Patents

Literature

61results about How to "High crystal content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

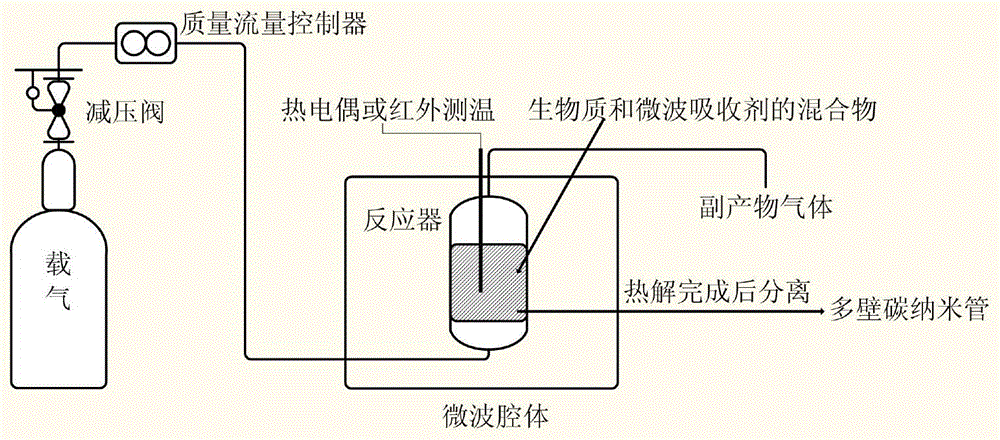

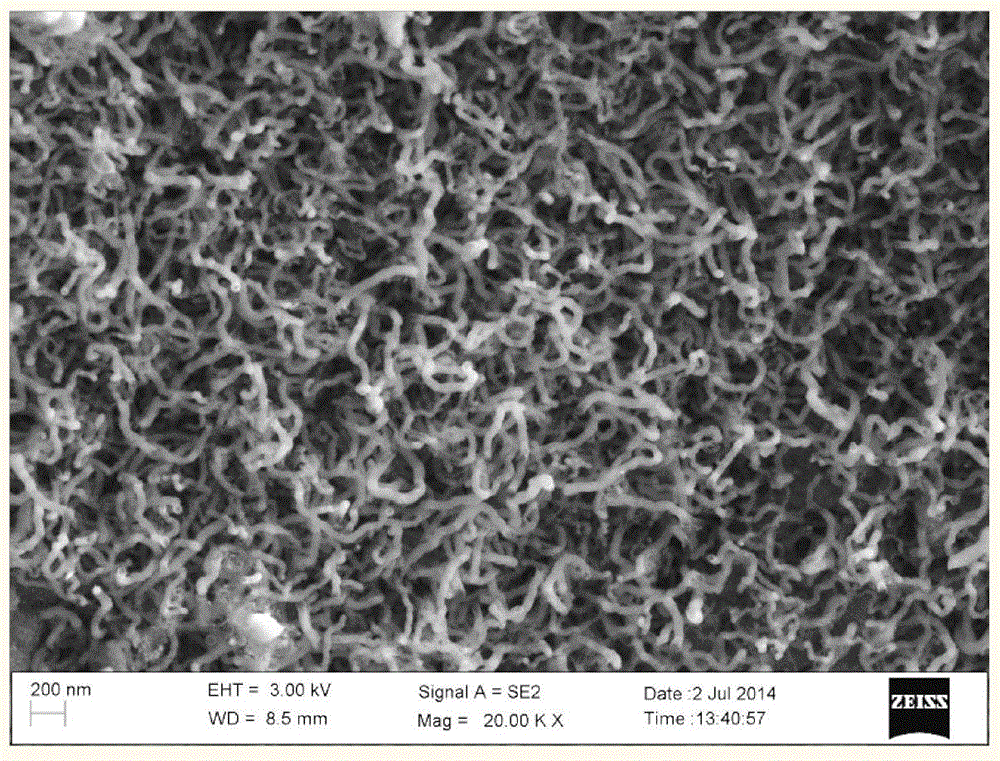

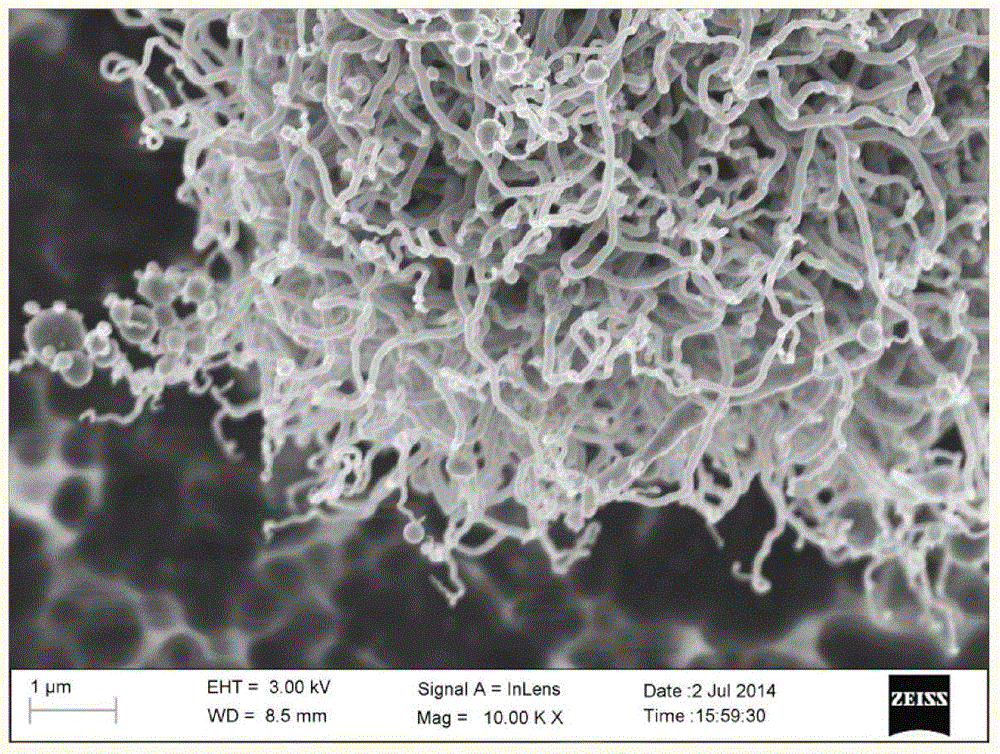

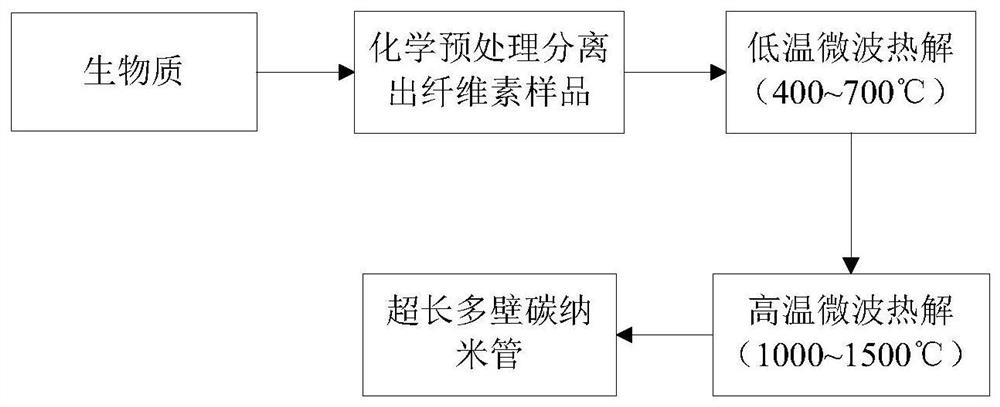

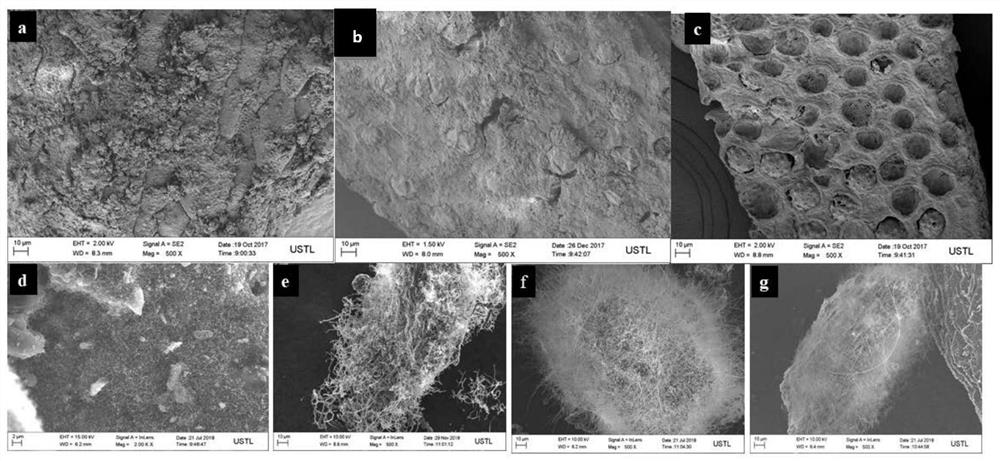

Method for preparing multiwalled carbon nanotube through microwave enhanced fast pyrolysis of biomass and/or carbonaceous organic waste

ActiveCN104787747AFast pyrolysisReduce manufacturing costMaterial nanotechnologyMean diameterMicrowave cavity

The invention discloses a method for preparing a multiwalled carbon nanotube through microwave enhanced fast pyrolysis of biomass and / or carbonaceous organic waste. The method comprises the following steps: biomass, carbonaceous organic waste, a mixture of the biomass and carbonaceous organic waste or a mixture of the biomass and carbonaceous organic waste uniformly mixed with a microwave absorbent is placed in a reaction vessel in a microwave cavity; an inert gas is introduced into the reaction vessel until an oxygen-free environment is formed; the microwave input power is adjusted to be higher than 500w, and the reaction vessel is heated to 400-1,500 DEG C for a pyrolytic reaction; the multiwalled carbon nanotube is obtained after the reaction. The method for preparing the multiwalled carbon nanotube is cheap and easy, the prepared carbon nanotube is curly, has the mean diameter of 3 nm-200 nm, can be applied to the fields of composites, electrode materials, catalyst preparation and the like and has a broad application prospect.

