Patents

Literature

84 results about "Tetrahydrophthalamic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hot melt adhesive composition

A hot melt adhesive composition comprising: (a) a functional copolymer obtained from copolymerization of ethylene and a comonomer selected from maleic anhydride, citraconic anhydride, itaconic anhydride, tetrahydrophthalic anhydride, maleic acid, citraconic acid, itaconic acid, fumaric acid, tetrahydrophthalic acid, the corresponding salts, monoesters and diesters of these acids, and mixtures of any of these, wherein the functional copolymer is present in an amount from about 5 to about 95 weight % of the combined total amount of (a) and (b); and (b) at least one ethylene copolymer obtained from copolymerization of ethylene with a polar monomer wherein said polar comonomer is present in the copolymer in an amount of from 8 to 40 weight %, wherein said ethylene copolymer is selected from the group consisting of ethylene / vinyl acetate copolymers, ethylene / alkyl (meth)acrylate copolymers and ethylene / alkyl (meth)acrylate / carbon monoxide terpolymers, in an amount from about 5 to about 95 weight % of the combined total amount of (a) and (b); wherein the composition has a melt index of 100 grams / 10 minutes or higher. Articles comprising and process using the hot melt adhesive are also disclosed.

Owner:DOW GLOBAL TECH LLC

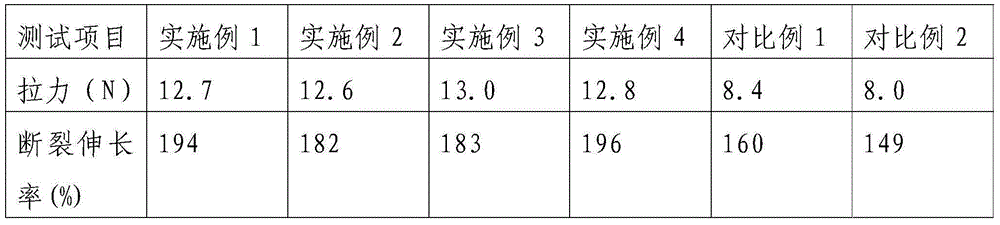

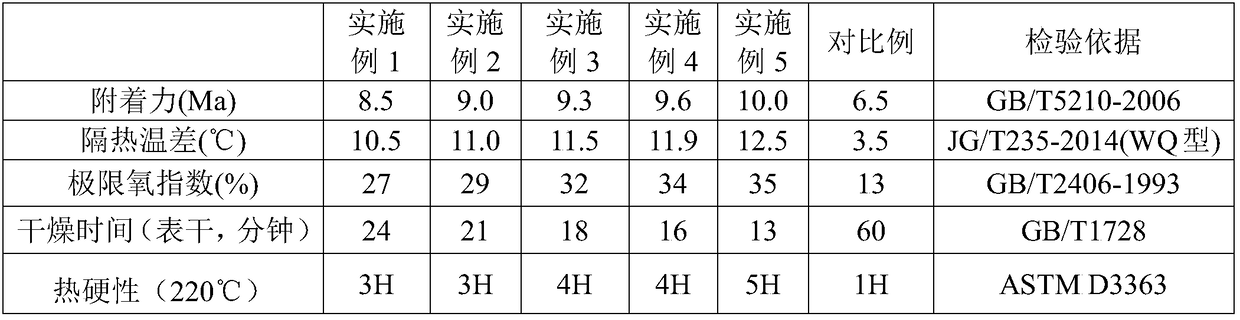

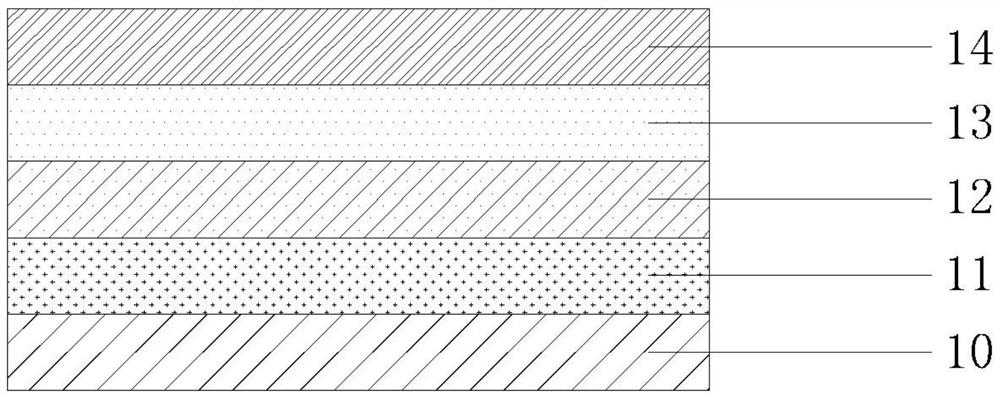

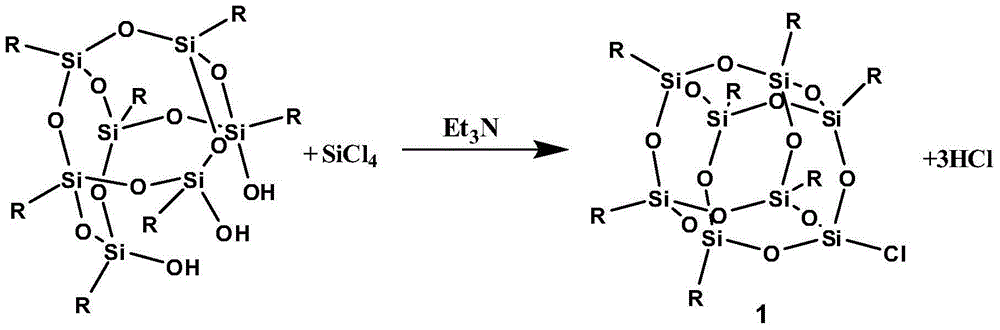

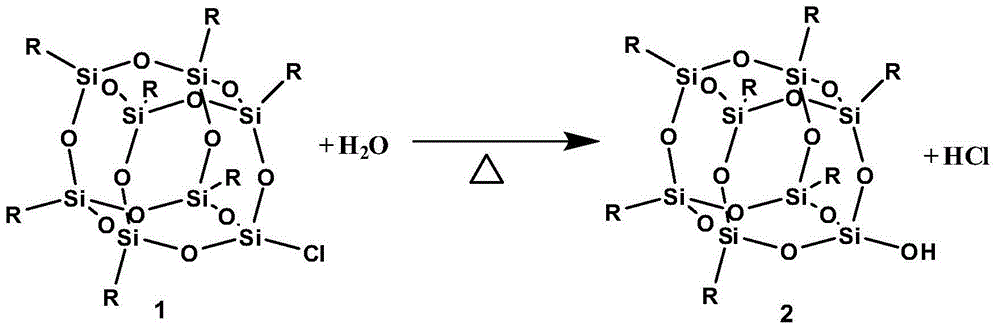

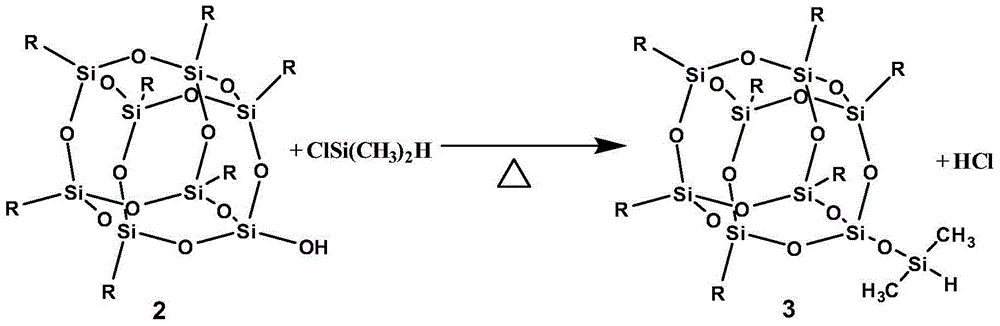

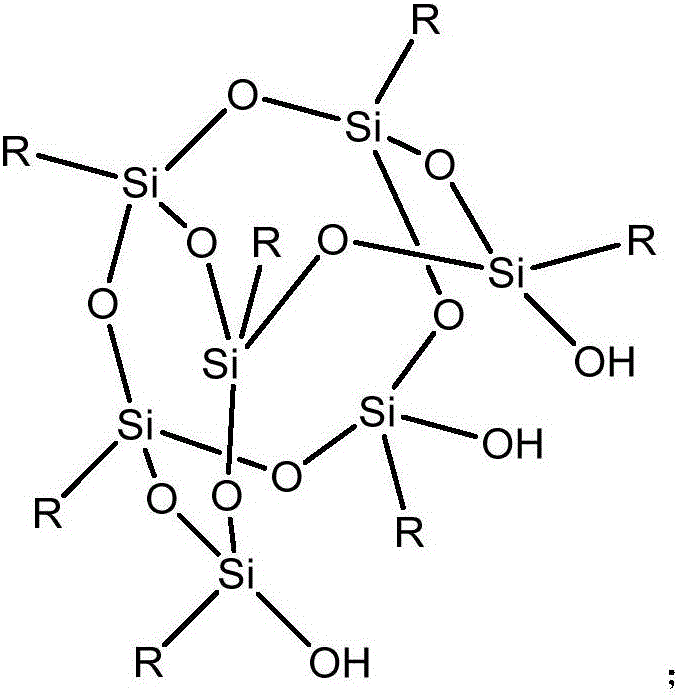

Preparation method of POSS modified polyurethane resin

InactiveCN104592473AImprove mechanical propertiesHigh tensile strengthPolyesterTetrahydrophthalamic acid

A preparation method of POSS (polyhedral oligomeric silsesquioxane) modified polyurethane resin comprises the following steps: preparing POSS diol by using trihydroxy cage-like siloxane heptamer, triethylamine, tetrahydrofuran, SiCl4, dimethylchlorosilane, tetrahydrophthalic anhydride, LiAlH4 and potassium sodium tartrate; and polymerizing the POSS diol, polyether diol, polyester diol and isocyanate to obtain the POSS modified polyurethane resin. The method allows the novel POSS modified polyurethane resin to be obtained by using the POSS diol, and can effectively overcome the compatibility problem existing in the modification of common inorganic substances; and the obtained POSS modified polyurethane resin has large tensile strength, impact strength, shearing strength and other mechanical performances, and also has the advantages of low surface energy, good heat resistance and good wear resistance.

Owner:JIAXING HEXIN CHEM IND

Resin for Oxygen-absorbing Adhesive and Oxygen-absorbing Adhesive

InactiveUS20130143734A1Improve oxygen removal effectLow costNon-macromolecular adhesive additivesOther chemical processesPolyesterPolymer science

The purpose of the present invention is to provide a two-component curable oxygen-absorbing resin composition that has both oxygen-absorbing and adhesive properties and cohesive power. The resin for an oxygen-absorbing adhesive is a polyester comprising structural units derived from an acid component (A) and an acid component (B), wherein the ratio of the acid component (A) to total acid components is 70 to 95 mol %, the ratio of the acid component (B) to total acid components is 0 to 15 mol %, the polyester has a glass transition temperature of −20° C. to 2° C., the resin is cured using a hardening agent, the acid component (A) is tetrahydrophthalic acid or a derivative thereof, or tetrahydrophthalic acid anhydride or a derivative thereof, and the acid component (B) is phthalic acid.

