Sapphire camera lens

A camera and sapphire technology, which is applied in the field of camera lens, can solve problems such as uneven coating, transmittance and wear resistance, and achieve the effects of increasing light transmittance, increasing hardness, improving waterproof performance and anti-fingerprint performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

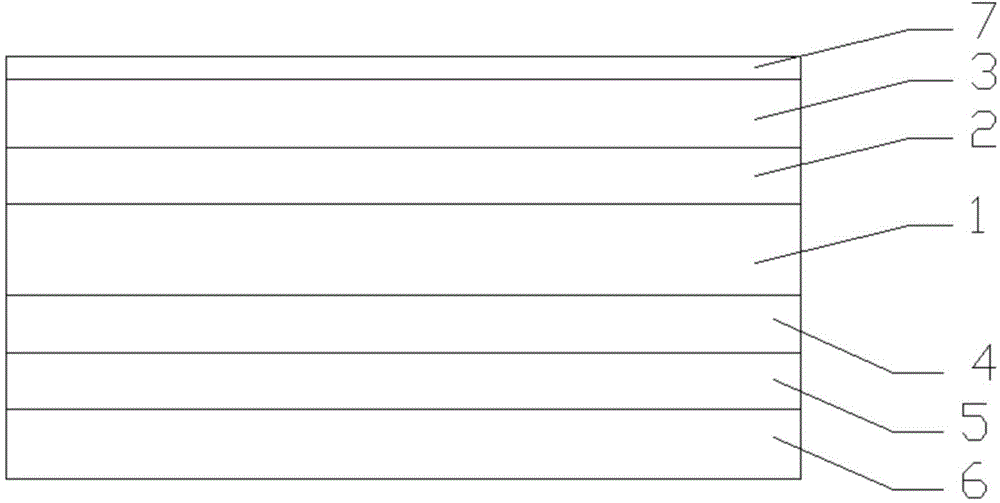

[0022] Such as figure 1 As shown, a sapphire camera lens includes a lens substrate 1, a titanium pentoxide film 1 2, a silicon dioxide film 3, an ink layer 4, a titanium pentoxide film 2 5, a silicon dioxide film 2 6, and an AF anti-fingerprint 7 film, the surface of the lens substrate 1 is coated with a layer of 400-500nm titanium pentoxide film-2, and the titanium pentoxide film-2 is coated with a layer of 500-600nm silicon dioxide film-3, so The silicon dioxide film-3 is coated with a layer of 10-15nmAF anti-fingerprint film 7, the lower surface of the lens substrate 1 is coated with an ink layer 4, and the ink layer 4 is coated with a layer of 400-500nm titanium pentoxide film 25, the 500-600nm silicon dioxide film 26 is coated on the titanium pentoxide thin film 25. The sapphire camera lens is electroplated with one or more layers of film to produce blue-green in the light-transmitting area. The material of the ink layer 4 is ink, and the ink on the edge of the sapphire...

Embodiment 2

[0032] A sapphire camera lens, comprising a lens substrate 1, a titanium pentoxide film 2, a silicon dioxide film 3, an ink layer 4, a titanium pentoxide film 2 5, a silicon dioxide film 2 6, and an AF anti-fingerprint 7 film, the surface of the lens substrate 1 is coated with a layer of 400-500nm titanium pentoxide thin film-2, the titanium dioxide thin film-2 is coated with a layer of 500-600nm silicon dioxide thin film-3, and the titanium dioxide A layer of 10-15nm AF anti-fingerprint film 7 is coated on the silicon thin film 1, an ink layer 4 is coated on the lower surface of the lens substrate 1, and a layer of 400-500nm titanium pentoxide thin film 2 5 is coated on the ink layer 4, A layer of 500-600nm silicon dioxide film 2 6 is coated on the titanium pentoxide thin film 2 5 . The sapphire camera lens is electroplated with one or more layers of film to produce blue-green in the light-transmitting area. The material of the ink layer 4 is ink, and the ink on the edge of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com