Owner:THE UNIV OF NOTTINGHAM NINGBO CHINA

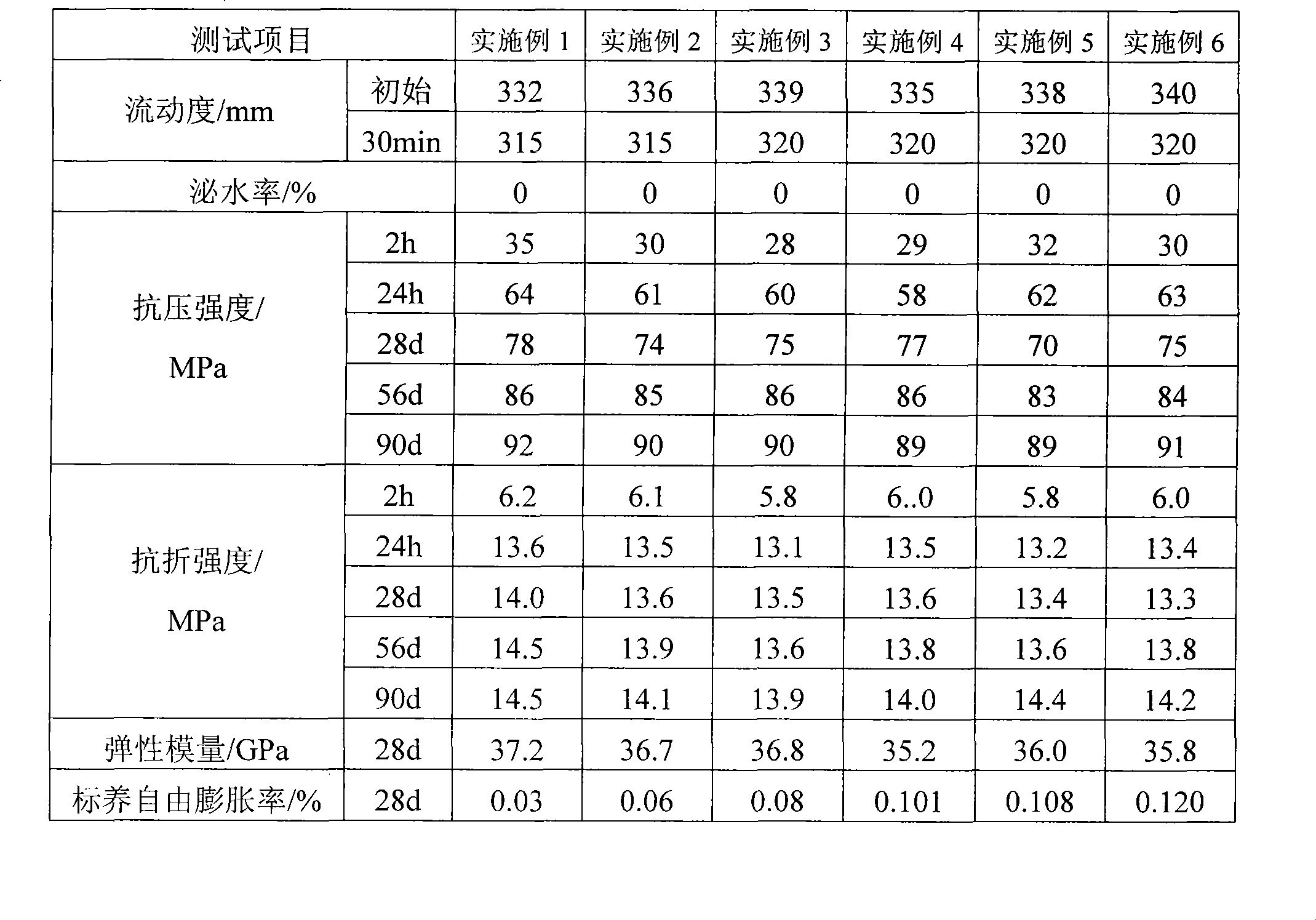

Expansion controllable ultra high-early strength support saddle mortar material

The invention relates to an expansion-controllable super early strength saddle sand pulp material which is prepared by the components with the weight percentage as follows: 36 to 50 percent of quick hardening cement, 0 to 10 percent of expansion admixture, 42 to 54 percent of quartz sand of 20 meshes to 100 meshes, 0.15 to 0.9 percent of retarder, 0.1 to 0.8 percent of early strength admixture, 0.3 to 0.6 percent of water reducing agent, 0.06 to 0.26 percent of foam killer, as well as 0.01 to 0.08 percent of fiber. The invention has the advantages of good liquidity, high early strength, good expansion filling performance, no reversed shrinking of later strength, convenient use and the like, is suitable for the construction under various environment conditions (including low and subzero temperature as well as high temperature conditions), can be used for quickly repairing the foundation grouting, concrete structures and pavements of various devices, and is suitable for the gravity grouting of the prefabricated bridge basin-type rubber saddle of a passenger dedicated line in particular.

