Fingerprint-resistant water-based coating and preparation process thereof

A water-based paint and preparation technology, applied in the direction of anti-fouling/underwater paint, anti-corrosion paint, coating, etc., can solve the problems of high volatility, easy to pollute the environment, etc., and achieve outstanding fingerprint resistance, Effect of improving compatibility and service life, improving compatibility and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

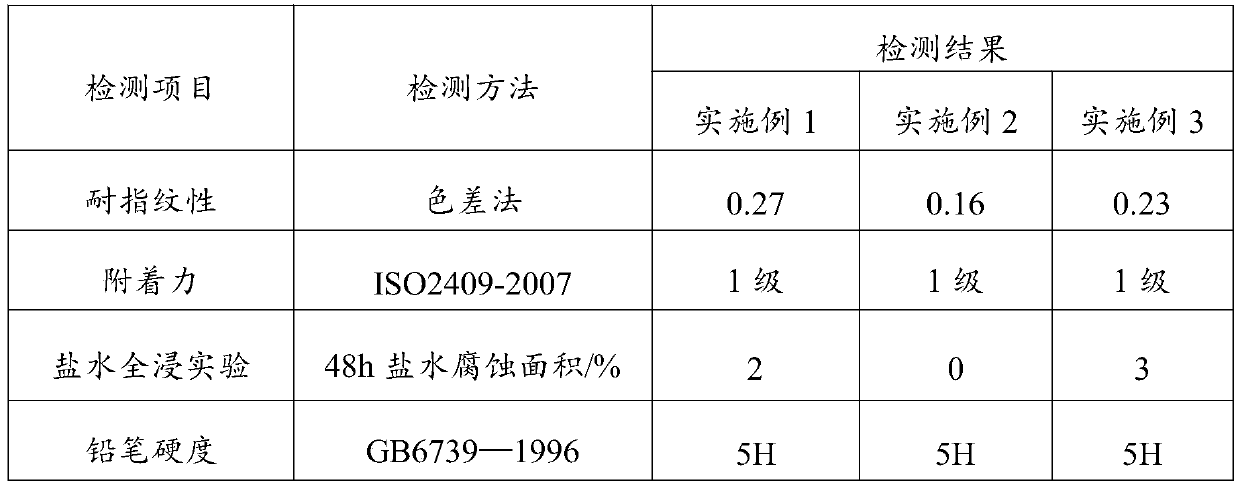

Examples

preparation example Construction

[0039] The present invention also proposes a preparation process of a fingerprint-resistant water-based paint, which includes the following steps: adding modified water-based acrylic emulsion, modified fluorocarbon emulsion and defoamer to the container in order by weight, and stirring and dispersing for 20-25min to obtain Mixing system A; adding a pH regulator dropwise while stirring in the mixing system A, and adjusting the pH value to 8-9 to obtain a mixing system B; adding a passivating agent dropwise while stirring in the mixing system B, adjusting the pH value to Mixed system C is obtained at 6.8-7.2; solvent and wetting agent are added to mixed system C while stirring, thickener is added dropwise after stirring for 15-20 minutes, and the fingerprint-resistant water-based coating is obtained by continuing to stir and disperse.

[0040] The preparation process of anti-fingerprint water-based paint is divided into three steps. First, the modified water-based acrylic emulsio...

Embodiment 1

[0049] (1) The preparation of surface-modified graphene oxide dispersion liquid comprises the following steps:

[0050] Add 100ml of distilled water and 0.1g of graphene oxide to the Erlenmeyer flask, stir and disperse, place in an ultrasonic instrument, and react in a water bath at 60°C for 1 hour to obtain a 1mg / ml graphene oxide dispersion;

[0051] Add 100mL of 1mg / ml graphene oxide dispersion and 10mL of PEG400 to another Erlenmeyer flask, place in an ultrasonic instrument, and react for 1h in a water bath at 60°C to obtain a surface-modified graphene oxide dispersion .

[0052] (2) the preparation of modified water-based acrylic acid emulsion, comprises the following steps:

[0053] In parts by weight, at 25°C, add 2.5 parts of deionized water, 6 parts of emulsifier (3 parts of cetyl alcohol, 3 parts of sodium lauryl sulfate) and 10 parts of surface-modified graphene oxide into the beaker. Liquid, stirred at a stirring rate of 1200rpm / min for 30min to obtain dispersion...

Embodiment 2

[0070] (1) The preparation of surface-modified graphene oxide dispersion liquid comprises the following steps:

[0071] Add 100ml of distilled water and 0.1g of graphene oxide to the Erlenmeyer flask, stir and disperse, place in an ultrasonic instrument, and react in a water bath at 55°C for 1.5h to obtain a 1mg / ml graphene oxide dispersion;

[0072] Add 100mL of 1mg / ml graphene oxide dispersion and 8mL of PEG600 to another Erlenmeyer flask, place in an ultrasonic instrument, and react for 2h in a water bath at 55°C to obtain a surface-modified graphene oxide dispersion .

[0073] (2) the preparation of modified water-based acrylic acid emulsion, comprises the following steps:

[0074] In parts by weight, at 20°C, add 5 parts of deionized water, 9 parts of emulsifier (6 parts of cetyl alcohol, 3 parts of sodium lauryl sulfate) and 15 parts of surface-modified graphene oxide into the beaker to disperse Liquid, stirred at a stirring rate of 1300rpm / min for 40min to obtain disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com