Owner:TOYO SEIKAN GRP HLDG LTD

Hot melt adhesive composition

A hot melt adhesive composition comprising: (a) a functional copolymer obtained from copolymerization of ethylene and a comonomer selected from maleic anhydride, citraconic anhydride, itaconic anhydride, tetrahydrophthalic anhydride, maleic acid, citraconic acid, itaconic acid, fumaric acid, tetrahydrophthalic acid, the corresponding salts, monoesters and diesters of these acids, and mixtures of any of these, wherein the functional copolymer is present in an amount from about 5 to about 95 weight % of the combined total amount of (a) and (b); and (b) at least one ethylene copolymer obtained from copolymerization of ethylene with a polar monomer wherein said polar comonomer is present in the copolymer in an amount of from 8 to 40 weight %, wherein said ethylene copolymer is selected from the group consisting of ethylene / vinyl acetate copolymers, ethylene / alkyl (meth)acrylate copolymers and ethylene / alkyl (meth)acrylate / carbon monoxide terpolymers, in an amount from about 5 to about 95 weight % of the combined total amount of (a) and (b); wherein the composition has a melt index of 100 grams / 10 minutes or higher. Articles comprising and process using the hot melt adhesive are also disclosed.

Owner:DOW GLOBAL TECH LLC

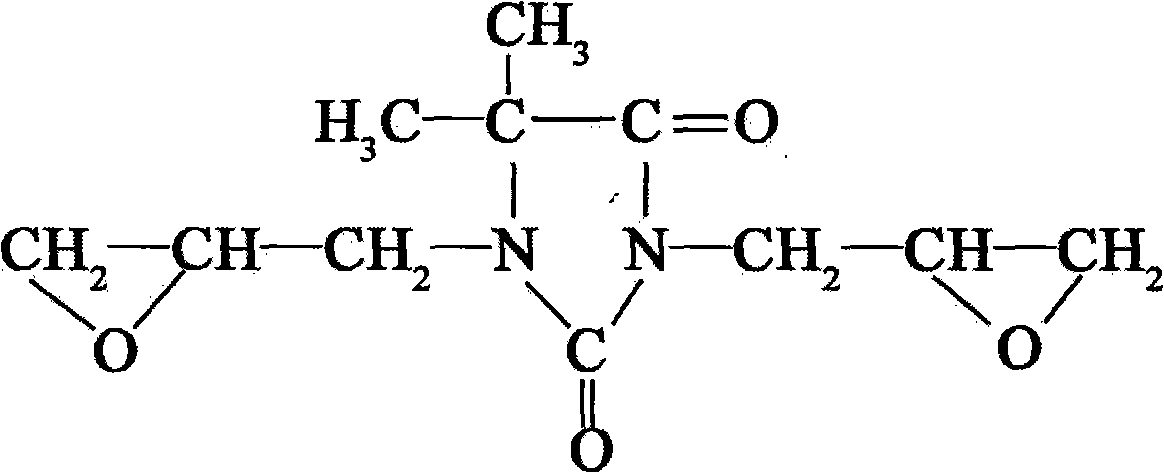

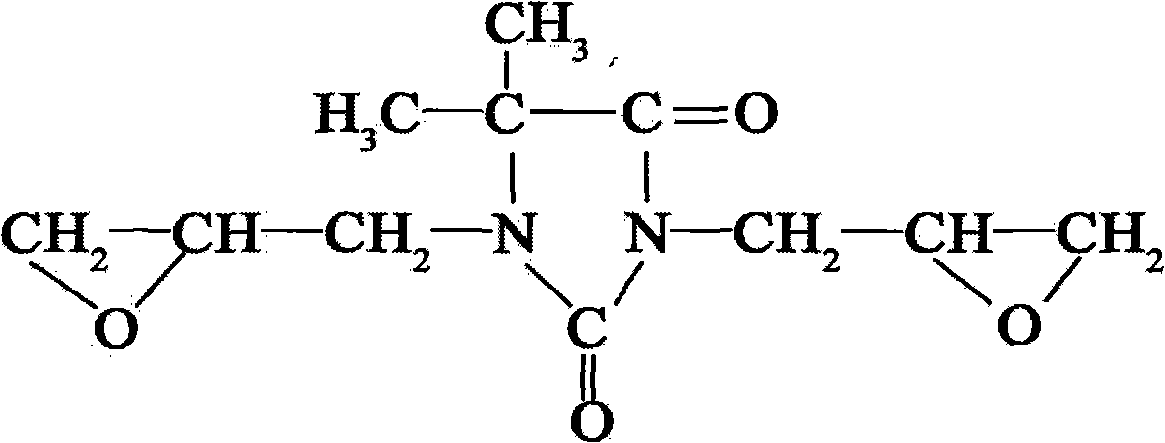

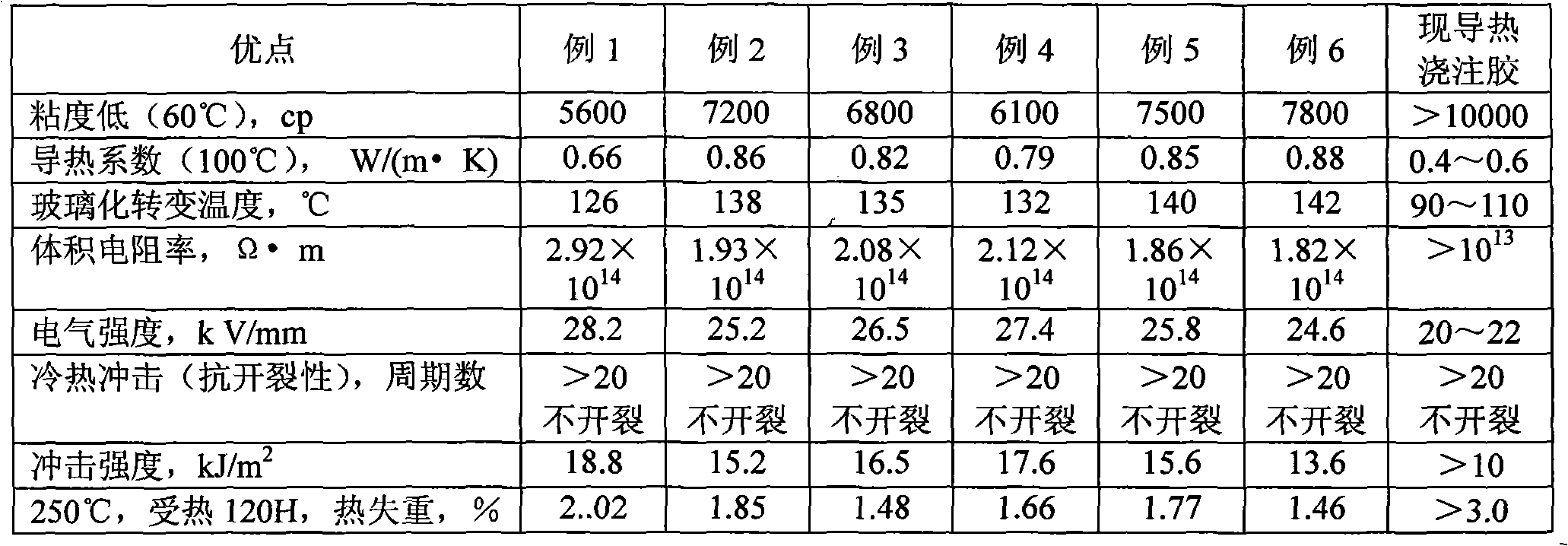

Heat conduction insulating casting glue and preparation method thereof

ActiveCN102093665ALow viscosityGood workmanshipInorganic insulatorsHeat-exchange elementsEpoxyTetrahydrophthalamic acid

The invention relates to a heat conduction insulating casting glue and a preparation method thereof. The casting compound comprises the following main components in parts by weight: (A) 100 parts of hydantoin epoxy resin, (B) 60-120 parts of anhydride curing agent, and (C) 200-400 parts of inorganic heat conductive filler, wherein the component A (per 100 weight parts) contains 10-15 weight partsof alcohol plasticizer; the component B is one or more of hexahydrophthalic anhydride, tetrahydrophthalic anhydride, methyltetrahydrophthalic anhydride, methylhexahydrophthalic anhydride and methylnadic anhydride; and the component C is one or more of silica micropowder, aluminum oxide, aluminum nitride and boron nitride in 300-900 meshes. The preparation method of the casting compound comprises the following steps: mixing A and B proportionally; soaking C in ethanol solution of silane coupling agent, dispersing at a high speed, filtering, and oven-drying; heating the mixture of A and B, adding C, mixing, and debubbling; and casing, and curing. The casting compound provided by the invention has low viscosity, greatly improved heat-conducting property and improved mechanical properties, and is convenient in casting. The preparation method of the casting compound is solvent-free, and has no pollution to the environment.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

Hot melt adhesive composition

A hot melt adhesive composition comprising: (a) a functional copolymer obtained from copolymerization of ethylene and a comonomer selected from maleic anhydride, citraconic anhydride, itaconic anhydride, tetrahydrophthalic anhydride, maleic acid, citraconic acid, itaconic acid, fumaric acid, tetrahydrophthalic acid, the corresponding salts, monoesters and diesters of these acids, and mixtures of any of these, wherein the functional copolymer is present in an amount from about 5 to about 95 weight % of the combined total amount of (a) and (b); and (b) at least one ethylene copolymer obtained from copolymerization of ethylene with a polar monomer wherein said polar comonomer is present in the copolymer in an amount of from 8 to 40 weight %, wherein said ethylene copolymer is selected from the group consisting of ethylene / vinyl acetate copolymers, ethylene / alkyl (meth)acrylate copolymers and ethylene / alkyl (meth)acrylate / carbon monoxide terpolymers, in an amount from about 5 to about 95 weight % of the combined total amount of (a) and (b); wherein the composition has a melt index of 100 grams / 10 minutes or higher. Articles comprising and process using the hot melt adhesive are also disclosed.

Owner:DOW GLOBAL TECH LLC

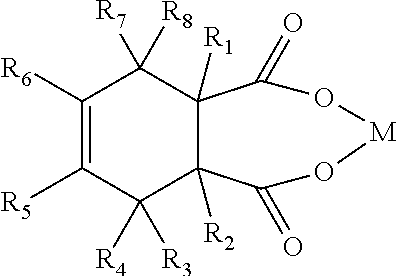

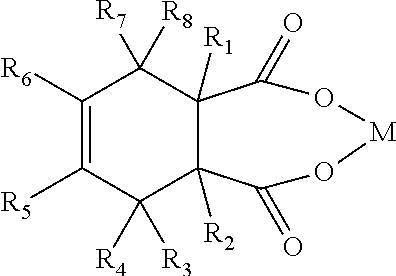

B-crystal form nucleating agent composition for polypropylene and use thereof

Disclosed are a β-crystal form nucleating agent composition for polypropylene and an application thereof. The composition is prepared by proportionally mixing barium tetrahydrophthalate, calcium tetrahydrophthalate and the like with adjuvants, such as hydrotalcite or calcium carbonate. The composition has better functions than a single-component β-nucleating agent. The impact strength of polypropylene subjected to nucleation modification by the β-crystal form nucleating agent composition can be improved by up to 6 times, and the heat distortion temperature is improved by about 10° C. to 20° C.; in addition, while the impact strength is improved, the flexural modulus of polypropylene can be improved, namely, the rigidity of polypropylene is improved. Therefore, the mechanical and thermal properties of polypropylene are improved. The use amount of the composition is low, and the application range of polypropylene is expanded; the β-crystal form nucleating agent composition for polypropylene can be widely used in the processing application of polypropylene resin.

