Method for preparing copper titanate bismuth sodium ceramic

A technology of copper bismuth sodium titanate and ceramics, which is applied in the field of preparation of copper bismuth sodium titanate ceramics, which can solve the problems of restricting the production and application of NBCTO ceramics, failing to meet high dielectric requirements, and the difference in dielectric properties, and achieve the effect of expanding interface transfer , increase the interface effect, good compactness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

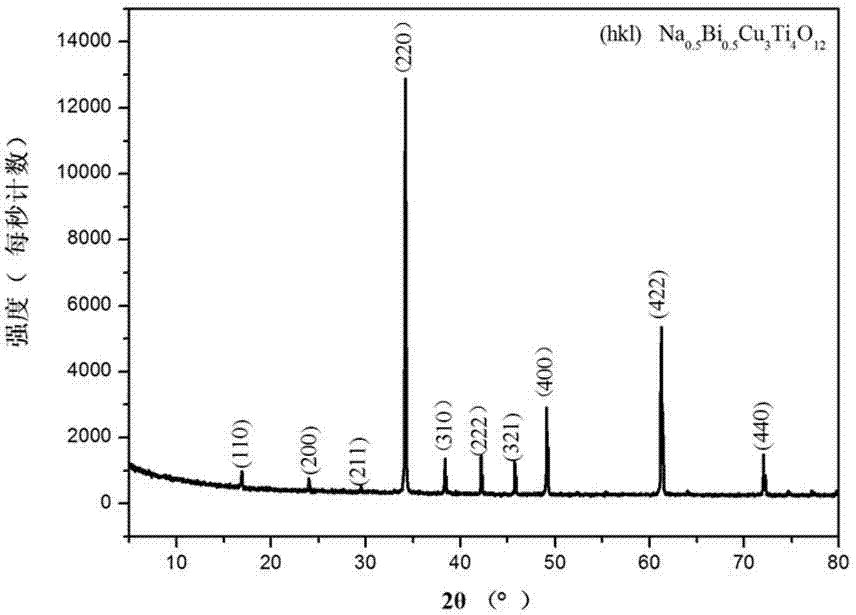

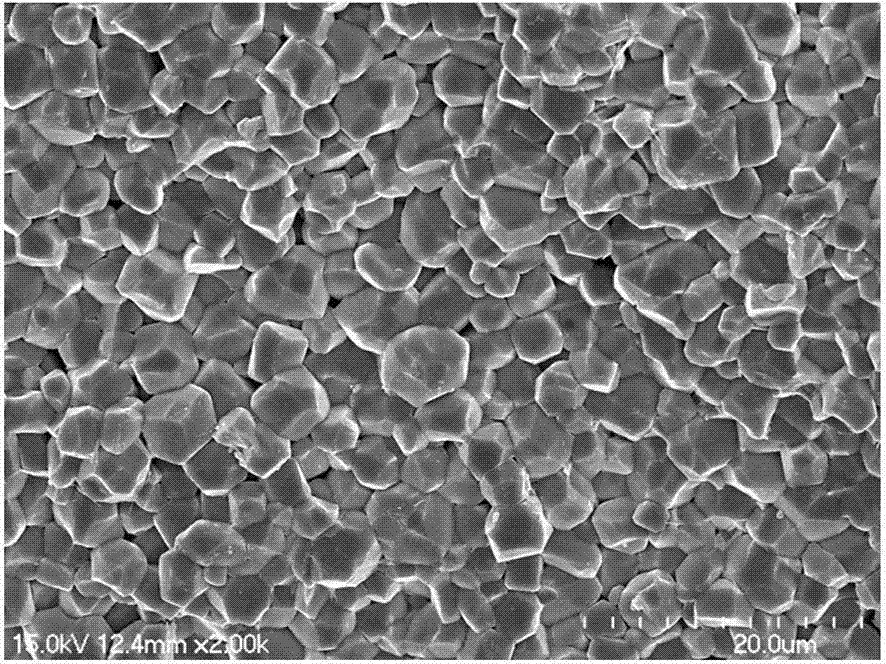

[0033] To prepare the general formula Na 0.5 Bi 0.5 Cu 3 Ti 4 o 12 The dielectric ceramic material 6.897 grams of expression is example, used raw material and preparation method thereof are as follows:

