Patents

Literature

54results about How to "Improve anti-fingerprint performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-abrasion resistant ultraviolet light solidifying fingerprint resistant coating

InactiveCN101701129AGood hardness and wear resistanceMeet wear resistancePolyurea/polyurethane coatingsSolventFingerprint

The invention relates to a light solidifying high-abrasion resistant fingerprint resistant coating which is used for the surfaces of plastic shells of portable electronic products, such as mobile phones, MP3, digital cameras, handheld computers, and the like and comprises the following components: 10-35 percent of high-functionality urethane acrylate, 5-25 percent of bifunctional urethane acrylate, 0.01-20 percent of acrylic ester monomer, 5-20 percent of high-functionality acrylic ester, 5-40 percent of fluorin-contained acrylic ester, 0.01-10 percent of nano inorganic powder filler, 1-5 percent of light initiating agent, 0.01-5 percent of auxiliary agent and 5-30 percent of solvent. The invention improves the fingerprint resistant capability of a coating film by the enrichment and microphase separation of a fluorin-contained group added into the coating on the surface of a coating surface, provides excellent abrasion resistance and hardness by using the polyurethane structure in the coating and the added nano abrasion resistant filler and meets the requirements of abrasion resistance, scratch resistance and fingerprint resistance of the portable electronic products.

Owner:武汉嘉特利佰联创科技有限公司

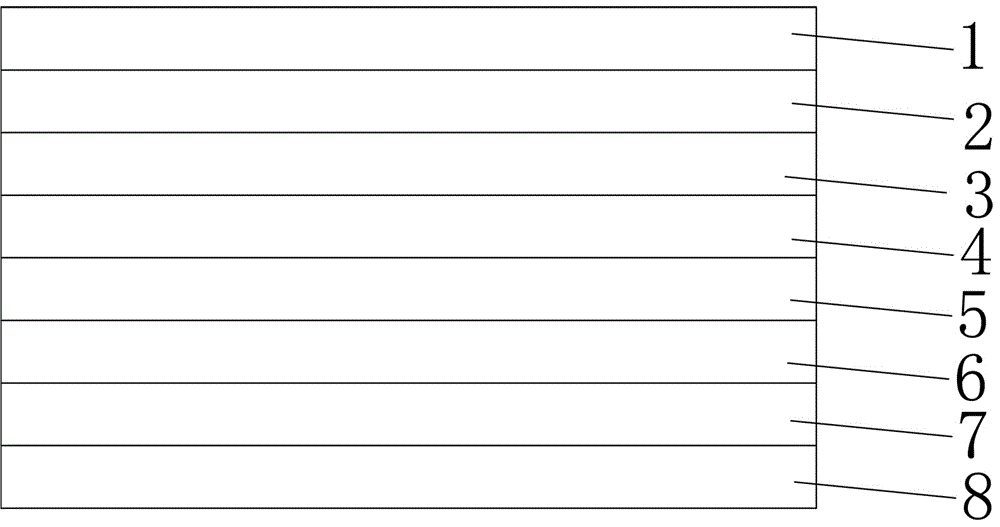

Anti-fingerprint film and preparation method thereof

InactiveCN101879801AChange the phenomenon of easy to get fingerprints and dirtNot easy to paveSynthetic resin layered productsVacuum evaporation coatingPolymer sciencePerfluoropolyether

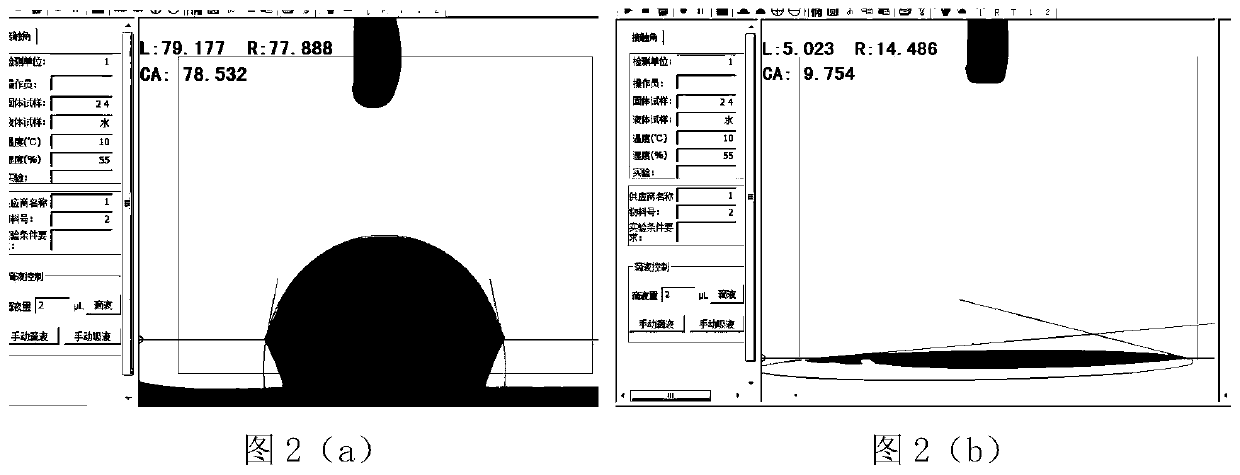

The invention discloses an anti-fingerprint film, comprising a plastic cement base material and perfluoropolyether or an organosilicon polymer film, wherein the perfluoropolyether or the organosilicon polymer film is deposited on the surface of the plastic cement base material; the thickness of the film is 5-30nm; and the invention also discloses a preparation method of the anti-fingerprint film. The surface of the base material of the invention is deposited with the perfluoropolyether or the organosilicon polymer film; the contact angle of water and oil stain on the film is increased, thus being difficult to be paved smoothly; the anti-fingerprint film has the advantages of hydrophobicity, oleophobicity, low sliding angle, wear resistance and ageing resistance; the anti-fingerprint performance of the surface of a product is improved; the phenomenon of easy-sticking with fingerprint smudginess of the traditional product is changed; and the attractive appearance of the product can be guaranteed all the time in the use process.

Owner:GUANGDONG JANUS SMART GRP CO LTD

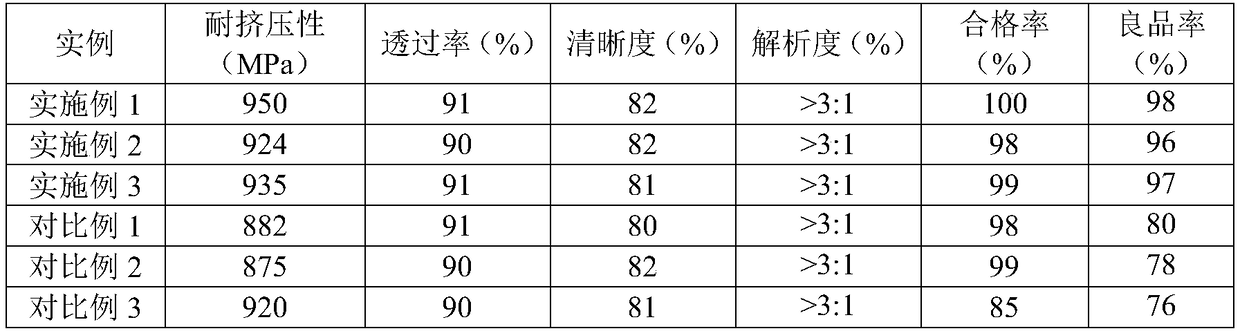

3D (three-dimensional) glass processing technology

InactiveCN109206002AImprove pass rateAvoid temporary blindnessGlass reforming apparatusGlass tempering apparatusEtchingMobile phone

The invention provides a 3D (three-dimensional) glass processing technology. According to the technology, 2D (two-dimensional) glass is subjected to the steps of cutting, CNC (computer numerical control) outline processing, hot bending shaping, strengthening, transfer printing, laser irradiation, AG (anti-glare) etching and the like, finally a 3D (three-dimensional) glass finished product is prepared, and therefore the problems of oxidization, glare, hook surface decoration and the like in the hot bending shaping process of glass in the processing and manufacturing process of 3D (three-dimensional) glass can be solved, meanwhile, the manufactured 3D (three-dimensional) glass product is excellent in performance and low in cost, and the application in the mobile phone industry, the computerindustry, the digital industry and optical lenses can be realized.

Owner:江苏优视光学科技有限公司

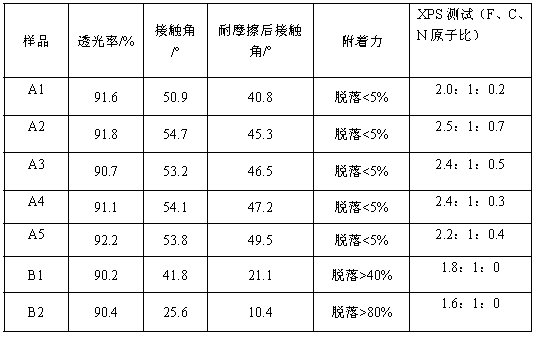

Preparation method for anti-fingerprint film and anti-fingerprint film prepared by method

ActiveCN103031528AImproves the effect of oil stainsImprove bindingVacuum evaporation coatingSputtering coatingChemistryTransmittance

The invention provides a preparation method for an anti-fingerprint film and the anti-fingerprint film prepared by the method, the method employs magnetron sputtering to form the anti-fingerprint film on the surface of a base material, the target material employed by the magnetron sputtering is a fluorine containing organic matter, a reaction gas is filled in a process of the magnetron sputtering, and the reaction gas is a mixed gas of CF4 and N2. The anti-fingerprint film prepared by the method contains three elements of F, C and N, and the ratio of fluorine to carbon is greater than or equal to 2:1. The high ratio of fluorine to carbon makes the film to have excellent antifouling effect, and the film has the characteristics of high light transmittance, strong adhesive force and good wear resistance. The anti-fingerprint film is suitable for a touch screen with a large size.

Owner:BYD CO LTD

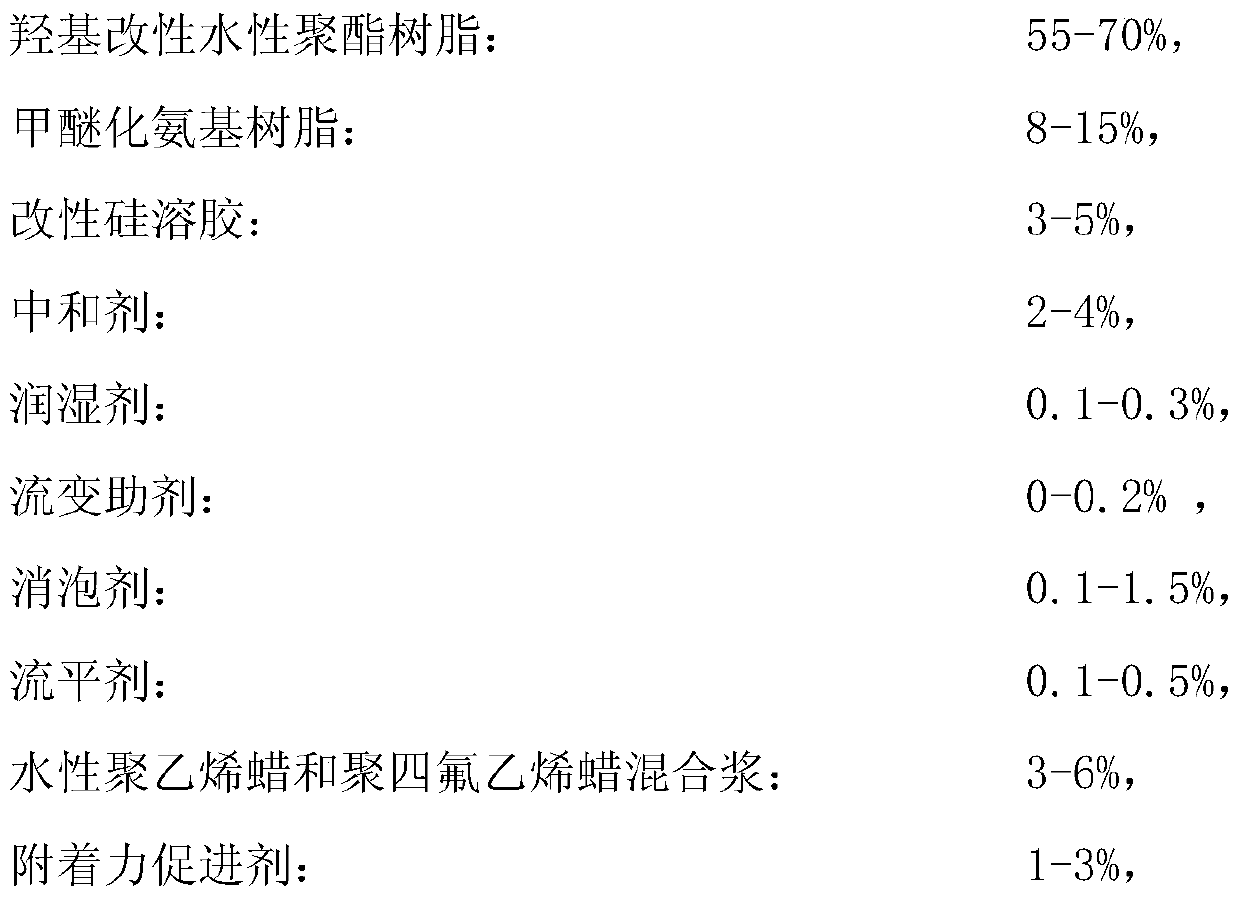

Anti-fouling and fingerprint-resistant stainless steel plate water-based paint and preparation method thereof

