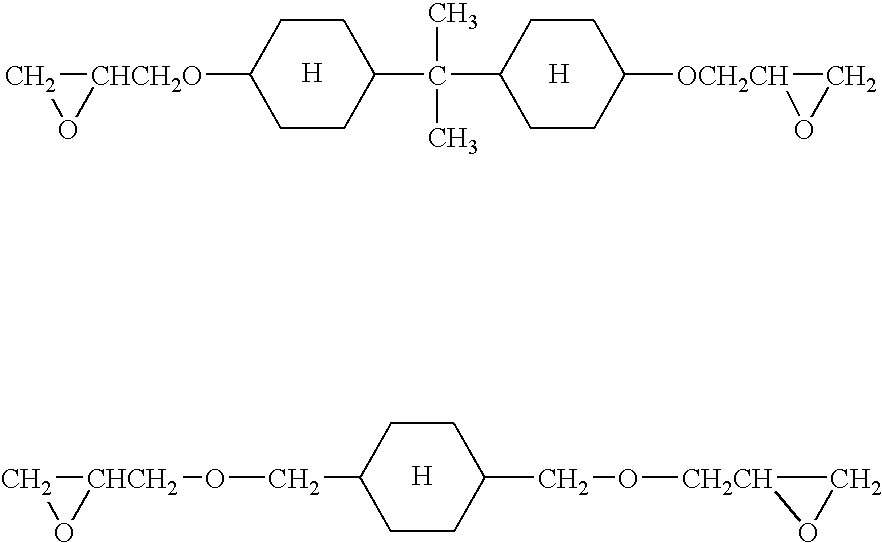

Disclosed is an epoxy resin composition which is solid at ordinary room temperature, cures with excellent light resistance and heat resistance and minimal shrinkage, and is useful for encapsulating LEDs. The epoxy resin composition is characterized by comprising as an essential component an epoxy resin having an epoxy equivalent of 300-1000 g / eq and a softening point of 65-110° C. obtained by reacting a nonaromatic polycarboxylic acid (A) having an acid value of 100-250 mgKOH / g with a nonaromatic epoxy resin (B) having an epoxy equivalent of 100-400 g / eq. The nonaromatic polycarboxylic acid (A) may be obtained by reacting 1,4-cyclohexanedimethanol, 2,2-bis(4-hydroxycyclohexyl)propane, or 3,9-bis(1,1-dimethyl-2-hydroxyethyl)-2,4,8,10-tetraoxaspiro[5,5]undecane with methylhexahydrophthalic acid or hexahydrophthalic acid.

Owner:NIPPON STEEL CHEMICAL CO LTD

Curable silicone composition

InactiveUS8119744B2Excellent flexibility and adhesionEasy to operateHeat-exchange elementsMethylhexahydrophthalic acidOrganic compound

A curable silicone composition comprising at least the following components: (A) an organopolysiloxane that contains epoxy groups and, preferably, has a branched molecular structure; (B) a phenolic-type curing agent such as an organosiloxane having in one molecule at least two phenolic hydroxyl groups; and (C) an acidic-anhydride type curing agent such as a methylhexahydrophthalic anhydride, as well as an arbitrary components such as (D) a curing accelerator, (E) a filler, or (F) an organic epoxy compound; is characterized by excellent handleability and reduced oil-bleeding during curing, and, when cured, forms a cured body of excellent flexibility and adhesion.

Owner:DOW CORNING TORAY CO LTD

Octadecylamine graft epoxy heat-conducting material and preparation method thereof

InactiveCN106633642ANo misalignmentCompact structureHeat-exchange elementsEpoxyHexagonal boron nitride

The invention discloses an octadecylamine graft epoxy heat-conducting material which is prepared from the following raw materials in parts by weight: 1.5-2 parts of sodium myristate soap, 0.3-1 part of diisopropyl ethanolamine, 37-40 parts of hexagonal boron nitride, 8-10 parts of methyl hexahydrophthalic anhydride, 0.4-1 part of neodymium acetylacetonate, 0.7-1.3 parts of octadecylamine, 4-6 parts of 3,5-diamidobenzoic acid, 2-3 parts of triphenyl phosphite, 0.3-0.5 part of pyridine, 32-40 parts of N-methylpyrrolidone, 100-110 parts of epoxy resin E40, 1-2 parts of sodium lignosulfonate, 2-3 parts of zinc dibutyl dithiocarbamate, 4-5 parts of allyl polyethyleneglycol, 0.6-1 part of 1,2-dimethyl imidazole, 10-12 parts of wollastonite powder and 0.6-1 part of hydroxystearic acid. The composite material has the advantages of high surface hardness, favorable hydrophobicity and excellent comprehensive properties.

Owner:ANQING JINHUIHUANG ELECTRONICS TECH CO LTD

Reversible self-repairing epoxy resin and preparation and recovery remoulding method therefor

