Method for mounting metal plate cylinder

An installation method and metal plate technology, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of stainless steel columns without a good installation method, difficult construction, rough manufacturing process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

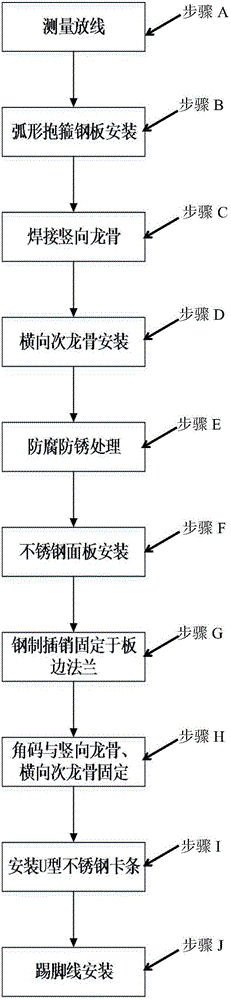

Method used

Image

Examples

Embodiment

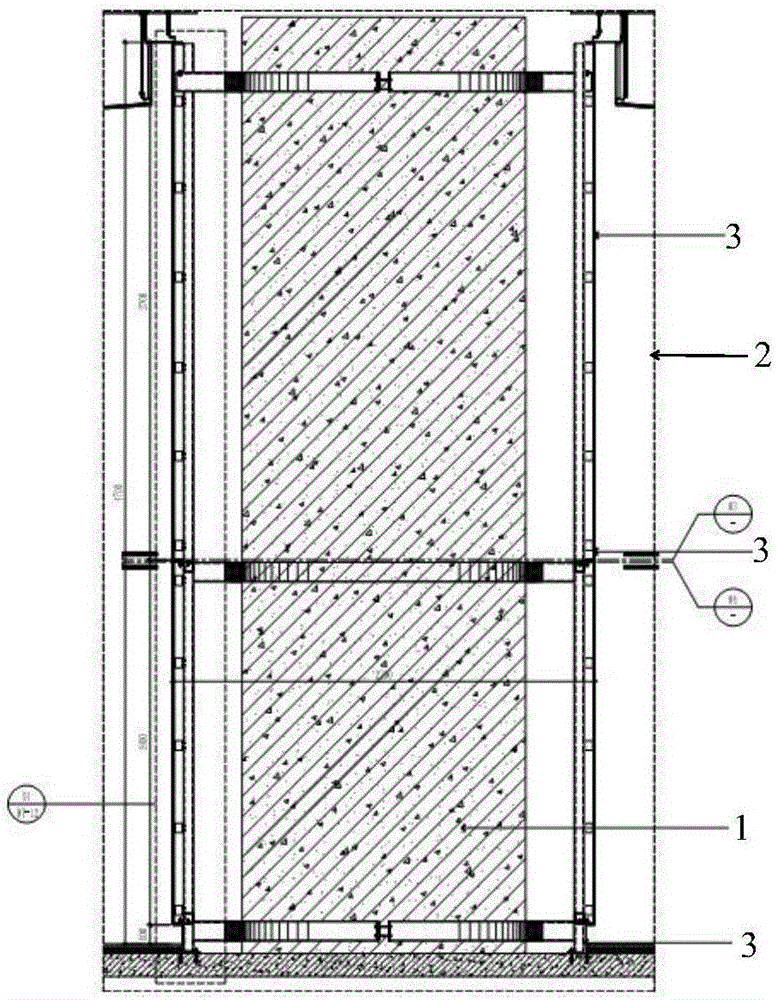

[0033] figure 1 It is an elevational cross-sectional view of the metal plate cylinder in the embodiment of the present invention.

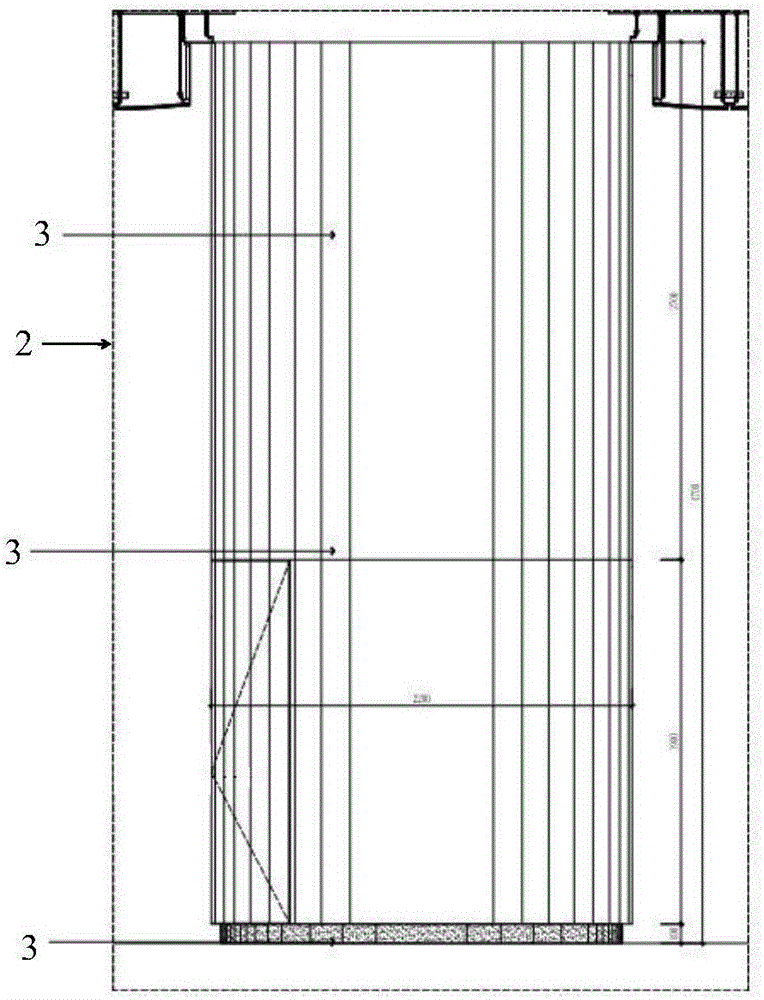

[0034] figure 2 It is an elevation view of the metal plate cylinder in the embodiment of the present invention.

[0035] Such as figure 1 with figure 2 As shown, the structural column of the metal plate cylinder is a steel structure column 1, and the surface layer is a fireproof coating 2. When the metal plate cylinder is used, no welding can be adopted to the original structural column, and a hoop bolting method is adopted.

[0036] The curved stainless steel panel 3 is formed by the arc radius on the roller arc machine. In order to make the horizontal seam of the curved stainless steel panel 3 beautiful, the curved stainless steel panel 3 has a small hemming R angle, and the curved stainless steel panel 3 is performed at the left and right sides and the upper and lower sides. Gouging treatment, the gouging depth is 70 threads, the upper and lower fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com