ActiveCN105462460AImprove stain resistanceGood anti-aging performanceAntifouling/underwater paintsPaints with biocidesWater basedSolvent

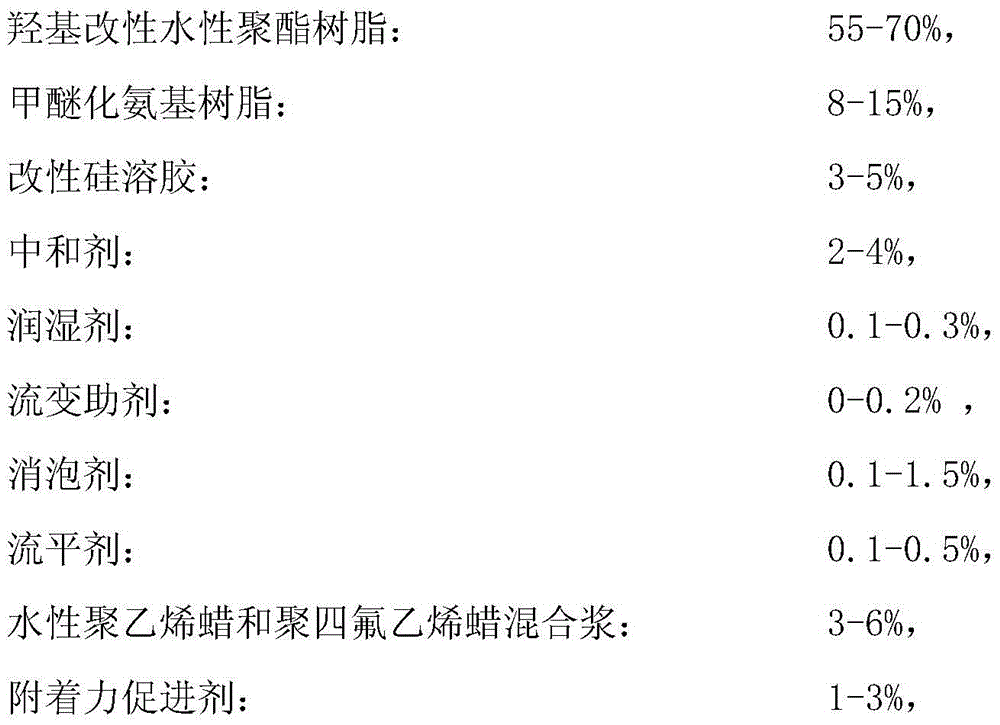

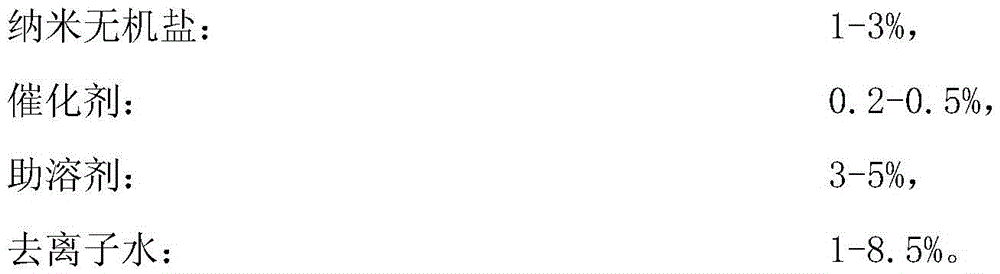

The invention discloses anti-fouling and fingerprint-resistant stainless steel plate water-based paint and a preparation method thereof. The anti-fouling and fingerprint-resistant stainless steel plate water-based paint is prepared from, by weight, 55-70% of hydroxy modified waterborne polyester resin, 8-15% of methylated amino resin, 3-5% of modified silica sol, 2-4% of a neutralizing agent, 0.1-0.3% of a wetting agent, 0-0.2% of theological additives, 0.1-1.5% of a defoaming agent, 0.1-0.5% of a flattening agent, 3-6% of aqueous polyethylene wax and polytetrafluoroethylene wax mixed paste, 1-3% of an adhesive force promoting agent, 1-3% of nanometer inorganic salt, 0.2-0.5% of a catalyst, 3-5% of a cosolvent and 1-8.5% of deionized water. The anti-fouling and fingerprint-resistant stainless steel plate water-based paint has excellent fingerprint resistance and hydrophobicity and oleophobicity, and is large in fingerprint-resistant coating water contact angle and oil contact angle, small in sliding angle, and excellent in abrasion resistant and aging resistance, and greasy dirt is prone to sliding. Meanwhile, the anti-fouling and fingerprint-resistant stainless steel plate water-based paint is environmentally friendly and healthy, and the method is simple.

