Liquid epoxy resin composition for packaging LED (Light Emitting Diode)

A liquid epoxy resin, LED packaging technology, used in semiconductor devices, electrical components, circuits, etc., can solve the problems of poor flexibility and crack resistance of cured products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

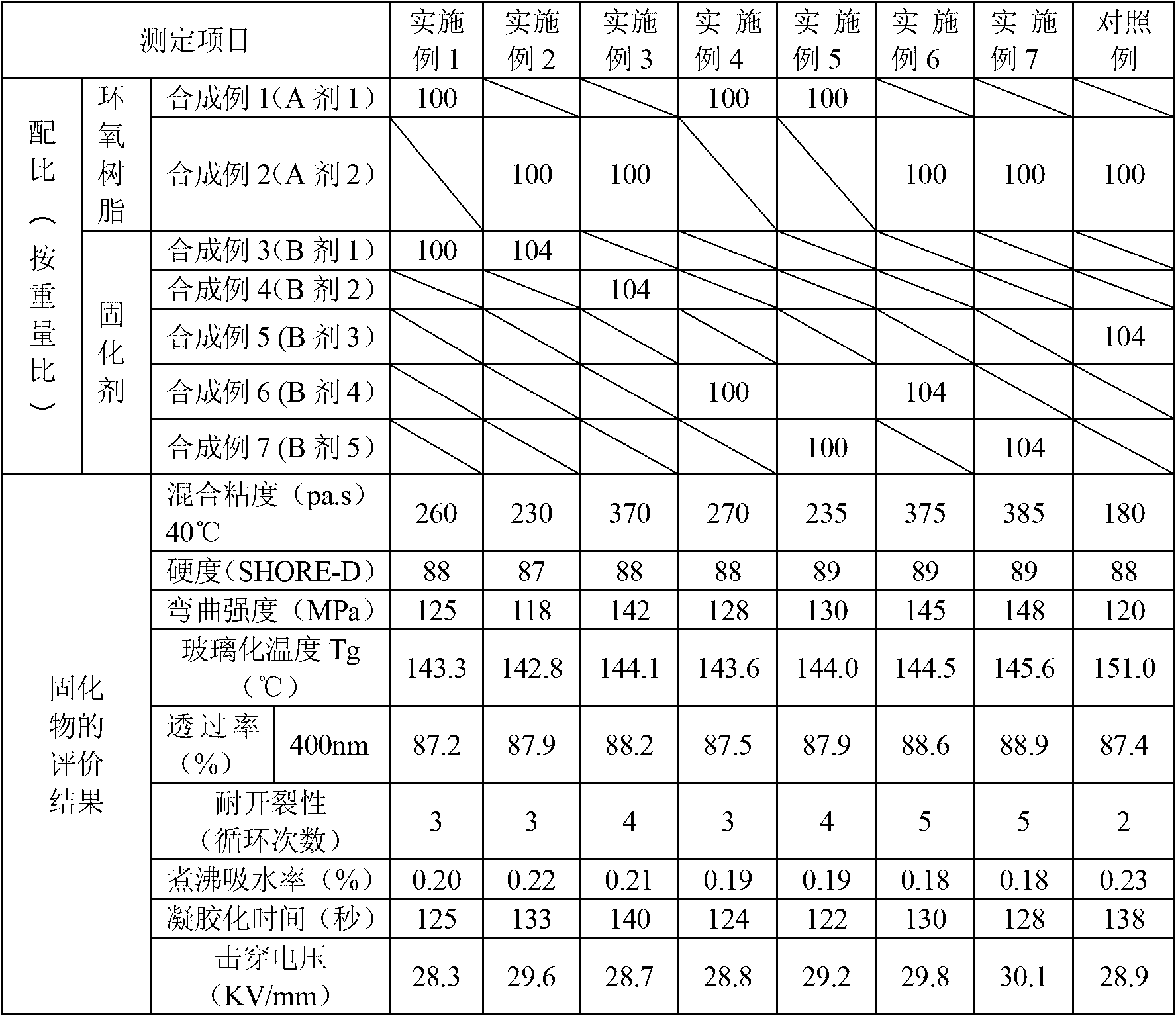

Examples

Synthetic example 1(A

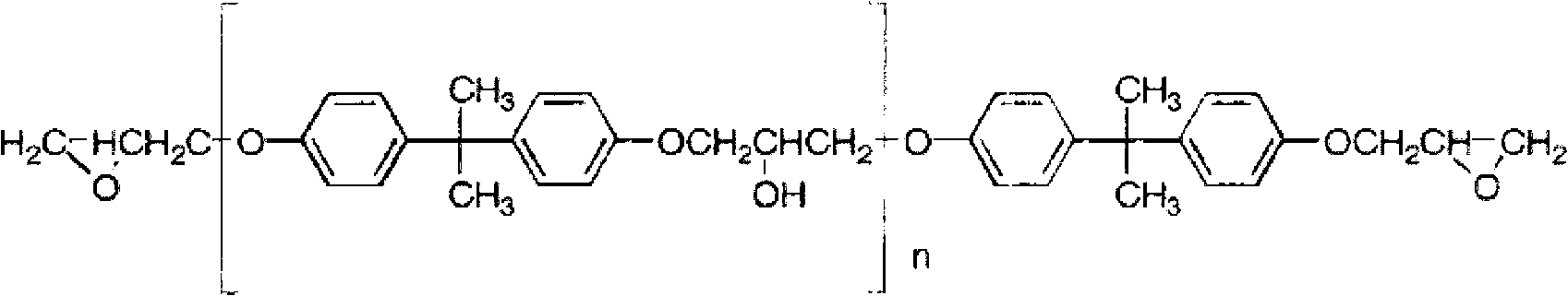

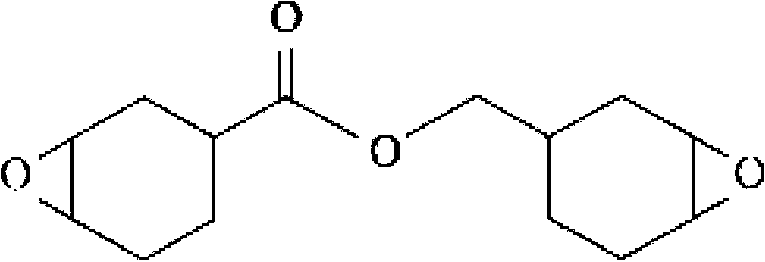

[0026] Synthesis Example 1 (Agent 1): Add 1800 grams of bisphenol A epoxy resin (R139S manufactured by Mitsui Chemicals, epoxy equivalent 190g / eq) in a 5L stainless steel reactor with electric heating and vacuum device, and heat up to After reaching 80°C, add 200 grams of 3,4-epoxycyclohexylmethyl 3,4-epoxycyclohexyl carboxylate (Hubei Xinjing New Material Co., Ltd., epoxy equivalent 130g / eq), defoamer 2 Gram (Deqian Chemical 5300), stir evenly and heat up to 110°C, keep the temperature, vacuumize for more than 30 minutes while stirring (vacuum degree to 3 Torr), cool to 60°C and discharge.

Synthetic example 2(A

[0027] Synthesis Example 2 (Agent 2): Add 1600 grams of bisphenol A epoxy resin (R139S manufactured by Mitsui Chemicals, epoxy equivalent 190g / eq) into a 5L stainless steel reactor with electric heating and vacuum device, and heat up to After reaching 80°C, add 400 grams of 