Reversible self-repairing epoxy resin and preparation method and recovery remodeling method thereof

An epoxy resin, self-healing technology, applied in plastic recycling, recycling technology, organic chemistry, etc., can solve the development trend of low energy consumption and fast recycling and remodeling of packaging resin, can not meet the electronic packaging technology, poor resistance Heat and other problems, to achieve excellent reversible self-healing performance, low remodeling temperature, and the effect of good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

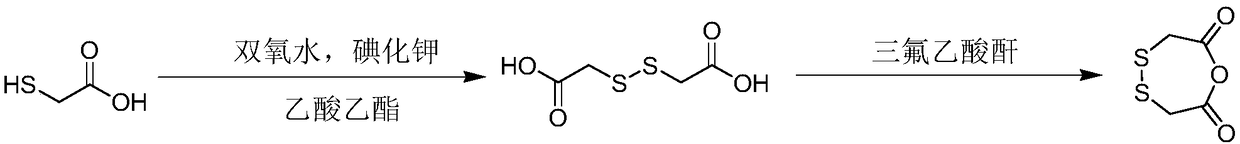

[0043] 1) Preparation of 2,2'-dithiooxalic acid

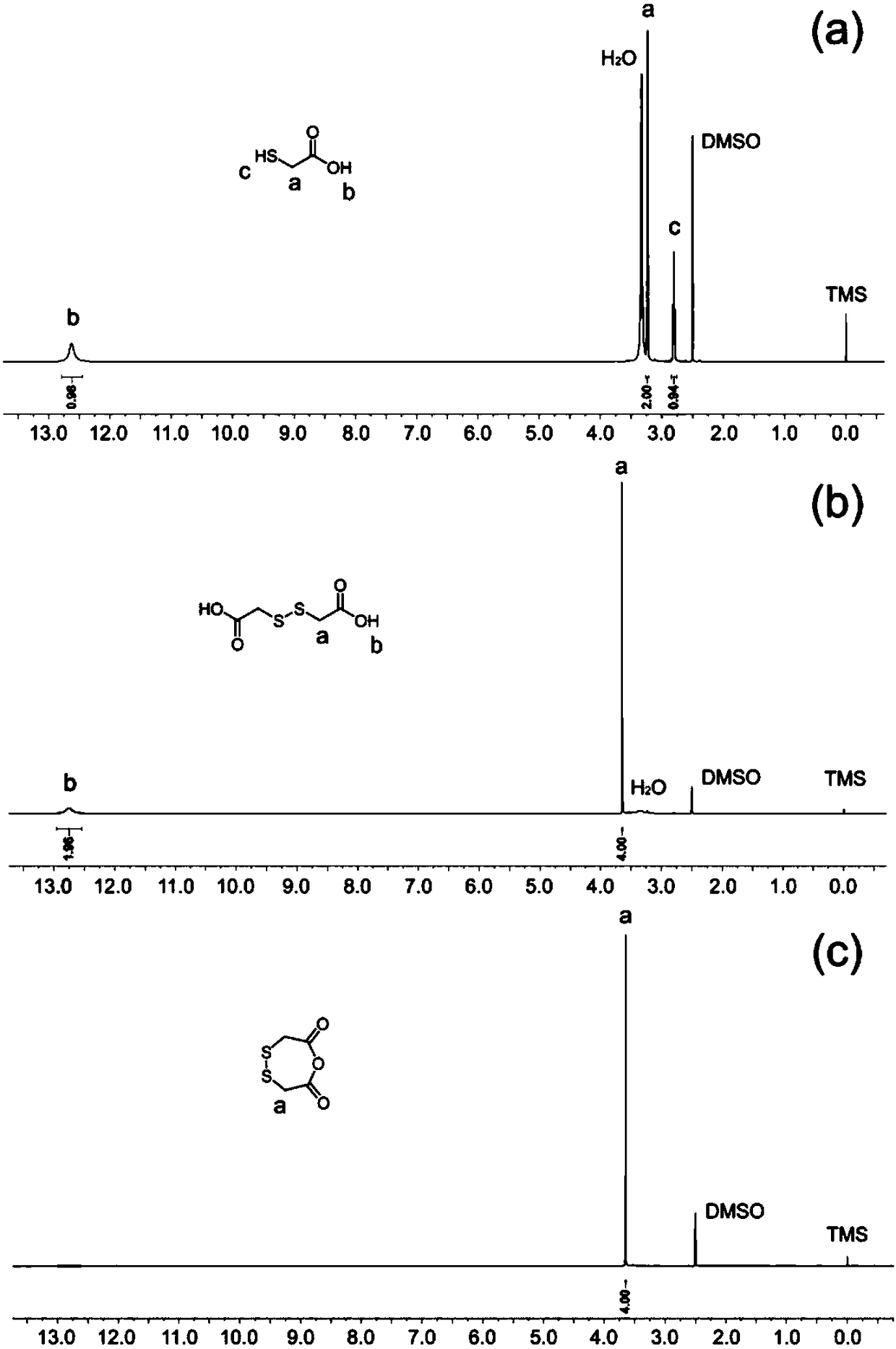

[0044] By mass, under the condition that the temperature is 20°C, 120g of 2-mercaptoacetic acid, 500g of ethyl acetate and 0.6g of potassium iodide are uniformly mixed to form solution A; slowly adding 80g of concentration to solution A is after 30wt% hydrogen peroxide, Insulated reaction for 2 hours; after the reaction, the obtained solution was washed with 300 mL of saturated sodium sulfite solution, and ethyl acetate was evaporated under reduced pressure to obtain 2,2'-dithiooxalic acid. For its H NMR spectrum, see the attached figure 1 .

[0045] 2) Preparation of 2,2'-dithiooxalic anhydride

[0046] In terms of mass, at a temperature of 20°C and stirring, 100g of 2,2'-dithiooxalic acid and 150g of trifluoroacetic anhydride were mixed and kept for 2 hours; the resulting solution was evaporated under reduced pressure to remove excess trifluoroacetic anhydride and the resulting After the trifluoroacetic acid of 2,2'-dithioo...

Embodiment 2

[0060] 1) Preparation of 2,2'-dithiooxalic acid

