Manufacturing method of copper-clad plate and glue solution for copper-clad plate

A production method and technology of copper clad laminates, which are applied in the directions of adhesives, epoxy resin glue, printed circuit manufacturing, etc., can solve the problems of high rigidity, high cost, poor support performance, etc., and achieve convenient installation and connection, maintain heat resistance, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

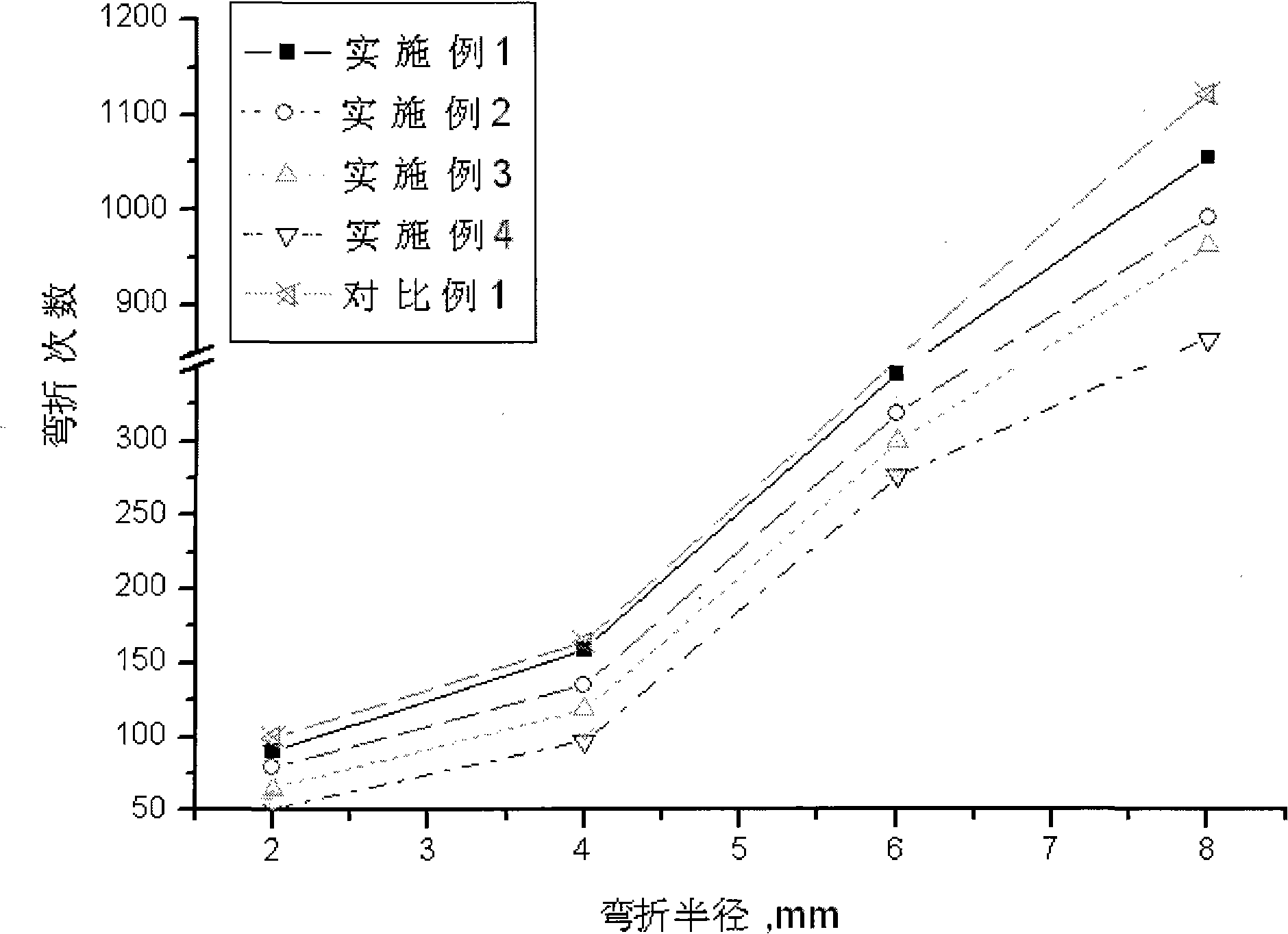

Examples

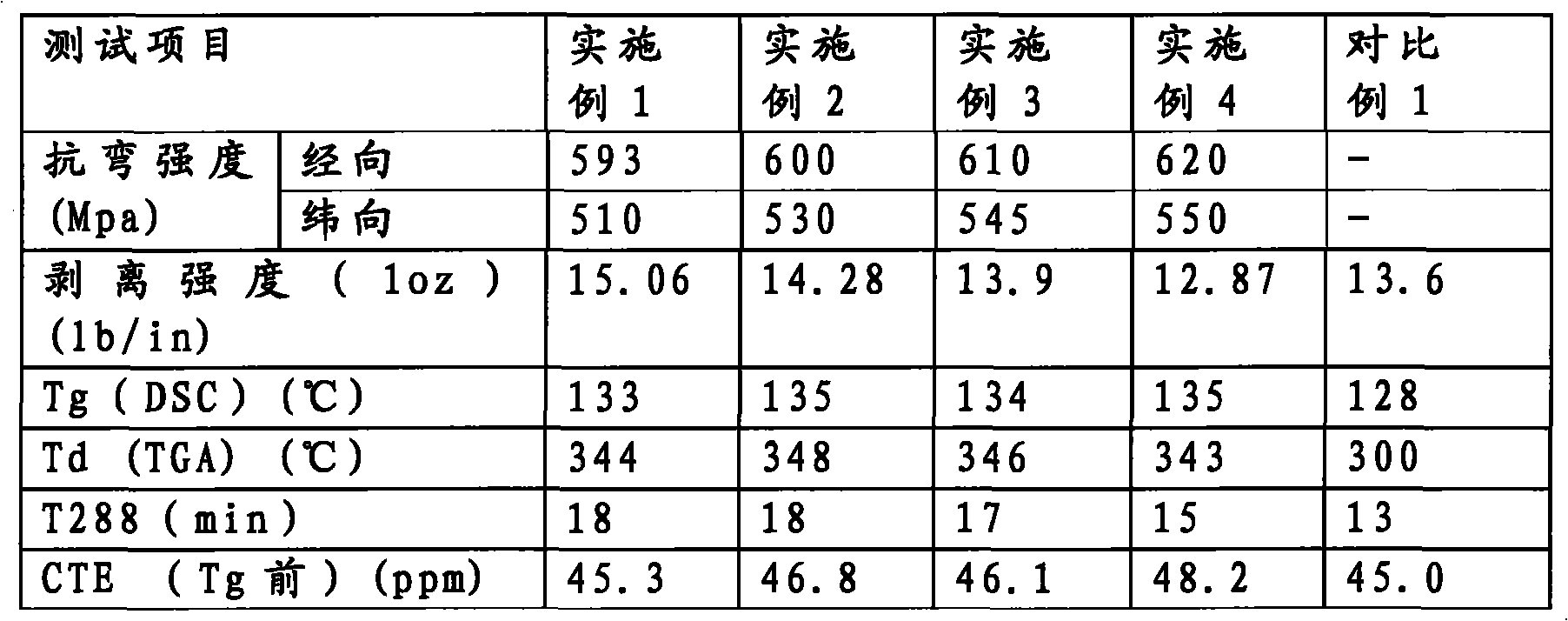

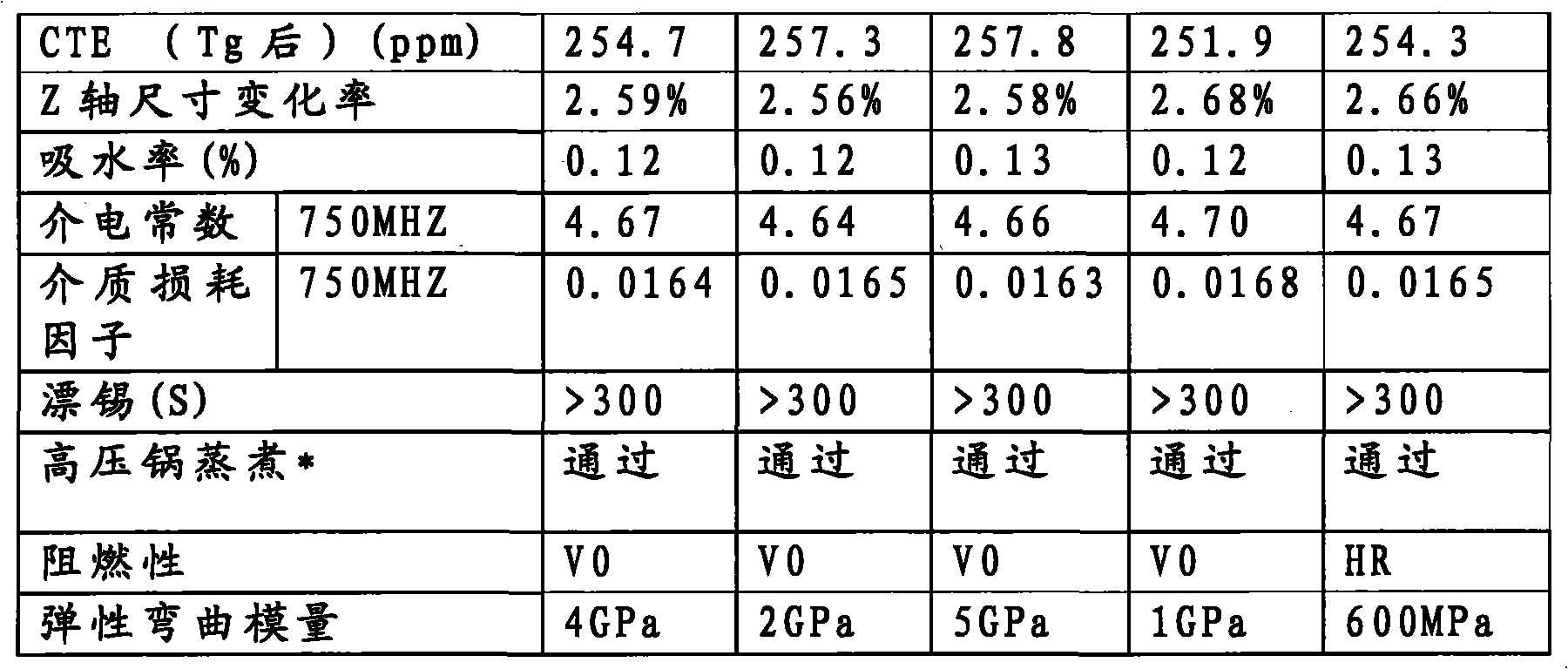

Embodiment 1

[0019] This embodiment provides a glue solution for copper-clad laminates and a method for manufacturing copper-clad laminates. The glue solution is composed of the following components in parts by weight: 78 parts of nitrile rubber modified epoxy resin (SC-024, SHIN-AT&C, the