Owner:GCH TECH

Red mud curing agent for paving road and preparation method of red mud curing agent

InactiveCN102584128ANo extravasationIncrease work intensityHydration reactionTetrahydrophthalamic acid

The invention relates to a red mud curing agent for paving a road and a preparation method of the red mud curing agent. The red mud curing agent is made of silicon oxide, aluminum oxide, calcium oxide, industrial byproduct alkali residue, tetrahydrophthalic anhydride and ethylene glycol double trimellitic anhydride ester. According to the preparation method, the active matters, such as silicon oxide, aluminum oxide and calcium oxide, are mixed; the active constituents of the matters are matched with one another, thereby obtaining curing agent and red mud; after being stirred, the curing agent and the red mud are subjected to ion exchange under the catalysis of concentrated material, thereby boosting the coagulation of red mud particles; and meanwhile, the red mud is coagulated and hardened, under the hydration reaction of a gelled material in the curing agent; the red mud has higher working strength within a short period of time; and the exosmose of heavy metal, radioactive elements and the like, is avoided. The red mud curing agent prepared by the preparation method disclosed by the invention is used together with red mud for paving the road. Compared with the prior art, the red mud curing agent has the advantages of high strength, excellent plate property, high durability, excellent water stability, excellent frost and melt resistance, excellent air shrinkage resistance, and the like.

Owner:HENAN UNIV OF SCI & TECH

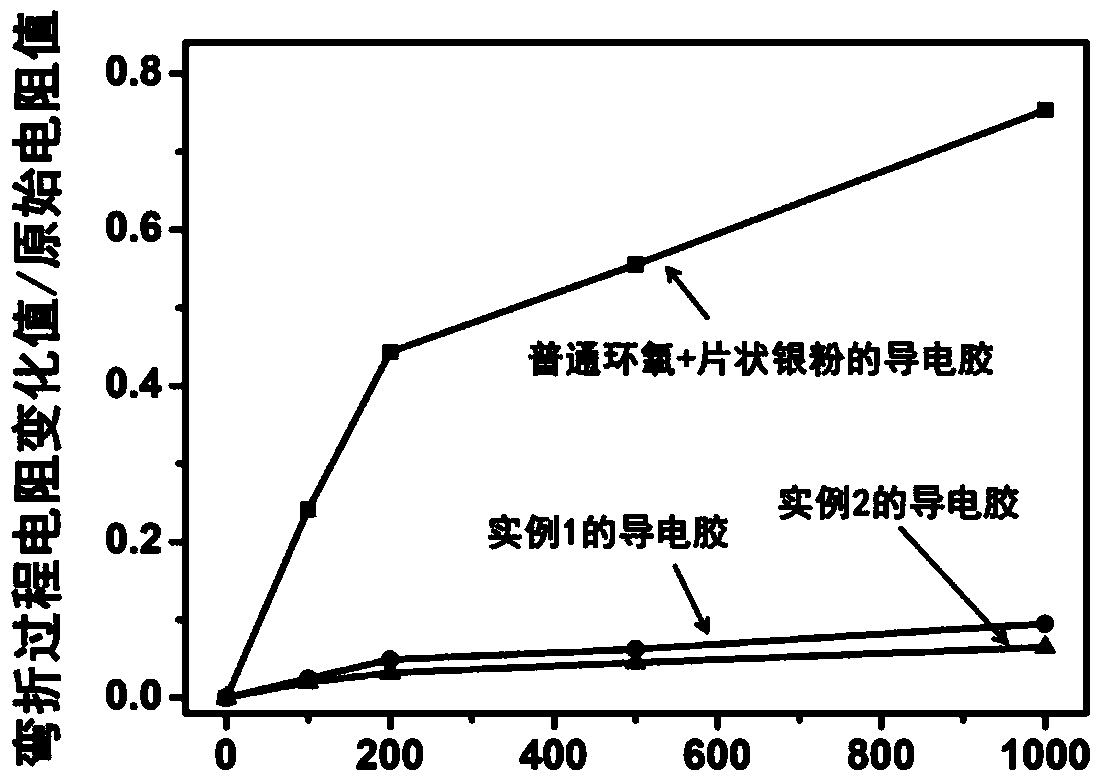

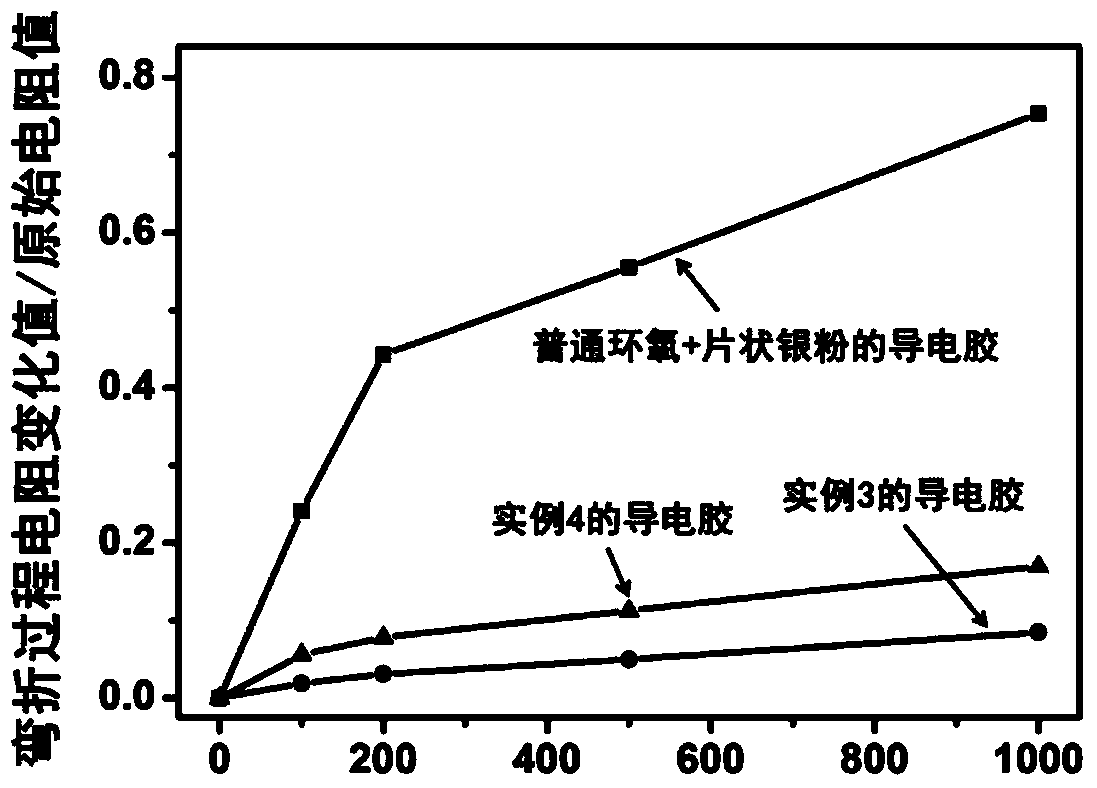

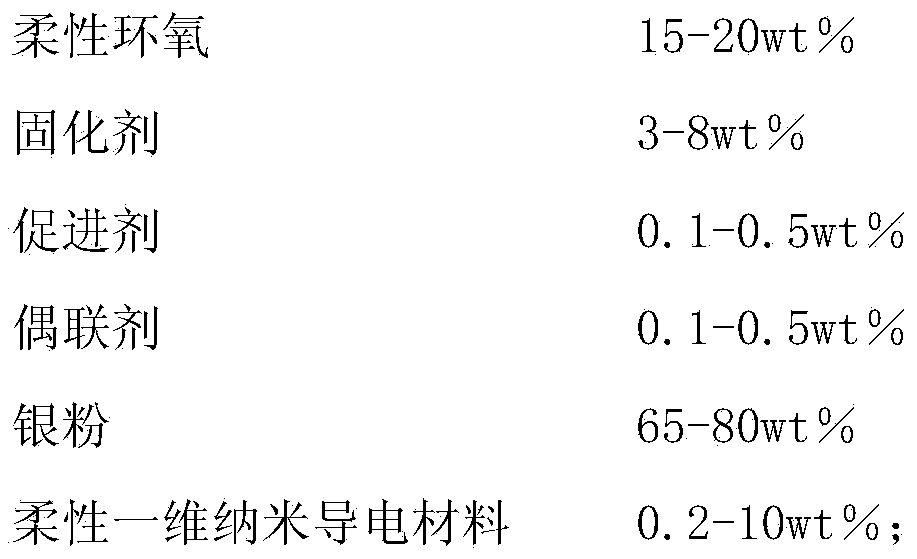

Flexible conductive adhesive capable of being used in direct coating manner and preparation method of flexible conductive adhesive

InactiveCN104263303AImprove conductivityGood flexibilityEpoxy resin adhesivesGraft polymer adhesivesTetrahydrophthalamic acidAdhesive

The invention discloses a flexible conductive adhesive capable of being used in a direct coating manner and a preparation method. The flexible conductive adhesive consists of 15-20wt% of flexible epoxy, 3-8wt% of a curing agent, 0.1-0.5wt% of an accelerant, 0.1-0.5wt% of a coupling agent, 65-80wt% of silver powder and 0.2-10wt% of flexible one-dimensional nano conductive material, wherein the flexible epoxy is a mixture of bisphenol-A epoxy resin with ethylene-vinyl acetate copolymer soft segments grafted and aliphatic glycidyl ether epoxy resin; the curing agent is one or more of methylhexahydrophthalic anhydride, methyl tetrahydrophthalic anhydride and tetrahydrophthalic anhydride; the accelerant is an imidazole compound; the coupling agent is one or more of KH 550, KH560 and KH570; the flexible one-dimensional nano conductive material is a carbon nano tube or a conductive metal nano wire. The flexible conductive adhesive has the excellent conductivity and the good flexibility, the conductivity is almost not changed after being bent repeatedly, and the flexible conductive adhesive can meet requirements of flexible electronic products.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

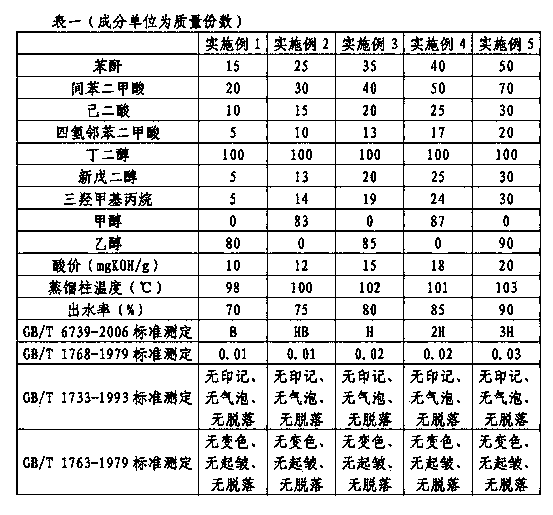

Hydroxyl-terminated water-based polyester resin and preparation method thereof

ActiveCN104193973AHigh bond energyImprove wear resistancePolyester coatingsWater basedTetrahydrophthalamic acid

The invention discloses hydroxyl-terminated water-based polyester resin. The hydroxyl-terminated water-based polyester resin is characterized by comprising the following components in parts by weight: 15-50 parts of phthalic anhydride, 20-70 parts of isophthalic acid, 10-30 parts of adipic acid, 5-20 parts of tetrahydro phthalic acid, 100 parts of butanediol, 5-30 parts of neopentyl glycol and 5-30 parts of trimethylolpropane. The hydroxyl-terminated water-based polyester resin has high hardness, good wearing resistance, excellent water resistance and chemical resistance.