[0034] According to the general formula Na 0.5 Bi 0.5 Cu 3 Ti 4 o 12 The stoichiometry of raw materials were weighed Na 2 CO 3 0.265g, Bi 2 o 3 1.165g, CuO 2.387g, TiO 2 3.195g, 0.758g of NaCl, and 0.964g of KCl are mixed evenly, wherein the sum of the mass of NaCl and KCl is 20% of the total mass of the mixture. Put prepared materials into a ball mill jar, add ball milling medium agate balls and dispersing medium absolute ethanol, and mill at a speed of 120 rpm for 6 hours to fully mix them evenly. Separate the agate balls, dry the mixture in a drying oven at 70°C for 24 hours, pulverize it with agate platinum, put it into an alumina crucible, cover it, and calcinate at 700°C for 2 hours to obtain NBCTO ceramic powder containing chloride salts. The NBCTO cer...

Embodiment 2

[0036] To prepare the general formula Na 0.5 Bi 0.5 Cu 3 Ti 4 o 12 The represented dielectric ceramic material 6.897 grams is example, and used raw material and preparation method thereof are consistent with embodiment 1, wherein:

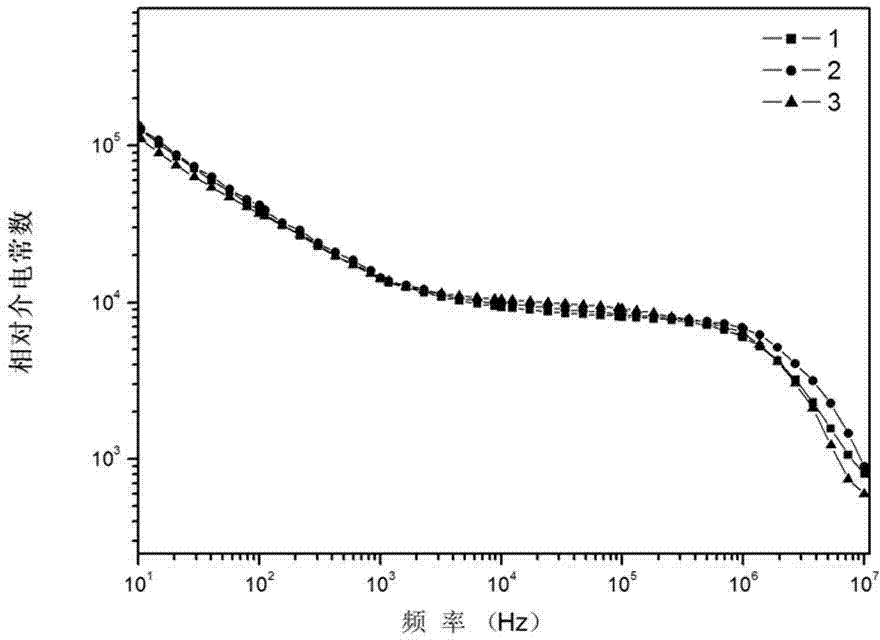

[0037] In the steps of this example, the pressed disc-shaped green body was sintered at 1020 ° C for 8 hours, and the other steps were the same as those in Example 1 to prepare Na 0.5 Bi 0.5 Cu 3 Ti 4 o 12 Giant dielectric ceramic materials. The two bottom surfaces of the sintered sample were made of silver electrodes, and the dielectric properties were tested, such as Figure 4 As shown, at 1KHz, the relative permittivity of NBCTO ceramics is 1.62×10 4 .

Embodiment 3

[0039] To prepare the general formula Na 0.5 Bi 0.5 Cu 3 Ti 4 o 12 The represented dielectric ceramic material 6.897 grams is example, and used raw material and preparation method thereof are consistent with embodiment 1, wherein:

[0040] In the steps of this example, the pressed disc-shaped green body was sintered at 1040°C for 12 hours, and the other steps were the same as those in Example 1 to prepare Na 0.5 Bi 0.5 Cu 3 Ti 4 o 12 Giant dielectric ceramic materials. The two bottom surfaces of the sintered sample were made of silver electrodes, and the dielectric properties were tested, such as Figure 5 As shown, at 1KHz, the relative permittivity of NBCTO ceramics is 1.57×10 4 .

[0041] As can be seen from the above figure, at room temperature, the relative permittivity of the NBCTO ceramics of the present invention can reach 1.4 × 10 at 1KHz. 4 , is superior to the properties of the existing NBCTO ceramics, which proves that the present invention obtains NBCT...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com