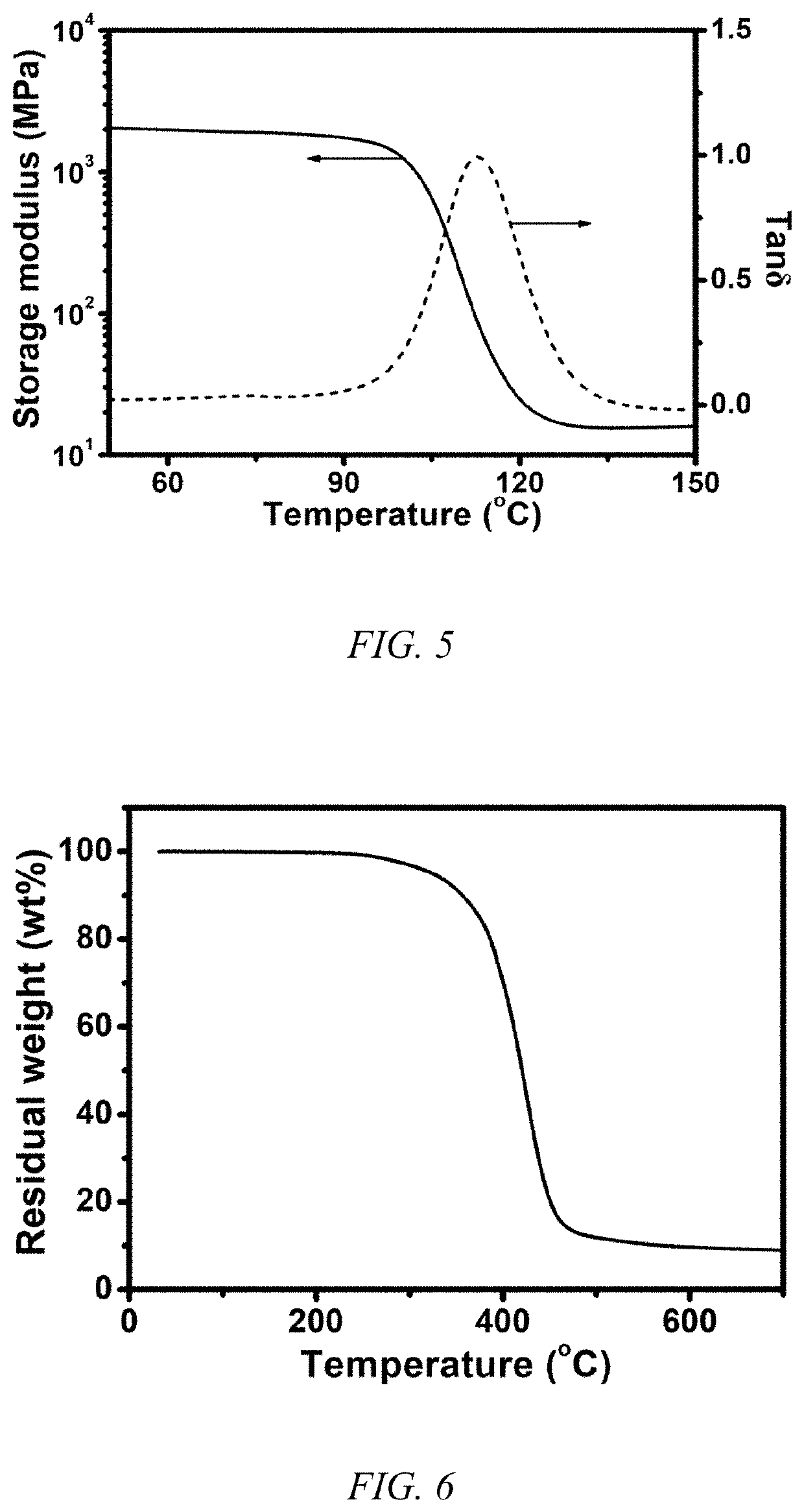

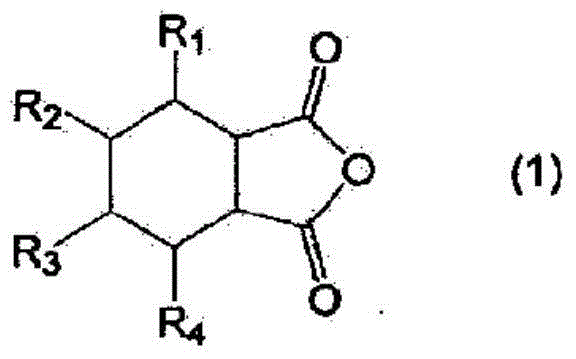

ActiveUS20200283595A1Improve heat resistanceImprove self-healing abilityOrganic chemistryPolymer sciencePtru catalyst