Owner:中山市巴德富化工科技有限公司

Heat transfer printing ink ribbon for metal material

InactiveCN104802541AImprove adhesionSolve application problemsInk ribbonsInksMethacrylateTetrahydrophthalamic acid

The invention provides a heat transfer printing ink ribbon for a metal material. The heat transfer printing ink ribbon for the metal material comprises a base membrane layer, wherein a heat transfer printing ink layer is arranged on one side of the base membrane layer, and a back coating is arranged on the other side of the base membrane layer. The heat transfer printing ink layer comprises, by weight, 20-25% of thermoplastic acrylic resin, 10-20% of E-20 bisphenol A epoxy resin, 5-10% of E-12 bisphenol A epoxy resin, 3-6% of tetra hydro phthalic anhydride, 20-35% of compound wax, 0.5-1% of 2-hydroxy ethyl methacrylate phosphate, 8-15% of coloring agents and 10-20% of solvent. According to the heat transfer printing ink ribbon, application of the heat transfer printing ink ribbon to metal printing media is achieved, the adhesion to metal is good, and the purpose that heat transfer printing operation is directly conducted on the metal printing media is achieved; the scraping resistance is good, printed patterns are clear and complete, and the application range of the heat transfer printing ink ribbon is broadened.

Owner:WUHAN HUAGONG IMAGE TECH & DEV

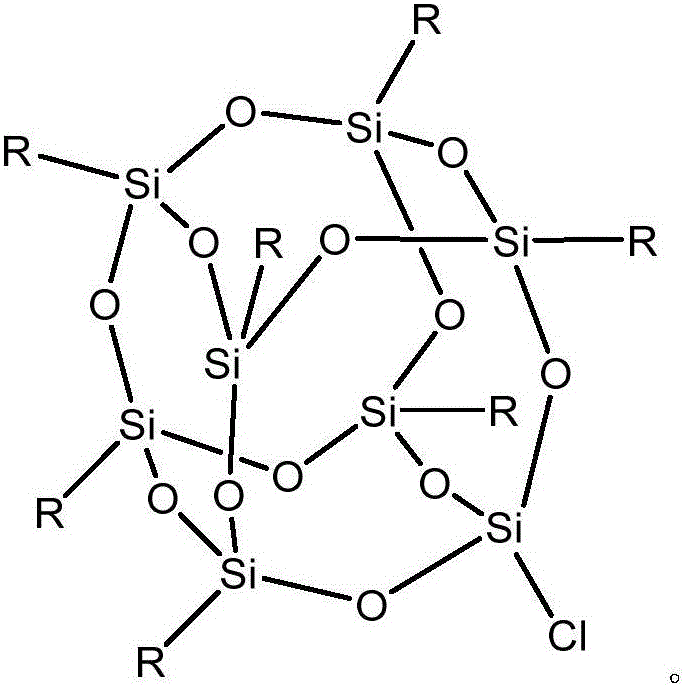

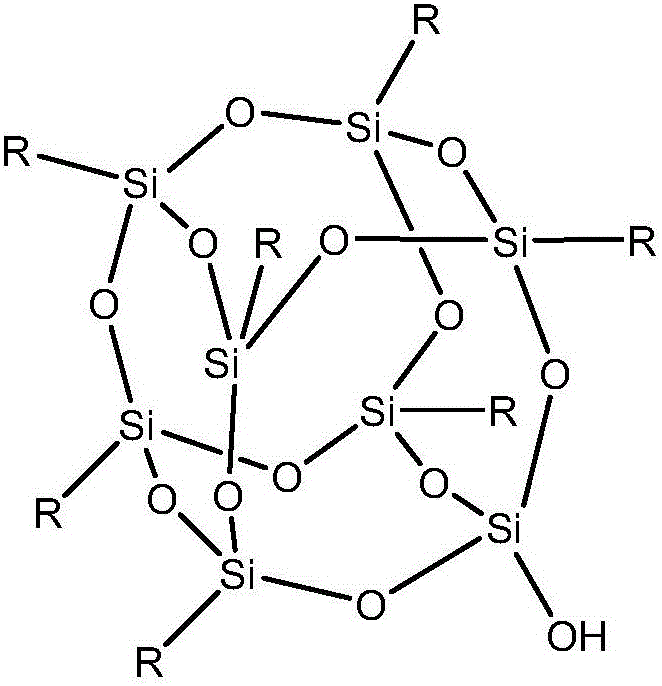

Preparing method of POSS modified poly-butylene succinate

The invention relates to a preparing method of polyhedral oligomeric silsesquioxane(POSS) modified poly-butylene succinate (PBS). 3-hydroxy siloxane heptamer cage-like siloxane, triethylamine, tetrahydrofuran, SiCl4, dimethyl chlorosilane, tetralin phthalic anhydride, LiAlH4 and potassium sodium tartrate are used for preparing POSS dihydric alcohol; and the POSS dihydric alcohol, succinic acid and butanediol are subject to esterification-polycondensation, and POSS modified PBS polyester is obtained. In the preparing method, the POSS dihydric alcohol is prepared, the hydroxyl reaction activity is achieved, and the problem about consistency in common inorganic substance modification can be effectively solved. The modified material has the mechanical property better than that of original PBS, for example, the tensile strength, the impact strength and the bending strength are high; and the preparing method has the beneficial effects that the surface energy is low, the heat resistance is good, and the abrasive resistance is excellent.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

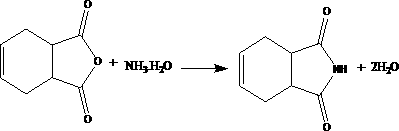

Production method of pesticide intermediate 1,2,3,6-tetrahydrophthalimide

InactiveCN108484475AImprove conversion rateProduce moreOrganic chemistryChemical synthesisTetrahydrophthalamic acid

The invention discloses a production method of 1,2,3,6-tetrahydrophthalimide, and belongs to the field of organic chemical synthesis. According to the method, 1,2,3,6-tetrahydrophthalic anhydride andammonia water are used as raw materials, excess water is distilled out while reacting at a certain raw material ratio and reaction temperature, and after the reaction is finished, the reaction solution is recrystallized by using distilled water. A crude product obtained by recrystallization is then centrifuged and dried to obtain a finished product of 1,2,3,6-tetrahydrophthalimide. The method hasthe advantages of mild reaction condition, easy control, high raw material conversion rate, and high product yield reaching 86% or more. The obtained product is a white needle crystal with high purityreaching 99.5% or more. The production method avoids the defects of large potential safety hazard and more waste gas generated in the traditional process, is more green and environment-friendly, hasa simple preparation process and a lower cost, is favorable for large-scale production, and has a good development prospect.

Owner:濮阳惠成新材料产业技术研究院有限公司

Oxygen-absorbable Solvent-soluble Resin and Oxygen-absorbable Adhesive Resin Composition

Disclosed is an oxygen-absorbable solvent-soluble resin having both oxygen absorbability and adhesive properties. Specifically disclosed is an oxygen-absorbable solvent-soluble resin which comprises an acid component (A), an acid component (B) and a polyester having a constituent unit derived from a glycol component, wherein the ratio of the amount of the acid component (A) to the total amount of the acid components is 40 to 80 mol % and the ratio of the amount of the acid component (B) to the total amount of the acid components is 15 to 35 mol %. The acid component (A): tetrahydrophthalic acid or a derivative thereof, or tetrahydrophthalic anhydride or a derivative thereof; and the acid component (B): terephthalic acid.

