Hydroxyl-terminated water-based polyester resin and preparation method thereof

A hydroxyl-terminated water-based polyester resin technology, used in polyester coatings, coatings, etc., can solve the problems of easy hydrolysis, poor wear resistance, peeling, etc., achieve excellent water resistance and chemical resistance, simplify processing procedures, The effect of reducing the processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of hydroxyl-terminated water-based polyester resin of the present invention comprises the following steps:

[0029] a: Weigh the raw materials according to the above ratio for later use;

[0030] b: Add phthalic anhydride, isophthalic acid, adipic acid, tetrahydrophthalic acid, butanediol, neopentyl glycol and trimethylolpropane into a four-necked flask under normal pressure and stir until uniform. A distillation column is arranged on the four-necked flask;

[0031] c: Introduce nitrogen gas into the four-necked flask, and raise the temperature of the mixture to 120-150°C, and the heating time is 0.5-2 hours;

[0032] d: Heat the mixture in step c to 170-190°C at a rate of 0.3-0.6°C / min, keep the temperature of the distillation column below 105°C, and the water yield is between 70-90%.

[0033] e: close the nitrogen, and connect the four-necked flask to the vacuum device;

[0034] f: Heat the mixture obtained in step e to 200-230°C at a rate of...

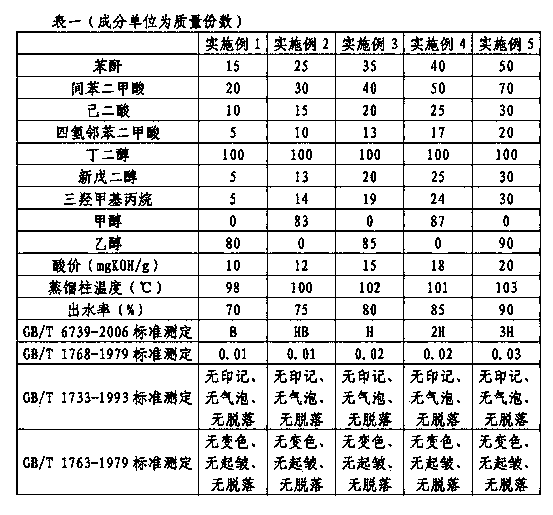

Embodiment 1

[0041] The hydroxyl-terminated water-based polyester resin of the present invention includes phthalic anhydride, isophthalic acid, adipic acid, tetrahydrophthalic acid, butanediol, neopentyl glycol and trimethylolpropane, and the content of the above components is by mass parts The calculations are: phthalic anhydride: 15 parts; isophthalic acid: 20 parts, adipic acid: 10 parts, tetrahydrophthalic acid: 5 parts, butanediol: 100 parts; neopentyl glycol: 5 parts, Trimethylolpropane: 5 parts. At the same time, ethanol was added into the reaction system as a hydrophilic solvent, and its content was calculated as 80 parts by mass.

[0042] The preparation method of hydroxyl-terminated water-based polyester resin of the present invention comprises the following steps:

[0043] a: Weigh the raw materials according to the above ratio for later use;

[0044] b: Add phthalic anhydride, isophthalic acid, adipic acid, tetrahydrophthalic acid, butanediol, neopentyl glycol and trimethylol...

Embodiment 2

[0054] The hydroxyl-terminated water-based polyester resin of the present invention includes phthalic anhydride, isophthalic acid, adipic acid, tetrahydrophthalic acid, butanediol, neopentyl glycol and trimethylolpropane, and the content of the above components is by mass parts The calculations are: phthalic anhydride: 25 parts; isophthalic acid: 30 parts, adipic acid: 15 parts, tetrahydrophthalic acid: 10 parts, butanediol: 100 parts; neopentyl glycol: 13 parts, Trimethylolpropane: 14 parts. At the same time, methanol was added into the reaction system as a hydrophilic solvent, and its content was calculated as 83 parts by mass.

[0055] The preparation method of hydroxyl-terminated water-based polyester resin of the present invention comprises the following steps:

[0056] a: Weigh the raw materials according to the above ratio for later use;

[0057] b: Add phthalic anhydride, isophthalic acid, adipic acid, tetrahydrophthalic acid, butanediol, neopentyl glycol and trimeth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com