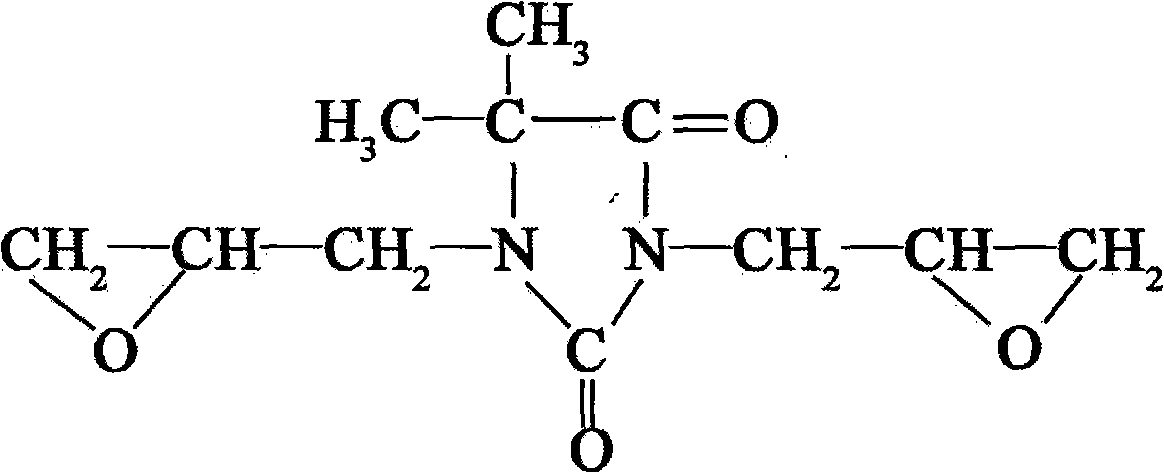

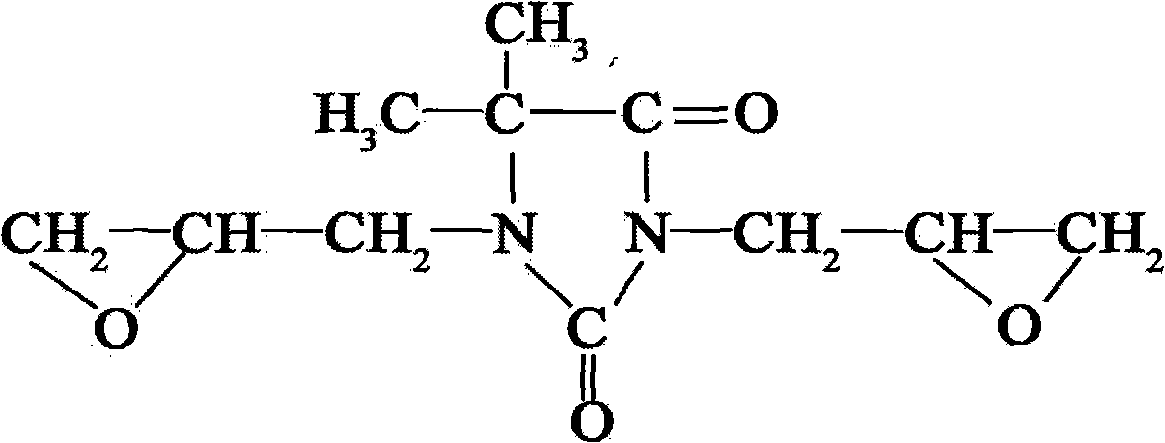

This invention provides a self-healable epoxy resin and its preparation, recycling and remolding method. With the catalyst of potassium iodide, an ester solution of 2-mercaptoacetic acid was oxidated by 30% H2O2 to form 2,2′-dithiodiacetic acid; then 2,2′-dithiodiacetic acid was dehydrated and cyclizated by anhydride to form 1,4,5-oxadithiepane-2,7-dione; 1,4,5-oxadithiepane-2,7-dione and methylhexahydrophthalic anhydride were mixed by mass ratio and cured with epoxides to get the self-healable epoxy resin. Through controlling dynamic and permanent three-dimensional crosslinked network, the self-healable epoxy resins provided in this invention exhibit high thermal resistance and improved mechanical properties as well as excellent self-healing ability, recyclability and remoldability. This invention provides a preparation method with the merits of low cost, simple production processes, broad application prospects and strong utility.

Owner:SUZHOU UNIV

Epoxy resin curing agent, epoxy resin composition, hardened material thereof, and optical semiconductor device

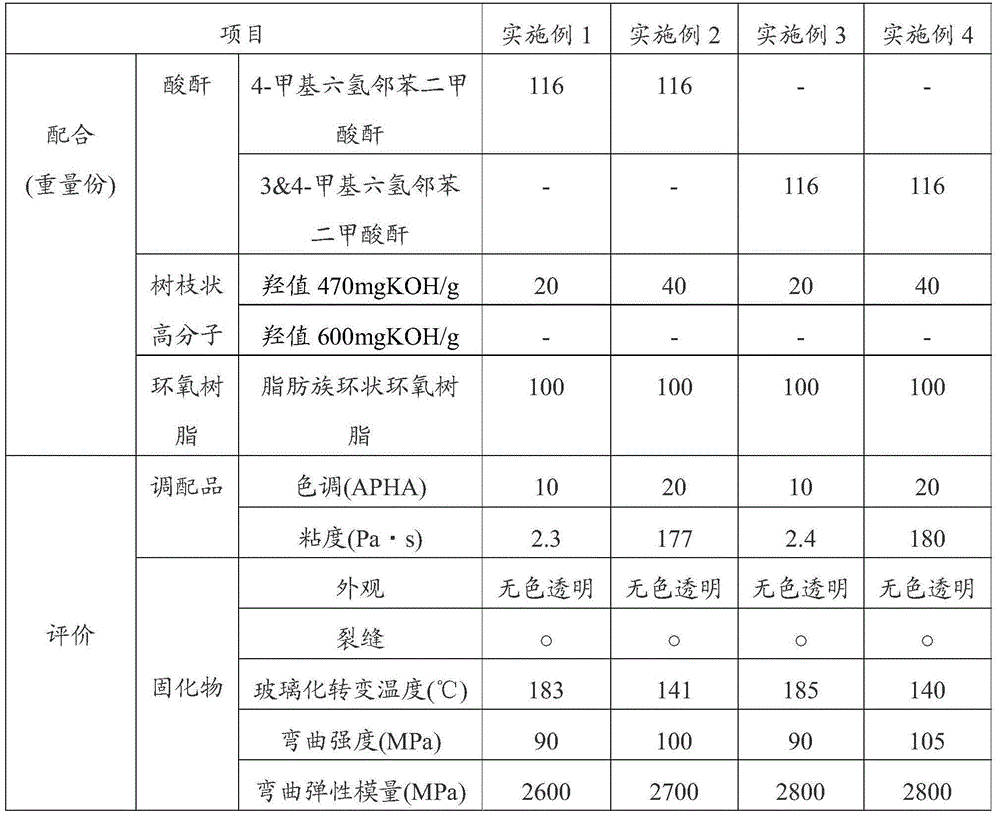

ActiveCN104693419ALow viscosityEasy to handleSemiconductor/solid-state device detailsSolid-state devicesEpoxyCrack resistance

Disclosed is an epoxy resin hardening agent that contains a multivalent carboxylic acid anhydride and a dendritic polymer with a hydroxy value of 550 mg KOH / g or less, with the aforementioned dendritic molecule preferably having a weight-average molecular weight of 2000 or less. Thus, an epoxy resin composition with low viscosity and good handling can be obtained, and a hardened material with little discoloration, excellent crack resistance, and excellent transparency can be obtained.