Owner:TOYO SEIKAN GRP HLDG LTD

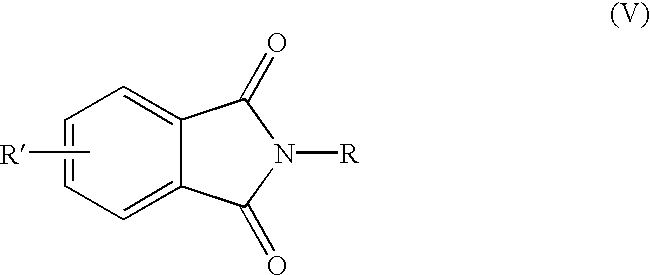

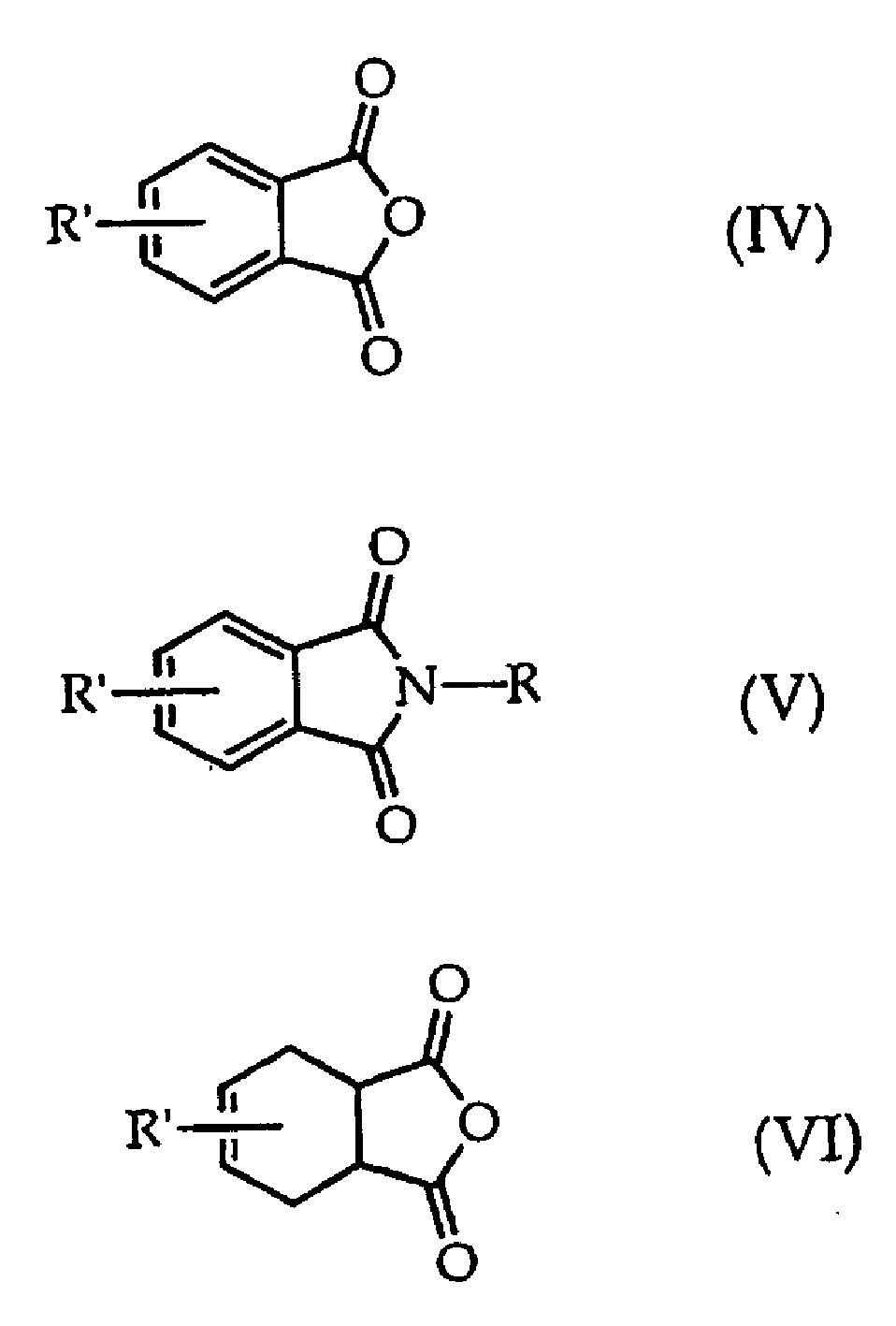

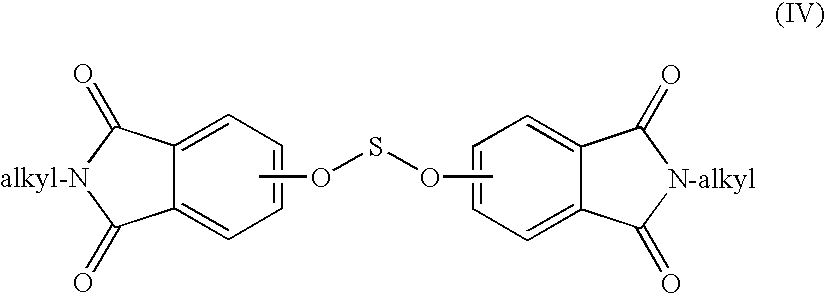

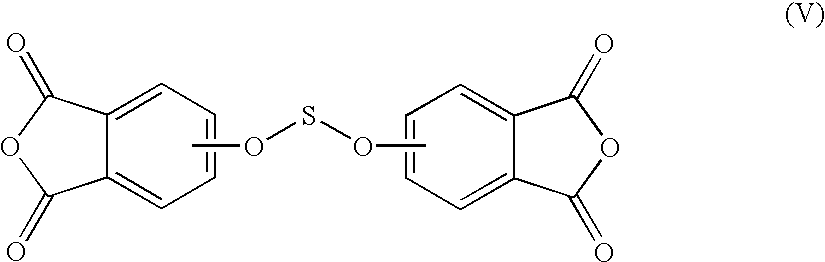

Methods for the preparation of dianhydrides

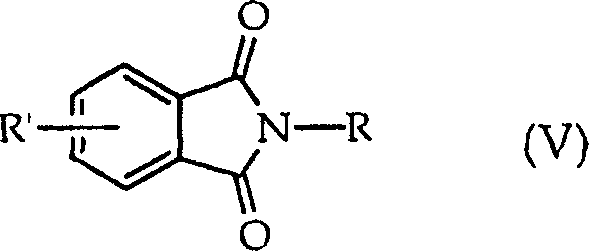

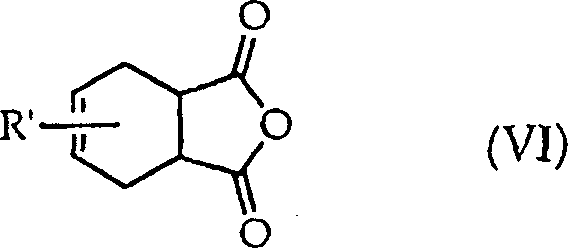

A method for the synthesis of a dianhydride comprises transimidation of bis (imide) (IV)in the presence of a substituted phthalic anhydride or 4-substituted tetrahydrophthalic anhydride to yield dianhydride (V)

Owner:SHPP GLOBAL TECH BV

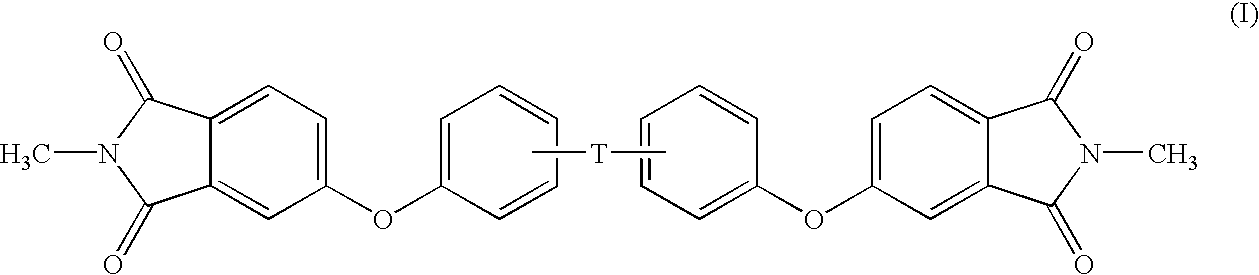

Synthetic method for aza-bicyclo octane[3.3.0] derivatives

InactiveCN102827064AMild reaction conditionsRaw materials are cheap and easy to getOrganic chemistryBulk chemical productionLeaving groupTetrahydrophthalamic acid

The invention discloses a synthetic method for aza-bicyclo octane[3.3.0] derivatives as represented by formula (I). According to the invention, 1,2,3,6-tetrahydrophthalic anhydride as represented by formula (XI) is used as a raw material and successively undergoes esterification, oxidation, cyclodecarboxylation, a ketal protection reaction for carbonyl groups, reduction, an easily-leaving cyclization group reaction on the carbonyl groups, a cyclization reaction for removal of easily-leaving groups, removal of substituted benzyl groups, a PG reaction on N atoms and removal of ketal protective groups so as to prepare the aza-bicyclo octane[3.3.0] derivatives as represented by formula (I). The invention has the following advantages: reaction conditions are mild; the raw material is easily available and cheap; synthetic route is simple; high yield is obtained; the products, i.e., the aza-bicyclo octane[3.3.0] derivatives can be extensively applied in industrial mass production as important medical intermediates.

Owner:EAST CHINA NORMAL UNIV

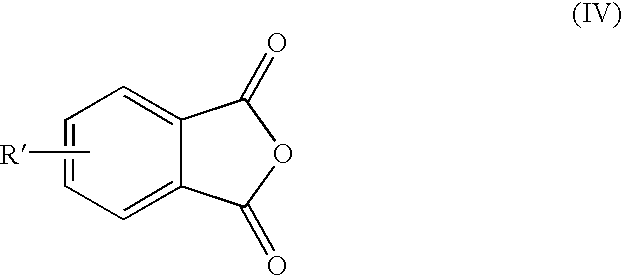

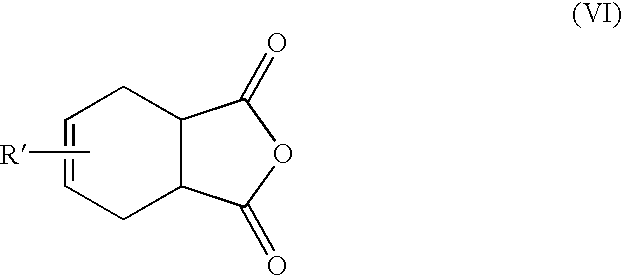

Methods for the preparation of 4-chlorophthalic anhydride

A method for the synthesis of substituted phthalic anhydrides (IV)wherein R' is a halogen, aromatic or aliphatic group comprising 1-18 carbons, hydrogen or nitro group is the transimidation between a substituted N-alkyl phthalimide (V)wherein R is an alkyl having from 1 to 18 carbons, and a substituted tetrahydrophthalic anhydride (VI):The by-product of this reaction, a substituted N-alkyl tetrahydrophthalimide (VII), may be converted by aromatization to the substituted N-alkyl phthalimide (V).

Owner:SABIC INNOVATIVE PLASTICS IP BV

Oxygen-absorbable solvent-soluble resin and oxygen-absorbable adhesive resin composition

Disclosed is an oxygen-absorbable solvent-soluble resin having both oxygen absorbability and adhesive properties. Specifically disclosed is an oxygen-absorbable solvent-soluble resin which comprises an acid component (A), an acid component (B) and a polyester having a constituent unit derived from a glycol component, wherein the ratio of the amount of the acid component (A) to the total amount of the acid components is 40 to 80 mol % and the ratio of the amount of the acid component (B) to the total amount of the acid components is 15 to 35 mol %. The acid component (A):tetrahydrophthalic acid or a derivative thereof, or tetrahydrophthalic anhydride or a derivative thereof; and the acid component (B):terephthalic acid.

Owner:TOYO SEIKAN GRP HLDG LTD

Modified tetrahydrophthalic acid diglycidyl acylic ester, preparation method and application

The present invention relates to a modified tetrahydrophthalic acid diglycidyl acylic ester, which uses made by modifying tetrahydrophthalic acid diglycidyl acylic ester with isocyanate group and molar ratio between isocyanate groups and hydroxy is 0. 1-0.8:1. the isocyanate group is chosen from one of toluene diisocyanate, methyl diphenylene diisocyanate, xylylene diisocyanate, hexamethylene diisocyanate, or isophorone diisocyanate. Two addition is adopted in the preparation, first tetrahydrophthalic acid diglycidyl ester type epoxide resin reacts with added acrylic acid, then generated tetrahydrophthalic acid diglycidyl acylic ester reacts with added isocyanate group. The technological progress effect of modified tetrahydrophthalic acid diglycidyl acylic ester in the invention on ultraviolet cured paint field lies in quick curing velocity of the coating, high hardness, high adhesion, and high tensile strength of the curing membrane, wherein the curing membrane has good resistance to water and resistance to solvent. The invention can be applied broadly on thermo-responsive basic materials like plastics, paper, woodware and leather etc.

Owner:HEBEI ENERGY RES INST +1

Disposable degradable table cloth and production technique thereof

InactiveCN105153525AReduce dosageRapid degradation functionTetrahydrophthalamic acidPhotodegradation

The invention discloses a disposable degradable table cloth. The invention is characterized in that the disposable degradable table cloth comprises the following raw materials in parts by weight: 20-25 parts of polyethylene, 50-75 parts of superfine calcium carbonate, 2-5 parts of hollow glass microsphere, 0.1-0.5 part of photodegradation agent, 0.5-2 parts of degradation induction period regulator and 0.1-0.5 part of calcium tetrahydrophthalate. The invention also discloses a production technique of the disposable degradable table cloth. The calcium carbonate loading level of the table cloth is 50% or above, thereby saving the cost, implementing quick degradation in the natural environment and keeping higher comprehensive properties (especially strength and flexibility); and the table cloth can not easily break when in use.

Owner:贵州石头造环保科技有限公司

Safe PVC (polyvinyl chloride) food preservative film

InactiveCN104262745AStrong toleranceBroad spectrum antibacterialFlexible coversWrappersTetrahydrophthalamic acidPolyvinyl chloride

The invention relates to a safe PVC (polyvinyl chloride) food preservative film. The safe PVC food preservative film comprises the following components: 100 parts of polyethylene, 2 parts of dioctyl tetrahydrophthalate, 4 parts of modified starch, 5 parts of plant polysaccharides, 4 parts of squalane, dioctyladipate, 8 parts of light calcium carbonate, 9 parts of sodium alginate, 5 parts of sorbitol, 7 parts of titanium dioxide, 2 parts of casein and 1 part of arabic gum. The safe PVC food preservative film further comprises 7 parts of chitosan. The safe PVC food preservative film provided by the invention has the beneficial effects of broad antibacterial spectrum, capability of inhibiting a variety of bacterial propagules and fungal spores, good oxygen permeability, long preservation period and strong temperature tolerance, is suitable for freezing preservation and microwave heating, is used as a food grade packaging material and is non-toxic and harmless.

