Image formation device

An image and separation device technology, applied in the direction of electric recording process applying charge pattern, electric recording process applying electric charge pattern, equipment of electric recording process applying electric charge pattern, etc. range, inability to improve carrier fluid resistivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

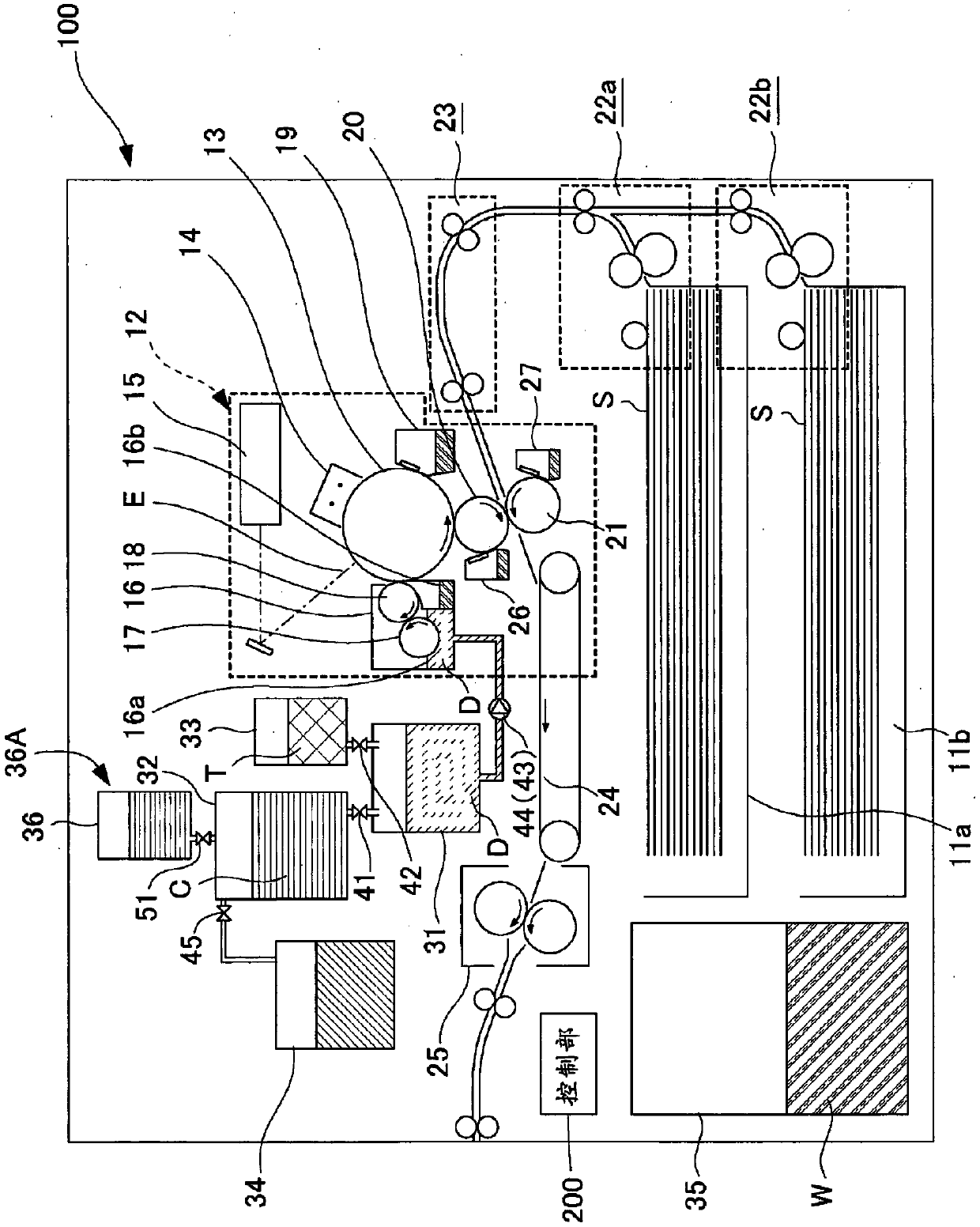

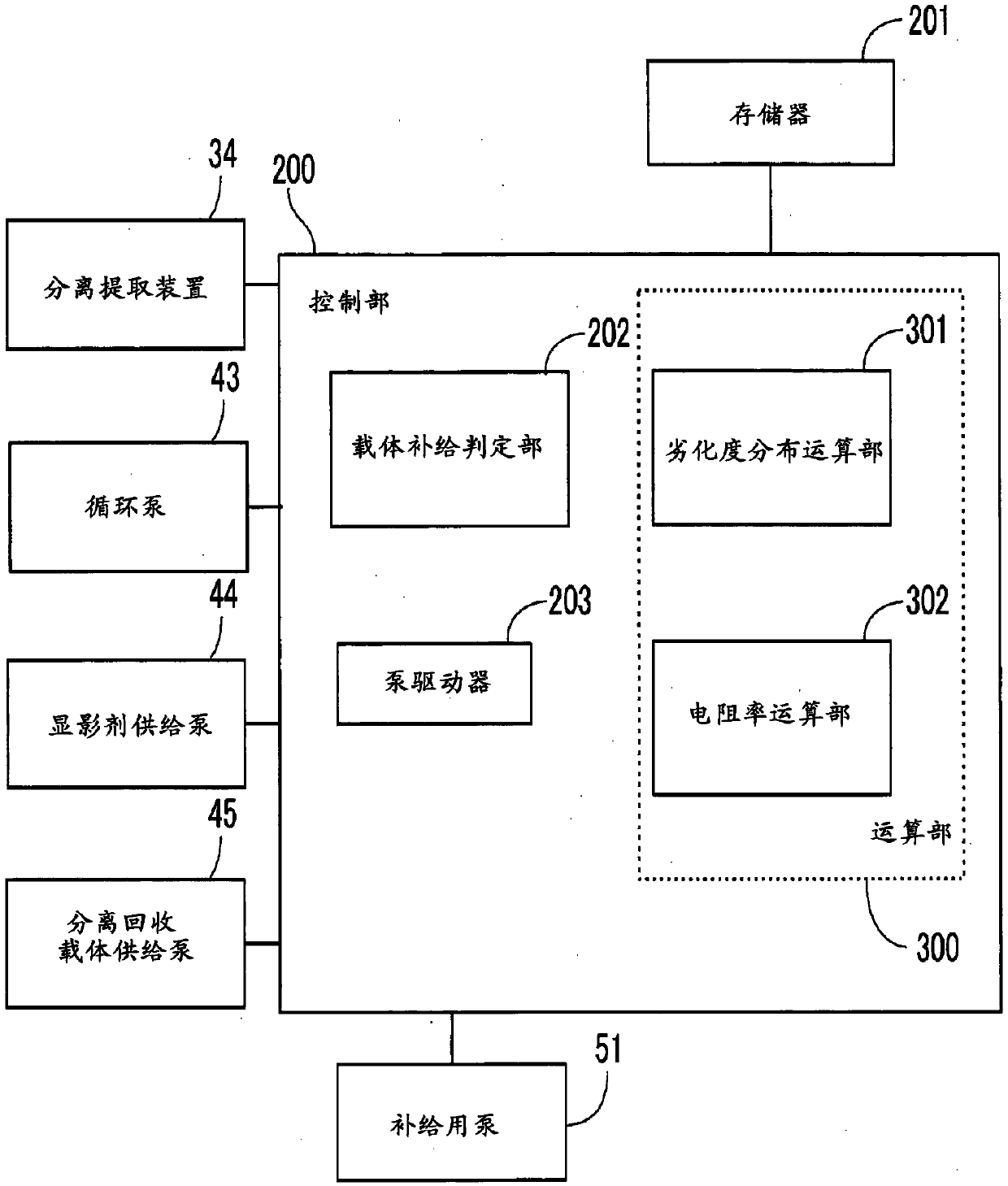

[0023] use Figure 1 to Figure 7 A first embodiment of the present invention will be described. First, use figure 1 A schematic configuration of the image forming apparatus of this embodiment will be described.

[0024] [Image forming device]

[0025] The image forming apparatus 100 of the present embodiment is an electrophotographic digital printer that forms a toner image on a recording material S (sheet material such as paper or OHP sheet). The image forming apparatus 100 operates based on an image signal, and transfers a toner image formed by the image forming unit 12 to a recording material S that is sequentially conveyed from the cartridges 11a and 11b, and then fixes it to obtain an image. The image signal is transmitted to image forming apparatus 100 from a scanner not shown, an external terminal such as a personal computer, and the like.

[0026] The image forming unit 12 includes a photosensitive drum 13 as an image carrier, a charger 14 , a laser exposure device...