Owner:RESONAC CORPORATION

High-polymer epoxy heat-conducting material and preparation method thereof

The invention discloses a high-polymer epoxy heat-conducting material which is prepared from the following raw materials in parts by weight: 2-3 parts of propenol, 0.4-1 part of tetrabutylammonium bromide, 37-40 parts of hexagonal boron nitride, 8-10 parts of methyl hexahydrophthalic anhydride, 0.4-1 part of neodymium acetylacetonate, 0.7-1 part of octadecylamine, 4-6 parts of 3,5-diamidobenzoic acid, 2-3 parts of triphenyl phosphite, 0.3-0.5 part of pyridine, 32-40 parts of N-methylpyrrolidone, 100-110 parts of epoxy resin E40, 0.6-1 part of polyacrylamide, 2-3 parts of sodium fluorborate, 3-4 parts of vinyl carboxylate, 0.6-1 part of polybenzimidazole, 10-12 parts of diatomite and 0.3-1 part of dodecyl glucoside. The added polyacrylamide can effectively enhance the dispersity of the filler among the resin and enhance the comprehensive properties of the finished product.

Owner:ANQING JINHUIHUANG ELECTRONICS TECH CO LTD

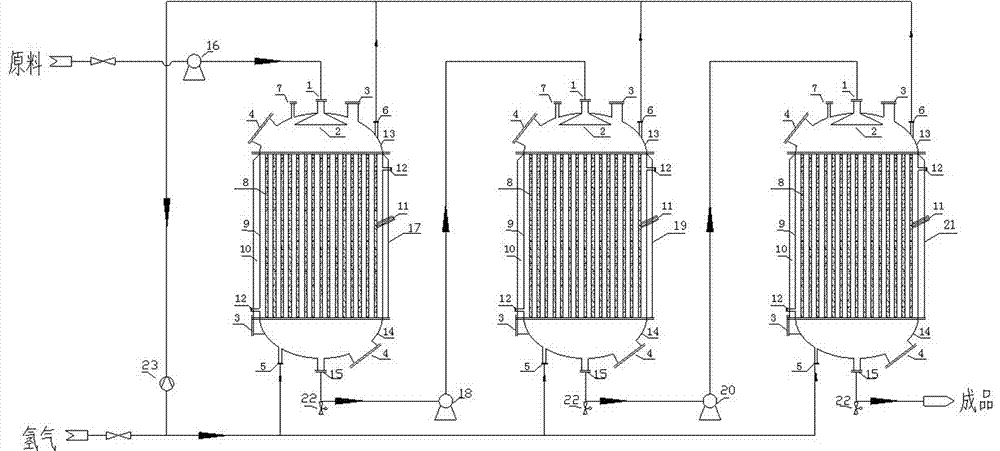

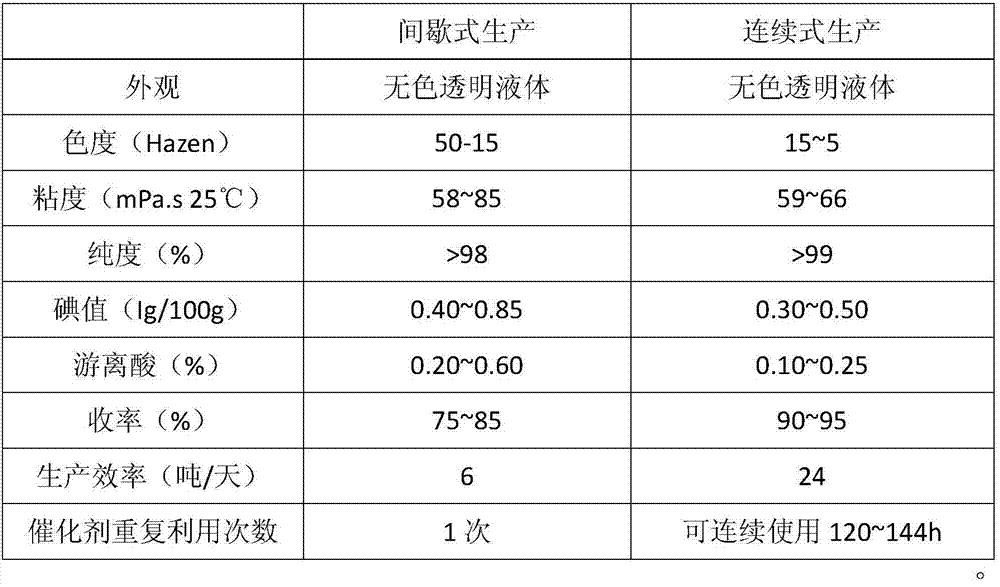

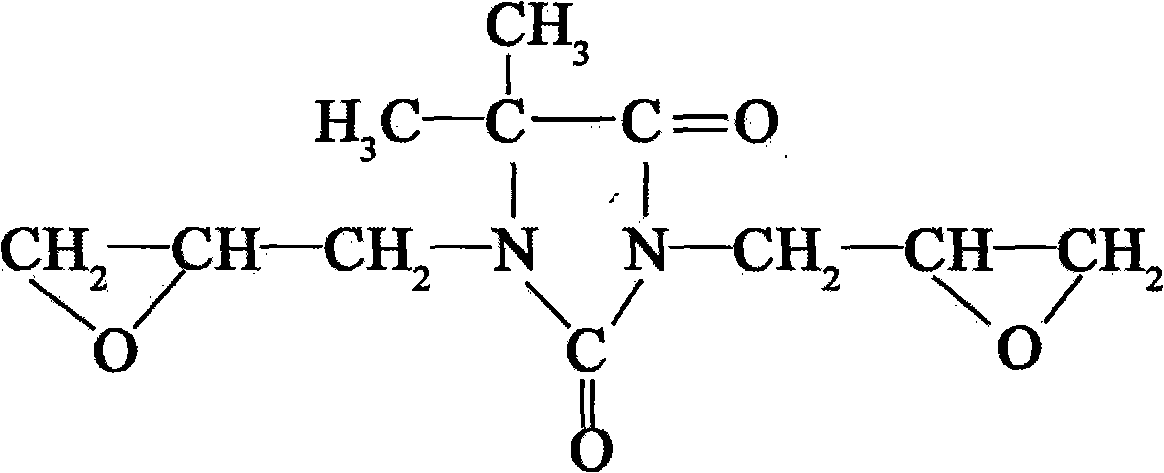

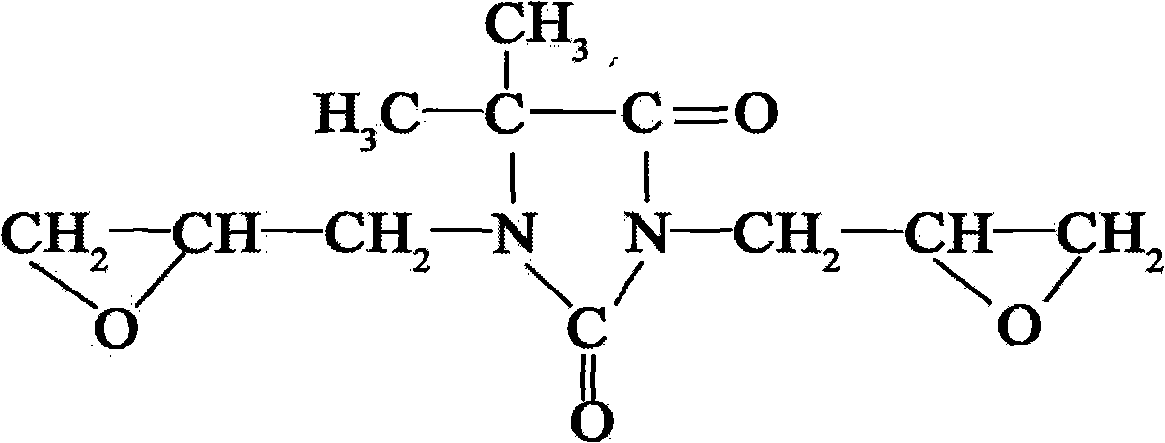

Method for preparing methylhexahydrophthalic anhydride by means of continuous hydrogenation

ActiveCN107089961AWell distributedImprove conversion rateOrganic chemistryChemical/physical processesThree levelFixed bed

The invention discloses a method for preparing methylhexahydrophthalic anhydride by means of continuous hydrogenation and belongs to the field of organic chemicals. A three-level split-tube fixed bed reactor is adopted for circularly continuous hydrogenating; a split-tube type structure is adopted in the split-tube fixed bed reactor; a solid catalyst is arranged between tube passes; a heat medium is arranged in a shell pass; hydrogen respectively enters from the bottom of each level of split-tube fixed bed reactor in parallel; unreacted hydrogen passes by each