Owner:QINGDAO HI TECH PATENT TECH TRANSFER PLATFORM

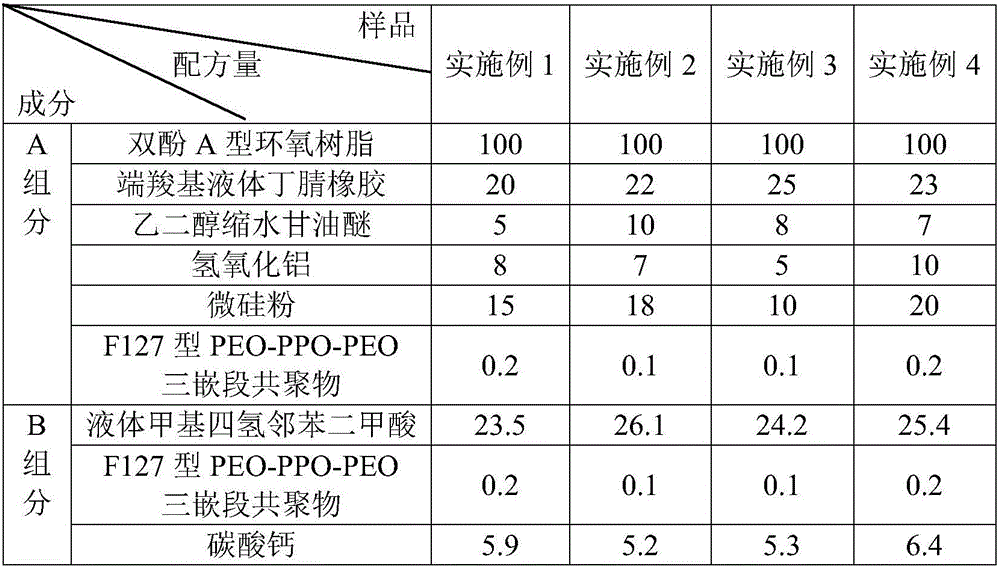

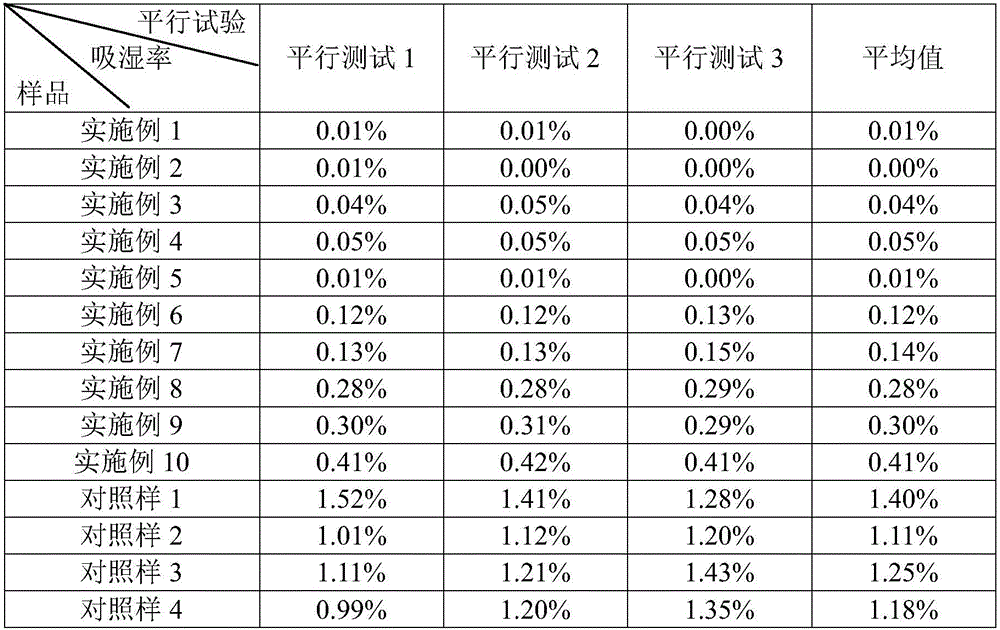

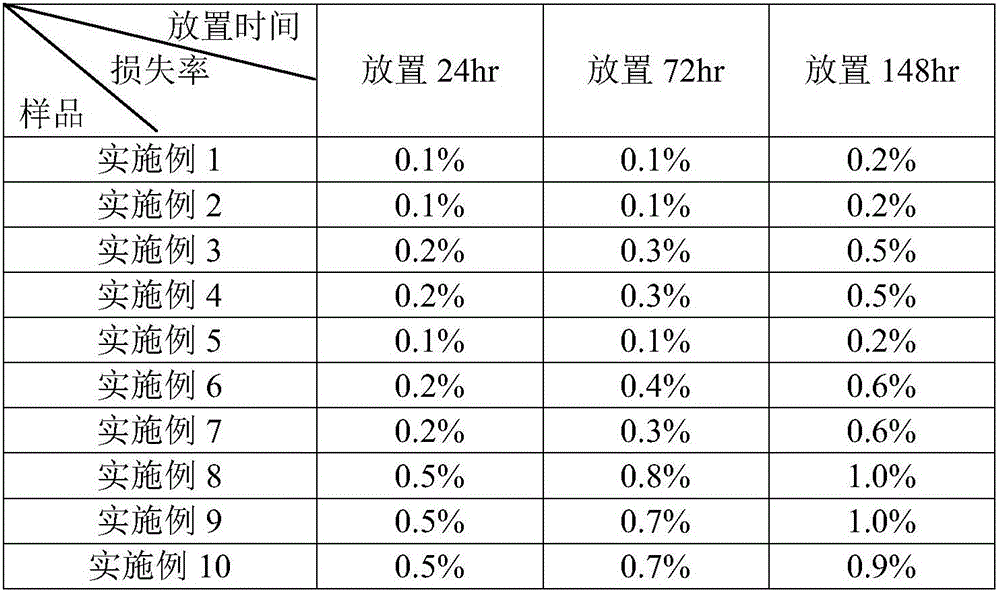

Special epoxy resin potting adhesive for ignition coils and preparation method thereof

ActiveCN106634752AGood electrical performanceReduce biasNon-macromolecular adhesive additivesMacromolecular adhesive additivesTetrahydrophthalamic acidIgnition coil

The invention discloses a special epoxy resin potting adhesive The special epoxy resin potting adhesive for ignition coils comprises a component A and a component B in a mass ratio of 5:1. The component A comprises the following ingredients in parts by mass: 100 parts of bisphenol A epoxy resin, 0.1-0.2 part of PEO-PPO-PEO (polyoxyethylene-polypropylene oxide-polyoxyethylene) triblock copolymer, 20-25 parts of carboxy-terminated liquid nitrile-butadiene rubber, 10-20 parts of micro silicon powder, 5-10 parts of aluminum hydroxide and 5-10 parts of ethylene glycol diglycidyl ether. The component B comprises the following ingredients in parts by mass: 100 parts of liquid methyltetrahydrophthalic acid, 0.5-1 part of PEO-PPO-PEO triblock copolymer and 20-25 parts of calcium carbonate. The special epoxy resin potting adhesive has the effect of lowering water absorptivity.

Owner:浙江嘉尔成汽车部件有限公司

Heat transfer printing colored tape for metal material and preparation method thereof

InactiveCN106183515AStrong adhesionSolve application problemsInksThermographyEpoxyTetrahydrophthalamic acid

The invention discloses a heat transfer printing colored tape for a metal material. The heat transfer printing colored tape comprises a tape base, an ink layer coated on one side of the tape base, and a heat resistant coating layer coated on the other side of the tape base; and the ink layer comprises the following raw materials in parts by weight: 35-38 parts of acrylic resins, 16-20 parts of epoxy resins, 31-34 parts of carnauba wax, 14-18 parts of lignite wax, 8-12 parts of tetra hydro phthalic anhydride, 17-20 parts of carbon black, 6-9 parts of sodium bentonite, 3-5 parts of montmorillonoid, 1-4 parts of aluminum phosphate, 4-6 parts of propylene glycol monomethyl ether, 1-2 parts of modified polyurea, and 1-5 parts of polydimethylsiloxane. The invention further discloses a preparation method of the heat transfer printing colored tape for the metal material. The heat transfer printing colored tape can clearly print on a metal printing medium, and widens the application range.

Owner:POMA IND SHANGHAI

Preparation of substituted phthalic anhydride, especially 4-chlorophthalic anhydride

InactiveCN1751017APreparation from carboxylic acid amidesCarboxylic acid anhydrides preparationImideHalogen

A method for the synthesis of substituted phthalic anhydrides (IV) wherein R' is a halogen, aromatic or aliphatic group comprising 1-18 carbons, hydrogen or nitro group is the transimidation between a substituted N-alkyl phthalimide (V) wherein R is an alkyl having from 1 to 18 carbons, and a substituted tetrahydrophthalic anhydride (VI): The by product of this reaction, a substituted N-alkyl tetrahydrophthalimide (VII), may be converted by aromatization to the substituted N-alkyl phthalimide (V).

