Preparation of CE:YAG glass-ceramics by combustion synthesis in hypergravity field

A technology of glass ceramics and supergravity field, which is applied in the field of combustion synthesis to prepare Ce:YAG glass ceramics, which can solve the problems of long preparation cycle, low YAG crystal phase content, and high production cost, and achieve short preparation cycle and high YAG crystal phase content , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

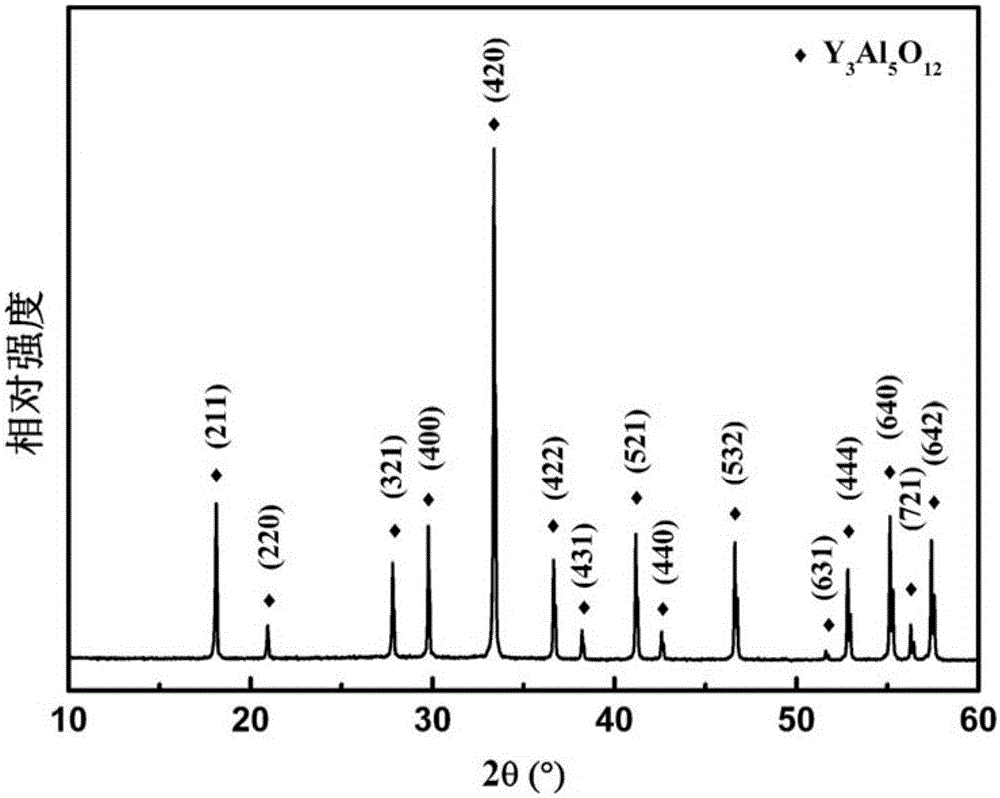

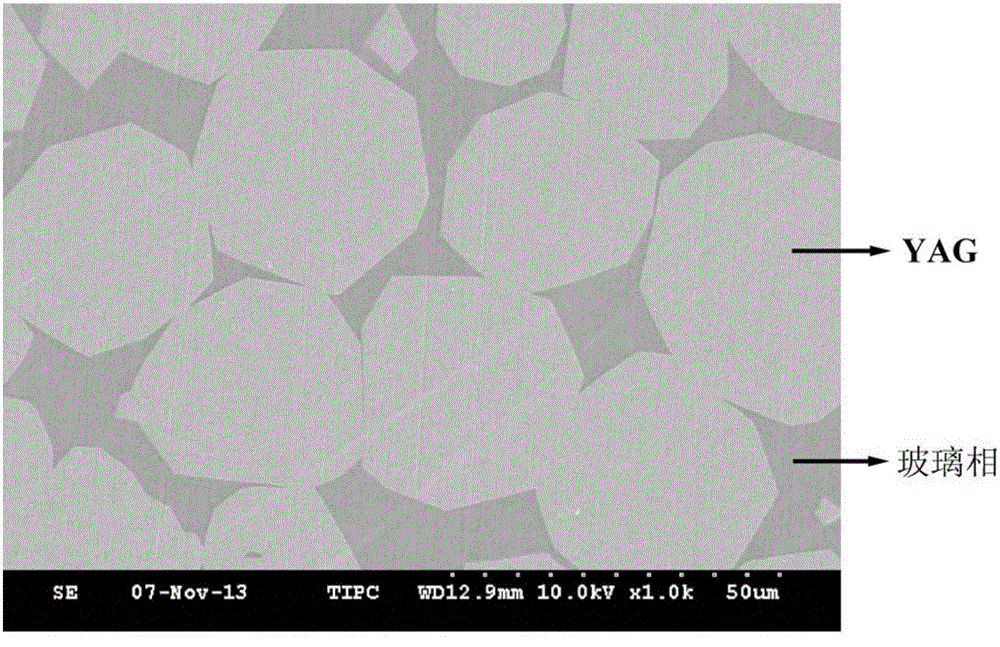

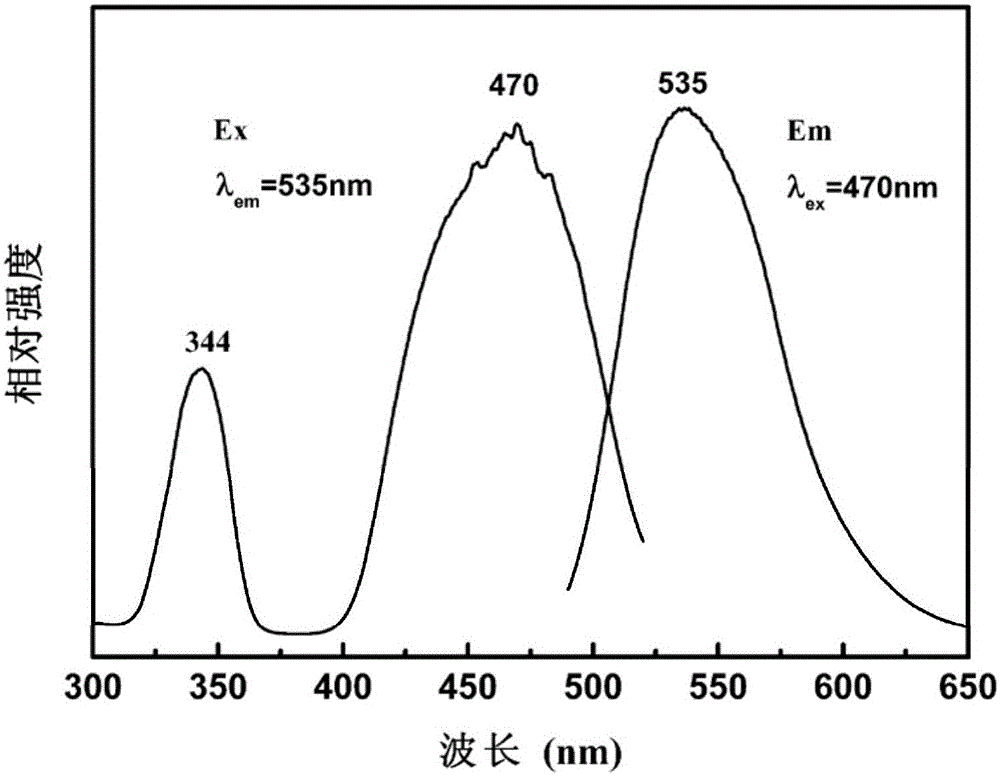

Embodiment 1

[0020] CuO, Al, Y 2 o 3 , SiO 2 , B 2 o 3 , CeF 3 The raw materials are uniformly mixed according to the proportions shown in Table 1 and compacted to obtain a thermite prefabricated block with a relative density of 60%, and the obtained thermite prefabricated block is put into a graphite crucible and placed in a high-gravity device; then In a supergravity field with a vacuum degree of 10Pa and a centrifugal force of 5000g, the heat generated by the electrified tungsten spiral wire induces a high-temperature thermite reaction between various raw materials in the thermite prefabricated block, and the product of the thermite reaction, the glass ceramic melt and Metal melts are rapidly separated, densified and cooled in a supergravity field to obtain glass-ceramic solids and metal solids, wherein the glass-ceramic solids are Ce:YAG glass-ceramics obtained by spontaneous crystallization of glass-ceramic melts during cooling.

[0021] Table 1

[0022] components

[...

Embodiment 2

