Anti-fingerprint glass coating with high friction coefficient and preparation method thereof

An anti-fingerprint and coating technology, applied in the coating and other directions, can solve the problems of broken, easy to slip, high maintenance cost, etc., and achieve the effects of mild reaction conditions, simple preparation method and high dynamic friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Synthesis of reactive perfluoropolyether alkylated oligomers, low surface energy hydrophobic and oleophobic components

[0035] Prepare a 100ml three-neck bottle device with temperature display and stirring functions, add 8.92g of undecafluoro-1-undecene, 3.80g of vinylmethoxysilane, and 2.74g of hexamethyldisiloxane, and stir evenly. Heating to 80°C-100°C, constant temperature for 10h-12h, adding to a double-layer glass kettle with stirring function, heating and purifying with silicone oil (4h) to obtain a perfluoropolyether alkylated oligomer with a molecular weight of 3000-4000 .

[0036] Add 8.75 g of nonafluoro-ethoxy-butane and 11.25 g of heptafluoro-ethoxy-difluoromethyl-propane to 5.0 g of perfluoropolyether alkylated oligomer, and stir evenly (30 min) Obtain perfluoropolyether alkylation coating, use Japan Shimadzu Corporation FTIR spectrometer to analyze infrared spectrum as Figure 4 .

[0037] Surface cleaning and activation treatment of glass materials ...

Embodiment 2

[0042] Synthesis of reactive perfluoropolyether alkylated oligomers, low surface energy hydrophobic and oleophobic components

[0043] Prepare a 100ml three-neck bottle device with temperature display and stirring functions, add 8.92g of undecafluoro-1-undecene, 3.80g of vinylmethoxysilane, and 2.74g of hexamethyldisiloxane, and stir evenly. Heat to 80°C-100°C, keep the temperature constant for 10h-12h, then add it into a double-layer glass kettle with stirring function, heat and purify (4h) through silicone oil to obtain perfluoropolyether alkylation low molecular weight 3000-4000 Polymer —.

[0044] Add 8.75 g of nonafluoro-ethoxy-butane and 11.25 g of heptafluoro-ethoxy-difluoromethyl-propane to 5.0 g of perfluoropolyether alkylated oligomer, and stir evenly (30 min) A perfluoropolyether alkylated coating is obtained.

[0045] Surface cleaning and activation treatment of glass materials

[0046] Clean the glass material in a 5-slot flat-bed washer to remove surface dirt....

PUM

| Property | Measurement | Unit |

|---|---|---|

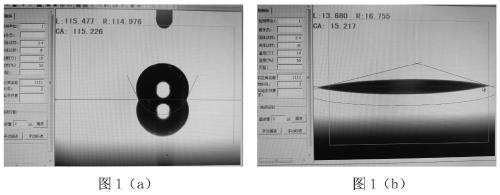

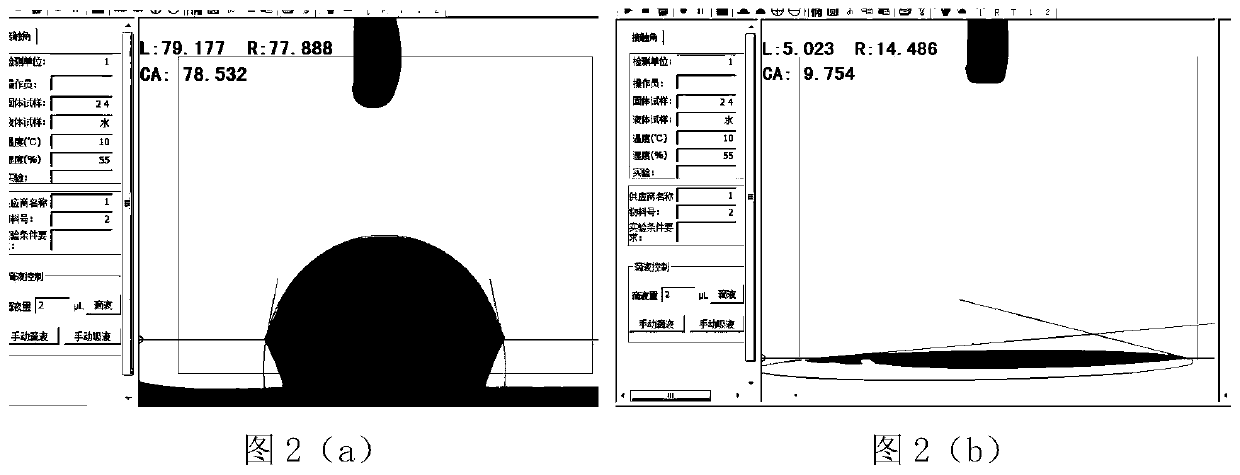

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com