Owner:SABIC INNOVATIVE PLASTICS IP BV

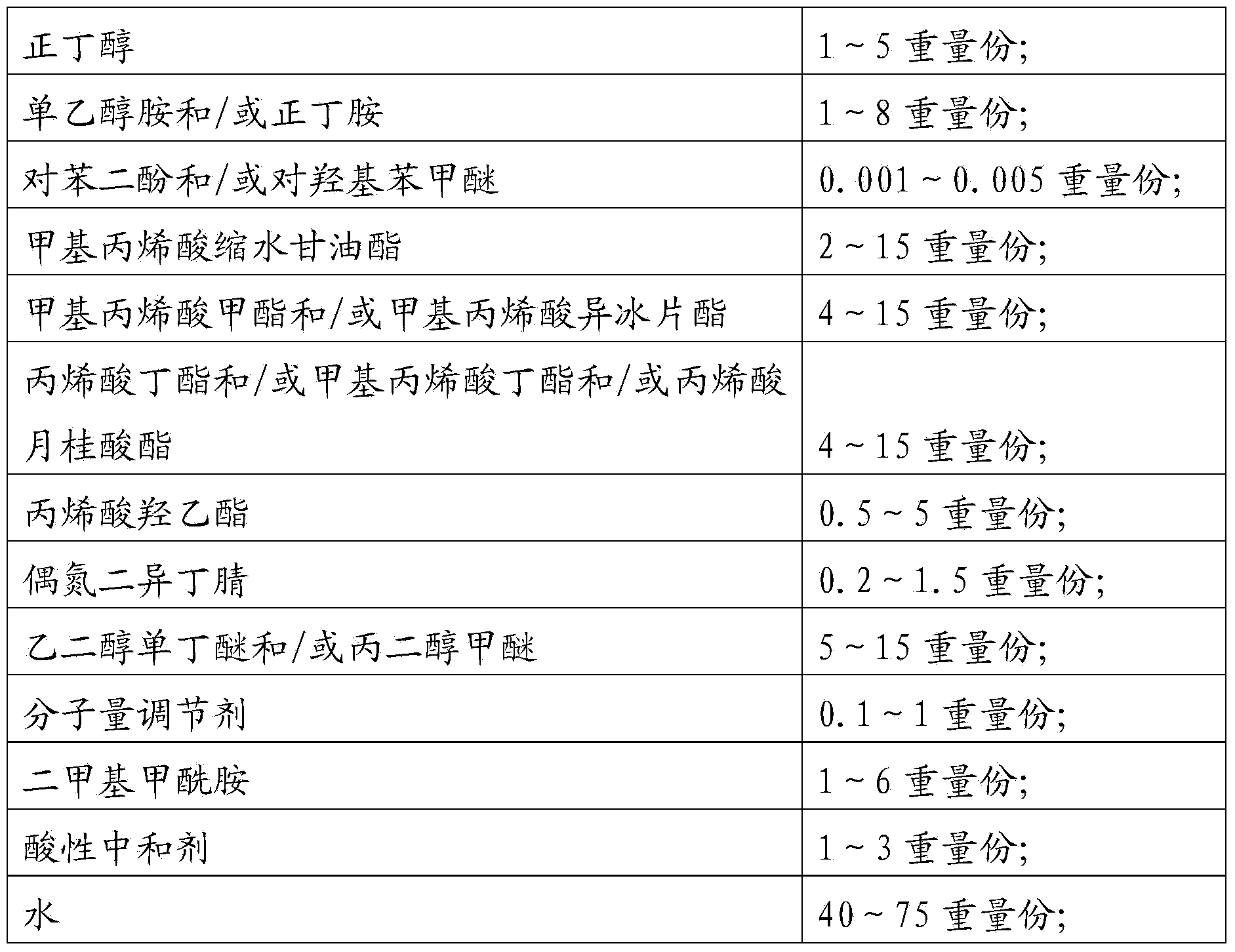

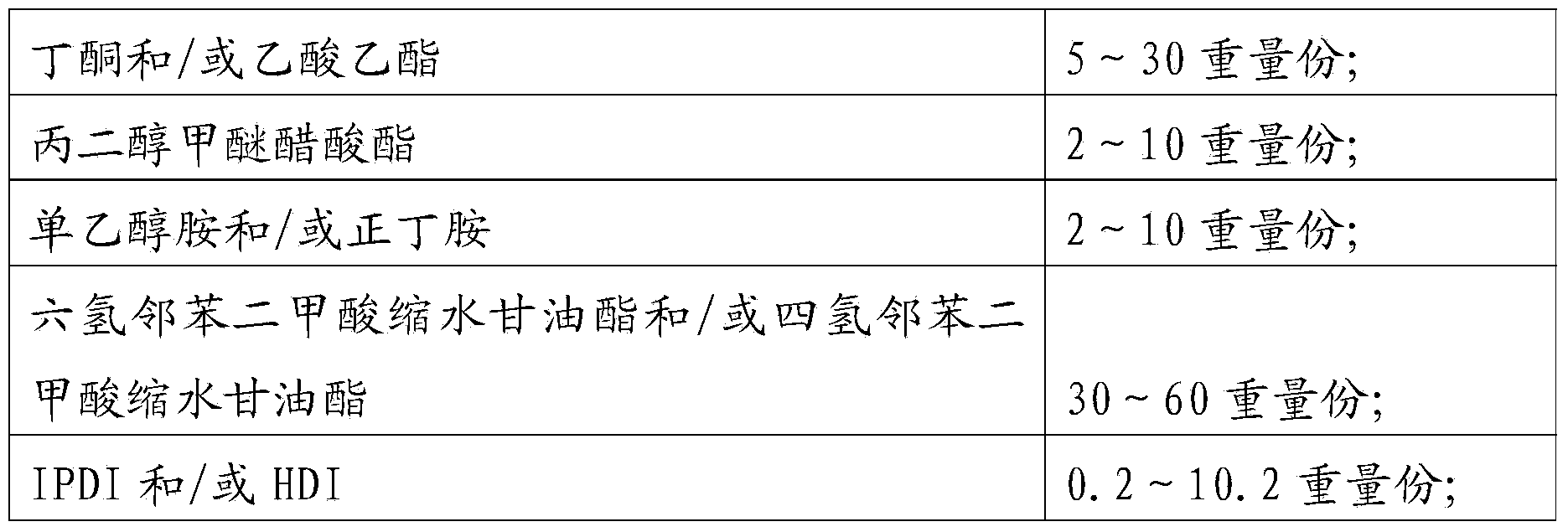

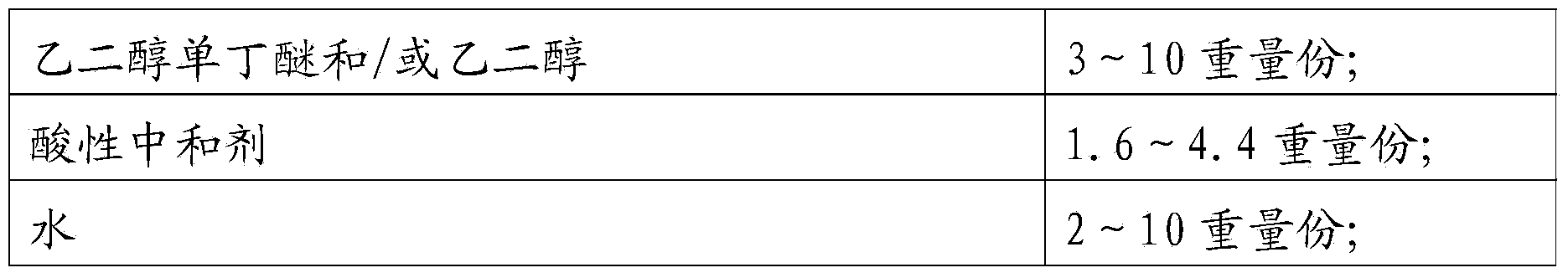

Aqueous bi-component acrylic acid-polyurethane resin and preparation method thereof

ActiveCN103554412ANo foamingPolyurea/polyurethane coatingsGlycidyl methacrylateIsophorone diisocyanate

The invention relates to an aqueous bi-component acrylic acid-polyurethane resin and a preparation method thereof. The aqueous bi-component acrylic acid-polyurethane resin comprises a component A and a component B, wherein the component A comprises n-butyl alcohol, monoethanolamine and / or n-butyl amine, hydroquinone and / or p-hydroxyanisole, glycidyl methacrylate, methyl methacrylate and / or isobornyl methacrylate, butyl acrylate and / or butyl methacrylate and / or acrylic acid laurate, hydroxyethyl acrylate, azodiisobutyronitrile, butylcellosolve and / or propylene glycol monomethyl ether, a molecular weight regulator, dimethylformamide, an acid neutralizer and water; the component B comprises butanone and / or ethyl acetate, propylene glycol methyl ether acetate, monoethanolamine and / or n-butylamine, cis-hexahydrophthalic acid glycidyl ester and / or tetrahydrophthalic acid glycidyl ester, IPDI (Isophorone Diisocyanate) and / or HDI (Hexamethylene Diisocyanate), ethylene glycol monobutyl ether and / or ethylene glycol, the acid neutralizer and the water; and the weight ratio of the component A to the component B is (4-7):1. A coating prepared from the aqueous bi-component acrylic acid-polyurethane resin is more than 150 microns in thickness and cannot generate bubbles or pinholes.

