UV-curable liquid and preparation method and application thereof

A technology of hardening fluid and compound, applied in the direction of coating, can solve the problem of reducing the wear resistance of the coating, and achieve the effect of improving the wear resistance and hardness, good anti-fingerprint performance and wear resistance, and reducing the production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be further described below through specific embodiments.

[0039] Unless specifically stated, various raw materials of the present invention can be purchased commercially, or can be prepared according to conventional methods in the art.

[0040] The present invention prepares UV hardening liquid by following preparation method:

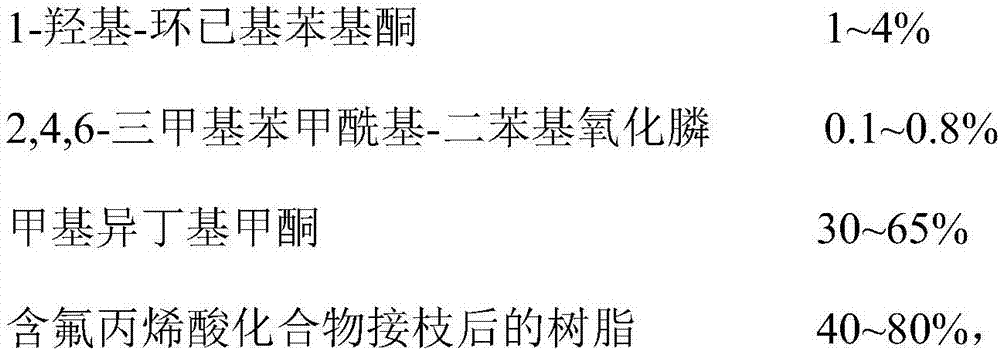

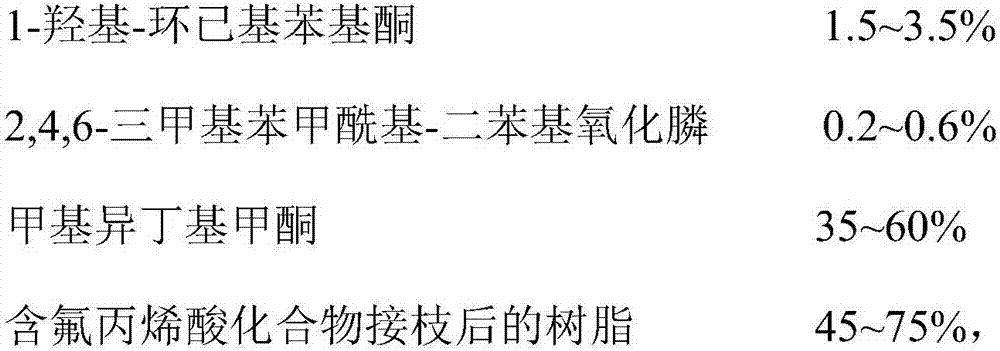

[0041] 1) In terms of mass percentage, 1-4% of 1-hydroxy-cyclohexyl phenyl ketone (184) and 0.1-0.8% of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide (TPO) was added into 30-65% methyl isobutyl ketone, stirred and dissolved, and stirred for 10-30 minutes to completely dissolve the initiator to obtain a mixed solution;

[0042] 2) In terms of mass percentage, add 40-80% of the resin grafted with fluorine-containing acrylic compound to the mixed liquid in step 1), and stir for 30-60 minutes to dissolve the resin;

[0043]3) Filter the solution obtained in step 2 with a 0.5-1 μm filter eleme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com