Preparation method of conductive titanium dioxide powder

A technology of conductive titanium dioxide and titanium dioxide, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of poor performance such as weather resistance and gloss, poor repeatability of the titanium dioxide method, and high product cost per unit mass, so as to achieve good dispersion , controllable stoichiometric ratio, excellent whiteness and conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of the conductive titanium dioxide powder, the steps are as follows:

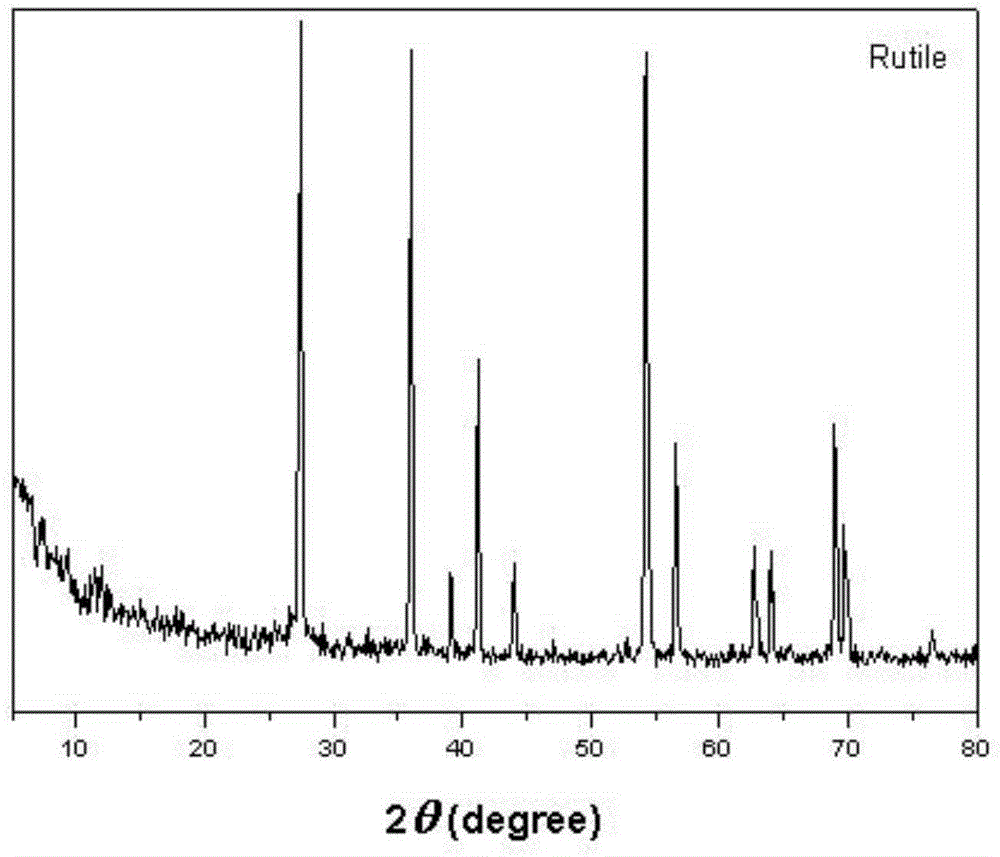

[0029] 1. Beat the rutile titanium dioxide produced by the chlorination method in distilled water, stir it evenly to obtain a slurry with a mass concentration of 20%, take 100ml, and add zirconium sulfate solution dropwise to the obtained slurry, wherein the mass of zirconium sulfate and titanium dioxide Than ZrO 2 / TiO 2 Calculated as 0.1%, the concentration of zirconium sulfate solution is ZrO 2 Count as 120g / L, obtain mixed solution A;

