Anti-fouling and fingerprint-resistant stainless steel plate water-based paint and preparation method thereof

A stainless steel and board water-based technology, applied in antifouling/underwater coatings, polyester coatings, coatings, etc., can solve problems such as ambient air pollution, organic solvent emissions, and difficulty in continuing production, and achieve environmental protection and high adhesion , excellent wear and scratch resistance properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: the preparation of antifouling, anti-fingerprint stainless steel plate water-based paint

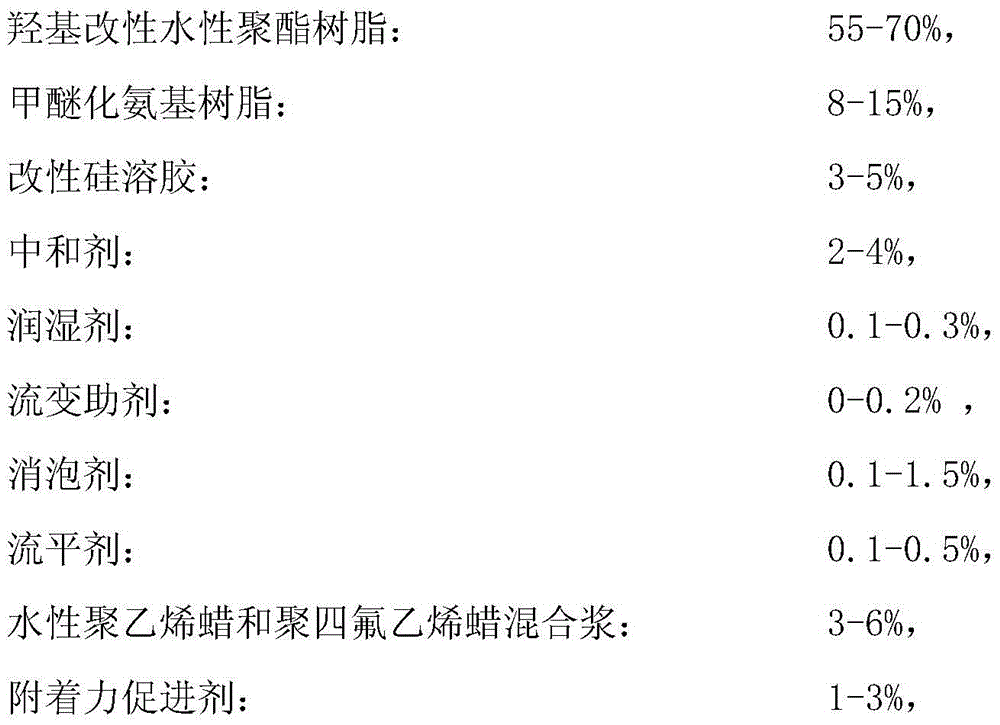

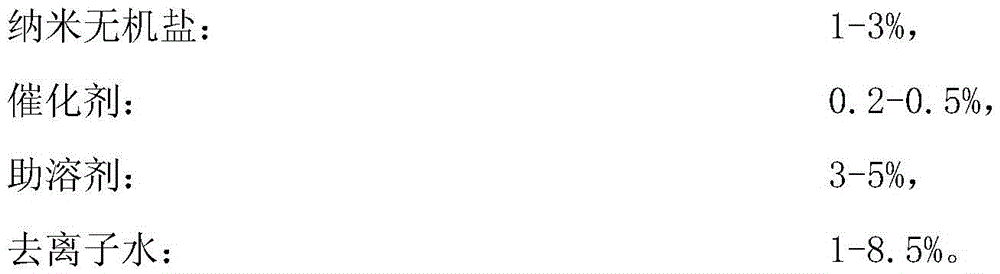

[0039] Raw materials: see Table 1.

[0040] Preparation steps: a. Add the hydroxyl-modified water-based polyester resin in the formula to a neutralizer to adjust the pH to 8.5, and then add the modified silica sol, wetting agent, rheological additive, water-based polyethylene wax and polytetrafluoroethylene Ethylene wax (1:2 mass ratio) mixed slurry, nano-inorganic salt, and co-solvent are mixed evenly, stirred evenly at a speed of 1500-2000 rpm, and then ball milled for 1 hour;

[0041] b. Then slowly add defoamer, leveling agent, catalyst, adhesion promoter, deionized water under stirring at 800 rpm, stir for 15-30 minutes, then add methyl etherified amino resin and stir evenly for 150- The finished product can be packaged after being filtered by a 200-mesh sieve.

[0042] c. The above coating is baked at 170-180°C for 10 minutes to prepare a coating sample.

[...

Embodiment 2

[0044] Embodiment 2: the preparation of antifouling, anti-fingerprint stainless steel plate water-based paint

[0045] Raw materials: see Table 1.

[0046] Preparation steps: with embodiment 1.

[0047] The results are shown in Table 2. The detection method is the same as in Example 1.

Embodiment 3

[0048] Embodiment 3: the preparation of antifouling, anti-fingerprint stainless steel plate water-based coating

[0049] Raw materials: see Table 1.

[0050] Preparation steps: with embodiment 1.

[0051] The results are shown in Table 2. The detection method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com