[0061] By mass, at a temperature of 25°C, 120g of 2-mercaptoacetic acid, 600g of methyl acetate and 0.8g of potassium iodide were mixed homogeneously to form a solution A; slowly adding 85g of concentration to the solution A was after 30wt% hydrogen peroxide, Insulated reaction for 3 hours; after the reaction, the obtained solution was washed with 300 mL of saturated sodium sulfite solution, and methyl acetate was evaporated under reduced pressure to obtain 2,2'-dithiooxalic acid.

[0062] 2) Preparation of 2,2'-dithiooxalic anhydride

[0063] In terms of mass, at a temperature of 25°C and under stirring conditions, mix 100g of 2,2'-dithiooxalic acid and 135g of acetic anhydride and keep it warm for 3 hours; 2,2'-Dithiooxalic anhydride is obtained.

[0064] 3) Preparation of reversible self-healing epoxy resin

[0065] In terms of mass, at a temperature of 60°C, glycidyl ester epoxy resin (brand: 672, epoxy equivalent: 161g / ...

Embodiment 3

[0071] 1) Preparation of 2,2'-dithiooxalic acid

[0072] By mass, at a temperature of 30°C, 120g of 2-mercaptoacetic acid, 700g of propyl acetate and 1.0g of potassium iodide were mixed homogeneously to form a solution A; after slowly adding 90g of hydrogen peroxide with a concentration of 30wt% in the solution A, Insulated reaction for 4 hours; after the reaction, the obtained solution was washed with 300 mL saturated sodium sulfite solution, and propyl acetate was evaporated under reduced pressure to obtain 2,2'-dithiooxalic acid.

[0073] 2) Preparation of 2,2'-dithiooxalic anhydride

[0074] In terms of mass, at a temperature of 30°C and under stirring conditions, mix 100g of 2,2'-dithiooxalic acid and 120g of acetic anhydride and keep it warm for 4 hours; 2,2'-Dithiooxalic anhydride is obtained.

[0075] 3) Preparation of reversible self-healing epoxy resin

[0076]By mass, 100g of glycidylamine epoxy resin (brand: AFG-90, epoxy equivalent: 118g / eq), 60g of 2,2'-dithio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com