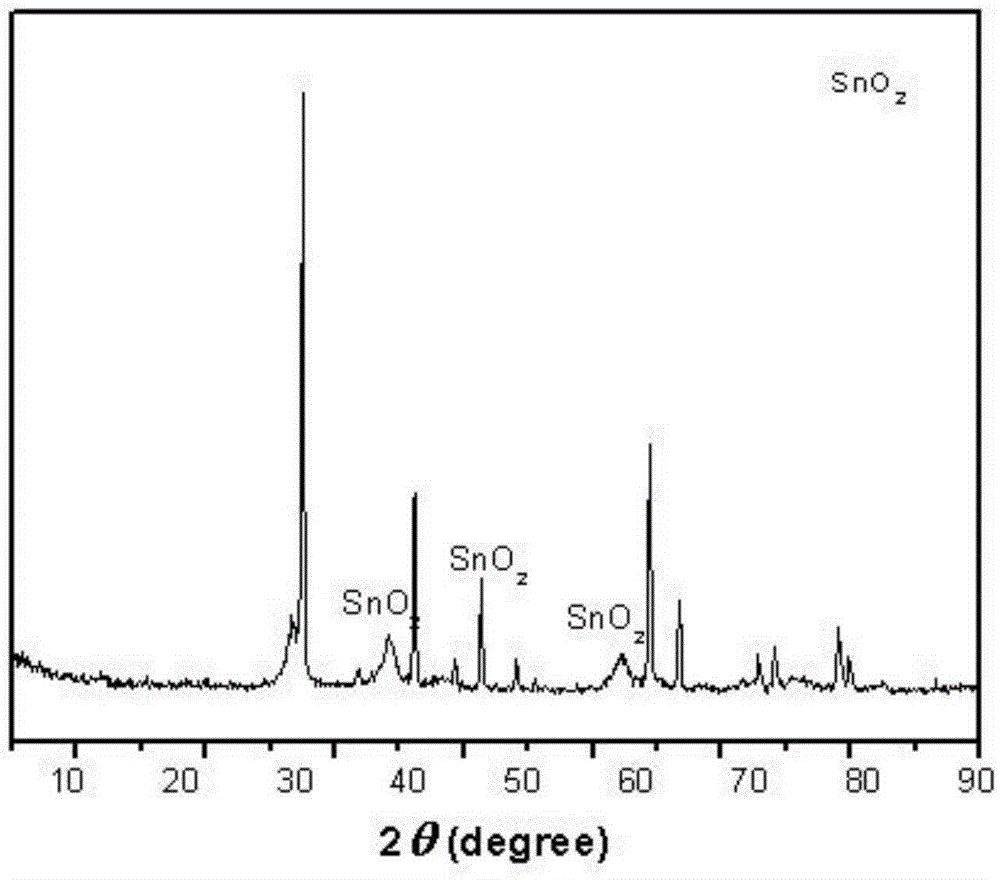

[0030] 2. Drop the mixed acid solution of tin sulfate and antimony trichloride prepared in advance into the mixed solution A at the same time, control the reaction pH=1, the reaction temperature is 60°C, the titration time is 3h, and the alkali solution is oxidized with hydrogen Sodium solution with a concentration of 6mol / L, wherein the concentration of hydrochloric acid in the mixed acidic solution is 20%, and the mass of tin sulfate is...

Embodiment 2

[0033] The preparation method of the conductive titanium dioxide powder, the steps are as follows:

[0034] 1. Beat the rutile titanium dioxide produced by the chlorination method in distilled water, stir evenly to obtain a slurry with a mass concentration of 25%, take 100ml, and add zirconium nitrate solution dropwise to the obtained slurry, wherein the mass of zirconium nitrate and titanium dioxide than ZrO 2 / TiO 2 Calculated as 0.3%, the concentration of zirconium nitrate solution is ZrO 2 Count as 150g / L, obtain mixed solution A;

[0035]2. Drop the pre-prepared mixed acid solution of tin nitrate and antimony trichloride and potassium hydroxide solution into the mixed solution A at the same time, control the reaction pH=2, the reaction temperature is 70°C, and the titration time is 4 hours. The concentration is 8mol / L, wherein the concentration of hydrochloric acid in the mixed solution is 25%, and the mass of tin nitrate is based on SnO 2 / TiO 2 Calculated as 25%, t...

Embodiment 3

[0040] The preparation method of the conductive titanium dioxide powder, the steps are as follows:

[0041] 1. Beat the rutile titanium dioxide produced by the chlorination method in distilled water, stir evenly to obtain a slurry with a mass concentration of 30%, take 100ml, add zirconium chloride solution dropwise to the obtained slurry, wherein zirconium chloride and titanium dioxide The mass ratio of ZrO 2 / TiO 2 Calculated as 0.5%, the concentration of zirconium chloride solution is ZrO 2 Count as 180g / L, obtain mixed solution A;

[0042] 2. Drop the pre-prepared tin salt and antimony salt mixed acidic solution and alkaline solution into the mixed solution A at the same time, control the reaction pH=3, the reaction temperature is 80°C, the titration time is 5 hours, and the concentration of the ammonia solution is 10mol / L. Wherein the concentration of hydrochloric acid in the mixed solution is 30%, the quality of tin tetrachloride is by SnO 2 / TiO 2 Calculated as 30%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume resistivity | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com