Owner:FUJIAN GANG HONG METAL TECH CO LTD

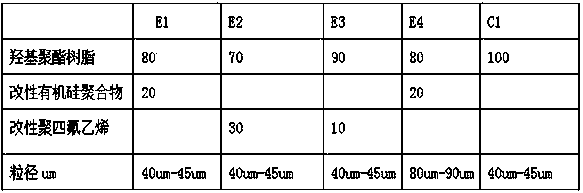

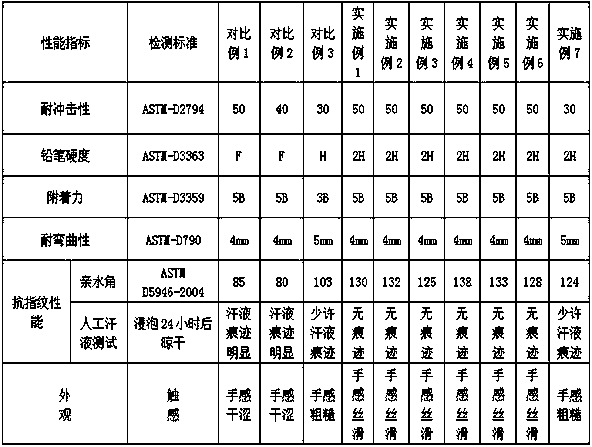

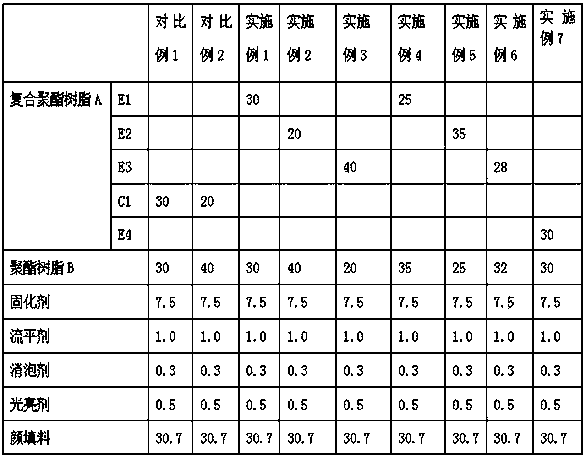

Anti-fingerprint powder coating and preparation method and application thereof

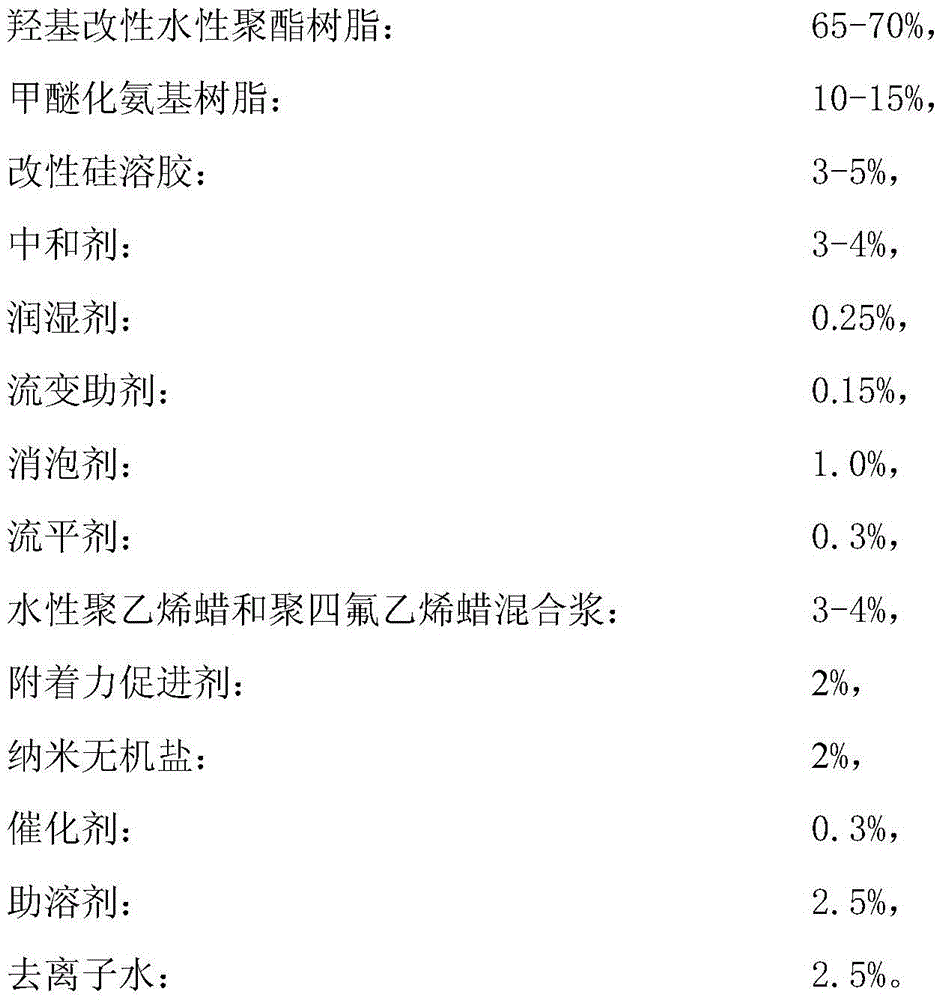

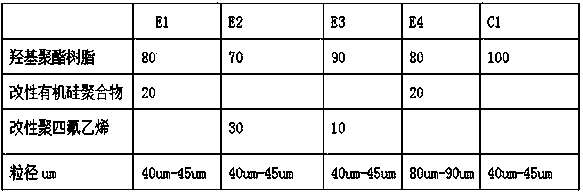

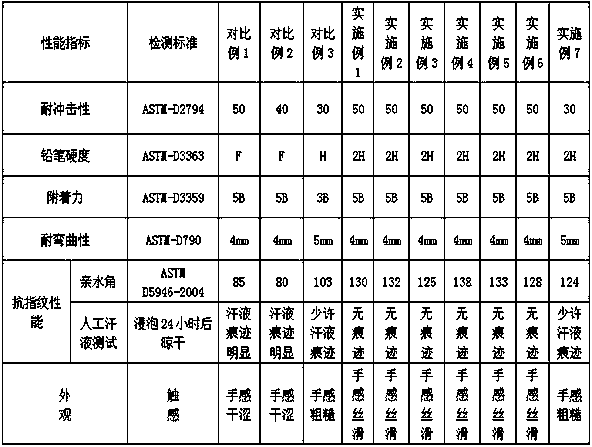

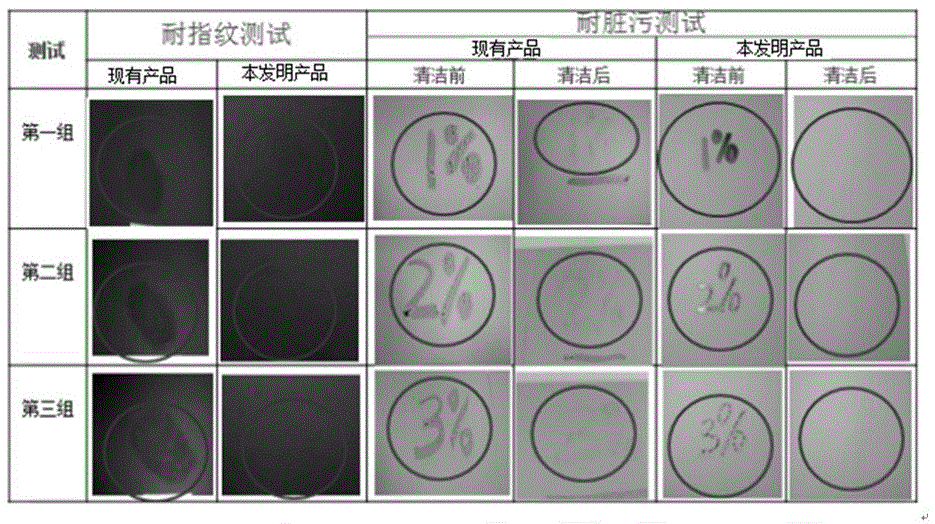

ActiveCN109082210AImprove anti-fingerprint performanceSilky feel goodPowdery paintsPolyester coatingsElectronic communicationPolyester resin

The invention discloses anti-fingerprint powder coating and a preparation method and application thereof. The anti-fingerprint powder coating is prepared from, by weight, 20-40 parts of composite polyester resin A, 30-50 parts of polyester resin B and 0-30 parts of other auxiliary agents. The preparation method includes: well mixing hydroxyl polyester resin and a composite material, subjecting tomelt extrusion through a double-screw extruder, cooling sheets to the normal temperature, and crushing to obtain the composite polyester resin A; adding the composite polyester resin A, the polyesterresin B and other auxiliary agents into a premixing tank, well mixing, subjecting to melt extrusion through a double-screw extruder, cooling sheets to the normal temperature, and finally crushing andgrading through a high-speed crusher to obtain powder in particle size of 33-38micron. By synergistic effects of the composite polyester resin A and the polyester resin B, a formed coating is easy toclean and remarkable in anti-fingerprint performance, automatic fingerprint clearing is realized, and the powder coating is silky and smooth to touch and especially suitable for terminal products including furniture, door and window accessories, decorative lamps, electronic communication equipment and the like and manifests high end and elegance of products.

Owner:广东歌丽斯化学有限公司

UV LED ultraviolet curing metal anti-fingerprint nano coating material and preparation method thereof and metal plate

InactiveCN112194976AFast curingHigh electrical-to-optical conversion efficiencyAntifouling/underwater paintsPretreated surfacesPolymer scienceMeth-

The invention discloses a UV LED ultraviolet curing metal anti-fingerprint nano coating material and a preparation method thereof and a metal plate. The coating material comprises the following components in parts by weight: a 2-functional aliphatic polyurethane acrylate oligomer, 8-15 parts of a silicon modified polyurethane acrylate oligomer, 6-functional aliphatic polyurethane acrylate oligomer, ethoxylated trimethylolpropane triacrylate, propoxylate neopentylene glycol diacrylate, dipentaerythritol hexaacrylate, a photoinitiator, an active ammonia co-initiator and an auxiliary agent. According to the coating material, UV LED can be effectively used as an ultraviolet light source for rapid curing, the coating material has the characteristics of energy consumption saving, use cost reduction and environmental protection, the curing speed of the coating is high, and a formed coating film is good in performance, high in adhesive force on a metal plate and good in stain resistance, waterresistance and fingerprint resistance; and the preparation method of the coating material is simple, full dispersion and full reaction of all the components can be achieved through a dispersion machine, and industrial production is easy to achieve.

Owner:FOSHAN GAOMING SUN YICAI COATING

Anti-fingerprint ultraviolet curing high-gloss varnish

InactiveCN105623477AImprove anti-fingerprint performanceImprove dirt resistanceAntifouling/underwater paintsPaints with biocidesPolymer scienceMeth-

The invention discloses anti-fingerprint ultraviolet curing high-gloss varnish. The high-gloss varnish is prepared from, by weight, 8-13% of nine-degree-of-functionality urethane acrylate, 3-16% of organic silicon modified acrylate polymer, 6-13% of epoxy acrylate resin, 3-18% of trimethylolpropane acrylate, 2-5% of dipropylene glycol 2-propenyl ester or hexanediol diacrylate, 1-5% of 2-phenoxyethyl acrylate, 1-5% of photoinitiator, 1-2% of an anti-fouling auxiliary, 0.1-0.15% of an anti-shrinkage-cavity auxiliary, 15-25% of ethyl acetate and the balance propylene glycol methyl ether acetate. The high-gloss varnish can further enrich selections of ultraviolet curing painting in coating of automobiles or mobile phones or other plastic shells, anti-fingerprint performance and dirt resistance of similar products are greatly improved, requirements of high-grade automobiles or electronic product shells are met, and good economic benefits can be generated.

Owner:柳州市凯佰化工股份有限公司

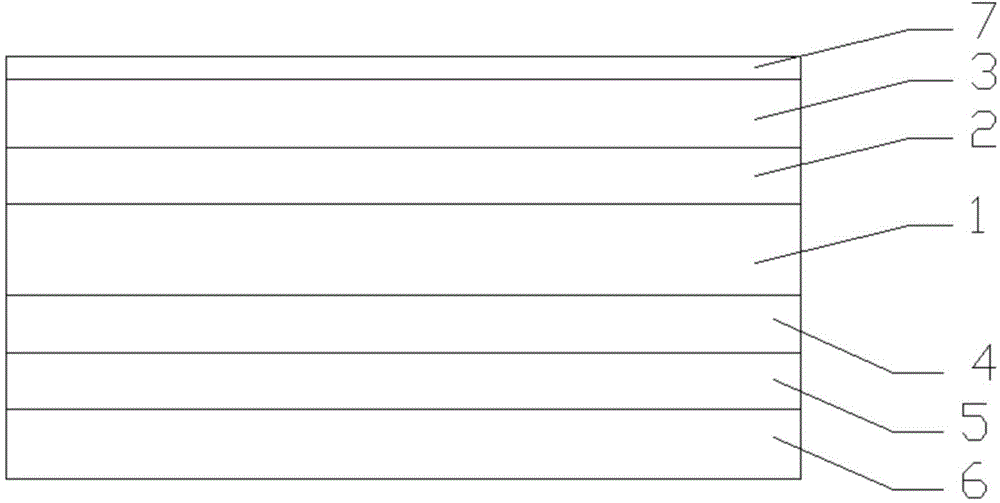

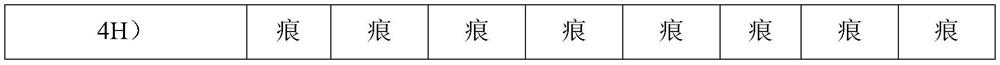

Sapphire camera lens

The invention discloses a sapphire camera lens, comprising a lens substrate, a trititanium pentoxide film I, a silicon dioxide film I, an ink layer, a trititanium pentoxide film II, a silicon dioxide film II and an AF (anti-fingerprint) film, wherein the upper surface of the lens substrate is coated with the trititanium pentoxide film I; the trititanium pentoxide film I is coated with the silicon dioxide film I; the silicon dioxide film I is coated with the AF film; the lower surface of the lens substrate is coated with the ink layer; the ink layer is coated with the trititanium pentoxide film II; the trititanium pentoxide film II is coated with the silicon dioxide film II. According to the sapphire camera lens, since the lens substrate is coated with the silicon dioxide films and the trititanium pentoxide films, the light transmission of the sapphire camera lens is increased, the imaging effect of the camera is very clear, and the night imaging capability is improved; moreover, the surface layer of the lens is coated with the AF film, so that the anti-pollution capability of lens glass is increased, the lens glass keeps blue-green for a long time, and in addition, the wear resistance of the lens glass is further improved.

Owner:林建国

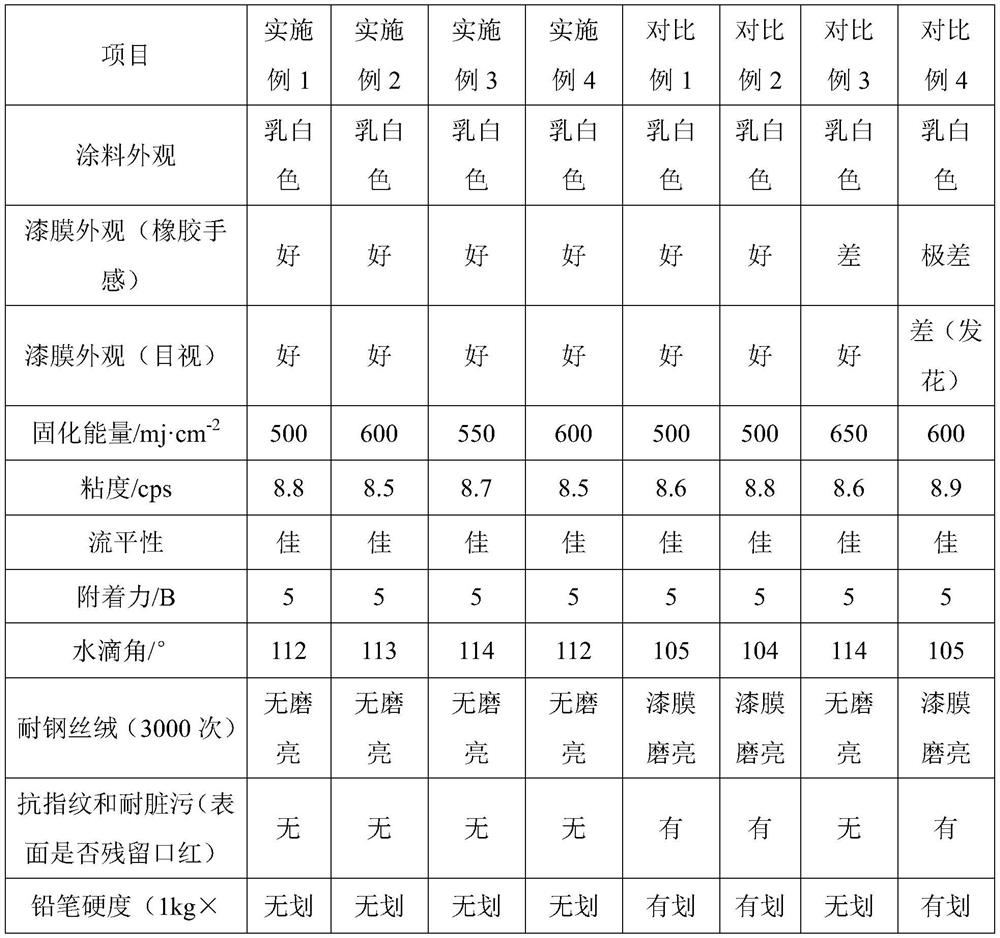

Anti-dazzle anti-fingerprint wear-resistant hardening liquid with rubber hand feeling, and preparation method thereof

PendingCN113683952AGood rubber skin feelGood slipperinessPolyurea/polyurethane coatingsPhotoinitiatorPolymer chemistry

The invention discloses an anti-dazzle anti-fingerprint wear-resistant hardening liquid with rubber hand feeling, and a preparation method thereof. The hardening liquid comprises, by weight, 40-50 parts of organic fluorine-silicon special modified polyurethane acrylic resin, 10-15 parts of special modified UV matte polyurethane acrylic resin, 5-10 parts of an acrylic monomer, 1-5 parts of a photoinitiator, 1-2 parts of fluorine-containing acrylic compound resin, 1-3 parts of a rubber skin feeling auxiliary agent, 4-5 parts of matting powder, 3-4 parts of wear-resistant powder, 1-2 parts of an anti-settling agent, 1-2 parts of a wetting dispersant and 20-30 parts of a solvent. The hardening liquid obtained by the invention is high in hardness, good in hand feeling, good in wear resistance and excellent in anti-fingerprint effect, can meet the higher requirements of the market on anti-glare hardening liquid, can be used for spraying and also can be used for shower coating, and compared with spraying, the shower coating can greatly reduce the production cost, avoid environmental pollution and relieve harm to human bodies.