Owner:JIANGSU SOBUTE NEW MATERIALS

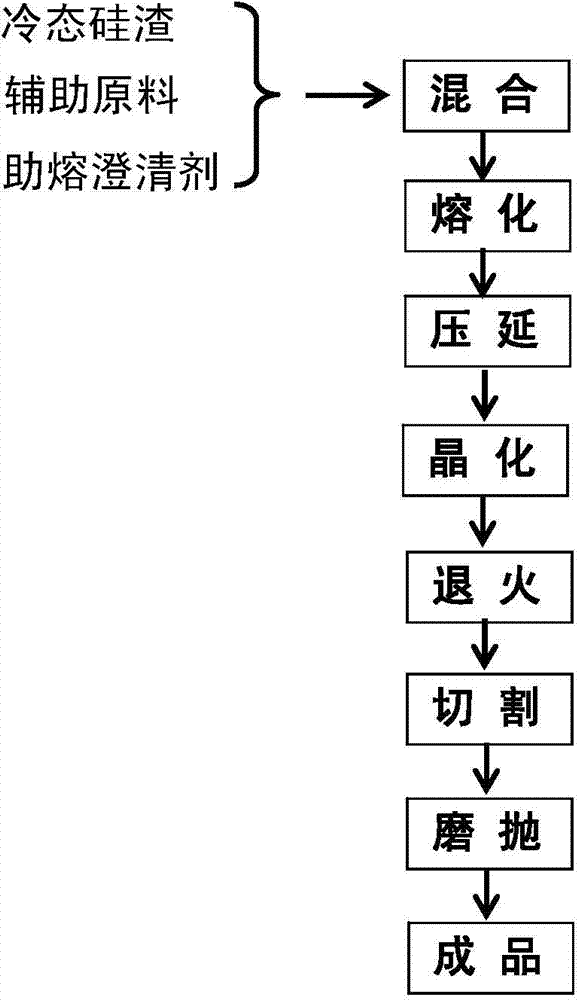

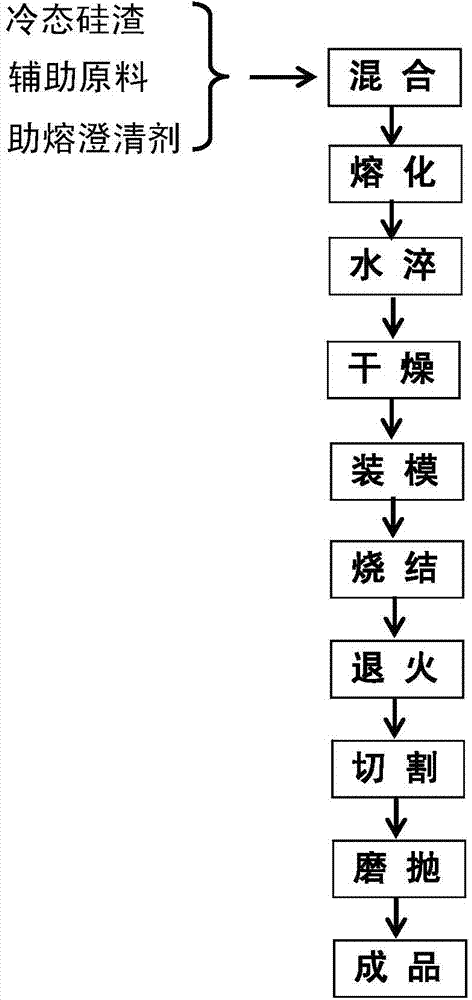

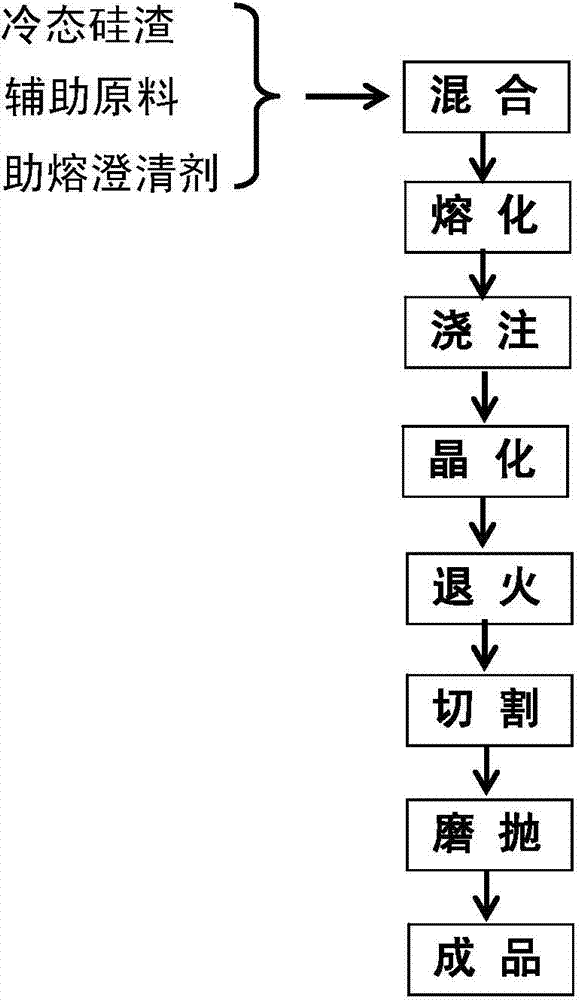

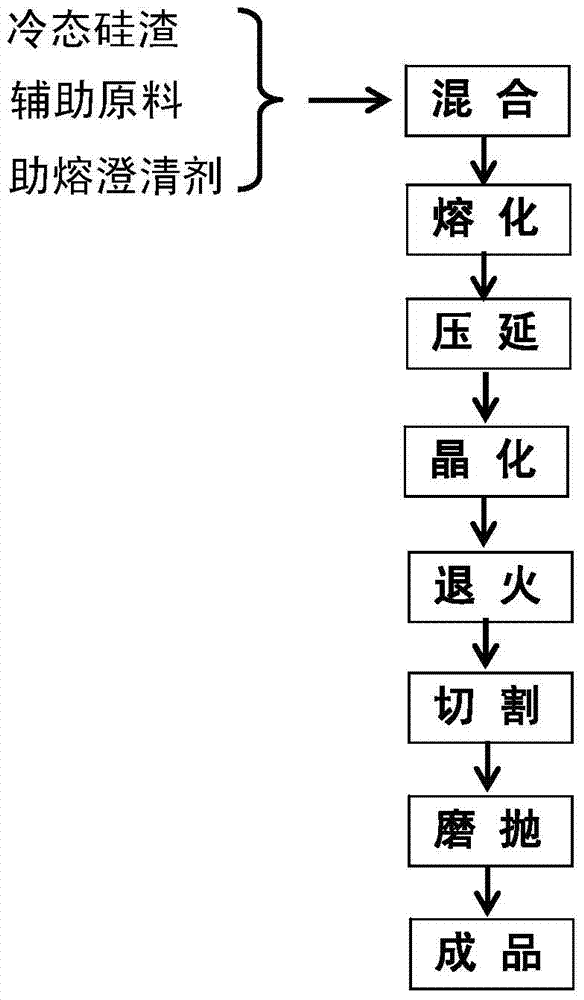

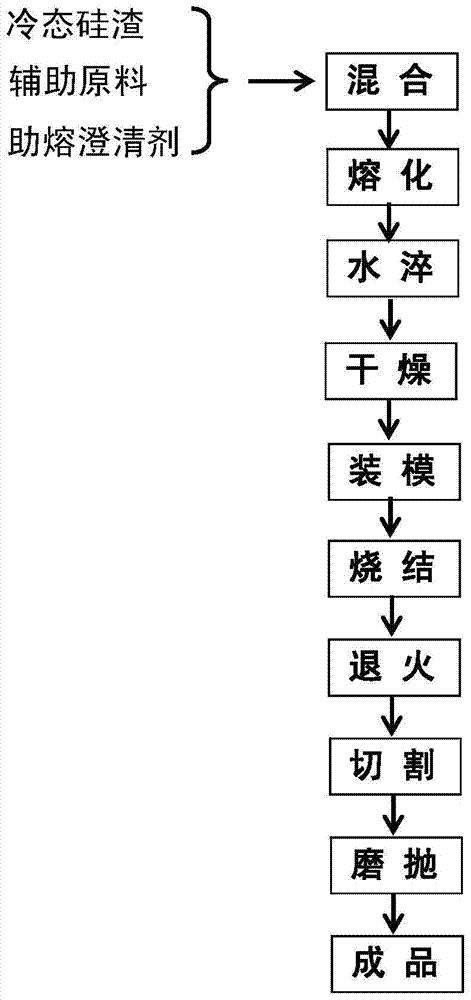

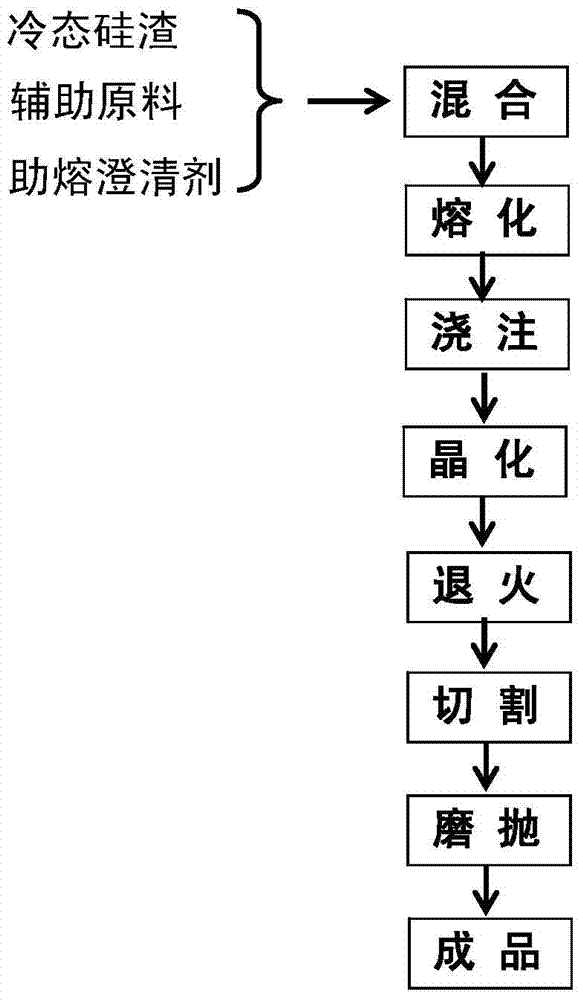

Silicon-slag microcrystalline glass and preparation method thereof

The invention relates to silicon-slag microcrystalline glass and a preparation method thereof. Silicon smelting waste slag is taken as a major raw material, and silicon dioxide or silica sand (SiO2), fluorite (CaF2), limestone or calcite (CaCO3), industrial sodium carbonate (Na2CO3), zinc oxide (ZnO) and potassium carbonate (K2CO3) are taken as auxiliary raw materials, wherein the dosage of the silicon smelting waste slag in the raw materials of the microcrystalline glass is 26.0-75.0wt%. The preparation method specifically comprises the following steps of: evenly mixing cold-state silicon slag with other auxiliary raw materials in a blender mixer to obtain a basic mixed batch, melting the basic mixed batch into qualified glass liquid in a melting furnace, and then performing calendering, casting or water quenching on the glass liquid to form a basic glass plate or granules; finally, subjecting the basic glass plate to crystallization heat treatment to obtain the microcrystalline glass. The density of the microcrystalline glass is 2.5-2.8 g / cm<3>, the rupture strength of the microcrystalline glass is 30.0-103.5 MPa, the compressive strength of the microcrystalline glass is 70.0-903.0 MPa, the Moh's hardness of the microcrystalline glass is 5-8 and the abrasive resistance of the microcrystalline glass is 0.063-0.15 g / cm<2>; the silicon-slag microcrystalline glass can be widely applied to the fields such as chemical engineering, metallurgy, architectural ornament, petroleum, mine and machinery.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

High-strength wear-resistant engineering microcrystalline glass prepared by using granite waste materials and preparation method thereof

InactiveCN102942303AImprove physical and mechanical propertiesSmall sizeChemical industryWear resistant