split tube and then returns to a hydrogen compressor from the upper part of the reactor; the raw material, methyltetrahydrophthalic anhydride, gradually passes by a high pressure pipe pump, is conveyed to the upper part of the split-tube reactor and is sprayed by a distributor located at the top in the reactor so as to be uniformly distributed on the surface of the solid catalyst and react with hydrogen; after circular reaction through the three-level reactor, the hydrogenating conversion rate is close to 100%. According to the method, the production of methylhexahydrophthalic anhydride by means of continuous hydrogenation is realized, the technical process is clean and the catalyst is reused.

Owner:河南惠成新材料有限公司

Thermosetting resin material for automotive relay shell and preparing method of thermosetting resin material

The invention discloses a thermosetting resin material for an automotive relay shell. The thermosetting resin material is characterized in by comprising the following raw materials including, by weight, 100-130 parts of epoxy resin E40, 10-12 parts of methylhexahydrophthalic anhydride, 3-4 parts of trimellitate, 2-3 parts of PTMG, 10-12 parts of zirconium carbonate, 0.7-1 part of ethoxylated alkyl phenol ammonium sulfate, 0.1-0.2 part of hexamethyl cyclotrisiloxane, 6-9 parts of maleic anhydride, 0.1-0.5 part of dicumyl peroxide, 17-20 parts of 3-(trifluoromethyl) benzophenone, 2-3 parts of hydroquinone, 0.1-0.4 part of 2-thiol group truxene imidazole and 3-4 parts of straw powder. The resin material has very good toughness and impact resistance, and is high in surface intensity, waterproof, good in corrosion resistance, high in protectiveness on a relay and good in insulation stability; and according to the thermosetting resin material, an acid anhydride grafting reaction is adopted, so that the dispersibility of fillers between the resin is effectively improved, and the comprehensive performance of the finished product material is improved.

