Thermosetting resin composition

A resin composition, thermosetting technology, applied in the field of thermosetting resin composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

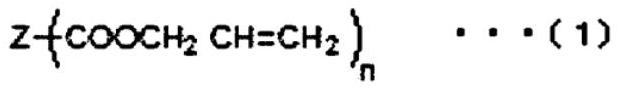

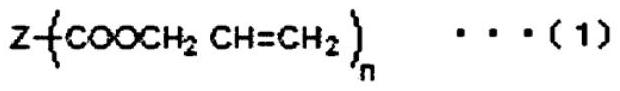

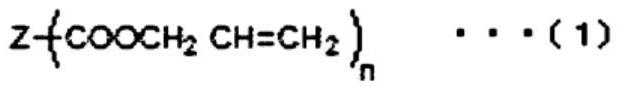

Method used

Image

Examples

Embodiment

[0103] Hereinafter, although an Example demonstrates this invention in more detail, this invention is not limited to an Example at all.

[0104] Materials used in Examples and Comparative Examples described later will be described below.

[0105] Unsaturated polyester resin

[0106] Unsaturated polyester resin: U-Pica 8552 manufactured by Japan U-pica Co., Ltd.

[0107] Initiator

[0108] Initiator 1; Perbutyl E (tert-butyl peroxy-2-ethylhexyl monocarboxylate; 1-minute half-life temperature: 161.4°C, molecular weight: 246.35, dehydrogenation ability: 49%, manufactured by NOF Corporation)

[0109] Initiator 2; Perhexyl Z (tert-hexyl peroxybenzoate; 1-minute half-life temperature: 160.3°C, molecular weight: 222.3, dehydrogenation ability: 27%, manufactured by NOF Corporation)

[0110] Initiator 3; Perhexa HC (1,1-bis(tert-hexylperoxy)cyclohexane; 1-minute half-life temperature: 149.2°C, molecular weight: 316.47, dehydrogenation ability: 10%, manufactured by NOF Corporatio...

Synthetic example 1

[0118] Synthesis Example 1: Synthesis of diallyl 1,2-cyclohexanedicarboxylate (crosslinking agent)

[0119] 170.5 g (2.93 mol) of allyl alcohol, 150.1 g (1.63 mol) of toluene, 241.1 g (1.40 mol) of 1,2-cyclohexanedicarboxylic acid, and 7.18 g of dodecylbenzenesulfonic acid were put into a 500 mL flask (0.022mol), stirred with a magnetic stirrer, and refluxed with an oil bath. After 20 hours, the heat was turned off and the flask was cooled. The obtained reaction solution was neutralized and washed with water, the low-boiling components were distilled off with a rotary evaporator, and the obtained concentrated solution was subjected to vacuum distillation to obtain the target diallyl 1,2-cyclohexanedicarboxylate 110.6g. The obtained compound 1 was used in Examples.

[0120] Tables 1 and 2 show the component compositions of the thermosetting resin compositions used in Examples and Comparative Examples. The numerical units of the compositions in the table are parts by weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com