Numerical control milling machine body lifter

A technology of CNC milling machines and lifts, which is applied in the direction of metal processing machinery parts, large fixed members, maintenance and safety accessories, etc. It can solve problems such as bed shaking, affecting parts processing procedures, and reduction of engagement force, so as to improve the level of stability and avoid Inaccurate processing of parts, avoiding the effect of bed down movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

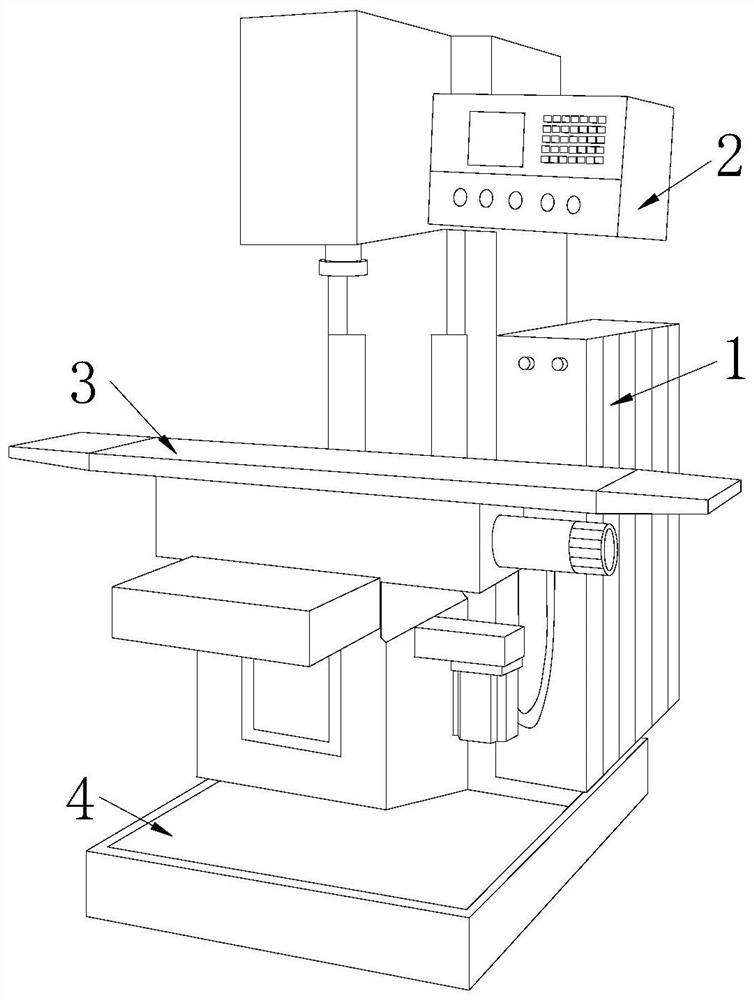

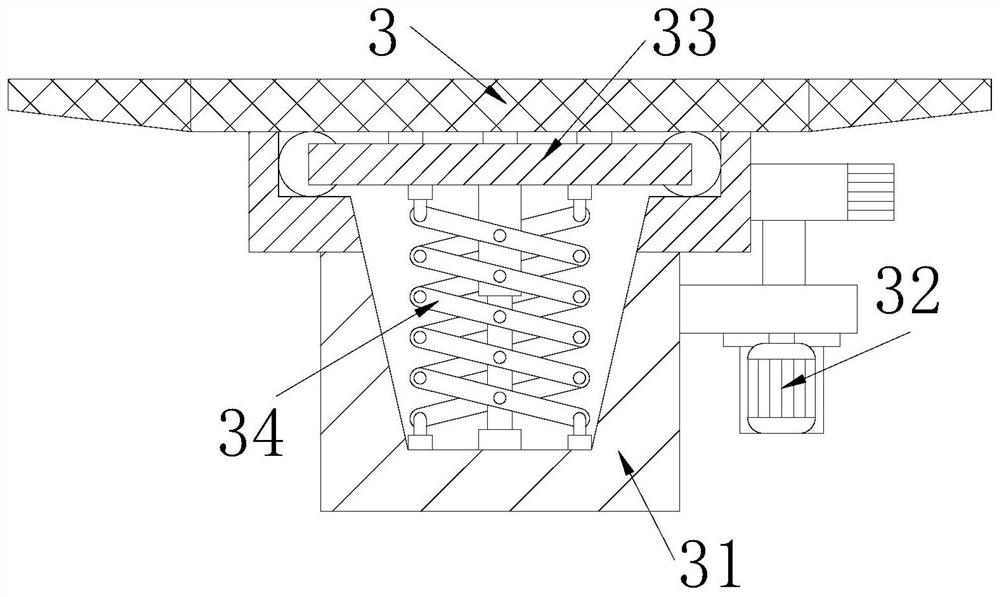

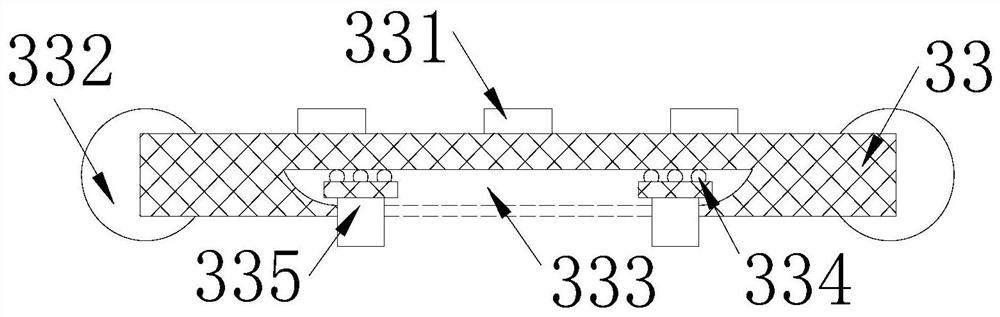

[0029] The present invention provides a CNC milling machine bed elevator, its structure includes a CNC milling machine 1, a control panel 2, a bed 3, a base 4, the bottom of the CNC milling machine 1 is welded on the upper surface of the base 4, and the control panel 2 is embedded in the The surface of the CNC milling machine 1, the bed 3 is installed on the front side of the CNC milling machine 1, the bed 3 includes a positioning table 31, a driver 32, a top plate 33, and a lifter 34, and the positioning table 31 is installed on the front side of the bed 3 Below, the driving machine 32 is installed on the right side of the positioning platform 31, the top plate 33 is connected to the upper interior of the positioning platform 31 through a gap, and the top of the top plate 33 is close to the lower surface of the bed 3, and the top of the lifter 34 passes through Bolts are connected to the bottom of the top plate 33, and the bottom of the lifter 34 is connected to the inner bott...

Embodiment 2

[0035] The present invention provides a CNC milling machine bed elevator, its structure includes a CNC milling machine 1, a control panel 2, a bed 3, a base 4, the bottom of the CNC milling machine 1 is welded on the upper surface of the base 4, and the control panel 2 is embedded in the The surface of the CNC milling machine 1, the bed 3 is installed on the front side of the CNC milling machine 1, the bed 3 includes a positioning table 31, a driver 32, a top plate 33, and a lifter 34, and the positioning table 31 is installed on the front side of the bed 3 Below, the driving machine 32 is installed on the right side of the positioning platform 31, the top plate 33 is connected to the upper interior of the positioning platform 31 through a gap, and the top of the top plate 33 is close to the lower surface of the bed 3, and the top of the lifter 34 passes through Bolts are connected to the bottom of the top plate 33, and the bottom of the lifter 34 is connected to the inner bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com