Anti-dazzle anti-fingerprint wear-resistant hardening liquid with rubber hand feeling, and preparation method thereof

An anti-glare and anti-fingerprint technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of rough surface, rough hand feeling and poor friction resistance of the paint film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

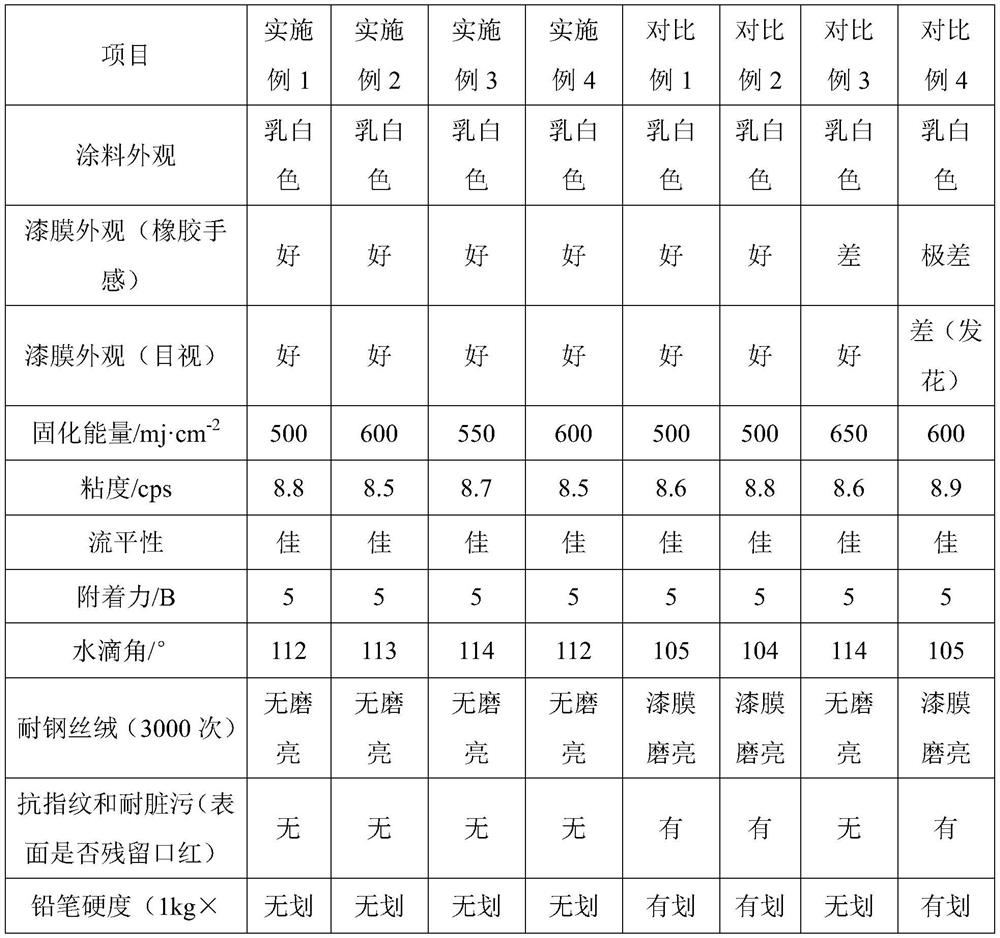

Examples

Embodiment 1

[0036] A kind of anti-glare anti-fingerprint anti-fingerprint wear-resistant hardening liquid with rubber feel, the mass parts of each component are: 40 parts of special modified polyurethane acrylic resin (UA-893) of organic fluorine silicon, 40 parts of special modified UV matte polyurethane acrylic resin (UV -5688) 10 parts, pentaerythritol tetraacrylate 10 parts, 2-hydroxy-2-methyl-1-phenylacetone 3 parts, fluorine-containing propylene compound (KY-1203) 1 part, rubber skin feeling aid (polyether Silicone copolymer) 1 part, matting powder (OK520) 4 parts, wear-resistant powder (PTFE modified wax powder) 3 parts, anti-settling agent (AT-720) 1 part, wetting and dispersing agent (BYK163 ) 2 parts, 10 parts of ethylene glycol butyl ether, 5 parts of cyclohexane, 10 parts of ethyl acetate.

Embodiment 2

[0038] A kind of anti-glare anti-fingerprint anti-fingerprint wear-resistant hardening liquid with rubber feel, the mass parts of each component are: 45 parts of organic fluorosilicon special modified polyurethane acrylic resin (UA5038), special modified UV matte polyurethane acrylic resin (L-8300 ) 10 parts, 5 parts of dipentaerythritol hexaacrylate, 2 parts of 1-hydroxycyclohexyl phenyl ketone, 3 parts of methyl benzoylformate, 2 parts of fluorine-containing propylene compound (KY-178), rubber skin feeling aid (polydimethylsiloxane dispersion liquid) 2 parts, matting powder (HD-703W) 4 parts, wear-resistant powder (PMMA modified microsphere wax powder) 4 parts, anti-settling agent 2 parts (Disparon 6500 ), 1 part of wetting and dispersing agent (TEGO760W), 10 parts of ethyl acetate, 10 parts of acetone.

Embodiment 3

[0040] A kind of rubber feel anti-glare anti-fingerprint anti-fingerprint wear-resistant hardening liquid, the mass parts of each component are: organofluorosilicon special modified polyurethane acrylic resin (UV-9843) 48 parts, special modified UV matte polyurethane acrylic resin (UVR -68) 10 parts, 5 parts of di-trimethylolpropane triacrylate, 1 part of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, 1 part of methyl benzoylformate, containing 1 part of fluoropropylene compound (FC-4430), 3 parts of rubber skin sensory additive (polydimethylsiloxane dispersion), 5 parts of matting powder (OMATT 2006), wear-resistant powder (polytetrafluoroethylene modified wax Powder) 4 parts, anti-settling agent 1 part (NEW-0451), wetting and dispersing agent (BYK410) 1 part, methyl isobutyl butanone 10 parts, cyclohexanone 10 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com