Epoxy resin curing agent, epoxy resin composition, hardened material thereof, and optical semiconductor device

An epoxy resin curing and epoxy resin technology, which is used in semiconductor devices, semiconductor/solid-state device parts, electric solid-state devices, etc., to achieve the effects of less coloring, good strength, and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

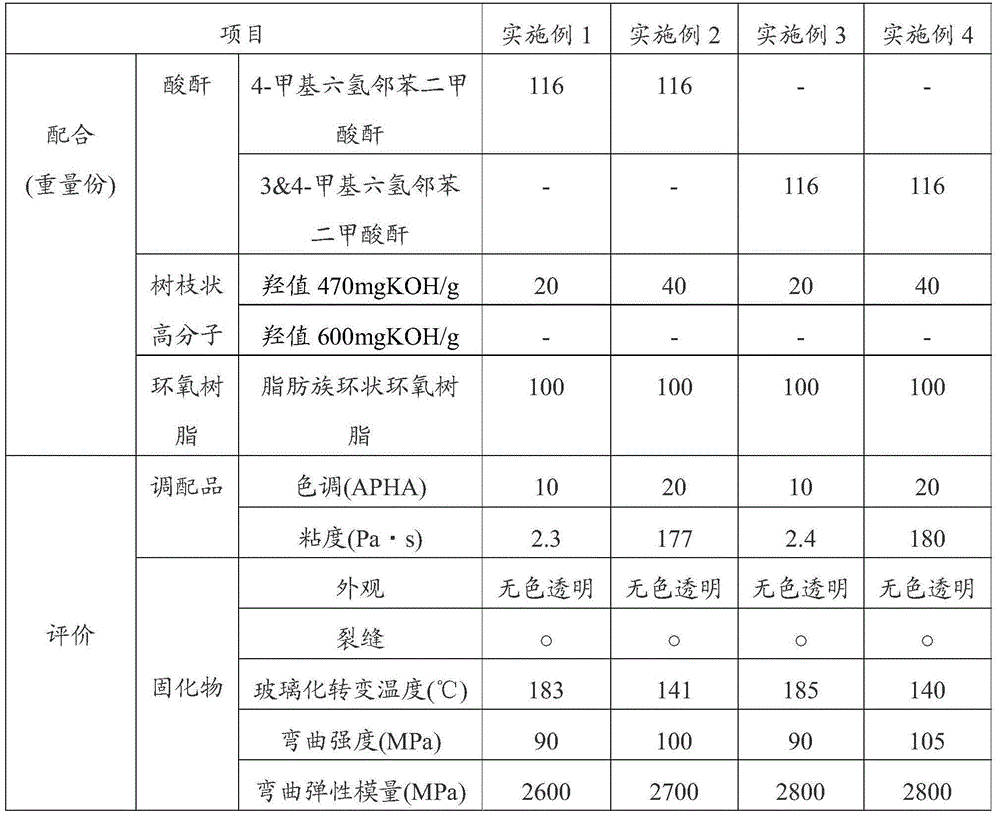

Embodiment 1

[0070] 20 parts by weight of polyester dendrimer (hydroxyl value 470 mgKOH / g, weight average molecular weight 1800, viscosity 7.6 Pa·s (25°C), BOLTORN P-1000: Perstorp trade name) Specifically, 116 parts by weight of 4-methylhexahydrophthalic anhydride (HN-7000: manufactured by Hitachi Chemical Industry Co., Ltd. / anhydride equivalent 168 (g / eq)) was added as a polycarboxylic acid anhydride, heated to 70° C. Stir and dissolve until it becomes uniform, thereby obtaining the epoxy resin curing agent (I).

[0071] With respect to 136 parts by weight of epoxy resin curing agent (I), add 3',4'-epoxycyclohexylmethyl-3,4-epoxycyclohexanecarboxylate (CELLOXIDE 2021P : DAICEL CHEMICAL INDUSTRIES, LTD. (DAICEL CHEMICAL INDUSTRIES, LTD.) product name / epoxy equivalent 138 (g / eq)) 100 parts by weight, tetra-n-butylphosphonium o, o-diethyl diethyl diethyl disulfide as a curing accelerator 1 part by weight of phosphodisulfate (Hishikorin (ヒシコーリン) PX-4ET: trade name manufactured by Nippon C...

Embodiment 2

[0074] An epoxy resin curing agent (II) was obtained in the same manner as in Example 1, except that 40 parts by weight of polyester dendrimers were used instead of 20 parts by weight of polyester dendrimers.

[0075] Except having used 156 weight part of epoxy resin curing agents (II) instead of epoxy resin curing agent (I), it carried out similarly to Example 1, and obtained the epoxy resin composition (II). Furthermore, it carried out similarly to Example 1, and obtained the hardened|cured material (II).

Embodiment 3

[0077] Except for the use of a mixture of 3-methylhexahydrophthalic anhydride and 4-methylhexahydrophthalic anhydride (hereinafter referred to as 3&4-methylhexahydrophthalic anhydride. HN-5500E: Hitachi Chemical An epoxy resin curing agent (III) was obtained in the same manner as in Example 1 except that Kogyo Co., Ltd. / acid anhydride equivalent weight 168 (g / eq)) was used as polyvalent carboxylic acid anhydride 116 parts by weight.

[0078] From the epoxy resin curing agent (III), it carried out similarly to Example 1, and obtained the epoxy resin composition (III). Furthermore, it carried out similarly to Example 1, and obtained the hardened|cured material (III).

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com