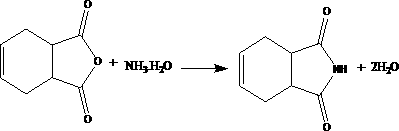

Production method of pesticide intermediate 1,2,3,6-tetrahydrophthalimide

A technology of tetrahydrophthalimide and tetrahydrophthalic anhydride, which is applied in the field of organic chemical synthesis and achieves the effects of good development prospects, great potential safety hazards, and mild and easy-to-control reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Add 235Kg of ammonia water with a mass fraction of 20% in a 500L reactor, and cool the jacket to 20% with cooling water. o C, 299Kg of 1,2,3,6-tetrahydrophthalic anhydride was dropped in batches under stirring, and the temperature of the control material was not more than 60 o c. After the feeding is completed, close the feeding port, release the jacket cooling water and slowly inject steam to start heating until the material temperature is 100 o At about C, water is evaporated, and after condensation, it enters the buffer tank and reacts while steaming water. As the amount of steamed water approaches the theoretical value, the temperature of the material gradually rises to 145 o C, keep the reaction temperature and continue the reaction until the central control sampling detects that the raw material 1,2,3,6-tetrahydrophthalic anhydride is 98.5%, stop heating, cool down to material temperature 70 o At about C, inject distilled water with nitrogen pressure from the fe...

Embodiment 2

[0017] Add 1417Kg of ammonia water with a mass fraction of 19.5% in a 3000L reactor, and cool the jacket to 20 with cooling water. o C, 1650Kg of 1,2,3,6-tetrahydrophthalic anhydride was dropped in batches under stirring, and the temperature of the control material was not more than 60 o c. After the feeding is completed, close the feeding port, release the jacket cooling water and slowly inject steam to start heating, and heat to the material temperature of 105 o At about C, water is evaporated, and after condensation, it enters the buffer tank and reacts while steaming water. As the amount of steamed water approaches the theoretical value, the temperature of the material gradually rises to 145 o C, keep the reaction temperature and continue the reaction until the central control sampling detects that the raw material 1,2,3,6-tetrahydrophthalic anhydride is 98.5%, stop heating, cool down to material temperature 70 o At about C, inject distilled water with nitrogen pressure ...

Embodiment 3

[0020] Add 2107Kg of ammonia water with a mass fraction of 20% in a 5000L reactor, and cool the jacket to 20% with cooling water. o C, put 2500Kg of 1,2,3,6-tetrahydrophthalic anhydride in batches under stirring, and control the material temperature not to exceed 60 o c. After the feeding is completed, close the feeding port, release the jacket cooling water and slowly inject steam to start heating until the material temperature is 110 o At about C, water is evaporated, and after condensation, it enters the buffer tank and reacts while steaming water. As the amount of steamed water approaches the theoretical value, the temperature of the material gradually rises to 145 o C, keep the reaction temperature and continue the reaction until the central control sampling detects that the raw material 1,2,3,6-tetrahydrophthalic anhydride is 98.5%, stop heating, cool down to material temperature 70 o At about C, inject distilled water with nitrogen pressure from the feed port, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com