Graphene composite shielding anti-interference power cable for environment-friendly intelligent high-speed rail and fabrication method of graphene composite shielding anti-interference power cable

A graphene composite, power cable technology, applied in power cables with shielding layer/conductive layer, cable/conductor manufacturing, insulated cables, etc. Unreasonable structural design and other problems, to reduce partial discharge phenomenon, enhance anti-interference performance, improve the effect of homogenization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings.

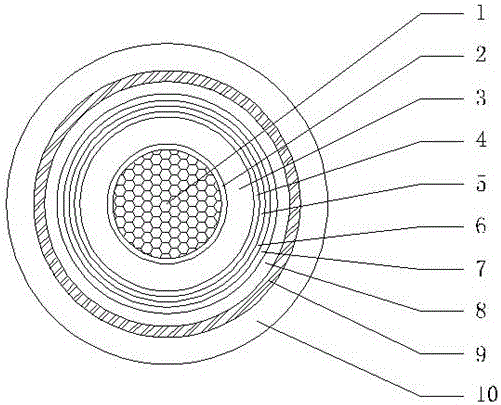

[0033] Such as figure 1 The shown is an environmentally friendly graphene composite shielded anti-interference power cable for intelligent high-speed rail, including a copper conductor 1 located at the center of the cable, and a three-layer co-extrusion method is used to extrude a low-resistance thermally stable graphene composite on the copper conductor 1. Conductor shielding layer 2 with a thickness of 0.8mm, an insulating layer 3 with a thickness of 4.5mm, and a low-resistance heat-stable graphene composite semiconductive shielding material with a thickness of 0.7mm and an outer diameter of 23.5mm. The insulating shielding layer 4 forms an insulating wire core; the metal inner shielding layer 5 with a thickness of 0.1mm and an outer diameter of 23.8mm formed by overlapping and wrapping an oxygen-free soft copper tape outside the insulating wire core; the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com