The invention discloses high-strength wear-resistant engineering microcrystalline glass prepared by using granite waste materials and a preparation method thereof. The microcrystalline glass disclosed herein comprises 10.0-55.0wt% of granite waste materials as the main raw material, and comprises SiO2, CaF2, CaCO3, ZnO, K2CO3, etc. as the auxiliary raw materials. The preparation method comprises the following steps: crushing the granite waste materials, uniformly mixing the crushed granite waste materials with other raw materials in a mixer to obtain a base mixed batch, using a tank furnace to carry out high temperature melting on the base mixed batch to obtain qualified liquid glass, carrying out calendaring, casting or water quenching on the liquid glass to form a base glass plate (or pellets), and carrying out crystallization heat treatment on the base glass plate (or pellets) to obtain the microcrystalline glass. The microcrystalline glass has a density of 2.5-2.8g / cm<3>, a flexural strength of 30.0-103.5MPa, a compressive strength of 70.0-903.0MPa, a Moh's hardness of 5-8, and a wear resistance of 0.063-0.15g / cm<2>, has the advantages of high strength, good toughness, strong wear resistance and corrosion resistance, and excellent cutting machinability, and an be widely applied in the fields of chemical industry, metallurgy, building decoration, petroleum, etc.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Medical fluorinated calcium phosphate coating material and its prepn process

InactiveCN1486751AHigh phase purityIncrease profitMetallic material coating processesCalcium phosphate coatingPhosphoric acid

The present invention relates to one kind of medical material used for hard tissue. It consists of medical base body and surface fluorinated calcium phosphate coating, which is fluorinated hydroxyapatite, fluorinated calciprivic hydroxyapatite, fluorinated tricalcium phosphate or carbonate radical substituted hydroxyapatite. During the preparation, alcohol solution of the mixture of alcohol soluble calcium salt and phosphate or partially esterified phosphoric acid is used as precursor and surface coating is formed on alumina ceramic or medical metal base body via conventional sol-gel soaking pulling process, rotary painting process, combined soaking pulling and centrifuging process or hot solution spraying process. The coating has high crystalline phase content, no impurity phase and high phase purity. The preparation process of th present invention can obtain coating with thickness adjustable from several hundred nanometers to several decade microns.

