Flame-retardant heat-insulating water-based paint and preparation method thereof

A technology of water-based paint and film-forming polymer, which is applied in coatings, reflective/signal coatings, fire-resistant coatings, etc., and can solve the problem of ineffective protection of substrate strength, low physical indicators such as wear resistance, and poor flame-retardant and heat-insulating properties And other problems, to achieve the effect of low equipment dependence, good flame retardant and heat insulation effect, and good heat insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

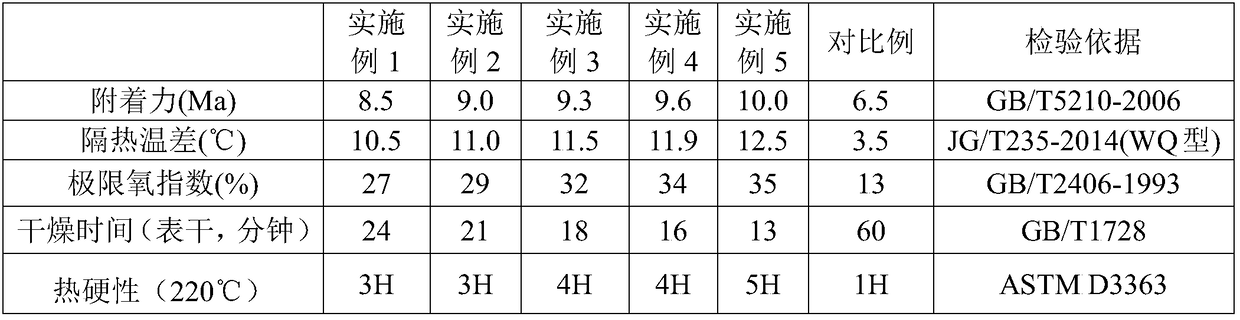

Examples

Embodiment 1

[0031] A flame-retardant water-based paint, which is made of the following components in parts by weight: 55 parts of film-forming polymer, 5 parts of surface-modified foamed aluminum-based nanotubes, 1 part of ethanol, 10 parts of water, 1 part of propylene glycol, 12 parts 1 part of sodium alkylbenzene sulfonate, 1 part of polydimethylsiloxane, 1 part of perfluoroalkyl sulfonate.

[0032] The film-forming polymer is composed of bis(2-aminoethyl)hydrogen phosphate, exo-3,6-epoxy-1,2,36-tetrahydrophthalic anhydride, 1,1-dimethoxy Made from 3-(trimethylsiloxy)-1,3-butadiene and polyetheramine.

[0033] The preparation method of described film-forming polymer, comprises the steps:

[0034] ⅠUnder a nitrogen atmosphere, mix 12.2 g of 1,1-dimethoxy-3-(trimethylsilyloxy)-1,3-butadiene with exo-3,6-epoxy-1,2, Add 10 g of 36-tetrahydrophthalic anhydride into 50 g of dimethyl sulfoxide, then place it in a three-neck flask equipped with a reflux condenser and an electric stirrer, and...

Embodiment 2

[0039] A fire-retardant water-based paint, made of the following components in parts by weight: 58 parts of film-forming polymer, 7 parts of surface-modified aluminum-based foam-based nanotubes, 2 parts of ethylene glycol, 12 parts of water, and 2 parts of methyl ether , 2 parts of polyoxypropylene polyvinyl glyceryl ether, 2 parts of alkyl modified organosiloxane, and 2 parts of alkyl aryl polyether.

[0040] The film-forming polymer is composed of bis(2-aminoethyl)hydrogen phosphate, exo-3,6-epoxy-1,2,36-tetrahydrophthalic anhydride, 1,1-dimethoxy Made from 3-(trimethylsiloxy)-1,3-butadiene and polyetheramine.

[0041] The preparation method of described film-forming polymer, comprises the steps:

[0042] ⅠUnder a helium atmosphere, mix 12.2 g of 1,1-dimethoxy-3-(trimethylsilyloxy)-1,3-butadiene with exo-3,6-epoxy-1,2 , 10g of 36-tetrahydrophthalic anhydride was added to 65g of N,N-dimethylformamide, then placed in a three-neck flask equipped with a reflux condenser and an...

Embodiment 3

[0047] A flame-retardant water-based paint, which is made of the following components in parts by weight: 60 parts of film-forming polymer, 7 parts of surface-modified aluminum-based foamed nanotubes, 4 parts of glycerol, 16 parts of water, alcohol ester dodecyl 2 parts, 3 parts of nonylphenol polyoxyethylene ether, 2 parts of polyether polyester modified organosiloxane, 3 parts of sodium octyl succinate sulfonate.

[0048] The film-forming polymer is composed of bis(2-aminoethyl)hydrogen phosphate, exo-3,6-epoxy-1,2,36-tetrahydrophthalic anhydride, 1,1-dimethoxy Made from 3-(trimethylsiloxy)-1,3-butadiene and polyetheramine.

[0049] The preparation method of described film-forming polymer, comprises the steps:

[0050] ⅠUnder a neon atmosphere, mix 12.2 g of 1,1-dimethoxy-3-(trimethylsilyloxy)-1,3-butadiene with exo-3,6-epoxy-1,2 , 10g of 36-tetrahydrophthalic anhydride was added to 85g of N-methylpyrrolidone, and then placed in a three-necked flask equipped with a reflux ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com