Coating composition

A composition and coating technology, which can be used in coatings, devices for coating liquids on surfaces, pre-treatment surfaces, etc., to solve problems such as the shell surface being easily contaminated by fingerprints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

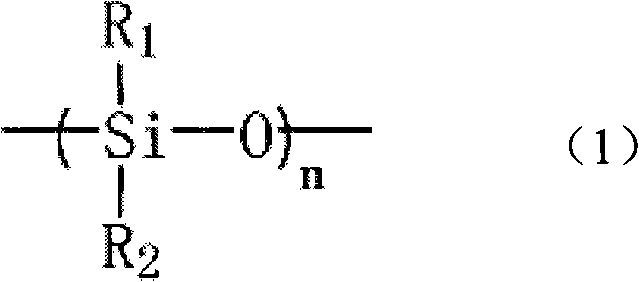

Method used

Image

Examples

preparation example Construction

[0028] The preparation of the coating composition only needs to uniformly mix the silicone resin, the fluorine-containing surfactant and the coupling agent in proportion.

[0029] The paint provided by the invention contains an organic solvent and the paint composition of the invention.

[0030] The organic solvent may be one or more of aliphatic hydrocarbon solvents, aromatic hydrocarbon solvents, alcohols and ester solvents. For example, it may be one or more of n-octane, n-heptane, toluene, xylene, n-butanol, isobutanol, ethyl acetate, and butyl acetate. The present invention preferably uses n-octane and / or n-heptane. When the organic solvent is a mixed solvent, the content of each organic solvent can be in any ratio. In the coating, the weight of the organic solvent is 4-10 times the weight of the coating composition.

[0031] The preparation method of the coating only needs to mix the coating composition and the organic solvent and stir evenly, and the mixing can be pe...

Embodiment 1

[0040] This example illustrates the coating composition of the present invention, coatings containing the composition, and coatings formed from the coating.

[0041] With 93 grams of silicone resin (SR2410 type of U.S. DOW CORNING company), 2 grams of fluorosurfactant (Zonyl 8857A type of U.S. DuPont Company), 5 grams of silane coupling agent (Z-6040 type of U.S. DOW CORNING company) Mix evenly to obtain a coating composition. In the composition, the content of the silicone resin is 93% by weight, the content of the fluorine-containing surfactant is 2% by weight, and the content of the silane coupling agent is 5% by weight. Add the coating composition into 600 g of mixed solvent (the weight ratio of n-octane and n-heptane is 1:1), and stir evenly to obtain the coating. Then the stainless steel base material (Dongguan Rongjia Stainless Steel Raw Material Company, 316 type) was soaked in the coating for 2 minutes and then taken out, left to stand for 0.5 hour in a clean environm...

Embodiment 2

[0043] This example illustrates the coating composition of the present invention, coatings containing the composition, and coatings formed from the coating.

[0044] With 96 grams of silicone resin (SR2410 type of U.S. DOW CORNING company), 1 gram of fluorosurfactant (Zonyl 8857A type of U.S. DuPont Company), 3 grams of silane coupling agent (Z-6040 type of U.S. DOW CORNING company) Mix evenly to obtain a coating composition. In the composition, the content of the silicone resin is 96% by weight, the content of the fluorine-containing surfactant is 1% by weight, and the content of the silane coupling agent is 3% by weight. Add the coating composition into 600 g of mixed solvent (the weight ratio of n-octane and n-heptane is 1:1), and stir evenly to obtain the coating. Then the stainless steel base material (Dongguan Rongjia Stainless Steel Raw Material Company, 316 type) was soaked in the coating for 2 minutes and then taken out, left to stand for 0.5 hour in a clean environme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com