Owner:ZHEJIANG UNIV

Preparation method for ultrahigh molecular weight polyethylene/biomass nanocrystal composite fibers

ActiveCN102383213AImprove mechanical propertiesHigh strengthMonocomponent polyolefin artificial filamentArtifical filament manufactureFiberWater baths

The invention relates to a preparation method for ultrahigh molecular weight polyethylene / biomass nanocrystal composite fibers. According to the method, fibrous biomass nanocrystals and stearic acid whose end groups have undergone acyl chlorination are prepared at first, wherein, the fibrous biomass nanocrystals are cellulose nanocrystals or chitin nanocrystals, and the stearic acid whose end groups have undergone acyl chlorination is prepared by subjecting stearic acid to stirring-reflux in the solvent of thionyl chloride and removing the solvent through extraction; the fibrous biomass nanocrystals are dispersed in the solvent of dichloromethane through ultrasonic dispersion and added into the stearic acid whose end groups have undergone acyl chlorination, and stirring-reflux is carried out to obtain stearic acid surface grafted biomass nanocrystals; the obtained biomass nanocrystals are blended into a swollen spinning solution of an ultrahigh molecular weight polyethylene resin, gelfibers are obtained by subjecting an obtained mixture to spinning with a metering pump and a spinneret and to fixation in water bath, and the gel fibers are subjected to multistage hot-stretching after extraction and drying so as to obtain a finished product. The method provided in the invention enables mechanical properties of fibers to be improved and high-strength and high-modulus ultrahigh molecular weight polyethylene fibers to be obtained.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Biological medical material with biological responding coating and preparing method

InactiveCN1743014AHigh crystal contentHigh phase purityCoatingsFlagellar basal bodyBiomedical engineering

The present invention discloses a biological medical material with biological resposibility coating layer and its preparation method. It is formed from medical basal body and metal-iron-doped fluorine-contained hydroxy apatite nano coating layer coated on the surface of medical basal body. Said biological medical material can stimulate osteoblast differentiation and proliferation in early stage of implatation, can promote growth of bone and can accelerate cure process. Said invention also provides the concrete steps of its preparation method.

Owner:ZHEJIANG UNIV

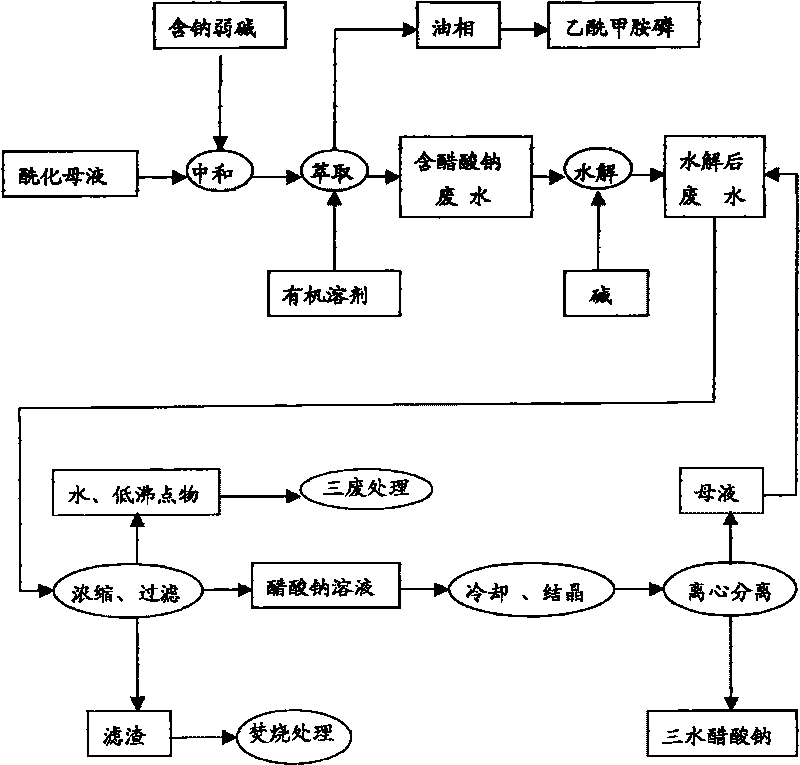

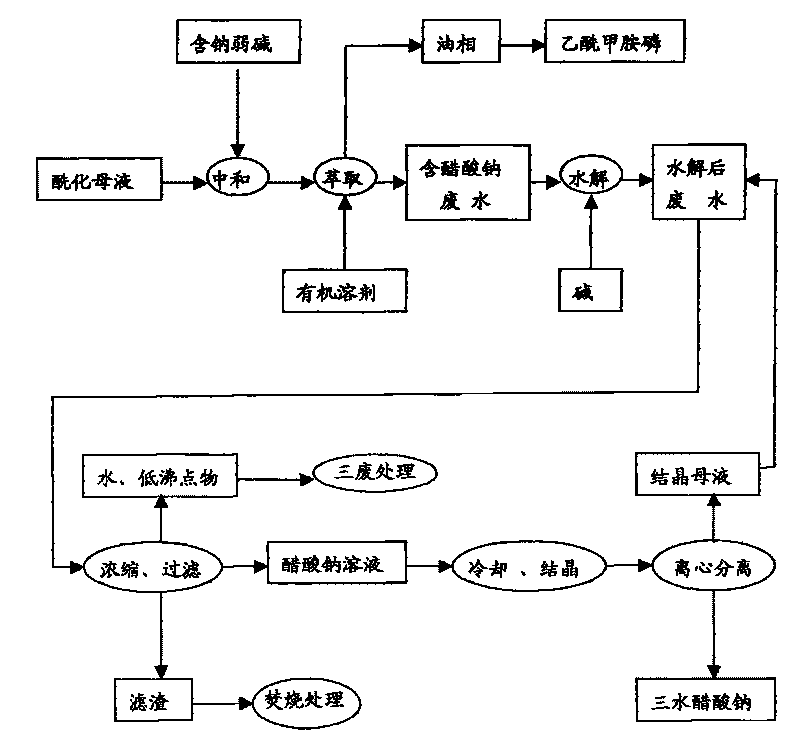

Process for post-treatment of acephate and method for recovering waste water resources

InactiveCN101735268AEmission reductionHigh crystal contentGroup 5/15 element organic compoundsMultistage water/sewage treatmentSolventChemistry

The invention provides a process for post-treatment of acephate and a method for recovering waste water resources. The process comprises the following steps of: a, using sodium-containing weak alkali to neutralize acidylated mother liquor; b, adding a solvent into the mother liquor for extraction, separation and recovery of acephate; c, adding alkali into the sodium acetate-containing waste water obtained by the step b to hydrolyze organic matters remained in the waste water into low-boiling point organic matters or salts; d, condensing the hydrolyzed waste water, wherein in the condensing process, the low-boiling point organic impurities are distilled out along with water, and the salts and other impurities which are generated by hydrolysis are separated by crystallization; and filtering condensed solution to obtain the solution of sodium acetate, which is more pure; and e, performing cooling crystallization and centrifugal separation of the solution of sodium acetate to obtain sodium acetate trihydrate crystals. The method has the advantages that: the emission of ammonia nitrogen is reduced from the source, and the acephate is effectively separated and recovered; the solution of sodium acetate is purified by means of hydrolysis and condensation, the crystal content of sodium acetate trihydrate is as high as 58 to 60 percent and meets the industrial grade requirement, so that the method can be widely applied in industries of weaving, dyeing, dyes and the like.