Owner:宁波永的电子科技有限公司

Carbon nano-tube thermal conductive composite material and preparation method thereof

InactiveCN106543645AHigh thermal conductivityImprove thermal conductivityHeat-exchange elementsHexamethylphosphoramideLithium chloride

The invention discloses a carbon nano-tube thermal conductive composite material, consisting of the following raw materials in parts by weight: 0.7 to 1 part of sodium myrastate, 10 to 13 parts of nano aluminum oxide, 1 to 2 parts of 3,5-diaminobenzoic acid, 0.3 to 0.7 part of pyridine, 2 to 3 parts of triphenyl phosphite, 0.1 to 0.2 part of lithium chloride, 0.6 to 1 part of a silane coupling agent kh560, 0.7 to 1 part of neodymium acetylacetonate, 1.6 to 2 parts of methylhexahydrophthalic anhydride, 80 to 90 parts of epoxy resin 6101, 1 to 2 parts of polyethylene benzenesulfonic acid, 0.4 to 1 part of hexamethyl cyclotrisiloxane, 3 to 5 parts of abietinol, 0.3 to 1 part of hexamethylphosphoramide, 5 to 6 parts of carbon nano-tubes and 0.3 to 1 part of 2-thiol benzimidazole. According to the carbon nano-tube thermal conductive composite material disclosed by the invention, with the addition of the carbon nano-tubes and the like, the thermal conductivity property of finished composite materials can be effectively improved.

Owner:邹小凤

Antistatic epoxy heat-conducting material and preparation method thereof

InactiveCN106633644ANo misalignmentCompact structureHeat-exchange elementsAcetylacetoneMethylhexahydrophthalic acid

The invention discloses an antistatic epoxy heat-conducting material. The antistatic epoxy heat-conducting material is composed of the following raw materials in parts by weight: 1-2 parts of aluminum ammonium sulfate, 3-4 parts of microcrystalline wax, 37-40 parts of hexagonal boron nitride, 8-10 parts of methyl hexahydrophthalic anhydride, 0.4-1 part of neodymium acetylacetonate, 0.7-1 part of octadecylamine, 4-6 parts of 3,5-diamidobenzoic acid, 2-3 parts of triphenyl phosphite, 0.3-0.5 part of pyridine, 32-40 parts of N-methylpyrrolidone, 100-110 parts of epoxy resin E40, 0.6-1 part of fatty acid diethanol amide, 2-3 parts of dodecyl dimethyl betaine, 4-5 parts of pentaerythritol, 0.7-1 part of 2-Mercaptobenzimidazole, 3-4 parts of dibutyl maleate, 0.1-0.2 part of butyltin trioctoate and 7-10 parts of talcum powder. The material disclosed by the invention has favorable antistatic property and high use safety.

Owner:ANQING JINHUIHUANG ELECTRONICS TECH CO LTD

Heat conduction insulating casting glue and preparation method thereof

ActiveCN102093665BLow viscosityGood workmanshipInorganic insulatorsHeat-exchange elementsEpoxyTetrahydrophthalamic acid

The invention relates to a heat conduction insulating casting glue and a preparation method thereof. The casting compound comprises the following main components in parts by weight: (A) 100 parts of hydantoin epoxy resin, (B) 60-120 parts of anhydride curing agent, and (C) 200-400 parts of inorganic heat conductive filler, wherein the component A (per 100 weight parts) contains 10-15 weight partsof alcohol plasticizer; the component B is one or more of hexahydrophthalic anhydride, tetrahydrophthalic anhydride, methyltetrahydrophthalic anhydride, methylhexahydrophthalic anhydride and methylnadic anhydride; and the component C is one or more of silica micropowder, aluminum oxide, aluminum nitride and boron nitride in 300-900 meshes. The preparation method of the casting compound comprises the following steps: mixing A and B proportionally; soaking C in ethanol solution of silane coupling agent, dispersing at a high speed, filtering, and oven-drying; heating the mixture of A and B, adding C, mixing, and debubbling; and casing, and curing. The casting compound provided by the invention has low viscosity, greatly improved heat-conducting property and improved mechanical properties, and is convenient in casting. The preparation method of the casting compound is solvent-free, and has no pollution to the environment.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