Owner:湖南宏泰新材料有限公司

Anti-blue-light flexible-glass explosion-proof membrane and preparing technology thereof

InactiveCN105856759AHigh hardnessImprove anti-fingerprint performanceSynthetic resin layered productsLaminationAdhesiveThin membrane

The invention discloses an anti-blue light flexible glass explosion-proof membrane and a preparation process thereof. The present invention makes finished products by using PC / PMMA film, UV-curing paint on it, and pasting acrylic and silica gel on the bottom. UV curable coatings have high hardness and anti-fingerprint performance, which can reach or approach the effect of glass surface; after PC / PMMA film is coated with UV curable coating, it can achieve the effect similar to glass breaking after bending; after PET is coated with acrylic and film Fitting, increasing the thickness and hardness of the product, so that the product has an explosion-proof effect; the PET lower layer coated with silicone pressure-sensitive adhesive can be attached to the surface of the screen. The anti-blue light coating is added in the production process, so that the product can effectively block the blue light of 450-480nm, and prevent the blue light from damaging the eyes when looking at the screen for a long time. The present invention has the function of preventing blue light and can well protect users' eyes.

Owner:DONGGUAN RETECK COATING TECH CO LTD

Preparation method of AF coated glass with antibacterial effect

The invention provides a preparation method of AF coated glass with an antibacterial effect. The preparation method comprises the following steps: S1, carrying out ultrasonic cleaning on a glass substrate by using a solvent or a cleaning agent, washing with deionized water, and blow-drying with nitrogen; S2, coating a SiO2 film base layer on the glass substrate in a vacuum coating manner; S3, adding nano-silver into an anti-fingerprint agent, uniformly spraying the treated anti-fingerprint agent onto the SiO2 film base layer on the surface of the glass substrate through a spraying machine, then drying the glass substrate, taking out the glass substrate, and cooling so as to form an antibacterial anti-fingerprint layer; and S4, dispersing SiO2 particles and nano-silver in a solvent to prepare an antibacterial solution, uniformly spraying the antibacterial solution on the antibacterial anti-fingerprint layer of the glass substrate through a spraying machine, drying the glass substrate, taking out the glass substrate, and cooling the glass substrate to form an antibacterial SiO2 film layer. The coated glass provided by the invention has anti-fingerprint and antibacterial effects.

Owner:江苏中新瑞光学材料有限公司

Anti-fingerprint glass coating with high friction coefficient and preparation method thereof

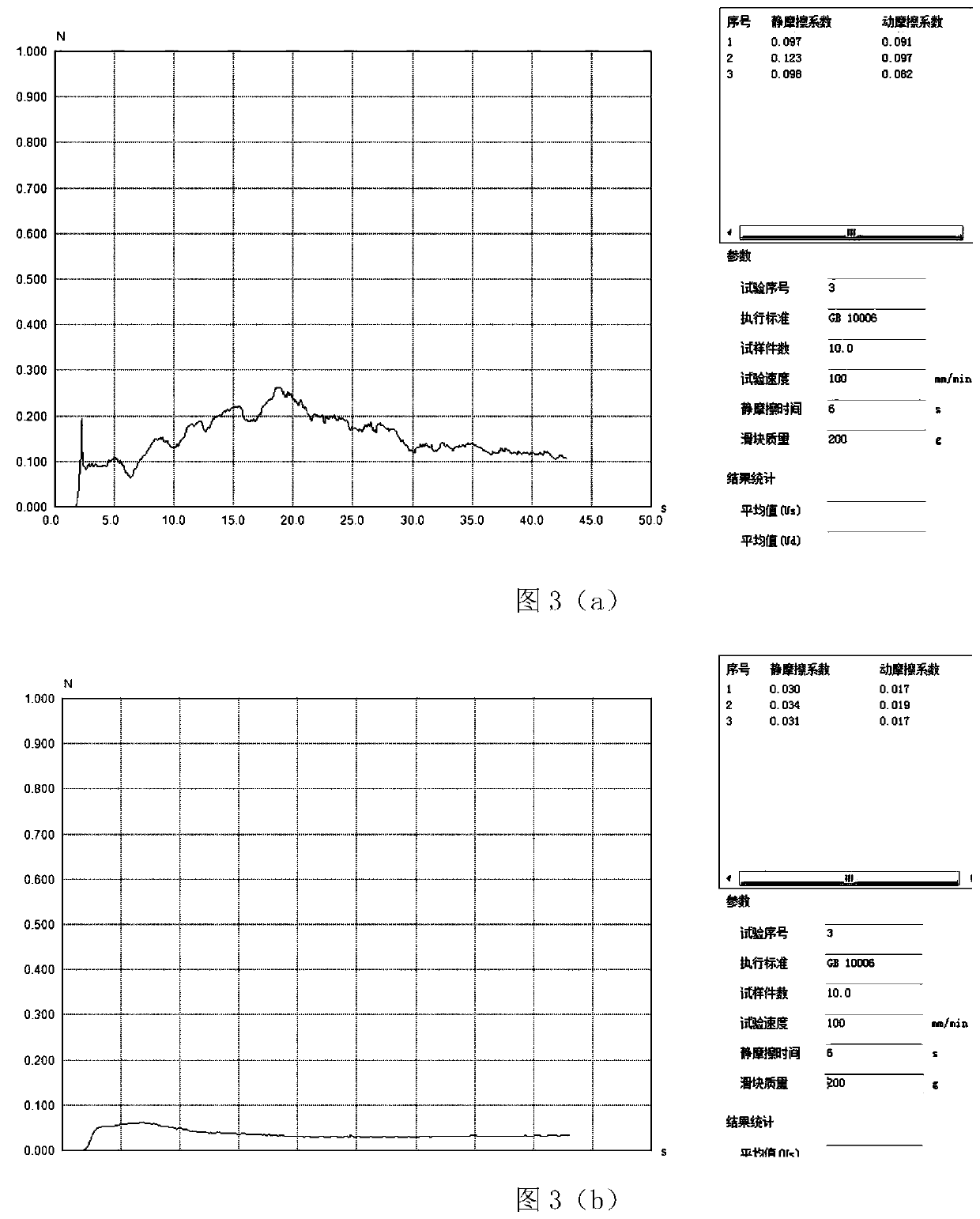

InactiveCN111410435AHigh coefficient of kinetic frictionImprove wear resistanceCoatingsMethyl palmoxirateStain

The invention provides a preparation method of an anti-fingerprint glass coating with a high friction coefficient. The preparation method of the paint used by the coating comprises the following steps: uniformly mixing 20-25 parts by mass of perfluoroalkyl olefin, 8-12 parts by mass of vinylmethoxysilane and 6-8 parts by mass of hexamethyldisiloxane, stirring, heating to 80-100 DEG C, keeping thetemperature constant for 10-12 hours, heating to 110-120 DEG C through silicone oil, and purifying for 4-6 hours to obtain a perfluoropolyether alkylated oligomer with the molecular weight of 3000-4000; and uniformly stirring the following components in parts by mass: 15-25 parts of the obtained perfluoropolyether alkylated oligomer, 25-35 parts of nonafluoro-ethoxy-butane and 45-55 parts of heptafluoro-ethoxy difluoro methyl-propane, so as to obtain the required coating. The glass carrier treated by the coating has the excellent performances of high dynamic friction coefficient, fingerprint resistance, oil stain resistance, scratch resistance and the like. According to the invention, the defect that a common anti-fingerprint coating is used on a 3C rear cover in the 5G era can be effectively overcome, and the preparation method is simple, mild in reaction condition, and free of pollution and harm to human bodies and the environment.

Owner:湖南宏泰新材料有限公司

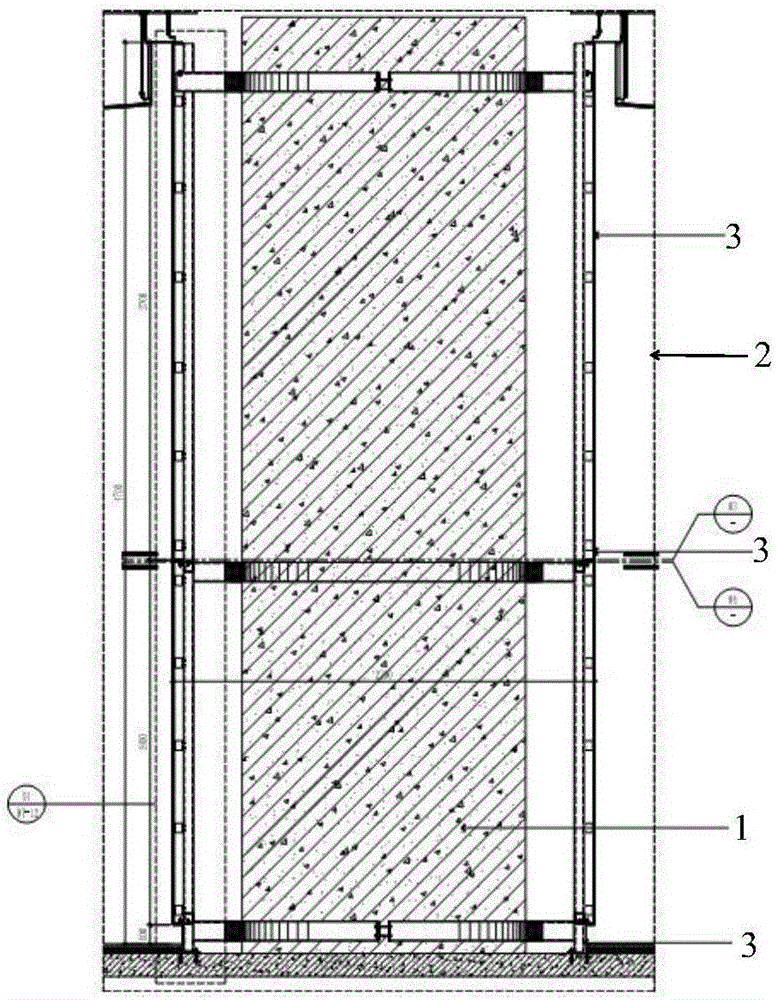

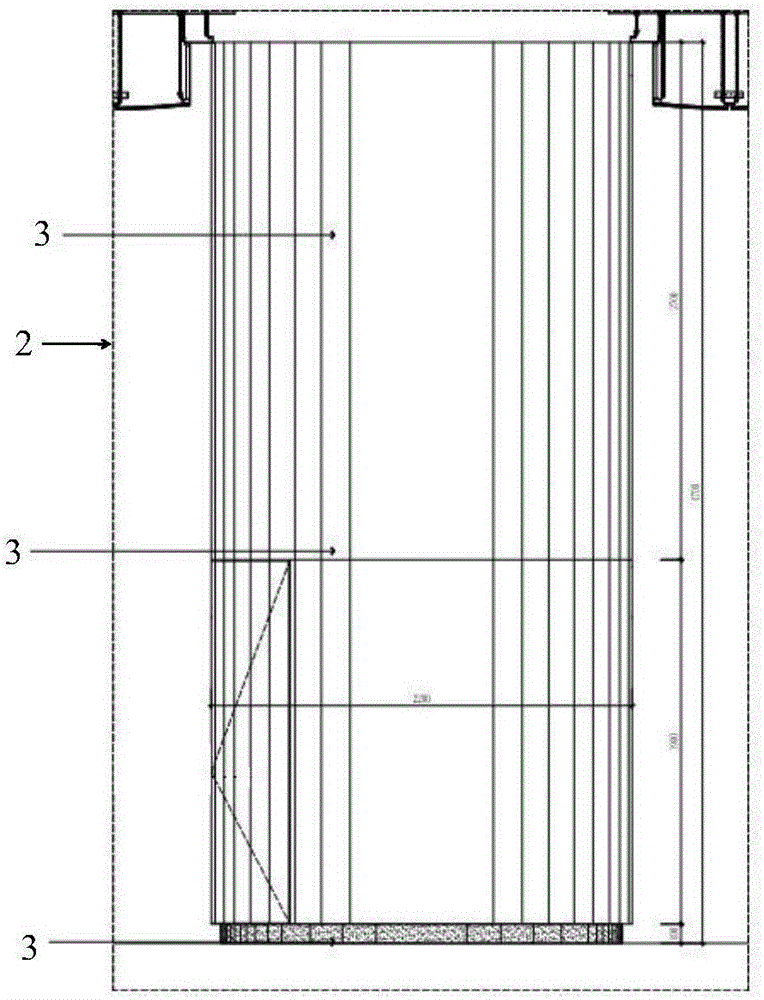

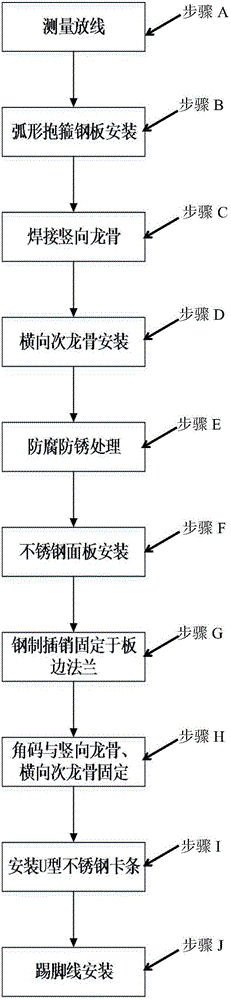

Method for mounting metal plate cylinder

ActiveCN106812247AImprove level stabilityImprove anti-fingerprint performanceStrutsPillarsSteel platesCorrosion resistant