Owner:浙江嘉化集团股份有限公司

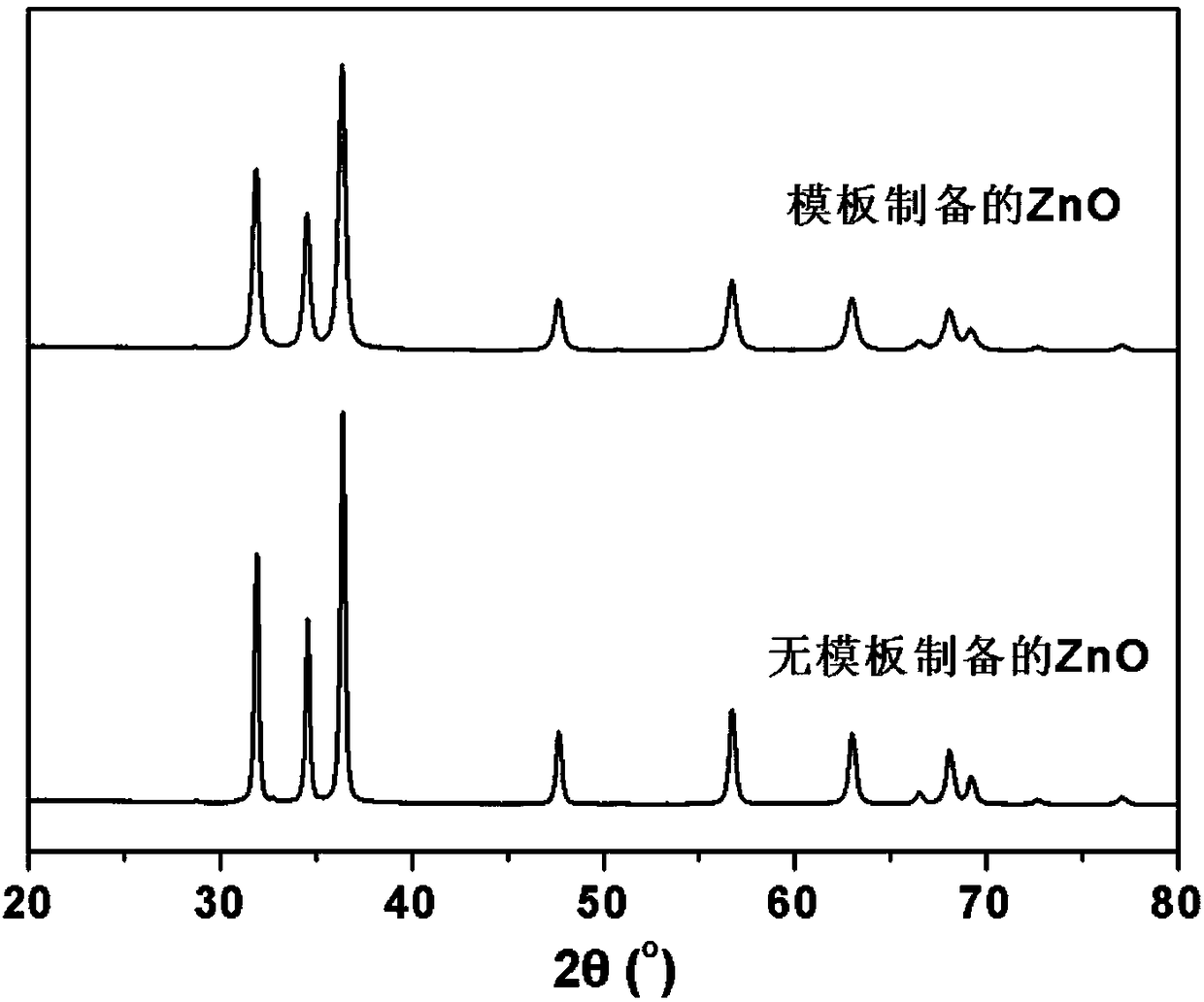

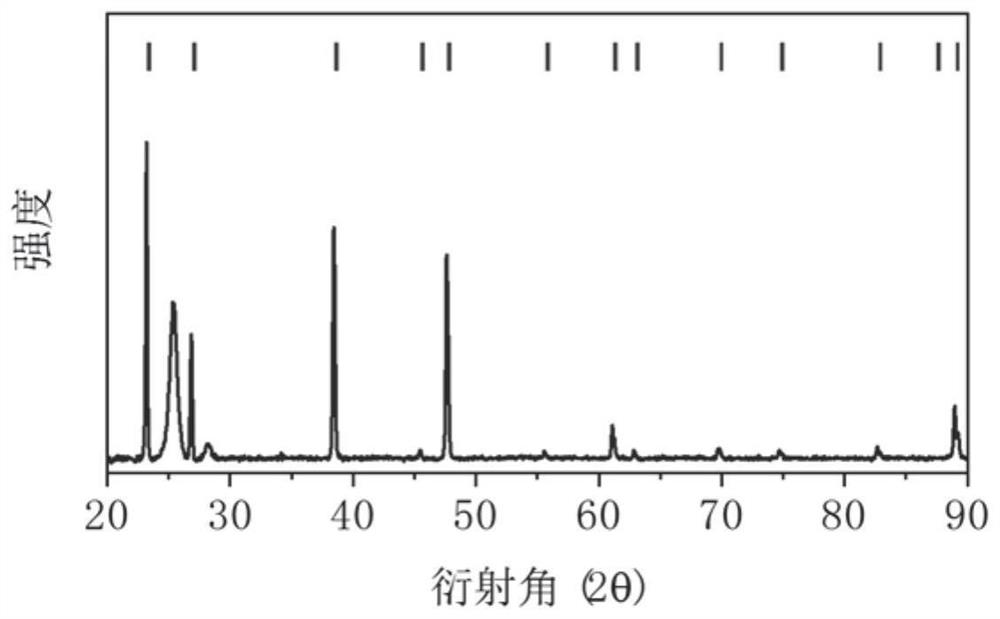

Preparation method of zinc oxide nanocrystal

ActiveCN108128800AHigh crystal contentIncrease the areaZinc oxides/hydroxidesChemical industryPolymer science

The invention belongs to the field of a chemical industry, and particularly relates to a preparation method of a zinc oxide nanocrystal, so that the photocatalytic activity of zinc oxide is improved.The method comprises the steps of firstly preparing TEMPO oxidized cellulose, then respectively grafting a polymer containing carboxyl, a polymer containing sulfonyl, or a polymer containing an epoxygroup through a heterogeneous free radical polymerization method, preparing to obtain modified TEMPO oxidized cellulose, then adopting the modified TEMPO oxidized cellulose as a template, adsorbing aprecursor zinc acetate of zinc oxide, obtaining cellulose / zinc oxide compound under hydrothermal reaction, calcining to remove the template, and finally obtaining the zinc oxide nanocrystal. The ZnOnanocrystal prepared through the method provided by the invention can replace an existing ZnO photocatalytic material, has the characteristics of high wurtzite crystal form content, large specific surface area and large pore volume, shows a better photocatalytic performance, is simple in preparation process, and belongs to an environment-friendly material.

Owner:SHANDONG HUATAI PAPER

Wet sintering production method for alumina-based magnesium aluminate spinel

The invention belongs to the technical field of refractory material production, in particular to a wet sintering production method for alumina-based magnesium aluminate spinel. The method comprises the following steps: preparing 50-80% alumina and 20-50% caustic-calcined magnesite by mass percent; adding water of which the mass is 1.2-1.5 times of the total mass of the alumina and the caustic-calcined magnesia, and 0.1-0.3% polyvinyl alcohol, obtaining slurry A by grinding; allowing the slurry A to be subject to dehydration, vacuum pugging, drying and sintering to obtain the alumina-based magnesium aluminate spinel. According to the invention, a traditional dry production technology is changed. The prepared alumina-based magnesium aluminate spinel is high in crystalline phase content, large in volume density and low in water absorption rate.