3,4-epoxycyclohexylmethyl 3,4-epoxycyclohexyl carboxylate (Hubei Xinjing New Material Co., Ltd., epoxy equivalent 130g / eq), defoamer 2 Gram (Deqian Chemical 5300), stir evenly and heat up to 110°C, keep the temperature, vacuumize for more than 30 minutes while stirring (vacuum degree to 3 Torr), cool to 60°C and discharge.

Synthetic example 3(B

[0028] Synthesis Example 3 (Agent B 1): Add 1930 grams of methylhexahydrophthalic anhydride (MEHHPA produced by Zhejiang Platino Chemical Co., Ltd.) into a 5L stainless steel reactor with electric heating and vacuum device, and heat up to 80°C Finally, add 10 grams of N,N-dimethylbenzylamine (manufactured by Changzhou Yuexin Chemical), 50 grams of neopentyl glycol (manufactured by Korea LG Chemicals), antioxidant 2,6-di-tert-butyl-4-methyl 1 gram of base phenol (manufactured by Jinan Genesis Chemical Industry Co., Ltd.), 1 gram of ultraviolet absorber 2-hydroxy-4-methoxybenzophenone (manufactured by Jinyicheng Fine Chemical Industry Co., Ltd., Xiangfan City) was heated to 100 ° C while stirring, and the temperature was maintained. While stirring, vacuumize for more than 30 minutes (vacuum degree to 31orr), cool to 60°C and discharge.

[0029] Synthesis Example 4 (Agent B 2): Add 1900 grams of methylhexahydrophthalic anhydride (MEHHPA produced by Zhejiang Platino Chemical Co., ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com