The invention provides a method for mounting a metal plate cylinder. The method is characterized by comprising the following steps: A, measuring and setting out; B, mounting an arc-shaped hoop steel plate; C, welding a vertical main keel; D, mounting a transverse secondary keel; E, performing corrosion-resistant and anti-rust treatment; F, mounting an arc-shaped stainless steel panel; G, fixing a steel plug pin in a stainless steel flange on the edge of the plate; H, fixing angle codes as well as the vertical main keel and the transverse secondary keel; I, mounting a U-shaped stainless steel clamping strip; J, mounting a skirting line.

Owner:中建八局装饰工程有限公司

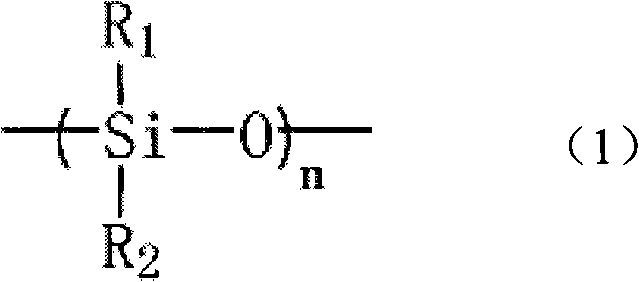

Coating composition

ActiveCN101338158AImprove anti-fingerprint performanceReduce the color difference value ΔEPretreated surfacesCoatingsFluorine containingSURFACTANT BLEND

The invention provides a painting combination which comprises silicon resin, fluorine-containing surfactant and coupling agent. Through the paint that is provided by the invention and painted on substrates to format a coating layer, the fingerprint blot resistance of the substrates can be improved greatly. For example, the fingerprint blot resistance of the material containing the coating layer of the invention is all above good.

Owner:重庆市光彩涂料有限公司

Metal plate surface fingerprint-resistant treatment method

InactiveCN111074186AImprove corrosion resistanceMeet assembly requirementsHot-dipping/immersion processesWax coatingsMetallurgyStain

The invention relates to the technical field of accessory devices, in particular to a metal plate surface fingerprint-resistant treatment method. The metal plate surface fingerprint-resistant treatment method can improve the corrosion resistance of a fingerprint-resistant plate, enables the fingerprint resistance, the ground connection performance and the corrosion resistance to be good and meet the requirement for a core assembly so as to meet the user requirement, passivation and the fingerprint-resistant treatment can be conveniently carried out at the same time, and consumed time is shortened; the method comprises the following steps that (1) oil stains are removed on the metal surface; (2) activating treatment is carried out; (3) hot galvanizing is carried out; (4) treating fluid is prepared; (5) treatment is carried out; (6) baking and curing are carried out; (7) cooling is carried out; (8) washing is carried out; and (9) drying is carried out.

Owner:CANGZHOU HUARUN CHEM

Intelligent garbage barrel and stainless steel barrel dedicated anti-fingerprint baked lacquer

InactiveCN104974659AImprove anti-fingerprint performanceSolve the problem of easy fingerprintsPolyurea/polyurethane coatingsLacquerDouble bond

The invention relates to an intelligent garbage barrel and stainless steel barrel dedicated anti-fingerprint baked lacquer composed of the following components in parts by weight: 35-42 parts of water, 18-21 parts of modified polyurethane acrylate, 16-18 parts of nanoparticles, 30-38 parts of an organic pigment, 1-3 parts of a defoaming agent, 0.5-1.5 parts of a levelling agent, 1.2-1.6 parts of a wetting agent, 1-2 parts of a curing agent, and 2-4 parts of a dispersant, wherein the water is deionized water, the modified polyurethane acrylate is modified polyurethane acrylate containing carbon-carbon double bonds and perfluorinated polyether functional groups, and the nanoparticles are one of silica or calcium carbonate. With utilization of good anti-fingerprint performance of the modified polyurethane acrylate and the nanoparticles, the anti-fingerprint performance of the baked lacquer is increased, and the problem that the surface of a conventional intelligent garbage barrel and stainless steel barrel is easily left with fingerprints is solved.

Owner:ANQING LIANTAI ELECTRONICS TECH

Ultrathin tempered film and preparation process thereof

InactiveCN110922052AImprove tempered strengthHigh hardnessFlexible article cleaningCoatingsNumerical controlCutting glass

The invention discloses an ultrathin tempered film and a preparation process thereof. The preparation process comprises the following processes: S1, cutting: cutting a glass substrate into required shapes and sizes by adopting a cutting machine; S2, CNC fine carving: carving a hole site corresponding to the type of an electronic product in the cut glass substrate by a numerical control machine tool; S3, primary ultrasonic cleaning: putting the glass substrate into an ultrasonic cleaning machine, and cleaning; S4, tempering and strengthening: tempering and strengthening the glass substrate through a physical method and a chemical method; S5, AF electric / spray plating: carrying out electric / spray plating of anti-fingerprint oil on the surface of the glass substrate; S6, secondary ultrasoniccleaning: putting the glass substrate into an ultrasonic cleaning machine, and carrying out secondary cleaning; and S7, protective film coating: laminating protective films on two surfaces of the glass substrate, packaging and warehousing. The prepared ultrathin tempered film is light and thinner, has good toughness and shock resistance, and can be safely used for a long time.

Owner:东莞市国基光电有限公司

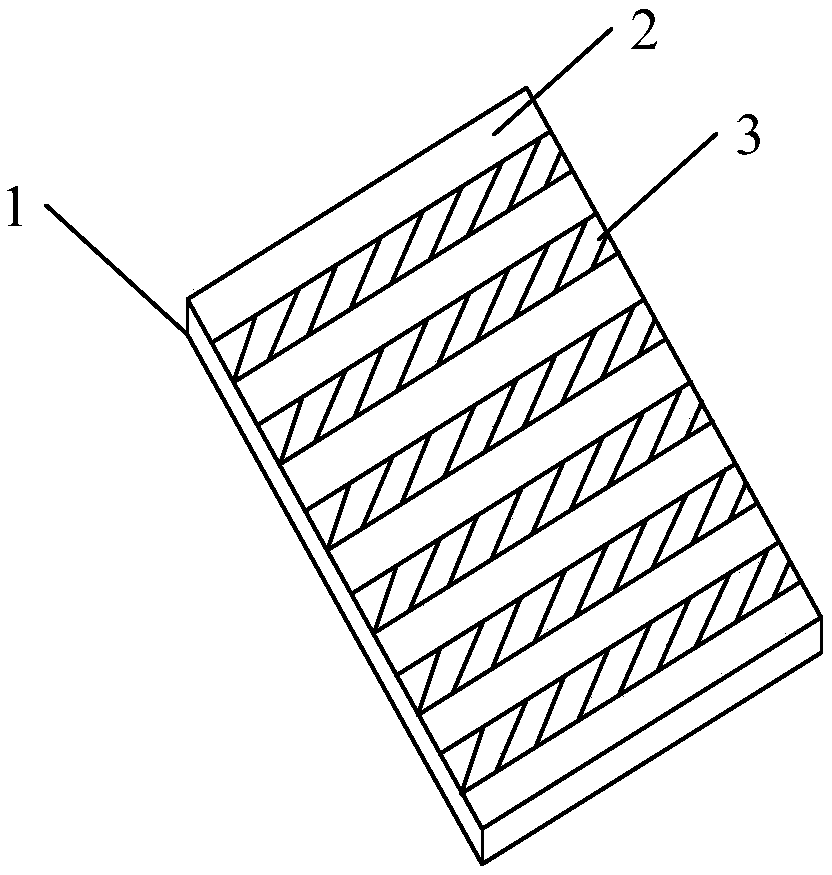

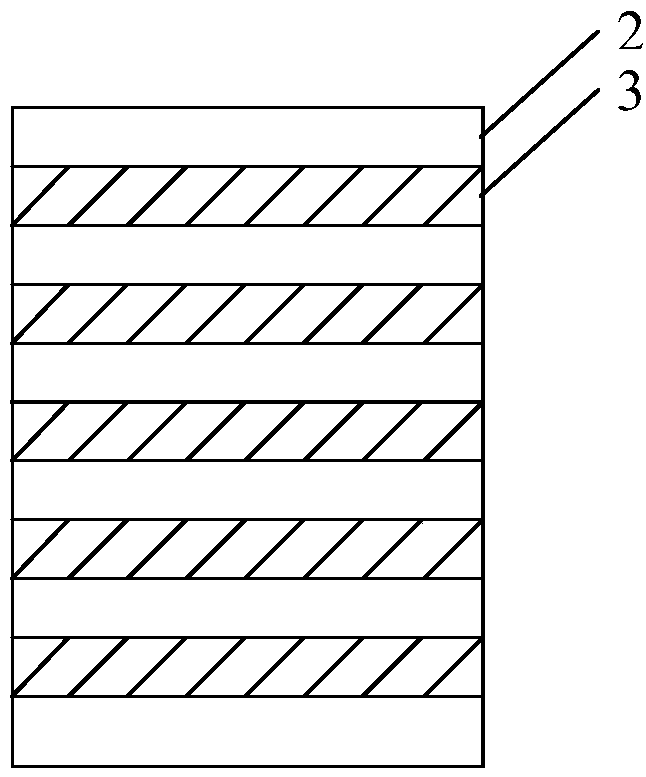

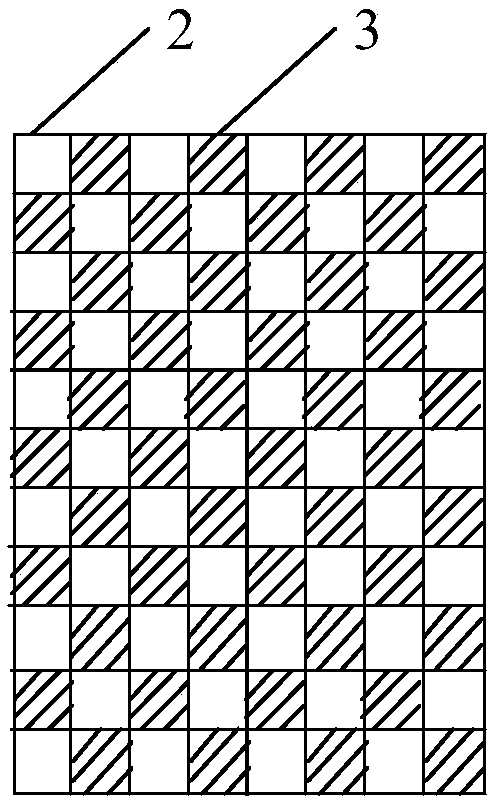

A touch screen cover plate and an intelligent device

InactiveCN108984029AEasy anti-fingerprintImprove anti-fingerprint performanceInput/output processes for data processingHydrophilic coatingCoated surface

The invention discloses a touch screen cover plate, comprising a cover plate substrate, a hydrophilic coating and a hydrophobic coating arranged on the surface of a touch control surface of the coverplate substrate and distributed alternately. The surface of the cover plate substrate is coated with the hydrophilic coat and the hydrophobic coating distribute alternately, so the touch screen coverplate has the advantage that the hydrophobic coating is easy to clean, and also has the characteristics of anti-fingerprint of hydrophilic coating, if the fingerprints fall on the surface of hydrophilic and hydrophobic coatings distributed alternately, water and the organic matters in the fingerprint printing can be quickly separated, rolled and finally dispersed on the surface of the coating between the two phases, so the fingerprint printing is difficult to be present and easy to clean. Compared with the touch screen cover plate using only hydrophobic fingerprint oil in the prior art, the cover plate has the advantages that the fingerprint prevention ability of the touch screen cover plate is greatly improved, and the viewing experience of the user is improved. The invention also discloses an intelligent device, which has the beneficial effects.