Owner:SANMENXIA XINYANGSHAO SYNTHETIC MATERIALS

Crystallization method for sucralose

InactiveCN102977157AHigh crystal contentEasy to operateSugar derivativesSugar derivatives preparationTO-18Organic solvent

The invention relates to a crystallization method for sucralose, which comprises the following steps of: (1), confecting a sucralose saturated solution under the condition of 60 DEG C to 80 DEG C; (2), filtering the sucralose saturated solution obtained in the step (1), thereby obtaining a filtered clear solution; (3), reducing the temperature of the filtered clear solution to 55 DEG C within 3 hours, then reducing the temperature to 18 DEG C with the cooling rate of 5 DEG C each two hours, and stopping cooling when the temperature is reduced to 18 DEG C; and (4), standing and filtering, thereby obtaining sucralose crystals. The crystallization method provided by the invention is simple in operation, an organic solvent is not required in the crystallization process, the obtained sucralose has no solvent residue, the filtrate obtained in filtering the sucralose crystals can be directly recycled without being treated, and the final waste solution can be exhausted directly, thus the process is reduced and the cost is saved. The sucralose crystals obtained according to the invention has high content, large crystal particle and shining crustal surface, and granulation equipment is not required, thus the crystallization method is beneficial for industrial production.

Owner:LIYANG WEIXIN CHEM

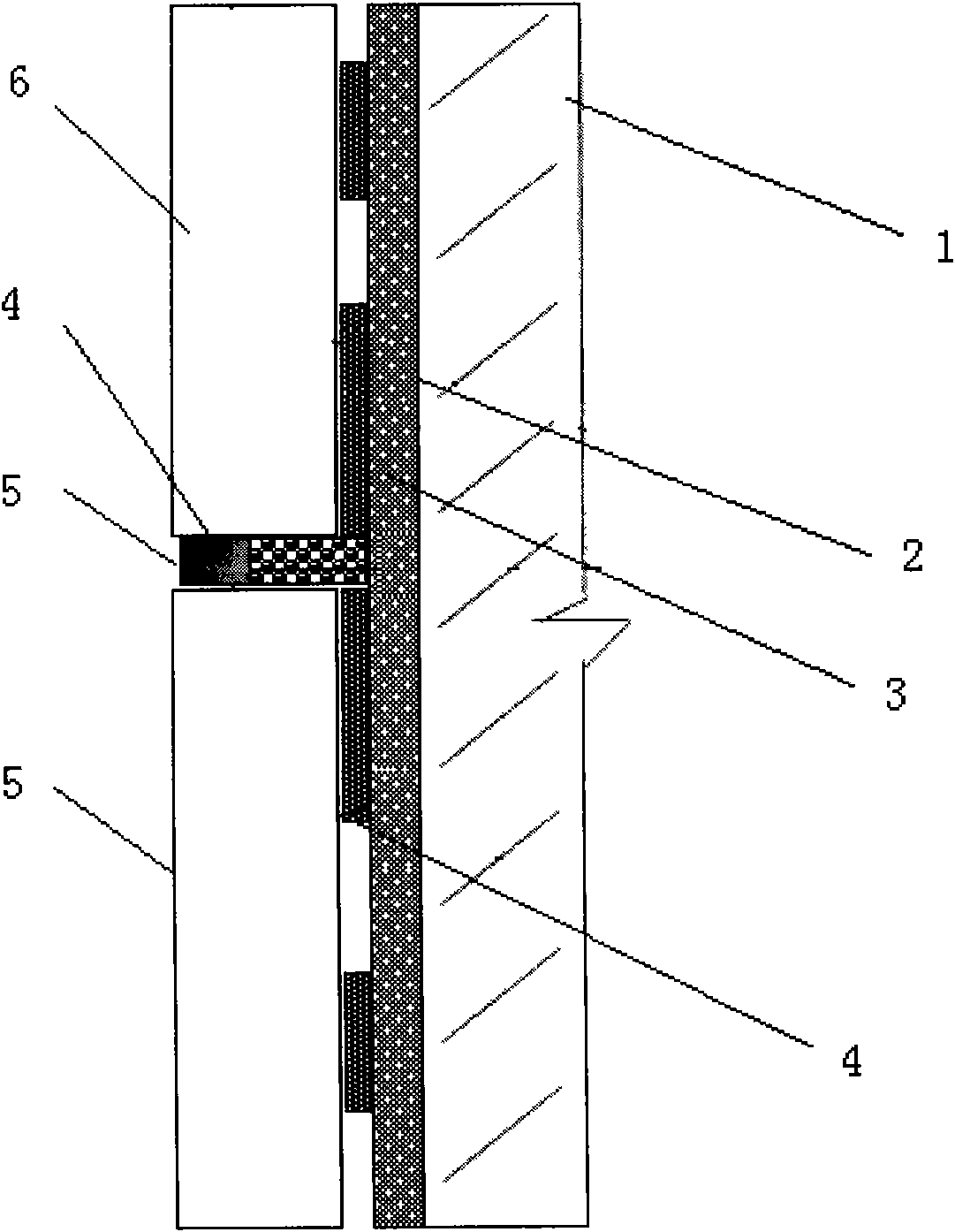

Dinging structure and dinging method for novel heat preservation and insulation building

InactiveCN101638930ARealization of thermal insulation functionLow thermal conductivityCovering/liningsPorosityCrack resistance

The invention discloses a dinging structure and a dinging method for a novel heat preservation and insulation building. The dinging structure is characterized in that the inside of the wall body (1) of a basic wall body is provided with a mortar levelling layer (2), a heat preservation and insulation layer (3), an anti-crack motor layer (4), an elastic water repellent facing layer (5) and a heat preservation and insulation decorative sheet layer (6), wherein the heat preservation and insulation layer (3) and the heat preservation and insulation decorative sheet layer (6) are made of the same material; and the heat preservation and insulation layer (3) can be made from foaming polystyrene / extruded polystyrene or made from polyurethane directly by foaming. The dinging method comprises the following steps: a, calking joints with a heat preservation and insulation material; b, extruding the anti-crack mortar into the joints; and c, treating the water repellent facing layer. The dinging structure and the dinging method have the advantages of increasing the crystal content of a mortar system, filling or blocking slit pores, reducing the porosity greatly, generating volume expansion, generating compression stress and compression strain in a body, compensating for various contraction distortions, and counteracting or partially counteracting corresponding pulling stress, thereby improving the overall cracking resistance and having the advantages of good heat insulation and preservation effect, strong anti-crack resistance and water resistance, good decorative performance, simple and convenient construction and the like.

