Preparing method of POSS modified poly-butylene succinate

A polybutylene succinate and modification technology is applied in the field of preparation of biodegradable modified polyester, can solve the problems of heat resistance, poor water resistance and stain resistance, etc., and achieves good heat resistance, The effect of excellent wear resistance and high flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of the POSS modified polybutylene succinate that the embodiment of the present invention provides comprises:

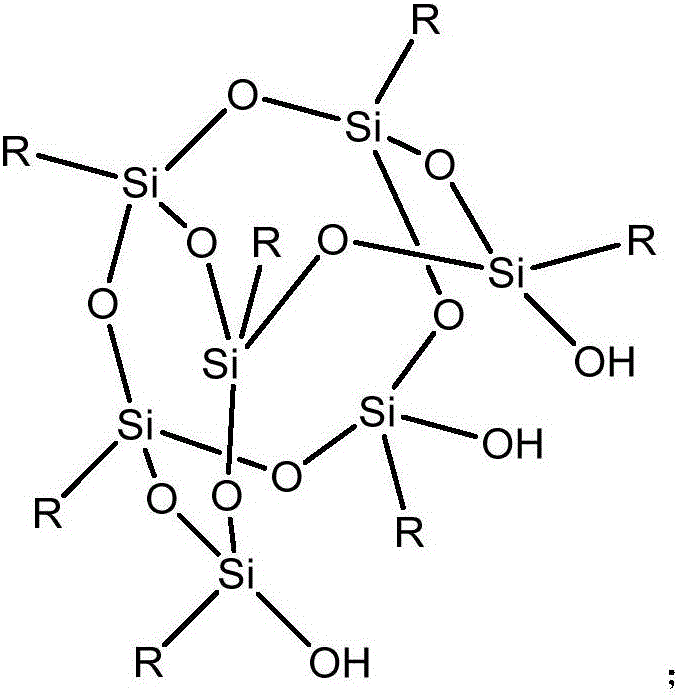

[0020] Step 1, under normal temperature trihydroxy heptapolycrate siloxane R 7 Si 8 o 9 (OH) 3 with SiCl 4 React in the solution of THF for more than 12h, then filter and dry to obtain POSS(R 7 Si 8 o 12 Cl) (wherein R is i-C 4 h 9 、CH 3 、C 6 h 5 One of them), during the reaction R 7 Si 8 o 9 (OH) 3 with SiCl 4 The molar ratio is set to 1:(1~1.3); among them, trihydroxyheptapolysiloxane R 7 Si 8 o 9 (OH) 3 The molecular structure is:

[0021]

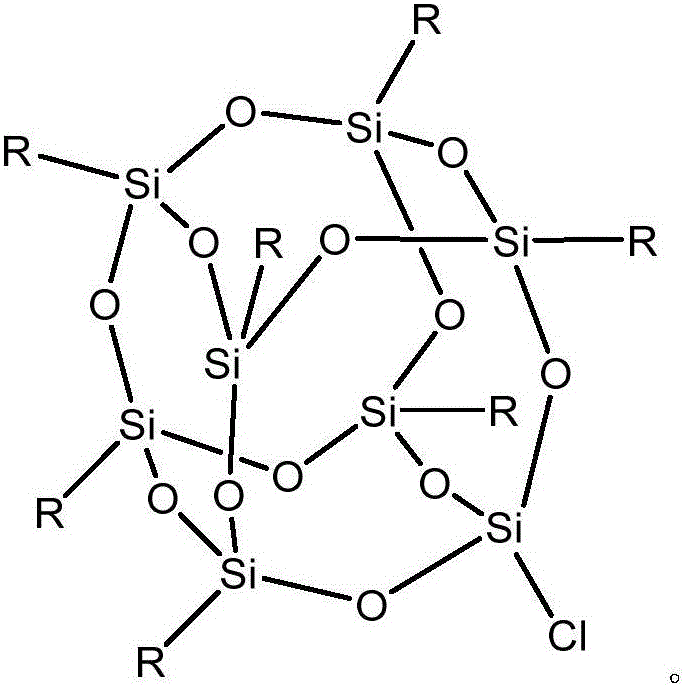

[0022] Chlorinated POSS(R 7 Si 8 o 12 The molecular structure of Cl) is:

[0023]

