Method for preparing methylhexahydrophthalic anhydride by means of continuous hydrogenation

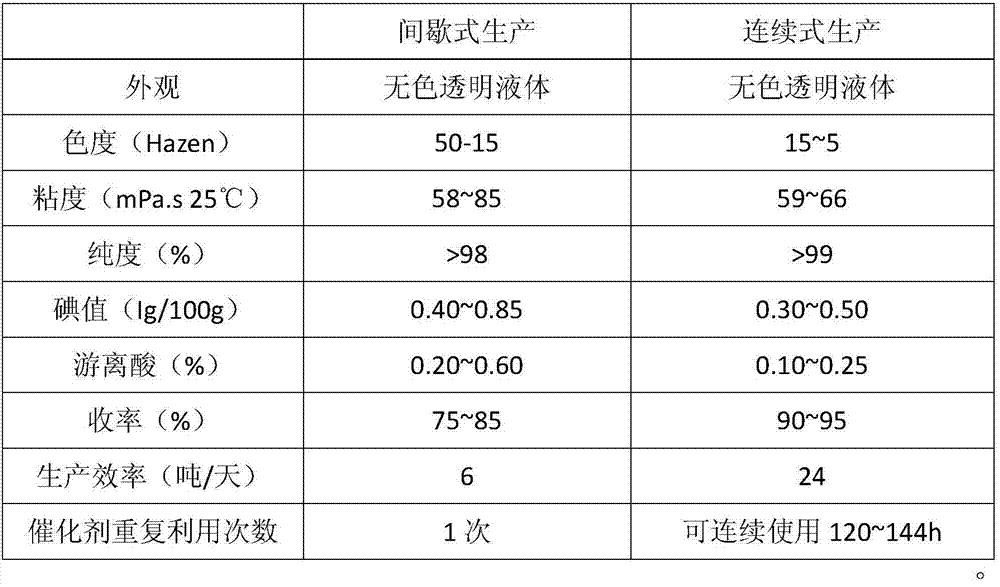

A technology of methyl hexahydrophthalic anhydride and methyl tetrahydrophthalic anhydride, which is applied in the field of continuous hydrogenation of methyl tetrahydrophthalic anhydride to prepare methyl hexahydrophthalic anhydride, can Solve the problems of poor product quality stability, inability to recycle, and large floor space, and achieve the effects of shortening hydrogenation time, small floor space, and small heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: industrial application

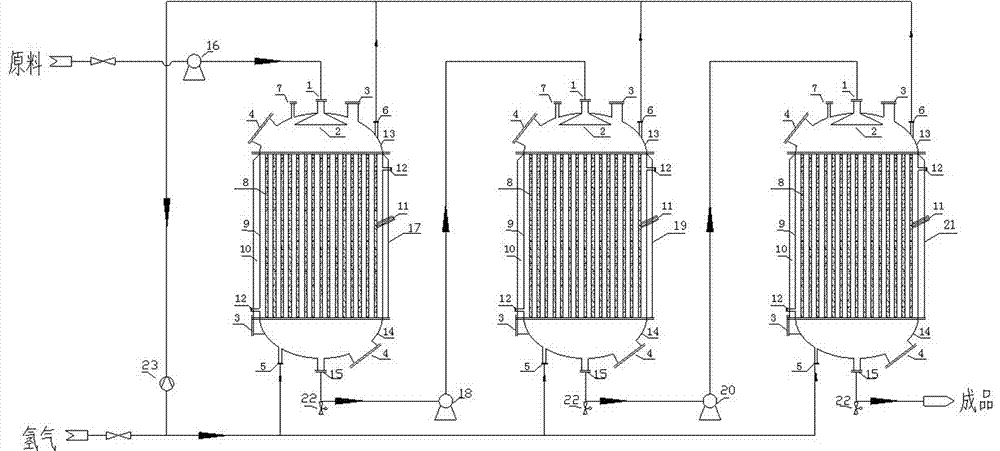

[0020] According to the present invention, the production process for preparing methyl hexahydrophthalic anhydride by continuous hydrogenation of methyltetrahydrophthalic anhydride as raw material is characterized in that three-stage split-tube fixed-bed reactors 17 and 19 are used , 21 carry out continuous hydrogenation in circulation, and each split-tube fixed-bed reactor is connected in series by raw material circulation pumps 16, 18, 20; the inside of the split-tube fixed-bed reactor adopts a split-tube structure. Composite solid catalyst 8 is filled, and coal medium is heated in the shell side; hydrogen enters in parallel from the bottom 5 of the split-tube reactors at all levels, and returns to the hydrogen compressor 23 through the outlet 6 after passing through the split tubes. The raw material methyltetrahydrophthalic anhydride is transported to the upper part of the primary reactor 17 through the primary high-pressure cir...

Embodiment 2

[0025] Example 2: actual production application

[0026] 100 parts of Raney nickel and 20 parts of palladium / alumina were dried in a double-cone dryer and mixed for 1.5 hours. The split-tube fixed-bed reactor removes the upper head, and the hydrogen inlet 5 at the bottom of the reactor has a flow rate of 5m 3 / h of nitrogen, the split tube was purged for 10 minutes, and the nitrogen flow rate was adjusted to 1m 3 / h, the pre-mixed and dried catalyst is filled into the split tube through the upper part of the kettle body, and the bulk density is 0.1-0.5g / ml. After filling, connect the upper head. The nitrogen flow rate is adjusted to 5m 3 / h, continue purging for 10min, and stop nitrogen flow.

[0027]Regulate the hydrogen pressure to be 6MPa, and the hydrogen enters in parallel from the bottom inlet 5 of the reactors 17, 19, 21, and the unreacted hydrogen returns to the hydrogen compressor 23 through the outlet 6 on the top of the reactors 17, 19, 21. Control the reaction...

Embodiment 3

[0028] Example 3: actual production application

[0029] 100 parts of Raney nickel, 40 times of palladium / alumina, dried in a double-cone dryer and mixed for 1.5 hours. The split-tube fixed-bed reactor removes the upper head, and the hydrogen inlet 5 at the bottom of the reactor has a flow rate of 5m 3 / h of nitrogen, the split tube was purged for 10 minutes, and the nitrogen flow rate was adjusted to 1m 3 / h, the pre-mixed and dried catalyst is filled into the split tube through the upper part of the kettle body, and the bulk density is 0.1-0.5g / ml. After filling, connect the upper head. The nitrogen flow rate is adjusted to 5m 3 / h, continue purging for 10min, and stop nitrogen flow.

[0030] Regulate the hydrogen pressure to be 3MPa. The hydrogen enters in parallel from the bottom inlet 5 of the reactors 17, 19, and 21, and the unreacted hydrogen returns to the hydrogen compressor 23 through the outlet 6 on the top of the reactors 17, 19, and 21. The reaction temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com