Owner:TRULY OPTO ELECTRONICS

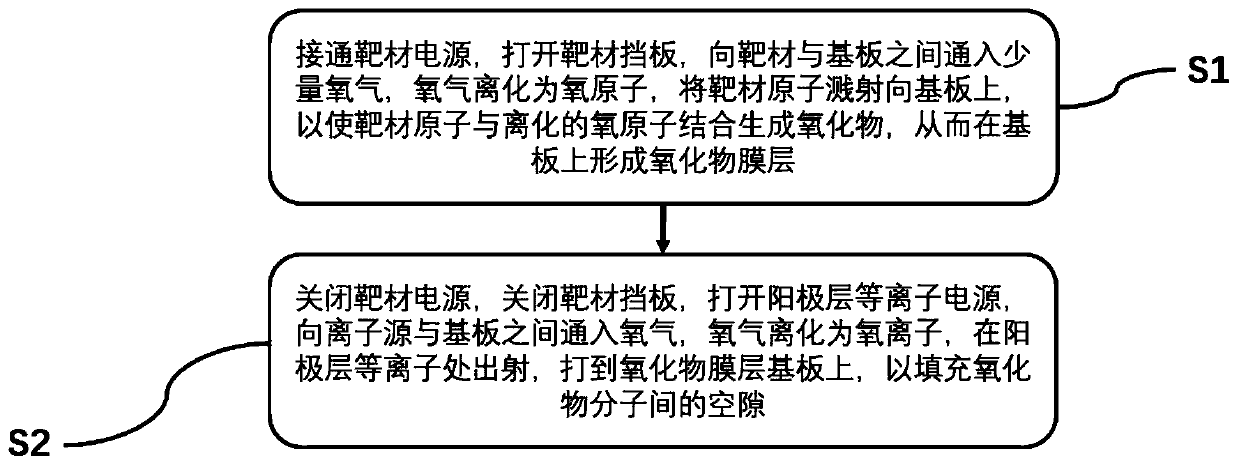

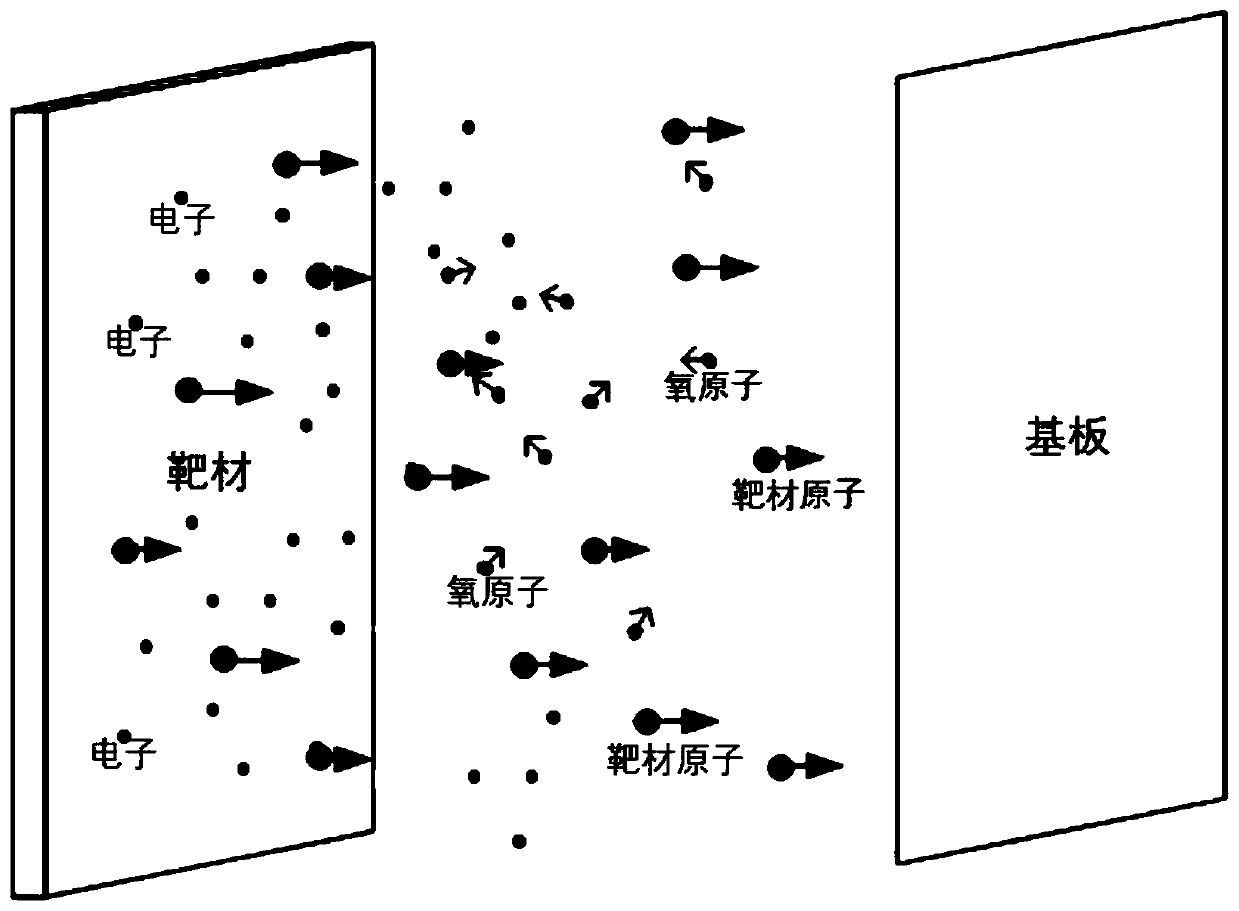

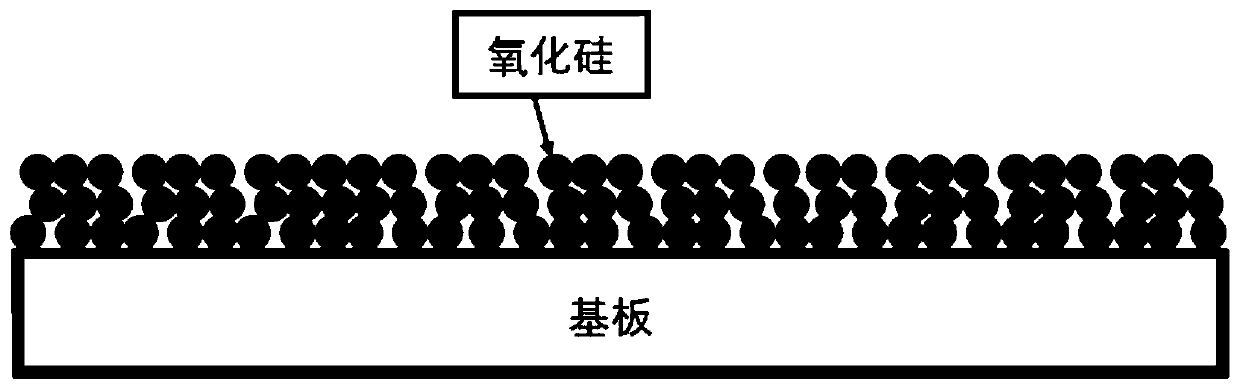

Preparation method of oxide film layer

InactiveCN110172669AImprove densification performanceImprove compactnessVacuum evaporation coatingSputtering coatingSputteringPhysical chemistry

The invention provides a preparation method of an oxide film layer. The preparation method comprises the following specific steps that a target material power source is turned on, a target material baffle is opened, a small amount of oxygen is introduced between target material and a base plate, the oxygen is ionized into oxygen atoms, target material atoms are sputtered onto the base plate, so that the target material atoms is combined with the ionized oxygen atoms to generate oxide, so that the oxide film layer is formed on the base plate; and the target material power source is turned off,the target material baffle is closed, a plasma power source of an anode layer is turned on, oxygen is introduced between an ion source and the base plate, the oxygen are ionized into oxygen ions, theoxygen ions are emitted from plasma part of the anode layer and to the oxide film layer base plate, so that gaps among the oxide molecules are filled. By adopting the technical scheme, the compactnessof silicon oxide film is greatly improved, the reliability of the silicon oxide film is improved, and the service life of the silicon oxide film is prolonged.

Owner:TRULY OPTO ELECTRONICS

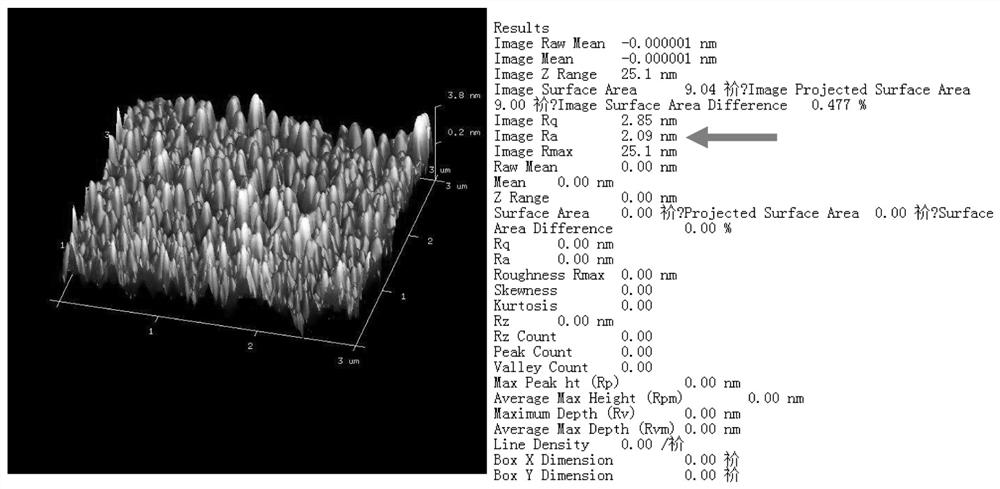

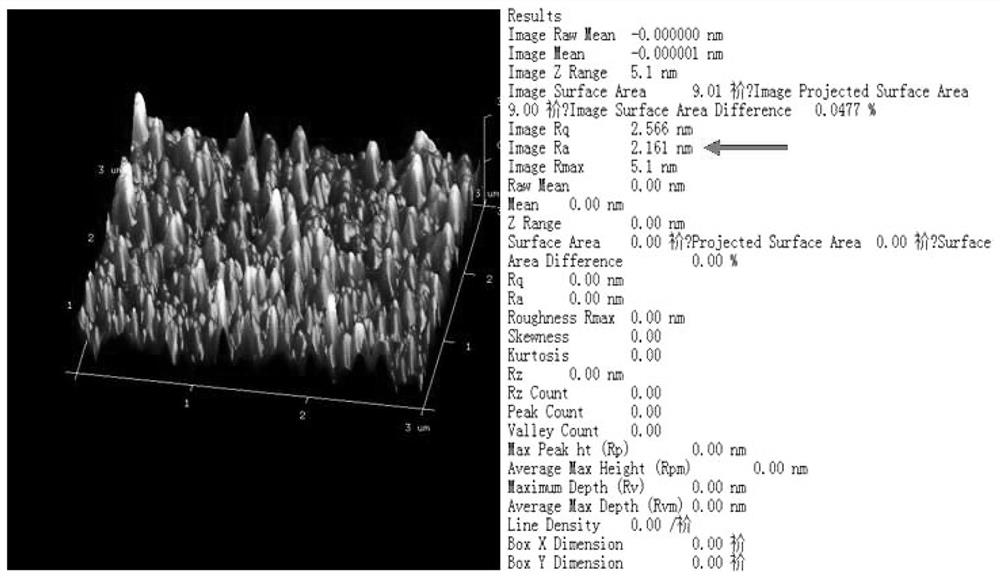

Preparation method of anti-fingerprint touch screen cover plate

ActiveCN112388415AImprove anti-fingerprint performanceThe anti-fingerprint effect will prolong the service life by 2-3 timesPlane surface grinding machinesGlass productionComposite materialEngineering

The invention discloses a preparation method of an anti-fingerprint touch screen cover plate. The method specifically comprises the following steps: polishing a bonding layer base material below an AFproduct by using a polishing machine to enable the surface appearance Ra of the base material to reach 2.0 nm or above, and then carrying out AF processing to obtain the anti-fingerprint touch screencover plate. According to the preparation method of the anti-fingerprint touch screen cover plate, soft polishing treatment is added to the surface of the base material of the AF to be processed, sothat the surface appearance of the bonding layer base material of the AF reaches 2.0 nm or above, and the abrasion resistance of the finally obtained AF product can reach the water drop contact angleof 100 degrees or above after 10000 times; and for mobile phone consumer electronics of a white glass + AF structure, the anti-fingerprint effect of the prepared product is prolonged by 2-3 times, andfor AR + AF, AG + AF and AG + AR + AF touch screen products, the anti-fingerprint effect is prolonged by 5 times or above.

