Preparation method of anti-fingerprint touch screen cover plate

A touch screen and anti-fingerprint technology, which is applied in the direction of manufacturing tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problem of insufficient bonding of the lower film layer, failure of the anti-fingerprint AF effect of the touch screen cover, AF and the lower bonding layer not strong enough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] To process the AF layer on the white glass, the main steps are: soft polishing treatment on the surface of the bonding layer of the AF surface to be processed → wet cleaning with pure water → plasma dry cleaning → spraying AF → standing at room temperature for 12 hours.

[0025] The specific steps are:

[0026] 1) Install the 10mm thick high-quality wool wheel to the head of the sander;

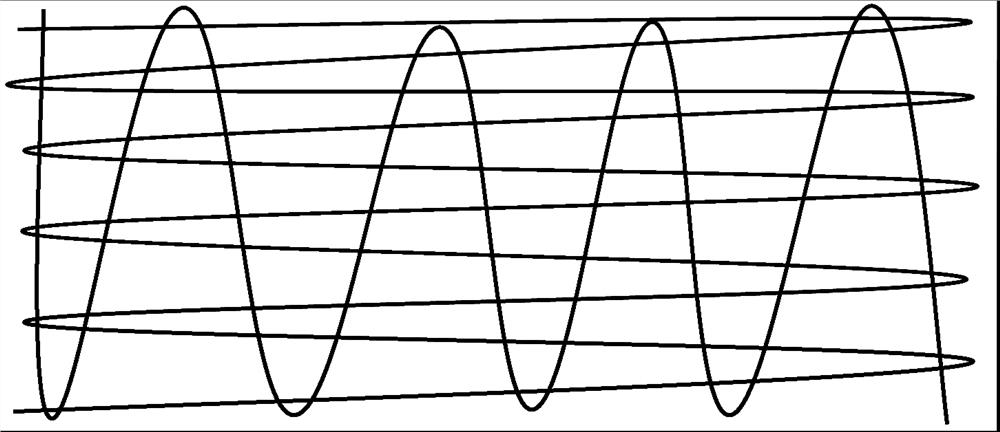

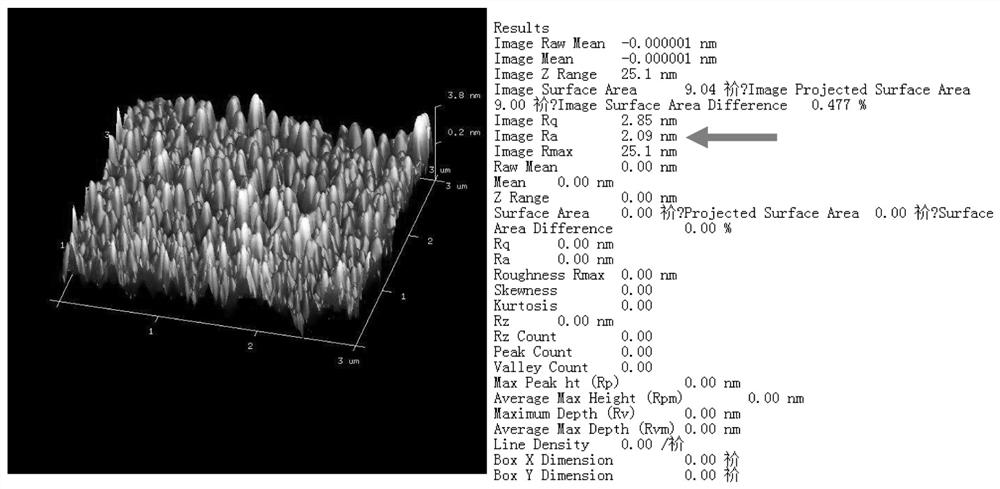

[0027] 2) Rotate the grinder, apply a pressure of 1.5kgf, and grind the surface of the AF layer of the white glass to be processed X, Y cross each circle, so as to ensure that each area is polished. The grinding route is as follows: figure 1 As shown, the surface morphology Ra of the substrate after polishing reaches more than 2nm, and the surface morphology of one of the samples is as follows figure 2 As shown; the pressure during the grinding process should not be too heavy, so as not to increase the appearance of grinding and scratching;

[0028] 3) After polishing, use pure wate...