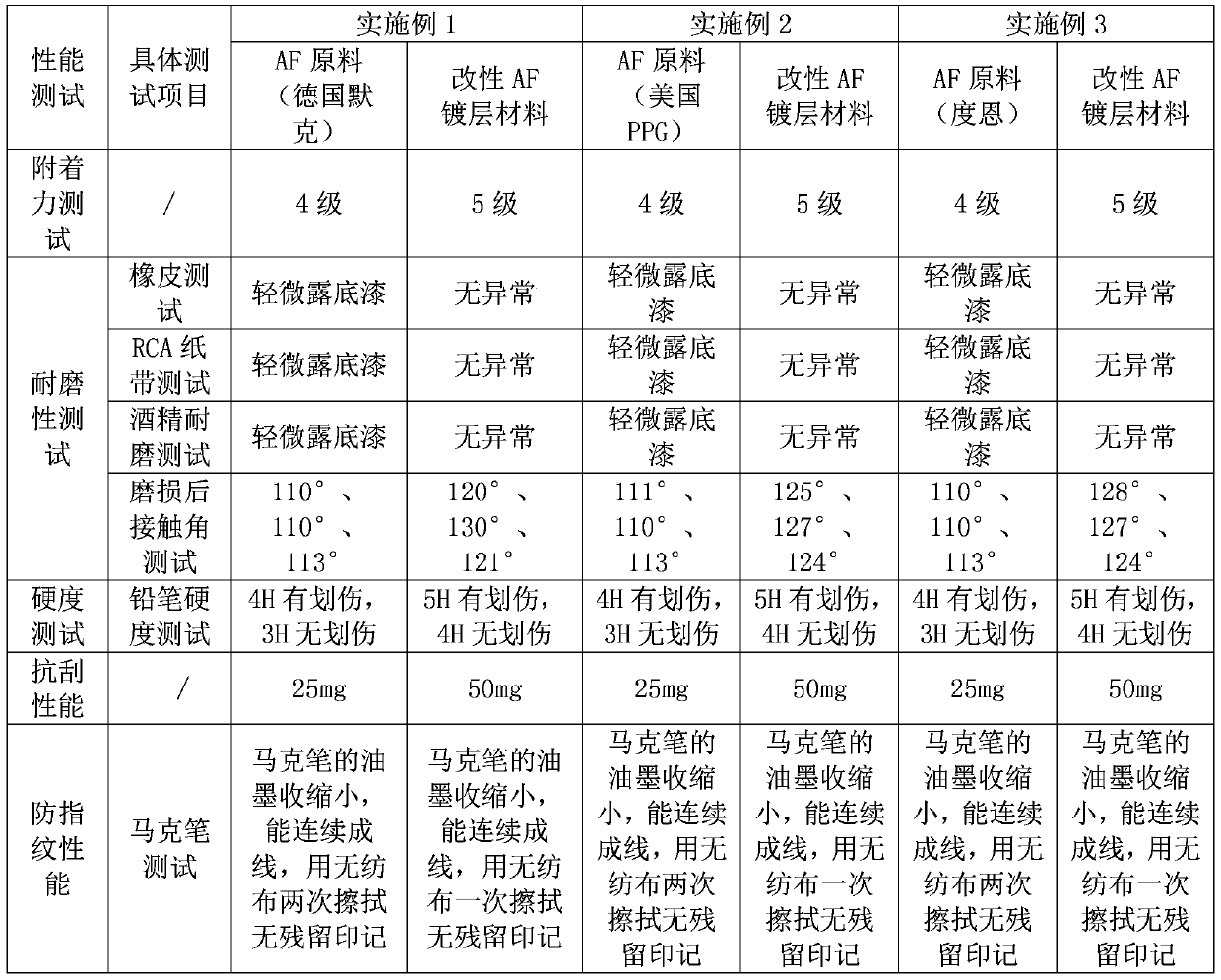

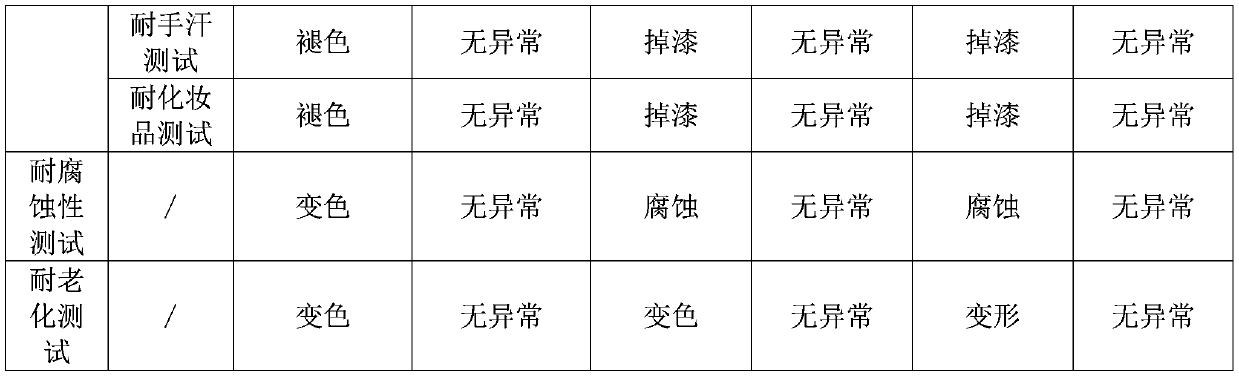

Modified AF coating material as well as preparation method and application thereof

ActiveCN110129728AImprove anti-fingerprint performanceGood antifoulingVacuum evaporation coatingSputtering coatingMethylhexahydrophthalic acidFatty acid

The invention discloses a modified AF coating material as well as a preparation method and application thereof. The modified AF coating material comprises an AF raw material and a modifier, wherein the mass ratio of the AF raw material to the modifier is 20:2.5-3.5, and the modifier comprises fatty acid lead salt, methylhexahydrophthalic anhydride, 4-Nonylphenol, a nanolayer additive and butyl-Phenol in the mass ratio of 1:1:1:1:2. According to the material, the original AF raw material is modified, the thickness of a nanolayer is increased, so that the antifouling property, the fingerprint resistance, the hydrophobicity and the adhesive force of the material are improved.

Owner:重庆广正亿科技有限公司

An outdoor electrical insulation epoxy resin castable for transformer

ActiveCN103709608BGood weather resistanceImprove thermal shock resistancePlastic/resin/waxes insulatorsAntioxidantSilanes

The invention relates to an electric-insulation epoxy resin castable for an outdoor mutual inductor. The epoxy resin castable comprises the following materials by weight percent: 21-26% of resin, 45-55% of filling, 15-25% of a curing agent and 2-6% of other auxiliary agents, wherein the resin is formed by mixing organic silicon modified epoxy resin, phenolic aldehyde epoxy resin, brominated epoxy resin and bisphenol F-type epoxy resin; the filling is silane-processed silica powder; the curing agent is modified methylhexahydrophthalic anhydride; the other auxiliary agents include a curing catalyst, a plasticizer, a reactive diluent, a silane coupling agent, a coloring agent and an antioxidant. The electric-insulation epoxy resin castable has excellent physical and chemical properties and has the performance of heat resistance, low temperature resistance, ultraviolet irradiation resistance, ageing resistance and the like. The electric-insulation epoxy resin castable is applicable to the electric insulation of the outdoor mutual inductor and other electrical equipment.