Owner:YICHANG NANBO DISPLAY +1

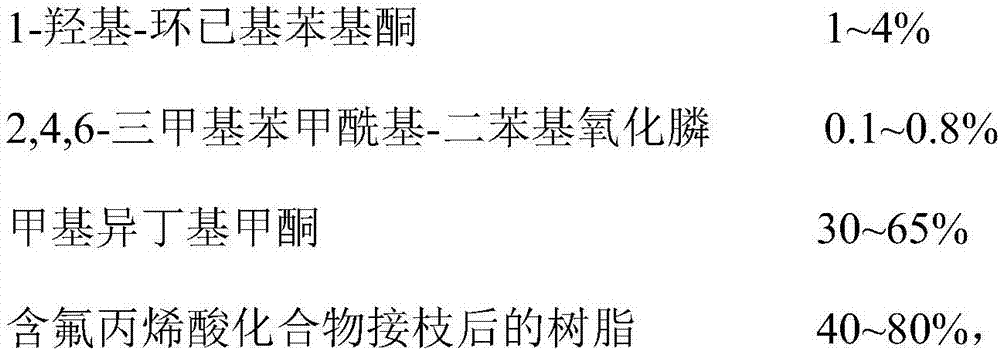

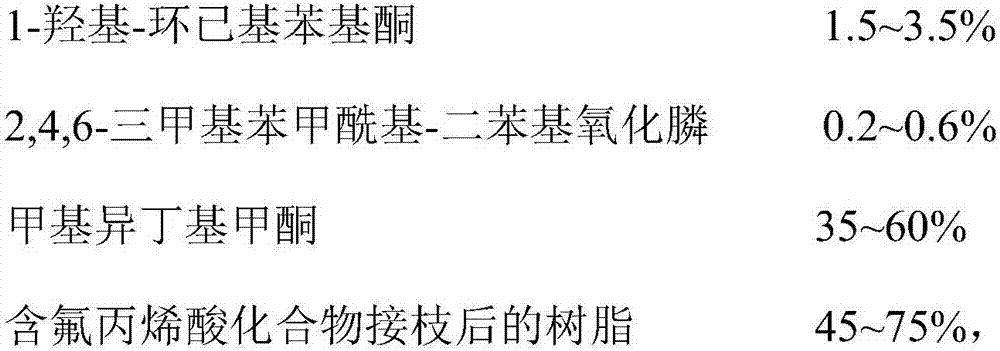

UV-curable liquid and preparation method and application thereof

ActiveCN107365545AImprove anti-fingerprint performanceImprove wear resistanceCoatingsMethyl isobutyl ketoneHardness

The invention provides a UV-curable liquid and a preparation method and an application thereof. The UV-curable liquid disclosed by the invention consists of the following substances in percentage by weight: 1 to 4 percent of 1-hydroxy-cyclohexyl phenyl ketone, 0.1 to 0.8 percent of 2,4,6-trimethylbenzoyldiphenyl phosphine oxide, 30 to 65 percent of methyl isobutyl ketone and 40 to 80 percent of fluoroacrylate compound-grafted rein, and the sum of the weight percentage contents of the substances is 100 percent. After the UV-curable liquid disclosed by the invention is cured to form a film, the film has high hardness and good wear resistance and fingerprint-proof property; and the UV-curable liquid can be used as curable liquid for PMMA (polymethylmethacrylate) board, and can be applied in the field of processing shells of electronic products.

Owner:KUNSHAN SANJING SCI & TECH

Nano anti-fingerprint anti-dazzle film and preparation process thereof

ActiveCN113831569AGood anti-glare effectExcellent anti-fouling and anti-fingerprint performancePolyurea/polyurethane coatingsPolyether coatingsWear resistanceHydroxy group

The invention discloses a nano anti-fingerprint anti-dazzle film and a preparation process thereof. Magnetic silicon dioxide is selected and introduced, dispersion improvement is conducted on the magnetic silicon dioxide through a dispersing agent to obtain a magnetic filler, the dispersing agent is tween-20, terminal hydroxyl of the tween-20 can be bonded with hydroxyl on the surface of silicon dioxide, and adsorption is conducted to improve the dispersing performance of the magnetic silicon dioxide, and the magnetic filler with excellent dispersity is obtained. According to the nano anti-fingerprint anti-dazzle film and the preparation process thereof, the process design is reasonable, the operation is simple, and the prepared anti-dazzle film not only has excellent anti-dazzle performance, but also has hydrophobic surface and excellent anti-fouling and anti-fingerprint performance; and magnetic fillers with different particle sizes are adopted for directional arrangement so the prepared anti-dazzle film is excellent in wear resistance and relatively high in practicability.

Owner:YILIKIM NEW MATERIALS CO LTD

Coating material for stainless steel plate surface fingerprint resistance treatment, and its preparation method

ActiveCN103923564AImprove flexibilityImprove rust resistanceNatural resin coatingsRosin coatingsSteel platesFingerprint

The invention discloses a coating material for stainless steel plate surface fingerprint resistance treatment, and its preparation method. The coating material is obtained by mixing 10-20 parts by weight of an additive with 1-3 parts by weight of an antioxidant, 5-8 parts by weight of oil-soluble resin, 0.5-1 part by weight of a water retaining agent and 50-70 parts by weight of machine oil. The preparation method of the coating material comprises the following steps: 1, adding the machine oil, the additive, the oil-soluble resin and the antioxidant to a stirrer, and stirring at a speed of 1000-2000rpm for 30-40min; 2, adding the water retaining agent, and stirring at a speed of 500-700rpm for 5-10min; and 3, carrying out heat insulation at normal temperature for 10-20min. The addition of the oil-soluble resin with good fusion to the machine oil increases the flexibility of a coat, so the coat material of an original metal panel is changed, and a new idea that resin and oil are mixed to form a coating protection layer is provided in order to make the metal panel have an incomplete hard feeling, increase the antirust function and substantially reinforce the fingerprint resistance.

Owner:浙江博海金属制品科技有限公司

A kind of anti-fingerprint powder coating and its preparation method and application

ActiveCN109082210BImprove anti-fingerprint performanceSilky feel goodPowdery paintsPolyester coatingsPolymer scienceElectronic communication

The invention discloses anti-fingerprint powder coating and a preparation method and application thereof. The anti-fingerprint powder coating is prepared from, by weight, 20-40 parts of composite polyester resin A, 30-50 parts of polyester resin B and 0-30 parts of other auxiliary agents. The preparation method includes: well mixing hydroxyl polyester resin and a composite material, subjecting tomelt extrusion through a double-screw extruder, cooling sheets to the normal temperature, and crushing to obtain the composite polyester resin A; adding the composite polyester resin A, the polyesterresin B and other auxiliary agents into a premixing tank, well mixing, subjecting to melt extrusion through a double-screw extruder, cooling sheets to the normal temperature, and finally crushing andgrading through a high-speed crusher to obtain powder in particle size of 33-38micron. By synergistic effects of the composite polyester resin A and the polyester resin B, a formed coating is easy toclean and remarkable in anti-fingerprint performance, automatic fingerprint clearing is realized, and the powder coating is silky and smooth to touch and especially suitable for terminal products including furniture, door and window accessories, decorative lamps, electronic communication equipment and the like and manifests high end and elegance of products.

