Components of anti-tensile insulated cable sheath and preparation process thereof

A technology for insulated cables and preparation processes, applied to insulated cables, insulated conductors, organic insulators, etc., can solve problems such as poor bonding performance, poor mechanical properties, loss of adhesion, etc., to increase natural crosslinking speed, improve resistance Tear strength, effect of improving tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

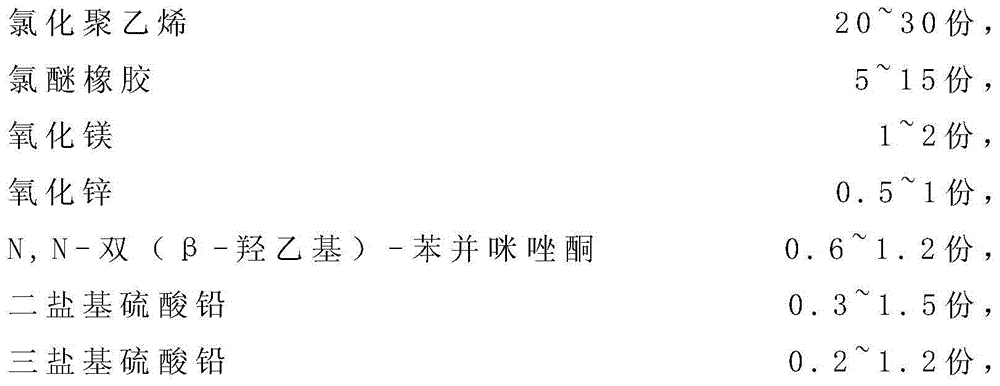

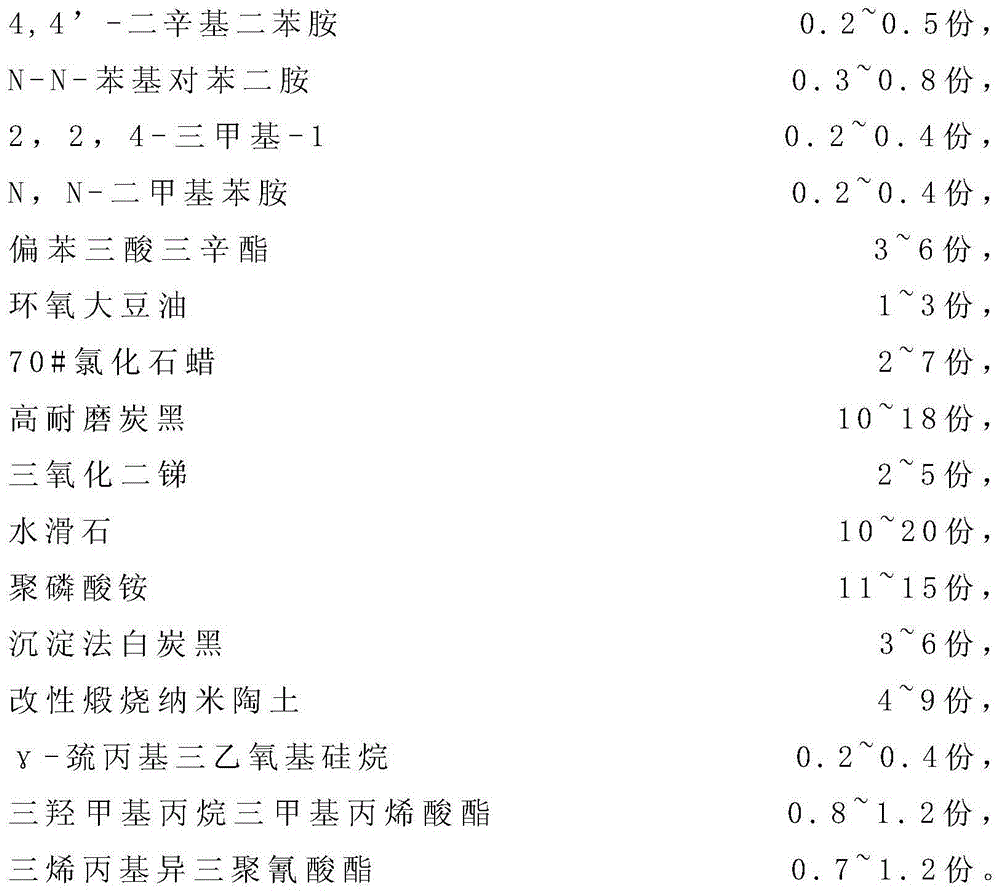

Method used

Image

Examples

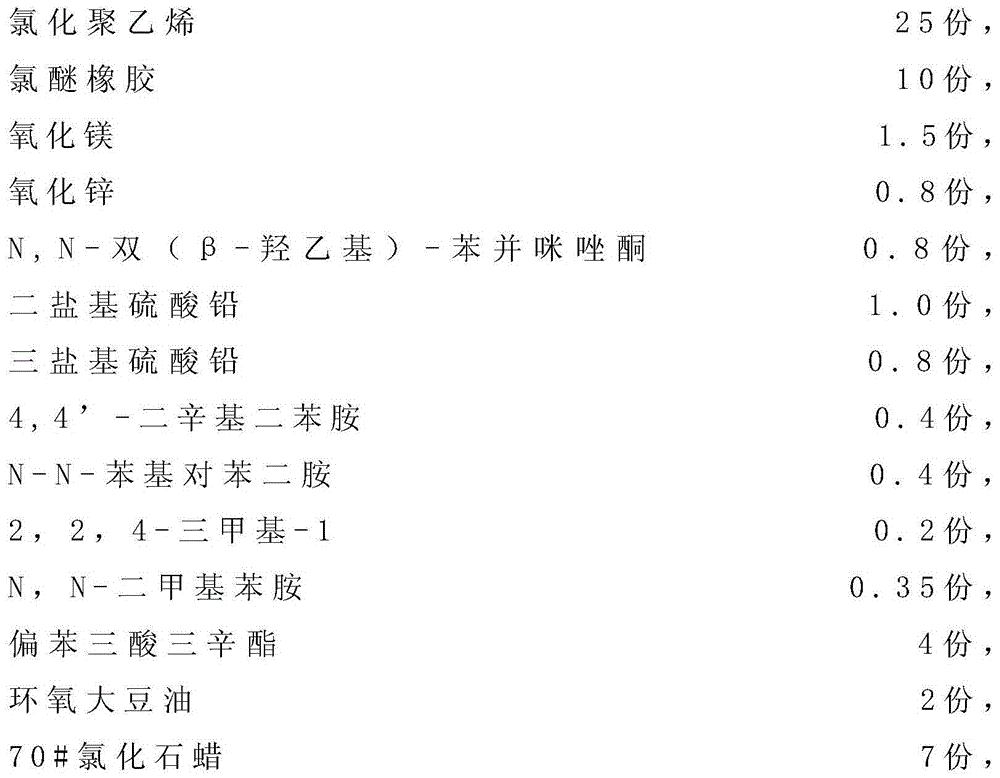

Embodiment 1

[0023] A component of a stretch-resistant insulated cable sheath, the formula of each component is: the formula of each component of the material is: 25 kg of chlorinated polyethylene, 10 kg of epichloride rubber, 1.5 kg of magnesium oxide, 0.5 kg of zinc oxide, N , N-bis(β-hydroxyethyl)-benzimidazolone 1 kg, dibasic lead sulfate 1.0 kg, tribasic lead sulfate 0.8 kg, 4,4'-dioctyl diphenylamine 0.2 kg, N-N- 0.3 kg of phenyl-p-phenylenediamine, 10.2 kg of 2,2,4-trimethyl-10.2 kg, 0.3 kg of N,N-dimethylaniline, 3.4 kg of trioctyl trimellitate, 1.3 kg of epoxidized soybean oil, 70# 7 kilograms of chlorinated paraffin, 12 kilograms of high wear-resistant carbon black, 5 kilograms of antimony trioxide, 15 kilograms of hydrotalcite, 13 kilograms of ammonium polyphosphate, 4 kilograms of precipitated white carbon black, 6 kilograms of modified calcined nano clay, 0.3 kg of gamma-mercaptopropyltriethoxysilane, 1 kg of trimethylolpropane trimethacrylate, and 0.9 kg of triallyl isocyanur...

Embodiment 2

