Preparation method of POSS modified polyurethane resin

A polyurethane resin and modification technology, which is applied in the field of preparation of POSS modified polyurethane resin, can solve the problems of affecting physical and mechanical properties, destroying polyurethane crystallization, insufficient wear resistance, etc., and achieves overcoming compatibility problems and high tensile strength , the effect of high impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] The preparation method of this POSS modified polyurethane resin comprises the following steps:

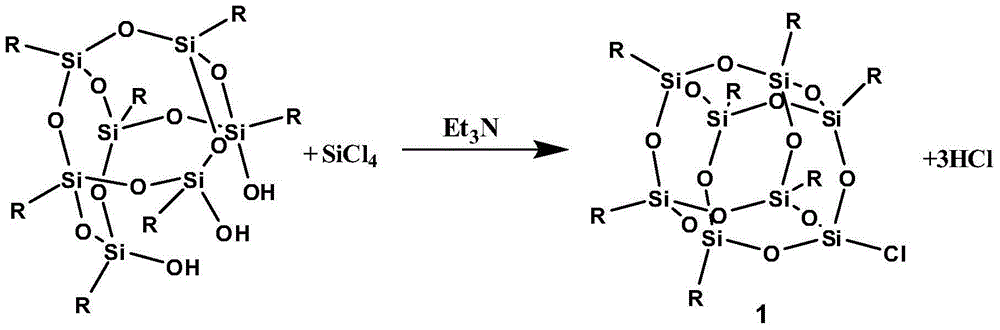

[0015] (1) Under the protection of nitrogen, add trihydroxy heptapolysiloxane (R 7 Si 7 o 9 (OH) 3 ), triethylamine and tetrahydrofuran, and then slowly inject SiCl 4 After stirring overnight, the Et was removed by filtration 3 NHCl, the filtrate rotary evaporation, obtains compound 1 chloride POSS ((i-C 4 h 9 ) 7 Si 7 o 12 Cl). Its reaction formula is as follows:

[0016]

[0017] where R is i-C 4 h 9 、CH 3 、C 6 h 5

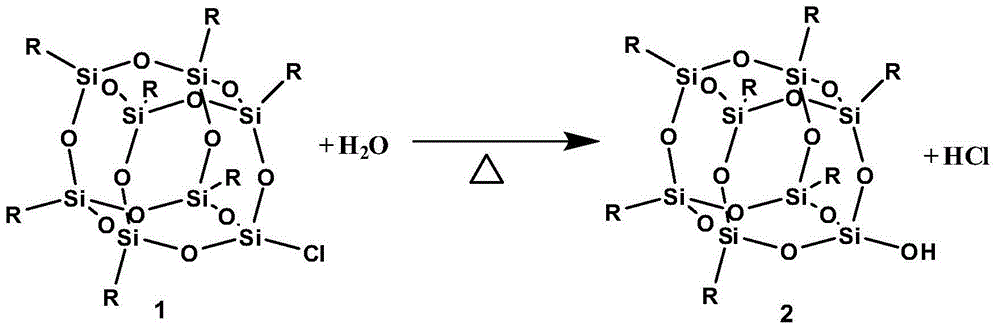

[0018] (2) Compound 1 (R 7 Si 8 o 12 Cl) in THF / H 2 O mixed solution was refluxed for 72-90h, and after the solvent was removed by rotary evaporation, compound 2 hydroxylated POSS (R 7 Si 8 o 12 (OH)). Its reaction formula is as follows:

[0019]

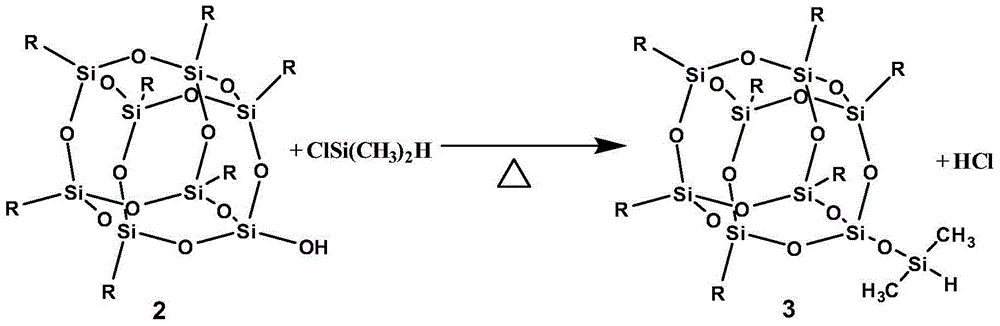

[0020] (3) Under nitrogen protection, compound 2 hydroxylated POSS (R 7 Si 8 o 12 (OH)), tetrahydrofuran, triethylamine, and then slowly add dimethyl monochlorosilane, a white preci...

Embodiment 1

[0038] (1) Under the protection of nitrogen, add trihydroxyheptaisobutyl heptapolysiloxane (i-C 4 h 9 ) 7 Si 8 o 9 (OH) 3 (97g, 100mmol), triethylamine (30.3g, 100mmol) and tetrahydrofuran (250ml), then slowly inject SiCl 4 (17g, 100mmol) After stirring overnight, the precipitate was removed by filtration, and the filtrate was rotary evaporated to obtain 73g of compound 1 POSS chloride ((i-C 4 h 9 ) 7 Si 8 o 12 Cl).

[0039] (2) 73g compound 1 chloride POSS ((i-C 4 h 9 ) 7 Si 8 o 12 Cl) in a mixed solution of tetrahydrofuran (100ml) and water (200ml) was refluxed for 78h, and after the solvent was removed by rotary evaporation, 68g of compound 2 hydroxylated POSS ((i-C 4 h 9 ) 7 Si 8 o 12 (OH)).

[0040] (3) Under nitrogen protection, compound 2 hydroxylated POSS ((i-C 4 h 9 ) 7 Si 8 o 12 (OH)) (65g, 78mmol), tetrahydrofuran (250ml), triethylamine (23g, 230mmol), then slowly add dimethyl monochlorosilane (7.38g, 78mmol), it can be seen that a white pre...

Embodiment 2

[0047] (1) Under the protection of nitrogen, add trihydroxyheptaisobutyl heptapolysiloxane (i-C 4 h 9 ) 7 Si 8 o 9 (OH) 3 (79g, 100mmol), triethylamine (33.3g, 110mmol) and tetrahydrofuran (250ml), then slowly inject SiCl 4 (20.4g, 120mmol) After stirring overnight, the precipitate was removed by filtration, and the filtrate was rotary evaporated to obtain 78g of compound 1 POSS chloride ((i-C 4 h 9 ) 7 Si 8 o 12 Cl).

[0048] (2) 78g compound 1 chloride POSS ((i-C 4 h 9 ) 7 Si 8 o 12 Cl) in a mixed solution of tetrahydrofuran (100ml) and water (200ml) was refluxed for 90h, and after the solvent was removed by rotary evaporation, 74g of compound 2 hydroxylated POSS ((i-C 4 h 9 ) 7 Si 8 o 12 (OH)).

[0049](3) Under nitrogen protection, compound 2 hydroxylated POSS ((i-C 4 h 9 ) 7 Si 8 o 12 (OH)) (65g, 78mmol), tetrahydrofuran (250ml), triethylamine (23g, 230mmol), and then slowly add dimethyl monochlorosilane (8.86g, 93.6mmol), a white precipitate can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com