Owner:广东歌丽斯化学有限公司

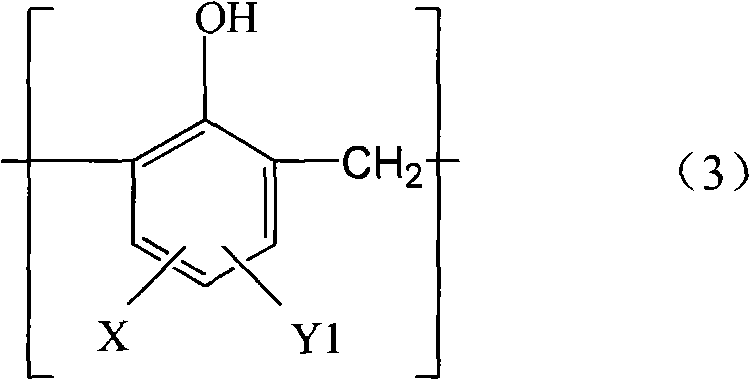

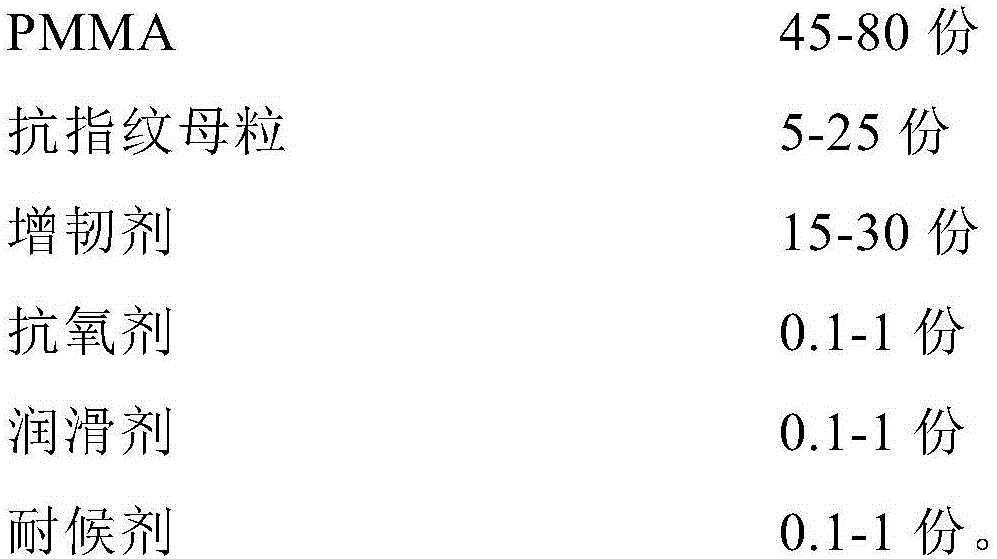

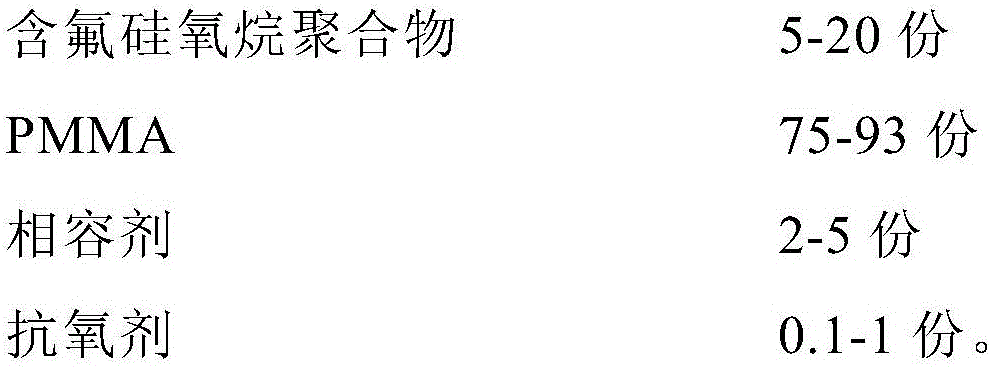

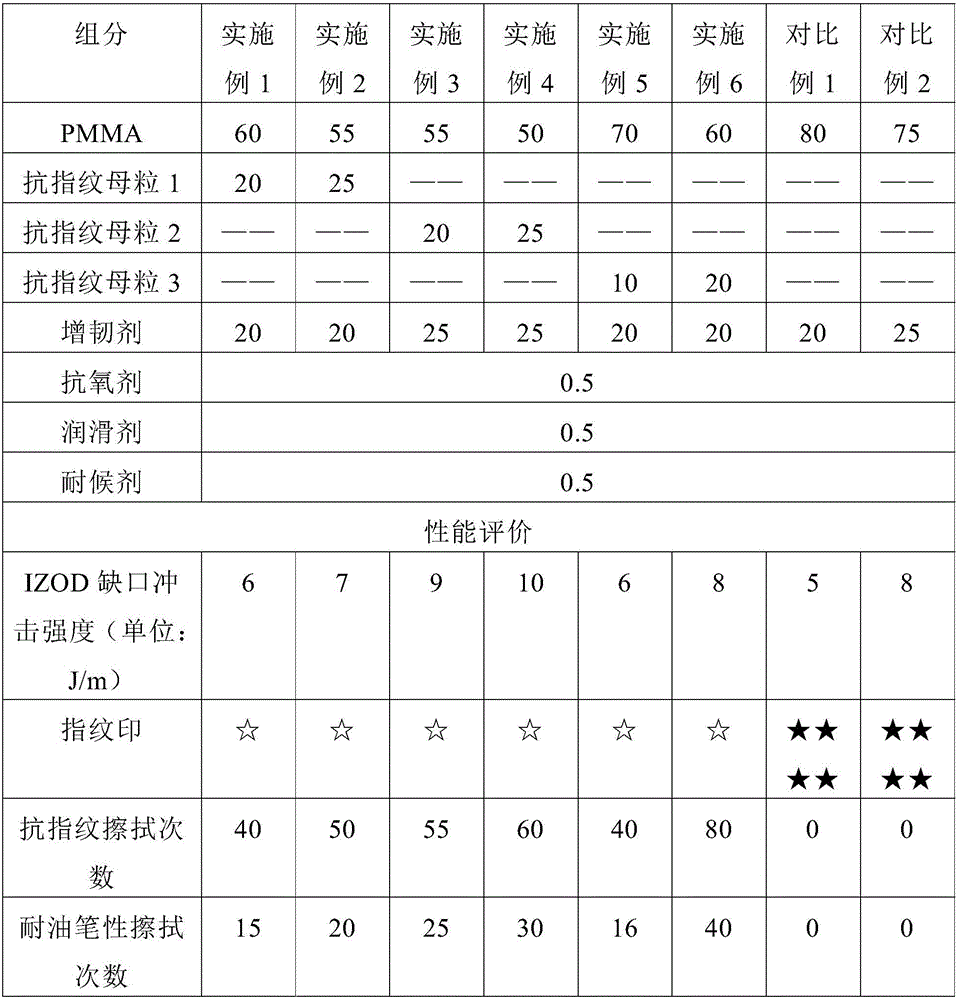

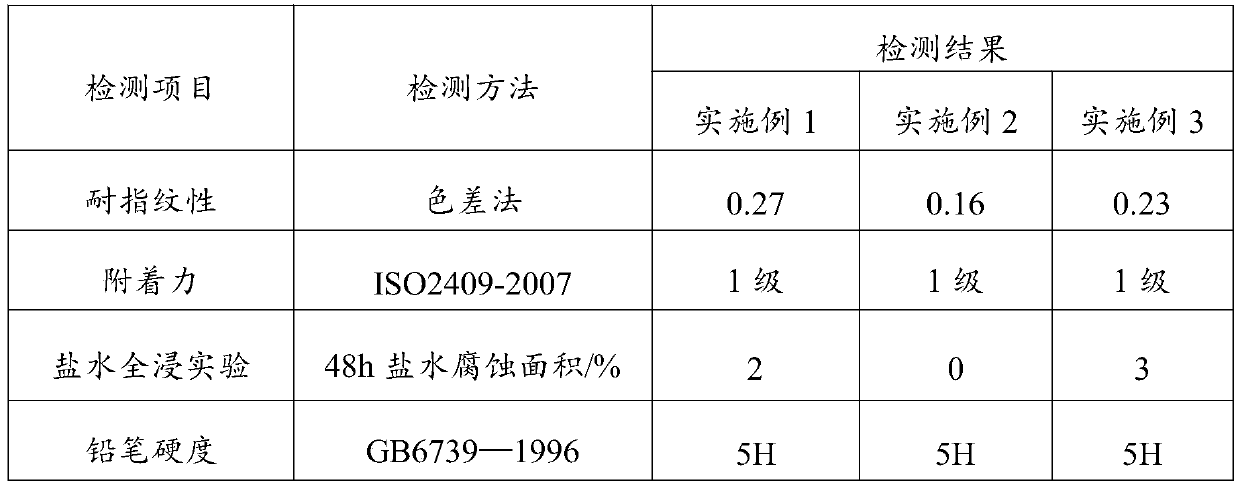

Anti-fingerprint stain-resistant PMMA resin and preparation method thereof

ActiveCN106674851AImprove anti-fingerprint performanceImprove antifouling performanceAntioxidantToughness

The invention relates to anti-fingerprint stain-resistant PMMA resin and a preparation method thereof. The anti-fingerprint stain-resistant PMMA resin comprises the following components in parts by weight: 45-80 parts of PMMA, 5-25 parts of anti-fingerprint master batches, 15-30 parts of a toughening agent, 0.1-1 part of an antioxidant, 0.1-1 part of a lubricating agent and 0.1-1 part of a weather-resistant agent. Compared with the prior art, the anti-fingerprint stain-resistant PMMA resin and the preparation method thereof provided by the invention have the benefits that a fluorosilicone polymer is introduced into PMMA resin and is made into the anti-fingerprint master batches together with the PMMA and a compatilizer, so that the compatibility of the polymer with the PMMA resin is improved, the fluorosilicone polymer is better dispersed in the PMMA, the surface tension of the PMMA resin is greatly reduced, the fingerprint resistance and the anti-fouling property of the PMMA resin are improved, and meanwhile, the low temperature toughness is also improved; the anti-fingerprint stain-resistant PMMA resin can meet the requirements of a host plant for fingerprint resistance to the surface of an automotive exterior part and can be used in automotive rearview mirrors, B-pillars, grilles and other automotive spraying-free exterior parts.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Fingerprint-resistant water-based coating and preparation process thereof

ActiveCN111117408AImprove anti-fingerprint performanceStrengthen and improve corrosion resistanceAntifouling/underwater paintsPaints with biocidesCoating systemPhytic acid

The invention relates to a fingerprint-resistant water-based coating and a preparation process thereof. The fingerprint-resistant water-based coating comprises the following raw materials in parts byweight: 40-60 parts of a modified water-based acrylic emulsion, 10-25 parts of a modified fluorocarbon emulsion, 2-7 parts of a passivator, 7-15 parts of an additive and 5-35 parts of a solvent, wherein the modified water-based acrylic emulsion comprises the following raw materials in parts by weight: 5-15 parts of a surface modified graphene oxide dispersion liquid, 25-50 parts of a monomer, 2-7parts of an initiator, 5-15 parts of an emulsifier, 5-25 parts of deionized water, 5-15 parts of a cosolvent and 3-12 parts of an auxiliary agent. According to the invention, a graphene oxide modifiedwater-based acrylic emulsion and a silica sol modified fluorocarbon emulsion are used as main film-forming substances; safe and nontoxic phytic acid is used as a passivation system; a filling material and an auxiliary agent applicable to a fingerprint-resistant water-based coating system are screened and optimized; thus, the prepared fingerprint-resistant coating has outstanding performance and excellent comprehensive performance; and the preparation process is simple.

Owner:陈婧晗

A kind of preparation method of AF coated glass with antibacterial effect

The invention provides a method for preparing AF coated glass with antibacterial effect, comprising the following steps: S1, ultrasonically cleaning the glass substrate with a solvent or cleaning agent, then rinsing with deionized water, and blowing dry with nitrogen; S2, Coating a layer of SiO on the glass substrate by vacuum coating 2 Film base layer; S3. Add nano-silver to the anti-fingerprint agent, and spray the treated anti-fingerprint agent evenly onto the SiO on the surface of the glass substrate by a spraying machine. 2 On the base layer of the film, then dry the glass substrate, take it out and cool it, so as to form an antibacterial and anti-fingerprint layer; S4, disperse SiO in a solvent 2 Particles and nano-silver are prepared into an antibacterial coating solution, and the antibacterial solution is evenly sprayed on the antibacterial and anti-fingerprint layer of the glass substrate by a spraying machine, and then the glass substrate is dried, taken out and cooled to form an antibacterial SiO 2 film layer. The coated glass of the invention has anti-fingerprint and antibacterial effects.

Owner:江苏中新瑞光学材料有限公司

A kind of anti-fouling, anti-fingerprint stainless steel plate water-based paint and preparation method thereof

ActiveCN105462460BImprove anti-fingerprint performanceImprove hydrophobicity and oleophobicityAntifouling/underwater paintsPaints with biocidesWater basedSolvent

The invention discloses anti-fouling and fingerprint-resistant stainless steel plate water-based paint and a preparation method thereof. The anti-fouling and fingerprint-resistant stainless steel plate water-based paint is prepared from, by weight, 55-70% of hydroxy modified waterborne polyester resin, 8-15% of methylated amino resin, 3-5% of modified silica sol, 2-4% of a neutralizing agent, 0.1-0.3% of a wetting agent, 0-0.2% of theological additives, 0.1-1.5% of a defoaming agent, 0.1-0.5% of a flattening agent, 3-6% of aqueous polyethylene wax and polytetrafluoroethylene wax mixed paste, 1-3% of an adhesive force promoting agent, 1-3% of nanometer inorganic salt, 0.2-0.5% of a catalyst, 3-5% of a cosolvent and 1-8.5% of deionized water. The anti-fouling and fingerprint-resistant stainless steel plate water-based paint has excellent fingerprint resistance and hydrophobicity and oleophobicity, and is large in fingerprint-resistant coating water contact angle and oil contact angle, small in sliding angle, and excellent in abrasion resistant and aging resistance, and greasy dirt is prone to sliding. Meanwhile, the anti-fouling and fingerprint-resistant stainless steel plate water-based paint is environmentally friendly and healthy, and the method is simple.

Owner:FUJIAN GANG HONG METAL TECH CO LTD

Preparation method of superhard anti-fingerprint film for glass panel of mobile phone

ActiveCN105543843AHigh light transmittanceImprove the decorative effectSuperimposed coating processFingerprintTransmittance

The invention relates to the technical field of film plating for glass panels of mobile phones, in particular to a preparation method of a superhard anti-fingerprint film for a glass panel of a mobile phone. The method includes the steps of carrying out pretreatment, specifically, the glass printed surface of the mobile phone is subjected to ultrasonic cleaning through cleaning fluid and then is dried; carrying out coating of a bottom film layer, specifically, the cleaned glass printing layer surface of the mobile phone is coated with the gold bottom film layer; plating a SiO2 film, specifically, the surface of the solidified bottom film layer of the glass of the mobile phone is plated with the SiO2 film in a vacuum mode; plating a TiO2 film, specifically, the SiO2 film is plated with the TiO2 film; and spraying UV finish paint, specifically, the UV finish paint is sprayed to the surface of the TiO2 film. The obtained gold transparent film layer can show a shiny gold color at different visions, the transmittance of light is high, and abrasion resistance is good; moreover, the method has the characteristics that the process is simple and the film layer has good compactness.

Owner:萍乡星星精密玻璃科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com