[0036]A component of a stretch-resistant insulated cable sheath, the formulation of each component is: 25 kg of chlorinated polyethylene, 10 kg of epichlorohydrin rubber, 1 kg of magnesium oxide, 1 kg of zinc oxide, N,N-bis(β- 1 kg of hydroxyethyl)-benzimidazolone, 1.0 kg of dibasic lead sulfate, 0.8 kg of tribasic lead sulfate, 0.4 kg of 4,4'-dioctyl diphenylamine, 0.4 kg of N-N-phenyl-p-phenylenediamine kg, 2,2,4-trimethyl-10.2 kg, N,N-dimethylaniline 0.35 kg, trioctyl trimellitate 4 kg, epoxy soybean oil 2 kg, 70# chlorinated paraffin 7 kg , 12 kg of high wear-resistant carbon black, 3 kg of antimony trioxide, 11 kg of hydrotalcite, 12 kg of ammonium polyphosphate, 4 kg of precipitated white carbon black, 6 kg of modified calcined nano clay, γ-mercaptopropyl triethyl 0.3 kilogram of oxysilane, 1 kilogram of trimethylolpropane trimethacrylate, 0.9 kilogram of triallyl isocyanurate, and the preparation method is the same as in specific example 1.

[0037] The stretch-resista...

Embodiment 3

[0043] A component of a stretch-resistant insulated cable sheath, the formulation of each component is: 25 kg of chlorinated polyethylene, 10 kg of epichlorohydrin rubber, 2 kg of magnesium oxide, 0.5 kg of zinc oxide, N,N-bis(β- 0.6 kg of hydroxyethyl)-benzimidazolone, 1.0 kg of dibasic lead sulfate, 0.8 kg of tribasic lead sulfate, 0.4 kg of 4,4'-dioctyl diphenylamine, 0.4 kg of N-N-phenyl-p-phenylenediamine kg, 2,2,4-trimethyl-10.2 kg, N,N-dimethylaniline 0.25 kg, trioctyl trimellitate 4 kg, epoxy soybean oil 2 kg, 70# chlorinated paraffin 7 kg , 12 kg of high wear-resistant carbon black, 3 kg of antimony trioxide, 11 kg of hydrotalcite, 12 kg of ammonium polyphosphate, 4 kg of precipitated white carbon black, 6 kg of modified calcined nano clay, γ-mercaptopropyl triethyl 0.3 kilograms of oxysilane, 1.2 kilograms of trimethylolpropane trimethacrylate, 0.8 kilograms of triallyl isocyanurate, and the preparation method is the same as in specific example 1.

[0044] The stret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com