[0025] CuO, Al, Y 2 o 3 , SiO 2 , B 2 o 3 , CeF 3 The raw materials are uniformly mixed according to the proportion shown in Table 2 and compacted to obtain a thermite prefabricated block with a relative density of 50%, and the obtained thermite prefabricated block is put into a graphite crucible and placed in a high-gravity device; then In a supergravity field with a vacuum degree of 500Pa and a centrifugal force of 3000g, the heat generated by the electrified tungsten spiral wire induces a high-temperature thermite reaction between various raw materials in the thermite prefabricated block, and the product of the thermite reaction, the glass ceramic melt and Metal melts are rapidly separated, densified and cooled in a supergravity field to obtain glass-ceramic solids and metal solids, wherein the glass-ceramic solids are Ce:YAG glass-ceramics obtained by spontaneous crystallization of glass-ceramic melts during cooling.

[0026] Table 2

[0027] components

[...

Embodiment 3

[0030] CuO, Al, Y 2 o 3 , SiO 2 , B 2 o 3 , CeF 3The raw materials are uniformly mixed according to the proportions shown in Table 3 and compacted to obtain a thermite prefabricated block with a relative density of 40%, and the obtained thermite prefabricated block is put into a graphite crucible and placed in a high-gravity device; then In a supergravity field with a vacuum degree of 1000Pa and a centrifugal force of 500g, the heat generated by the energized tungsten spiral wire induces a high-temperature thermite reaction between various raw materials in the thermite prefabricated block, and the product of the thermite reaction is the glass ceramic melt. Metal melts are rapidly separated, densified and cooled in a supergravity field to obtain glass-ceramic solids and metal solids, wherein the glass-ceramic solids are Ce:YAG glass-ceramics obtained by spontaneous crystallization of glass-ceramic melts during cooling.

[0031] table 3

[0032] components

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com