Owner:BEIJING JINHWEILI APPLIED CHEM PROD +1

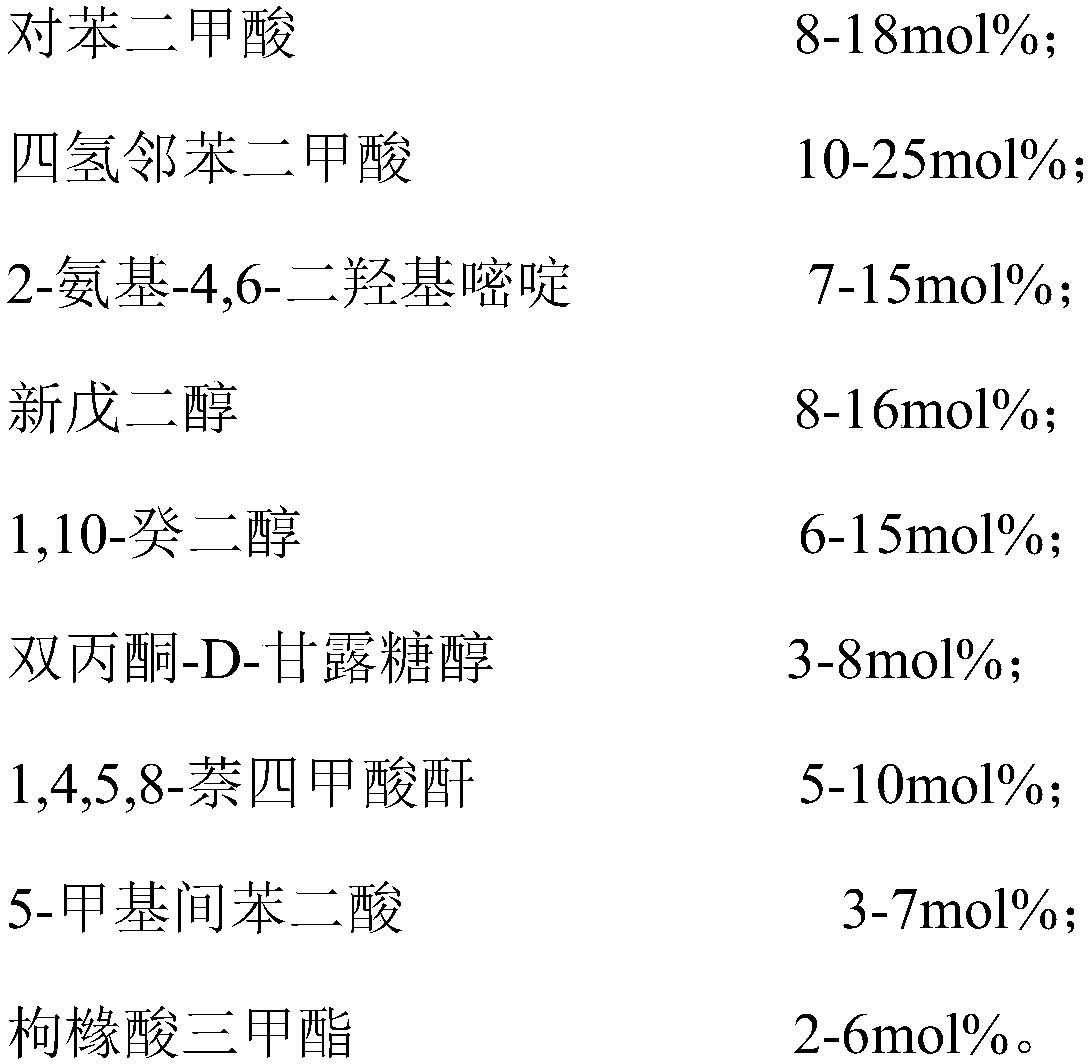

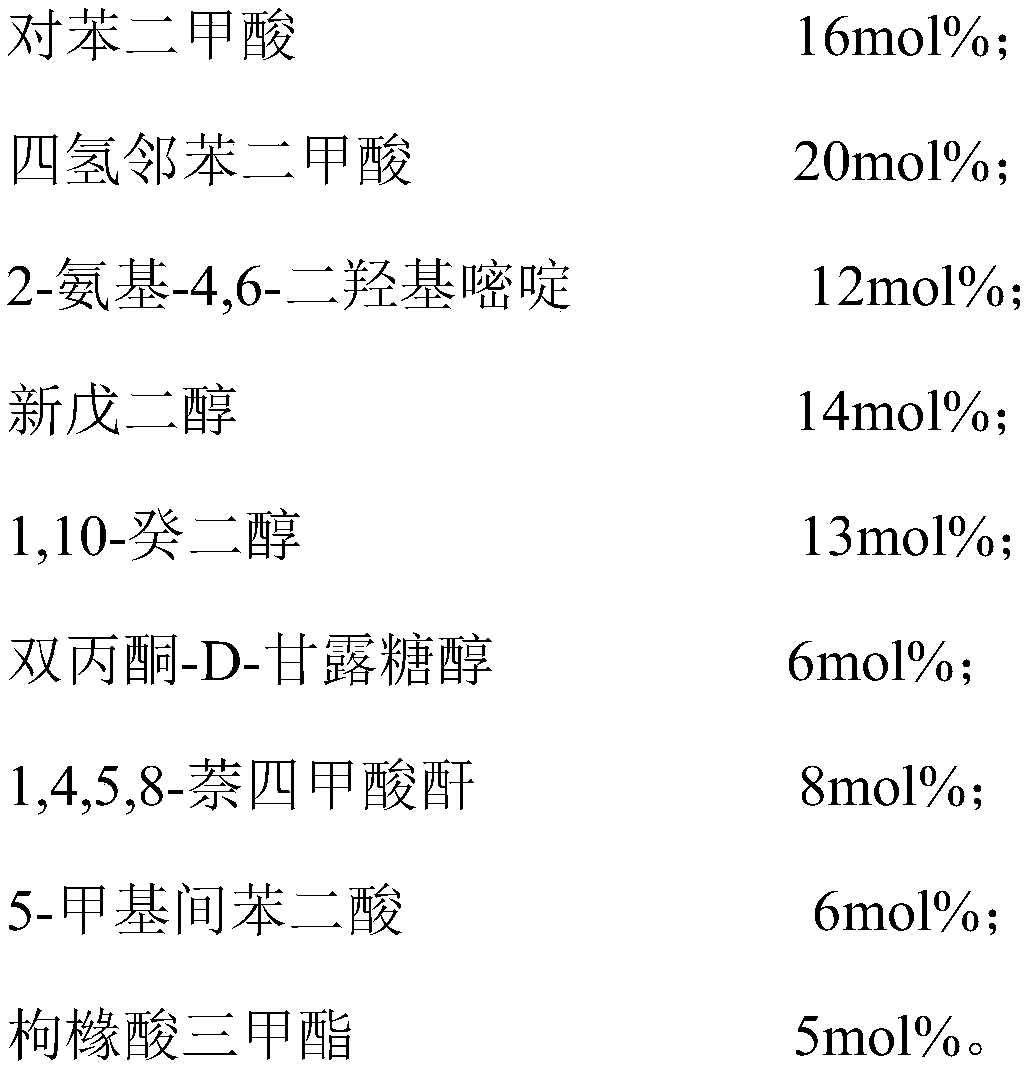

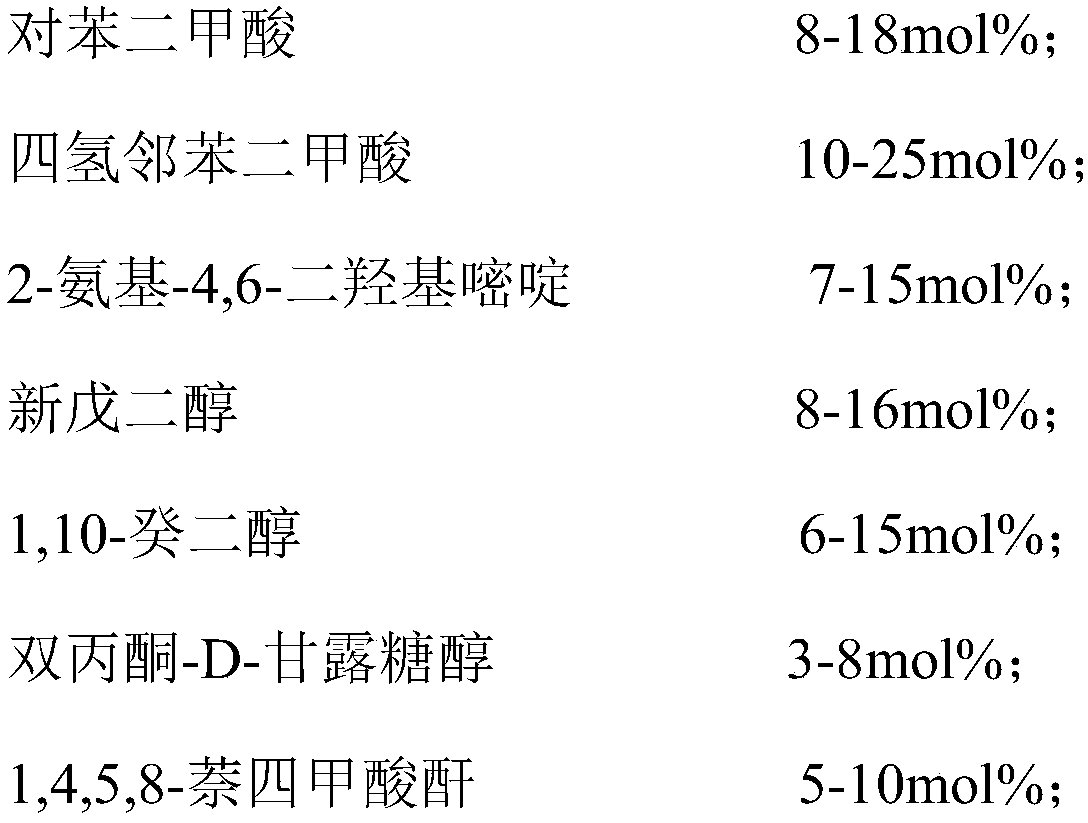

Extinction type polyester resin for HAA system as well as preparation method and application thereof

InactiveCN110483751APowdery paintsPolyester coatingsNaphthalenetetracarboxylic dianhydrideD-mannitol

The invention relates to extinction type polyester resin for an HAA system. Terephthalic acid, tetrahydrophthalic acid, 2-amino-4,6-dihydroxypyrimidine, neopentyl glycol, 1,10-decanediol, diacetone-D-mannitol, 1,4,5,8-naphthalenetetracarboxylic dianhydride, 5-methyl isophthalic acid and trimethyl citrate are adopted as raw materials. All the components are matched with one another and have a synergistic effect so that the molecular weight distribution of the finally obtained polyester resin is not uniform and polybasic acids for end capping are different in type, and therefore, when the polyester resin with different end-capping functional groups and HAA are cured, the reaction activity difference is large, the curing process cannot be synchronously carried out, the cured coating surface shrinks, and the surface gloss is effectively low. Experimental data show that when the prepared extinction type polyester resin is used for preparing extinction type powder coating of an HAA system, acoating film with the glossiness smaller than 15% can be obtained, and excellent comprehensive performance is achieved.

Owner:HUANGSHAN UNIV

Flame-retardant heat-insulating water-based paint and preparation method thereof

InactiveCN109321134ASimple manufacturing methodRaw materials are easy to getFireproof paintsReflecting/signal paintsWater basedEpoxy

The invention provides a flame-retardant heat-insulating water-based paint, and the paint is prepared from the following components: 55-65 parts by weight of a film-forming polymer, 5-10 parts by weight of surface-modified foamed aluminum-based nanotubes, 1-5 parts by weight of a cosolvent, 10-20 parts by weight of water, 1-3 parts by weight of a film-forming auxiliary agent, 1-3 parts by weight of an emulsifier, 1-3 parts by weight of a leveling agent, and 1-3 parts by weight of a wetting agent. The film-forming polymer is prepared from bis(2-aminoethyl)hydrogen phosphate, exo-3,6-epoxy-1,2,3,6-tetrahydrophthalic anhydride, 1,1-dimethoxy-3-(trimethylsiloxy)-1,3-butadiene, polyetheramine. The invention also discloses a preparation method of the flame-retardant heat-insulating water-based paint. The flame-retardant heat-insulating water-based paint prepared by the invention has the advantages of low cost, good flame-retardant and heat-insulating effects, excellent water resistance, alkali resistance, abrasion resistance, weather resistance, small environmental impact, safe and environmentally friendly use.

Owner:深圳恒固纳米科技有限公司

High-temperature-resistant protective film, preparation process thereof and ITO conductive film

PendingCN112457791AAvoid separabilityAvoid tearing difficultiesConductive layers on insulating-supportsNon-macromolecular adhesive additivesTetrahydrophthalamic acidLayer thickness

The invention discloses a high-temperature-resistant protective film, a preparation process thereof and an ITO conductive film, the high-temperature-resistant protective film comprises a protective film substrate layer and an adhesive layer covering the protective film substrate layer, the adhesive layer is an acrylic acid adhesive layer, wherein the adhesive layer is an acrylic acid adhesive layer doped with 2-8wt% of hexahydrophthalic acid diglycidyl ester or 2-8wt% of tetrahydrophthalic acid diglycidyl ester, and the thickness of the adhesive layer is 4-30 microns. The high-temperature-resistant protective film and an ITO conductive film using a base material of the same material have a relatively matched thermal shrinkage rate, so that the process yield can be greatly improved, the flatness of an ITO conductive film application process is ensured, and the smoothness of the ITO conductive film application process is ensured, through the ITO conductive film application process, the temperature is high, the separation or tearing difficulty of the high-temperature-resistant protective film is avoided, no residual glue is transferred to the ITO film, the product quality is ensured,the attenuation of the surface energy of the HC surface of the ITO conductive film is ensured to be small, the excellent printing performance is ensured, the process yield is high, and the product performance is better.

Owner:JIANGSU RIJIU OPTOELECTRONICS LTD

Two-part curable oxygen-absorbable resin composition, and oxygen-absorbable adhesive agent

ActiveUS9102853B2Improve oxygen removal effectLow costPolyureas/polyurethane adhesivesSynthetic resin layered productsPolyesterPolyol

The purpose of the present invention is to provide a two-part curable oxygen-absorbable resin composition which has all of oxygen absorbability, adhesion properties and a cohesive force. The present invention provides a two-part curable oxygen-absorbable resin composition comprising: a main component which comprises a polyester polyol containing tetrahydrophthalic acid or a derivative thereof or tetrahydrophthalic acid anhydride or a derivative thereof as a raw material; and an aliphatic and / or alicyclic isocyanate curing agent component.

Owner:TOYO SEIKAN GRP HLDG LTD

Low-temperature impact-resistant tubular product

InactiveCN103554604AHigh low temperature impact resistanceImprove scratch resistanceEpoxyDiacetone alcohol

The invention discloses a low-temperature impact-resistant tubular product, which is characterized by being composed of the following raw materials in parts by weight: 70-76 parts of polyethylene GF7750, 4-6 parts of drying oil alkyd resin, 2-3 parts of ethylene-octene copolymer, 1-2 parts of diacetone alcohol, 0.7-2 parts of triclosan, 2-3 parts of polyimide, 3-4 parts of di(2-ethylhexyl)-epoxy tetrahydrophthalate, 2-3 parts of carbon fibers, 3-4 parts of illite powder, 2-3 parts of aluminum stearate and 5-7 parts of composite filler. The PE pipe provided by the invention is prepared from recycled polyethylene material so that the production cost is reduced and resources are saved; the tubular product provided by the invention has excellent low-temperature impact resistance; for construction in winter, pipe breakage is avoided; the low-temperature impact-resistant tubular product also has high shear strength and excellent scratch resistance.

Owner:SINOMACH GENERAL MACHINERY SCIENCE & TECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Synthetic method for aza-bicyclo octane[3.3.0] derivatives Synthetic method for aza-bicyclo octane[3.3.0] derivatives](https://images-eureka.patsnap.com/patent_img/03df6eb0-4d82-43cb-b22b-5c4dd0895984/BDA00002010100700011.PNG)

![Synthetic method for aza-bicyclo octane[3.3.0] derivatives Synthetic method for aza-bicyclo octane[3.3.0] derivatives](https://images-eureka.patsnap.com/patent_img/03df6eb0-4d82-43cb-b22b-5c4dd0895984/BDA00002010100700021.PNG)

![Synthetic method for aza-bicyclo octane[3.3.0] derivatives Synthetic method for aza-bicyclo octane[3.3.0] derivatives](https://images-eureka.patsnap.com/patent_img/03df6eb0-4d82-43cb-b22b-5c4dd0895984/BDA00002010100700041.PNG)