Embodiment 2

[0034] The main steps to prepare the anti-fingerprint touch screen cover plate with white glass + AR + AF structure are: soft polishing treatment on the surface of the bonding layer (AR) on the AF surface to be processed → wet cleaning with pure water → dry cleaning with plasma plasma → spraying AF → static at room temperature Set 12h.

[0035] The specific steps are:

[0036] 1) Install the 10mm thick high-quality wool wheel to the head of the sander;

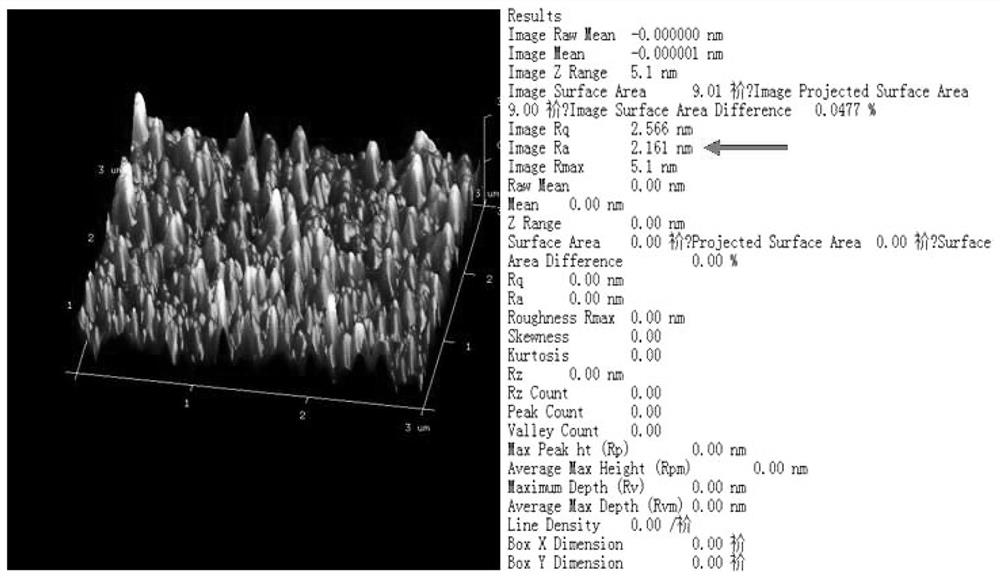

[0037] 2) Rotate the grinder, apply a pressure of 1.2kgf, and grind the surface of the AF layer of the white glass to be processed X, Y cross each circle, so as to ensure that each area is polished, and the surface morphology of the substrate after grinding Ra reaches above 2nm, and the surface morphology of one of the samples is as follows image 3 The displayed Ra is 2.161nm; the total color difference △E of the color variation before and after polishing is ≤0.25, so as to avoid color change NG and scratch NG caused by exc...

Embodiment 3

[0044] The main steps to prepare the anti-fingerprint touch screen cover plate with the structure of white glass+AG+AR+AF are: soft polishing treatment on the surface of the bonding layer (AR) on the AF surface to be processed→wet cleaning with pure water→plasma dry cleaning→spraying AF→ Stand at room temperature for 12h.

[0045] The specific steps are:

[0046] 1) Install the 10mm thick high-quality wool wheel to the head of the sander;

[0047] 2) Turn the grinder, apply a pressure of 1.0kgf, and grind the surface of the AF layer of the white glass to be processed X, Y cross each circle for a circle, so as to ensure that each area is polished, and the surface morphology of the substrate after grinding The Ra reaches above 2nm, and the surface morphology Rp change of the base material before and after polishing is less than or equal to 0.01μm; the total color difference △E before and after polishing is 0.06, so as to avoid color change NG and scratch NG caused by excessive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Drop angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com