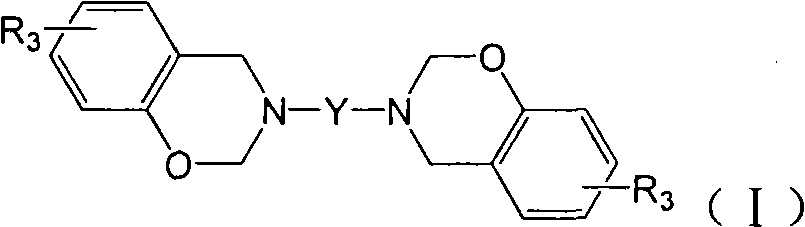

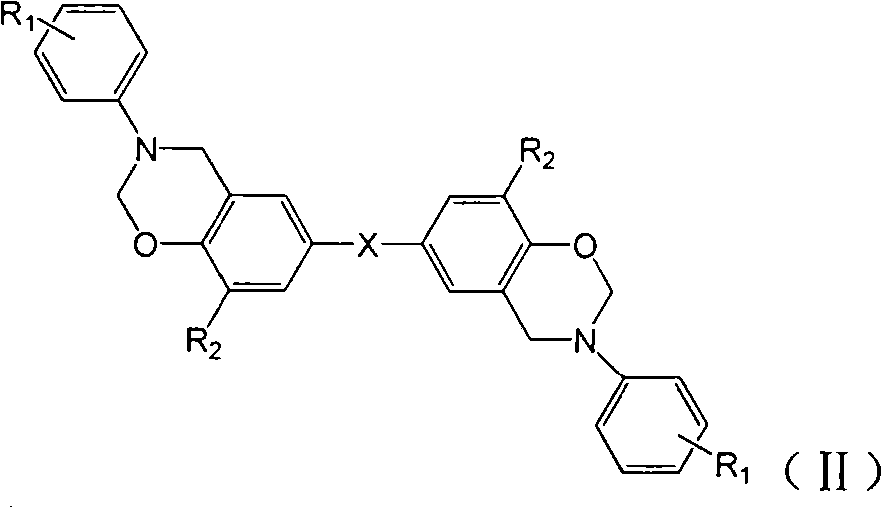

Thermoset polybenzoxazine-polyimide resin composite/mesoporous molecular sieve hybrid material and preparation method thereof

A technology of polyimide resin and polybenzoxazine, which is applied in the field of organic/inorganic hybrid materials, can solve the problems of the original performance loss of the matrix resin material, and reduce the dielectric constant of the matrix material.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] Disperse 0.338g of MCM-41 with a particle size of 500nm in 16ml of N,N-dimethylacetamide (DMAc), and ultrasonically disperse it for 15 hours at room temperature to obtain a mesoporous molecular sieve dispersion;

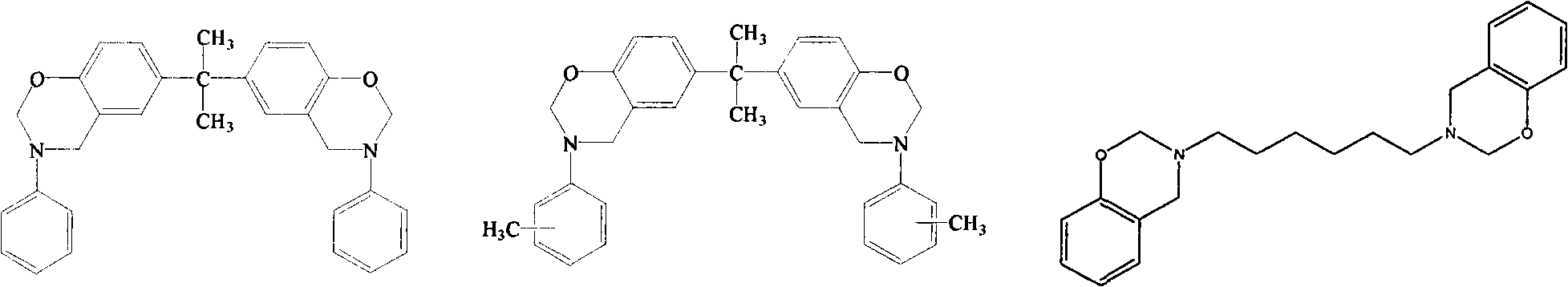

[0080] Add 2.470 g of bisphenol A-aniline benzoxazine compound (BZ) to the above liquid, and continue stirring at 27° C. for 20 hours to obtain a benzoxazine compound / mesoporous molecular sieve mixed liquid;

[0081] Under the protection of an inert gas, add 0.050g of 4,4'-diaminodiphenyl ether (ODA) into 1.3ml of DMAc, stir, and slowly add 0.080g of 3,3',4,4'- Benzophenone tetra-acid dianhydride (BTDA), after the addition is complete, react at 25°C for 16 hours under the protection of an inert gas to obtain a polyamic acid solution; add the solution to the above-mentioned benzoxazine compound / mesoporous molecular sieve and mix In the liquid, stirring was continued at 20°C for 9 hours to obtain a benzoxazine compound-polyamic acid / mesoporous molecular sieve mi...

Embodiment 2

[0084] Put the toluene solution of MCM-41 with a particle size of 500nm and γ-[(2,3)-glycidoxy]propyltrimethoxysilane in a three-necked flask, reflux for more than 24 hours, filter and wash to obtain Modified MCM-41.

[0085] Disperse 0.268g of the modified MCM-41 in 16ml of N-methylpyrrolidone (NMP) and ultrasonically disperse it for 16 hours at room temperature to obtain a mesoporous molecular sieve dispersion;

[0086] Add 2.546g of bisphenol A-aniline benzoxazine compound (BZ) into the above liquid, and continue stirring at 18°C for 24 hours to obtain a benzoxazine compound / mesoporous molecular sieve mixed liquid;

[0087] Under the protection of an inert gas, add 0.050g 4,4'-diaminodiphenyl ether (ODA) into 1.3ml NMP, stir, and slowly add 0.084g 3,3',4,4'- Benzophenone tetra-acid dianhydride (BTDA); after the addition is complete, react at 20°C for 20 hours under the protection of an inert gas to obtain a polyamic acid solution; add the solution to the above-mentioned ...

Embodiment 3

[0090] The toluene solution of MCM-41 with a particle size of 150nm and methyltriethoxysilane was placed in a three-necked flask, refluxed for more than 24 hours, filtered and washed to obtain the modified MCM-41 with methyl groups on the surface.

[0091] Disperse 0.132g of the modified MCM-41 in 16ml of N,N-dimethylformamide (DMF) at room temperature for 18 hours and ultrasonically disperse it uniformly to obtain a mesoporous molecular sieve dispersion;

[0092] Add 2.508g of bisphenol A-aniline benzoxazine compound (BZ) into the above liquid, and continue stirring at 20°C for 22 hours to obtain a benzoxazine compound / mesoporous molecular sieve mixed liquid;

[0093] Under the protection of an inert gas, add 0.050g of 4,4'-diaminodiphenyl ether (ODA) into 1.3ml of DMF, stir, and slowly add 0.082g of 3,3',4,4'- Benzophenone tetra-acid dianhydride (BTDA); after the addition is complete, react at 27°C for 20 hours under the protection of an inert gas to obtain a polyamic acid s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com