Epoxy resin pouring sealant and usage method

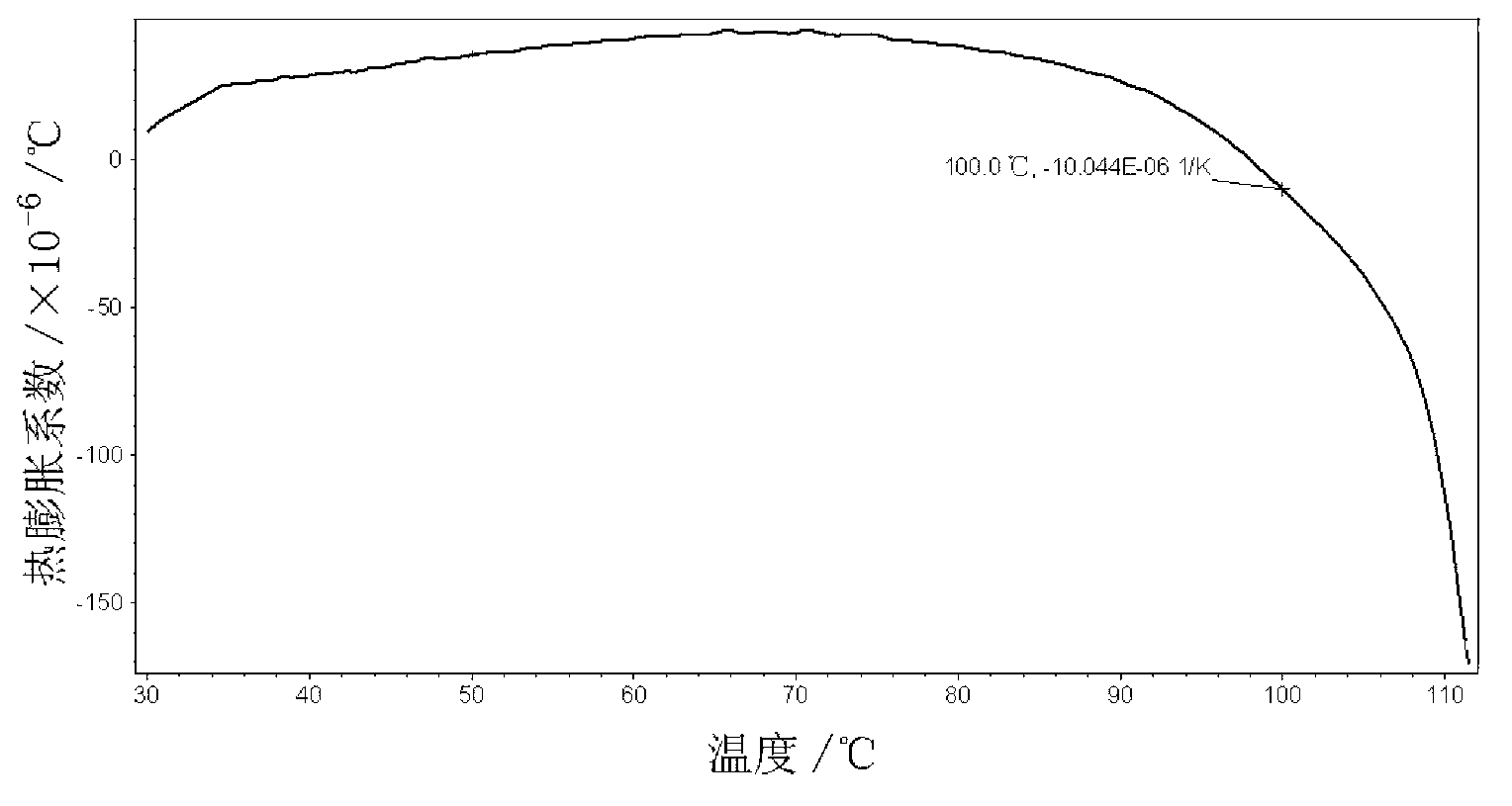

A technology of epoxy resin and potting glue, which is applied in epoxy resin potting glue, epoxy resin potting glue with high bending and compressive strength, and low thermal expansion coefficient. Compressive strength and other issues, to achieve the effect of good high temperature electrical properties, long service life, and small internal friction

Active Publication Date: 2013-01-02

CENT SOUTH UNIV

View PDF6 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Epoxy resin potting materials satisfying low thermal expansion coefficient, high flexural and compressive strength at the same time have not been reported yet

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0015] Prepared epoxy resin potting glue, the content of each component is

[0016]

Embodiment 2

[0017] Embodiment 2: the epoxy resin encapsulant material of low thermal expansion coefficient, high bending resistance and compressive strength that the present invention relates to, the content of each component is

[0018]

Embodiment 3

[0020] Prepared epoxy resin potting glue, the content of each component is

[0021]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to an epoxy resin pouring sealant and a usage method. The epoxy resin pouring sealant is composed of an o-cresol-formaldehude epoxy resin matrix, a methylhexahydrophthalic anhydride curing agent, an electronic grade torispherical silica micro powder filler, a diluent and an antifoaming agent, wherein the composition ratio of the epoxy resin matrix to the curing agent is 1: (0.6-1.4), and the composition ratio of the epoxy resin matrix to the filler is 1: (0.3-2.4). According to the epoxy resin pouring sealant, a curing process is that pre-curing is performed at the temperature of 90 DEG C for 0.5-1 hour, and curing is performed at the temperature of 150 DEG C for 2-3 hours. The epoxy resin pouring sealant has the advantages of being low in toxicity, density, thermal expansivity coefficient and water absorption rate, high in bending strength and compressive strength and good in application prospect and can be widely applied to electronic controllers, sensors, aerospace components and the like.

Description

technical field [0001] The invention relates to an epoxy resin potting glue and a usage method thereof, in particular to an epoxy resin potting glue with a low coefficient of thermal expansion and high bending and compressive strength and a usage method thereof. The invention belongs to the technical field of adhesive preparation. Background technique [0002] Potting glue, also known as electronic glue, is a broad term. Used for bonding, sealing, potting and coating protection of electronic components. The potting glue is liquid before it is cured and has fluidity. The viscosity of the glue varies according to the material, performance and production process of the product. Only when the potting glue is completely cured can its use value be realized. After curing, it can play the role of waterproof, moisture-proof, dust-proof, insulation, heat conduction, confidentiality, corrosion resistance, temperature resistance, and shock resistance. With the expansion of the applic...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09J163/04C09J11/06C09J11/04C09K3/10

Inventor 卢安贤罗志伟刘学峰陈兴军瞿高

Owner CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com