no. 2 approach

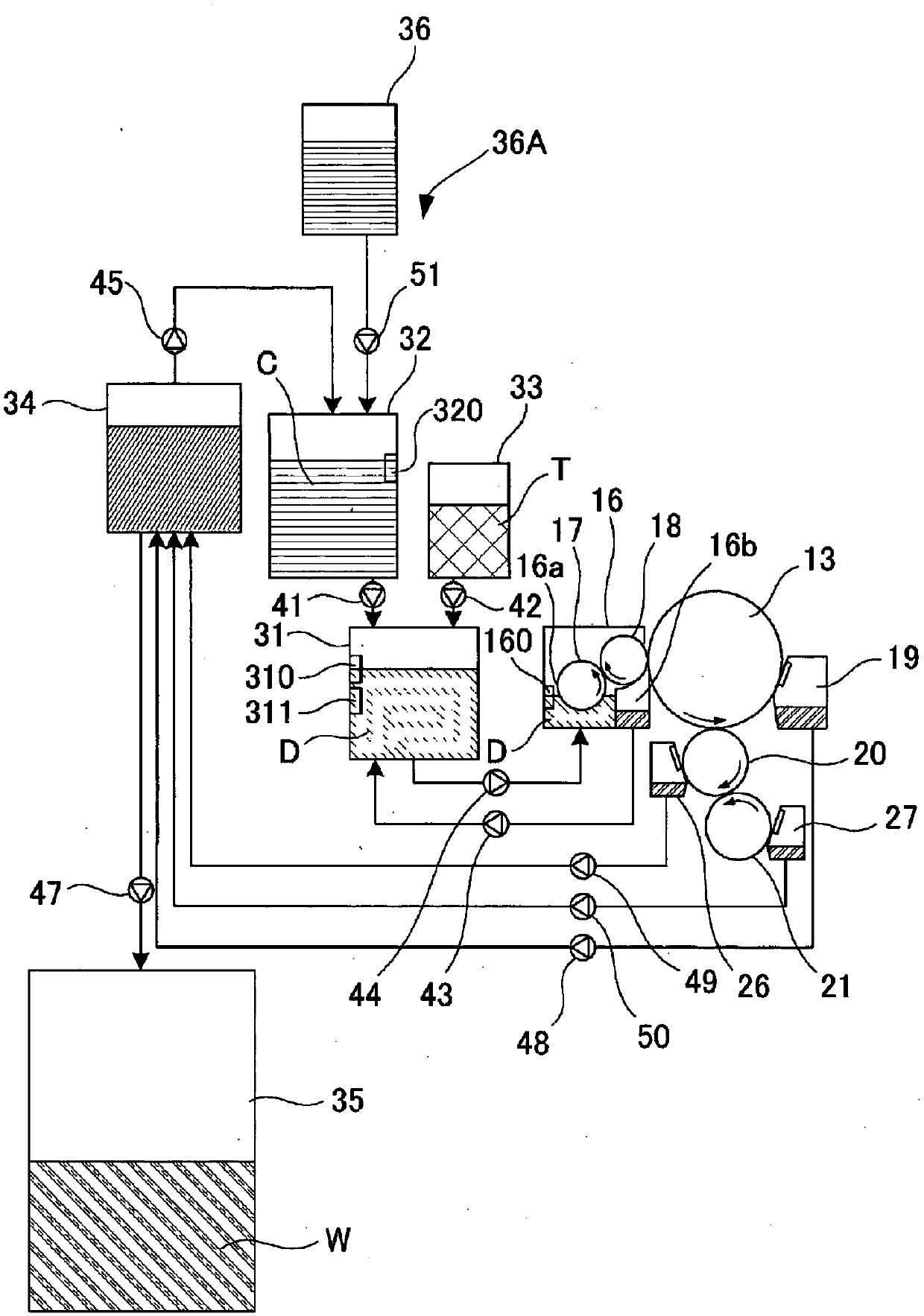

[0120] use Figure 10 A second embodiment will be described. In the first embodiment described above, the carrier liquid for replenishment is supplied to the carrier tank 32 from the replenishment device 36A. In contrast, in the image forming apparatus 100A of the second embodiment, the carrier liquid for replenishment is supplied from the replenishment device 60A to the mixer 31 . Since other basic structures and functions are the same as those of the above-mentioned first embodiment, description and illustration of the same structure will be omitted or simplified below, and the description will focus on the parts different from those of the first embodiment.

[0121] In the case of the present embodiment, a separation and extraction device 34 , a carrier tank 32 containing the carrier liquid separated by the separation and extraction device 34 , and a mixer 31 to which the carrier liquid is supplied from the carrier tank 32 are provided. In addition, in the present embodim...

Embodiment approach

[0124] In addition, when the carrier liquid for replenishment is replenished, it is only necessary to add the replenished amount to the "liquid amount passed zero times" in the first row and first column of the matrix C. Thereafter, using the matrix C to which the replenishment amount has been added, the calculation of "the liquid amount per number of passes" is performed as described above. by Figure 6 To briefly describe as an example, in the case where, for example, 20 ml of carrier fluid for replenishment is replenished after the second pass, the value in the first row and first column of matrix C is changed from "25" to "20" with the replenishment amount added. "45" after.

[0125] Conversely, when the carrier liquid is consumed during development, it is only necessary to subtract the liquid amount obtained by dividing the consumption evenly from each element of the matrix Q. Thereafter, using the matrix Q after subtracting the consumed amount, the calculation of "the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com