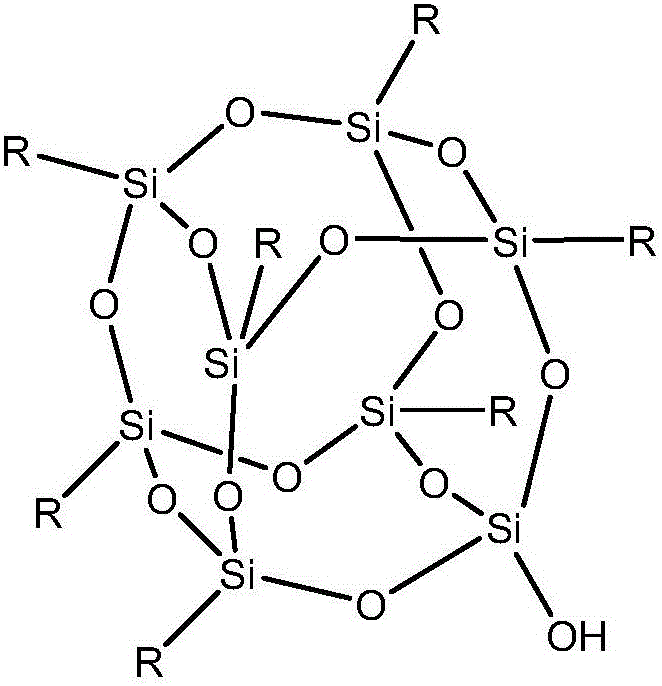

[0024] Step 2, the chlorinated POSS powder is refluxed 100h in tetrahydrofuran and water mixed solvent, after rotary evaporation back drying, obtain hydroxylated POSS (R 7 Si 8 o 12 (OH)); molecular structure is:

[0025]

[0026] Step 3. Under the protection of nitrogen, react t...

Embodiment 1

[0035] Trihydroxyheptaisobutyl polycrate siloxane (i-C 4 h 9 ) 7 Si 8 o 9 (OH) 3 with SiCl 4 React in a tetrahydrofuran solution at a ratio of 1:1 for more than 12h, filter and dry to obtain the chlorinated POSS ((i-C 4 h 9 ) 7 Si 8 o 12 Cl); The chlorinated POSS powder is refluxed 100h in tetrahydrofuran and water mixed solvent, makes hydroxylation POSS ((i-C 4 h 9 ) 7 Si 8 o 12 (OH)); Under the protection of nitrogen, the hydroxylated POSS and dimethyl monochlorosilane were reacted with triethylamine at 60° C. as a catalyst for 20 h at a ratio of 1:1, and then deionized water, 5% hydrochloric acid solution Wash with saturated NaCl solution, and obtain alkylated POSS ((i-C 4 h 9 ) 7 Si 8 o 12 Si(CH 3 ) 2 H); the toluene solution of alkylated POSS and tetrahydrophthalic anhydride THPA (the molar ratio is 1:1) is mixed, and Pt is used as a catalyst, reacted for 60h at 60°C, then rotary steamed, reflux washed, and dried to prepare Acid anhydride POSS ((i-C ...

Embodiment 2

[0038] Trihydroxyheptamethyl clathrosiloxane (CH 3 ) 7 Si 8 o 9 (OH) 3 with SiCl 4 With the ratio of 1:1.3, react in tetrahydrofuran solution for more than 12h, filter and dry to obtain chlorinated POSS ((CH 3 ) 7 Si 8 o 12 Cl); The chlorinated POSS powder is refluxed 100h in tetrahydrofuran and water mixed solvent, makes hydroxylated POSS ((CH 3 ) 7 Si 8 o 12 (OH)); Under the protection of nitrogen, the hydroxylated POSS and dimethyl monochlorosilane were reacted with triethylamine as a catalyst for 20 h at 70 ° C in a ratio of 1:1.2, and then deionized water, 5% hydrochloric acid solution Wash with saturated NaCl solution, and obtain alkylated POSS ((CH 3 ) 7 Si 8 o 12 Si(CH 3 ) 2 H); Mix the toluene solution of alkylated POSS and tetrahydrophthalic anhydride THPA (the molar ratio is 1:1.05), use Pt as the catalyst, react for 60h at 70°C, then rotary steam, reflux washing, and drying to prepare Acid anhydride POSS ((CH 3 ) 7 Si 8 o 12 Si(CH 3 ) 2 THPA...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com