Anti-fingerprint ultraviolet curing high-gloss varnish

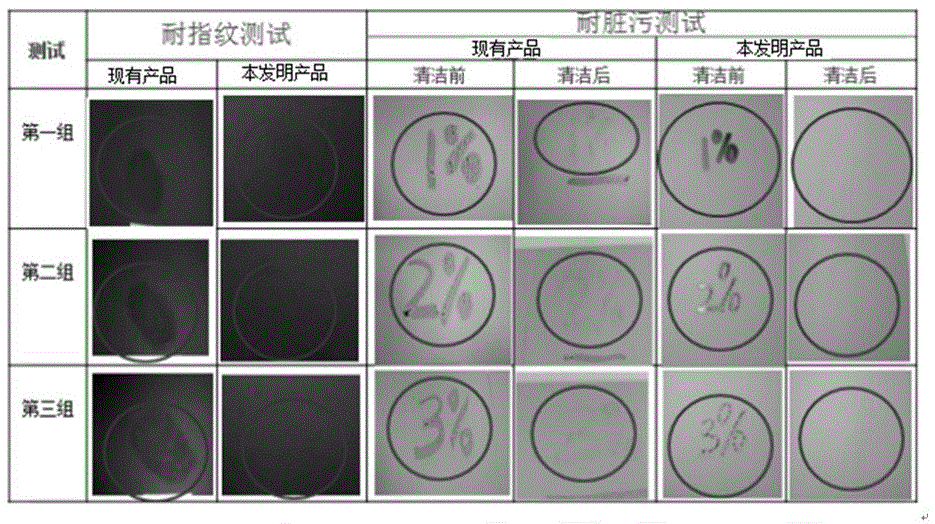

An ultraviolet light and anti-fingerprint technology, which is applied in the field of coatings to achieve good economic benefits, anti-fingerprint performance and anti-fouling performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Anti-fingerprint UV-curable high-gloss varnish, by weight percentage, the raw materials are as follows: 9-functionality polyurethane acrylate (SHIKOHUV-4251 in Japan) 8%, silicone-modified acrylate polymer (Sabis 13H) 10%, Epoxy Acrylic Resin (SYF306S) 13%, Trimethylolpropane Acrylate 18%, Dipropylene Glycol Dipropylene or Hexylene Glycol Diacrylate 5%, 2-Phenoxyethyl Acrylate 2%, 2-Hydroxy -2-methyl-1-phenyl-1-propanone (photoinitiator 1173) 3%, antifouling additive (BYKUV3500) 1%, anti-cratering additive (Japan DIC, RS-75) 0.12%, acetic acid Ethyl 20%, the balance is propylene glycol methyl ether acetate.

[0016] First, 9-functionality urethane acrylate, silicone modified acrylate polymer, epoxy acrylic resin, trimethylolpropane acrylate, dipropylene glycol dipropylene or hexanediol diacrylate, 2-phenoxyethylene base acrylate and stir well, then add 2-hydroxy-2-methyl-1-phenyl-1-propanone, stir well, then add anti-fouling additives and anti-crater additives in turn,...

Embodiment 2

[0018] Anti-fingerprint UV-curable high-gloss varnish, by weight percentage, the raw materials are as follows: 9-functionality polyurethane acrylate (SHIKOHUV-4251 in Japan) 13%, silicone-modified acrylate polymer (Sabis 13H) 16%, Epoxy Acrylic Resin (SYF306S) 6%, Trimethylolpropane Acrylate 15%, Dipropylene Glycol Dipropylene or Hexylene Glycol Diacrylate 2%, 2-Phenoxyethyl Acrylate 5%, Diphenyl (2,4,6-Trimethylbenzoyl)phosphorus oxide (photoinitiator TPO) 3%, antifouling additive (BYKUV3500) 2%, anti-cratering additive (Japan DIC, RS-75) 0.12% , 20% ethyl acetate, and the balance is propylene glycol methyl ether acetate.

[0019] The preparation method is the same as in Example 1.

Embodiment 3

[0021] Anti-fingerprint UV-curable high-gloss varnish, by weight percentage, the raw materials are as follows: 9-functionality polyurethane acrylate (SHIKOHUV-4251 in Japan) 11%, silicone-modified acrylate polymer (Sabis 13H) 3%, Epoxy acrylic resin (SYF306S) 13%, trimethylolpropane acrylate 18%, dipropylene glycol dipropylene or hexanediol diacrylate 5%, 2-phenoxyethyl acrylate 5%, diphenyl (2,4,6-Trimethylbenzoyl)phosphorus oxide (photoinitiator TPO) 3%, antifouling additive (BYKUV3500) 2%, anti-cratering additive (Japan DIC, RS-75) 0.12% , 20% ethyl acetate, and the balance is propylene glycol methyl ether acetate.

[0022] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com