Owner:JIANGXI TENGDE IND

Insulation epoxy resin material for automotive relay shell and preparing method of insulation epoxy resin material

The invention discloses an insulation epoxy resin material for an automotive relay shell. The insulation epoxy resin material is characterized in by comprising the following raw materials including, by weight, 100-130 parts of epoxy resin E40, 10-12 parts of methylhexahydrophthalic anhydride, 1-2 parts of magnesium stearate, 3-4 parts of triethyl acetyl citrate, 0.8-1 part of diphenyl imidazoline, 2-3 parts of alkenyl succinic anhydride, 1-2 parts of nickel aminosulfonate, 2-3 parts of acrylic polyoxyethylene glycol, 2-4 parts of microcrystalline wax, 0.6-1 part of trimethylbenzyl ammonium chloride, 10-12 parts of methyl acrylate, 0.04-0.1 part of ammonium persulfate, 0.01-0.02 part of divinyl benzene, 10-14 parts of nanosilicon dioxide and 0.1-0.3 part of coco fatty acid diethanol amide. According to the insulation epoxy resin material, the methyl acrylate serves as a monomer, the ammonium persulfate serves as an initiator, the diphenyl imidazoline is added into a mixture, and therefore obtained polymeric alcohol liquid has a certain antiseptic property; and the divinyl benzene serves as a cross-linking agent, nanosilicon dioxide dispersion liquid is added in the crosslinking process for modification, and therefore obtained nano-modification filler has very good intensity and toughness, and further has good compatibility with the epoxy resin.

Owner:宁波永的电子科技有限公司

Epoxy resin composite material for outdoor mutual inductor electrical insulating coating and preparation method for epoxy resin composite material

InactiveCN104293109ASingle performance solutionExcellent physical and chemical propertiesInsulatorsEpoxy resin coatingsEpoxyFiber

The invention discloses an epoxy resin composite material for an outdoor mutual inductor electrical insulating coating. The epoxy resin composite material is characterized by being prepared from the following raw materials in parts by weight: 55-60 parts of polybutadiene epoxy resin, 1-2 parts of flower seed powder, 2-3 parts of nylon 66 fiber, 3-5 parts of cocinic acid monoethanolamide, 10-12 parts of butanol, 9-11 parts of citric acid, 6-9 parts of methylhexahydrophthalic anhydride, 1.2-3.2 parts of nano-zinc oxide, 0.7-1.2 parts of dipotassium glycyrrhizinate, 0.9-1.4 parts of (3-aminopropyl)trimethoxysilane, 1.3-3.5 parts of methylisothiazolinone, 2.1-3.5 parts of N, N`-diphenylthiourea, 0.8-1.5 parts of isopropyl tri(dioctylpyrophosphate) titanate and 4-7 parts of an auxiliary. The preparation process is simple, the operation is simple and convenient, and the problem that the conventional epoxy resin is single in performance is solved effectively. The epoxy resin provided by the invention has the advantages of excellent physical and chemical property, high-temperature resistance, low-temperature resistance, ultraviolet irradiation resistance, ageing resistance, high hardness, and excellent insulation effect, and is suitable for electrical insulation of outdoor mutual inductors and other electrical equipment.

Owner:HEFEI DINGYA FURNITURE

Antistatic heat-conducting composite material and preparation method thereof

The invention discloses an antistatic heat-conducting composite material. The antistatic heat-conducting composite material is prepared from the following raw materials in parts by weight: 3 to 4 parts of polyethylene-diglycol adipate glycol, 10 to 13 parts of nano aluminum oxide, 1 to 2 parts of 3,5-diaminobenzoic acid, 0.3 to 0.7 part of pyridine, 2 to 3 parts of triphenyl phosphite, 0.1 to 0.2 part of lithium chloride, 0.6 to 1 part of a silane coupling agent kh560, 0.7 to 1 part of neodymium acetylacetonate, 1.6 to 2 parts of methylhexahydrophthalic anhydride, 80 to 90 parts of epoxy resin 6101, 1 to 2 parts of aluminum potassium sulfate, 0.4 to 1 part of triethanolamine oleic soap, 5 to 7 parts of dibutyl maleate, 0.6 to 1 part of ricinoleic acid, 2 to 3 parts of polyacrylamide, 2 to 4 parts of potassium zirconium carbonate and 0.6 to 1 part of hexabromocyclododecane. According to the antistatic heat-conducting composite material disclosed by the invention, the triethanolamine oleic soap and the like are added, so that the antistatic performance of the finished-product composite material can be effectively improved.

Owner:邹小凤

Hybridized grafted flame-retarding epoxy material and preparation method thereof

The invention discloses a hybridized grafted flame-retarding epoxy material. The hybridized grafted flame-retarding epoxy material is prepared from the following raw materials in parts by weight: 6 to 8 parts of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide, 1 to 2 parts of vinyltrimethoxysilane, 0.1 to 0.2 part of 2,2'-azobisisobutyronitrile, 2 to 3 parts of triglycidyl isocyanurate, a proper amount of dimethylformamide, 0.8 to 2 parts of 3-aminopropyltriethoxysilane, 17 to 20 parts of a 10% to 13% hydrochloric acid solution, 5 to 8 parts of methylhexahydrophthalic anhydride, 100 to 120 parts of epoxy resin E40 and a proper amount of ethanol. The epoxy material disclosed by the invention has very good flame-retarding and fireproof performance, good utilization safety and excellent comprehensive performance.

Owner:倪群

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com