Bisphenol A paraformaldehyde novolac epoxy resin conductive adhesive and preparation method thereof

A technology of phenolic epoxy resin and paraformaldehyde, applied in the direction of online phenolic epoxy resin adhesive, conductive adhesive, etc., can solve the problem of poor resistance stability, limited application range, poor heat resistance of epoxy resin, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A kind of preparation method of BPA-PA phenolic epoxy resin conductive glue of the present invention specifically comprises the steps:

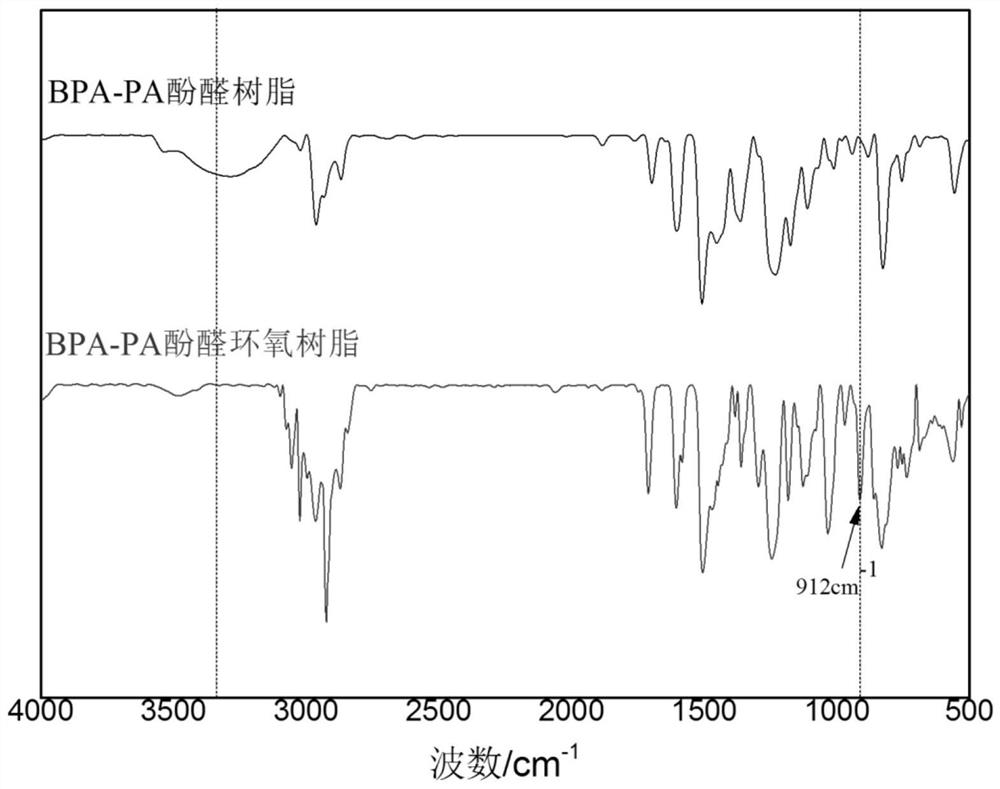

[0048] Step 1, when equipped with stirrer, reflux condenser, N 2 10 g of homemade BPA-PA phenolic resin, 80 g of epichlorohydrin and 0.5 g of tetrabutylammonium bromide were sequentially added to a protected 250 ml four-necked round bottom flask, stirred and heated to 80° C. for 3 h. Then the temperature was lowered to 60° C., 15 g of 10 wt % sodium hydroxide solution was added dropwise for 1.5 h, and the temperature was raised to 70° C. to react for 1 h to obtain the crude product of BPA-PA novolac epoxy resin.

[0049] Then wash with water to desalt to neutral, remove excess epichlorohydrin by distillation under reduced pressure, then add benzene to dissolve, wash with water 4 times, and finally process under reduced pressure distillation to obtain BPA-PA phenolic ring of light yellow viscous liquid oxygen resin.

[0050] Step 2: D...

Embodiment 2

[0058] A kind of preparation method of BPA-PA phenolic epoxy resin conductive glue of the present invention specifically comprises the steps:

[0059] Step 1, when equipped with stirrer, reflux condenser, N 2 10 g of homemade BPA-PA phenolic resin, 85 g of epichlorohydrin, and 0.3 g of tetrabutylammonium bromide were sequentially added to a protected 250 ml four-neck round bottom flask, stirred and heated to 80° C. for 2 h. Then the temperature was lowered to 60° C., 10 g of 10 wt % sodium hydroxide solution was added dropwise for 1.5 h, and the temperature was raised to 70° C. to react for 1 h to obtain the crude product of BPA-PA novolac epoxy resin.

[0060] Then wash with water to desalinate to neutral, remove excess epichlorohydrin by distillation under reduced pressure, then add benzene to dissolve, wash with water for 3 times, and finally process under reduced pressure distillation to obtain BPA-PA phenolic ring of light yellow viscous liquid oxygen resin.

[0061] St...

Embodiment 3

[0065] A kind of preparation method of BPA-PA phenolic epoxy resin conductive glue of the present invention specifically comprises the steps:

[0066] Step 1, when equipped with stirrer, reflux condenser, N 2 A protected 250ml four-neck round bottom flask was successively added with 10g of self-made BPA-PA phenolic resin, 90g of epichlorohydrin and 0.4g of tetrabutylammonium bromide, stirred and heated to 75°C for 3h. Then the temperature was lowered to 60° C., 15 g of 10 wt % sodium hydroxide solution was added dropwise for 1.5 h, and the temperature was raised to 70° C. to react for 1.5 h to obtain the crude product of BPA-PA novolac epoxy resin.

[0067] Then wash with water to desalt to neutral, remove excess epichlorohydrin by distillation under reduced pressure, then add benzene to dissolve, wash with water 4 times, and finally process under reduced pressure distillation to obtain BPA-PA phenolic ring of light yellow viscous liquid oxygen resin.

[0068] Step 2: Dissol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com