content of nitrile rubber is 38wt%); brominated epoxy resin 117 parts 5 parts of dicyandiamide; 0.02 part of 2-methylimidazole; 20 parts of tetrabromobisphenol A, solvent (butanone, 30 parts).

[0020] The manufacturing method of the copper clad laminate includes the following steps:

[0021] (1) Preparation of glue solution: According to the above formula, add brominated epoxy resin, dicyandiamide, 2-methylimidazole and half of the solvent to the glue solution tank in sequence, and start high-speed stirring at the same time; then add nitrile rubber Modified epoxy resin, after addition, add the remaining solvent.

[0022] (2) Gluing: use glass fiber cloth as the base cloth, apply glue on the surface of...

Embodiment 2

[0025] The manufacturing method of the copper-clad laminate according to the present embodiment is basically the same as in the embodiment 1, but adopts the glue solution having the following composition: 50 parts of nitrile rubber modified epoxy resin (model SC-024, SHIN-A T&C, nitrile rubber 145 parts of brominated epoxy resin (GEBR400, Hongchang electronic material); 5 parts of dicyandiamide; 0.02 part of 2-methylimidazole; 20 parts of tetrabromobisphenol A; solvent (butanone, 20 parts ).

Embodiment 3

[0027] The manufacturing method of the copper-clad laminate according to the present embodiment is basically the same as that of Embodiment 1, but adopts a glue solution having the following composition: 95 parts of nitrile rubber modified epoxy resin (model SC-024, SHIN-A T&C, nitrile rubber 100 parts of brominated epoxy resin (GEBR400, Hongchang electronic material); 5 parts of dicyandiamide; 0.02 part of 2-methylimidazole; 25 parts of tetrabromobisphenol A; solvent (butanone, 25 parts ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com