Owner:武汉公济墙体节能材料有限公司

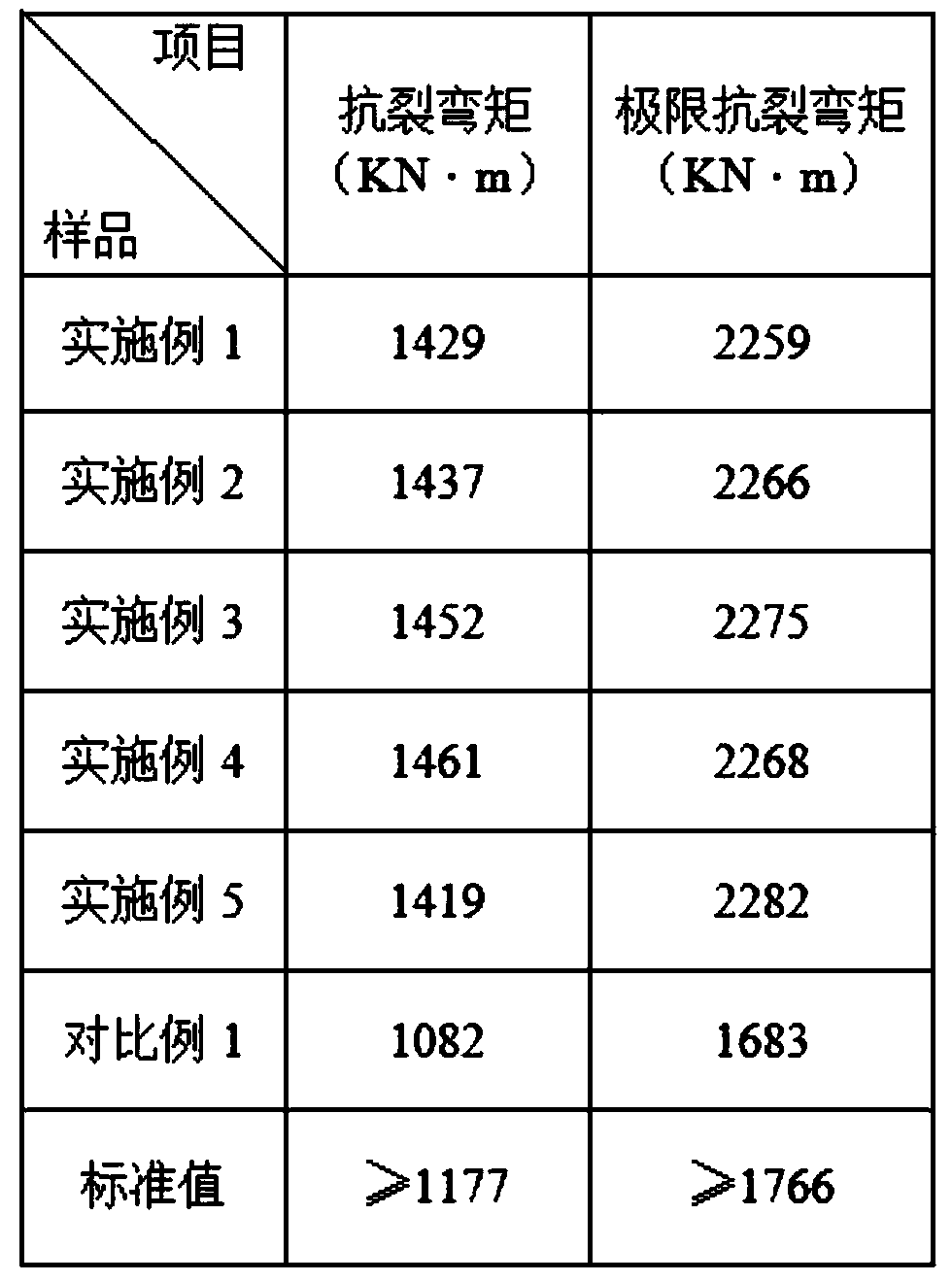

Photovoltaic anti-cracking cement pipe pile and preparation method thereof

InactiveCN109320169ASimple internal structureHigh affinityShaping reinforcementsCement mixing apparatusWork in processConstruction aggregate

The invention discloses a photovoltaic anti-cracking cement pipe pile and a preparation method thereof. The anti-cracking cement pipe pile is prepared from the following components: an aggregate, cement, an admixture, an additive, an anti-cracking component and water. The preparation method of the cement pipe pile comprises the steps of weighing the aggregate and the admixture, stirring, and uniformly mixing to obtain a first mixture; weighing the cement and the additive, adding water, stirring, and uniformly mixing to obtain a second mixture; adding the first mixture into the second mixture,stirring, and uniformly mixing to obtain concrete; putting the concrete into a mold, stretching and drawing, and centrifugally forming obtain a concrete pipe pile semi-finished product; maintaining the concrete pipe pile semi-finished product, demolding, and naturally maintaining to obtain a concrete pipe pile finished product. The experiment result shows that the prepared concrete pipe pile has an excellent anti-cracking ability.

Owner:泰州市恒瑞管桩有限公司

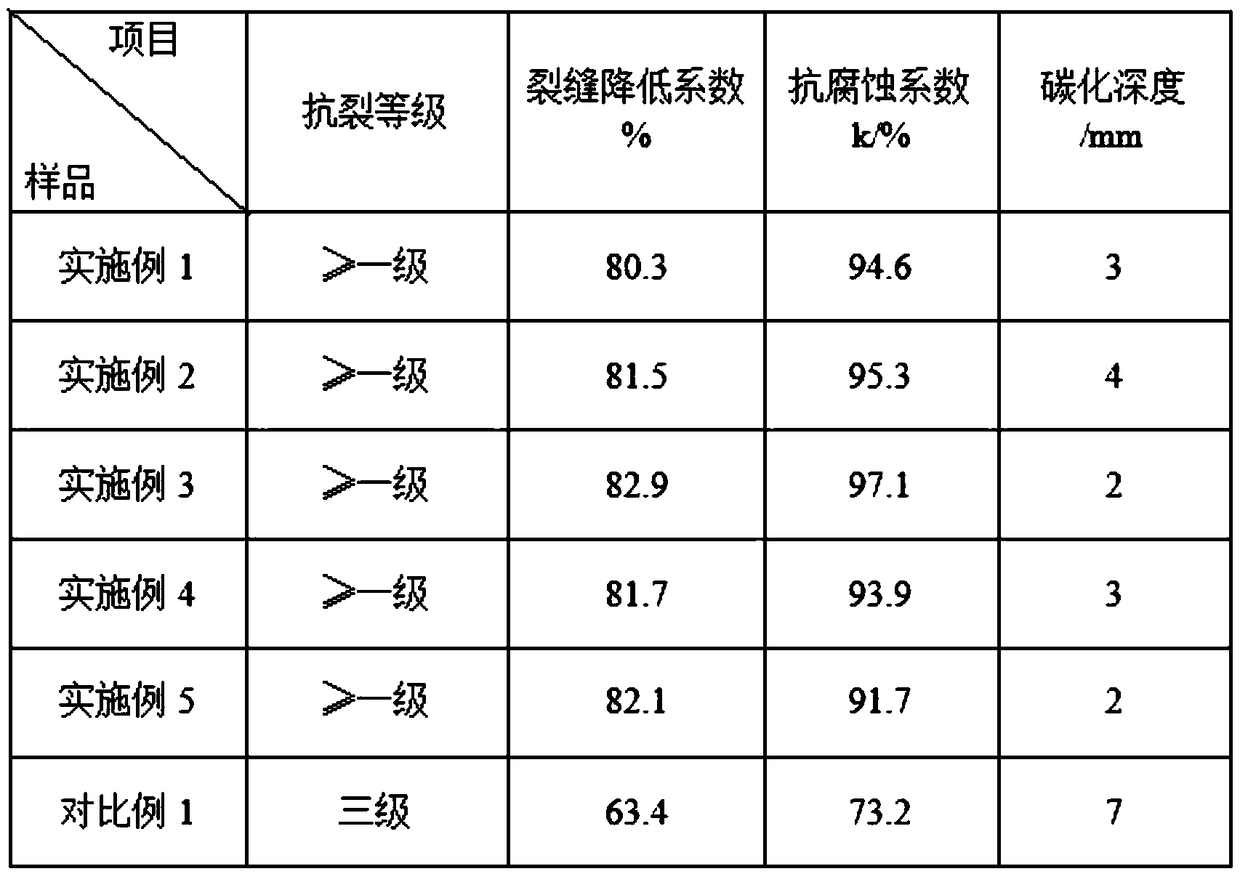

Method for preparing super-long multi-walled carbon nanotube from biomass through two-step microwave treatment

The invention discloses a method for preparing a super-long multi-walled carbon nanotube from biomass through two-step microwave treatment. The method comprises the following steps: (1) separating a cellulose sample from the biomass through a chemical pretreatment method; (2) carrying out low-temperature microwave pyrolysis on the cellulose sample to generate a biochar sample containing carbon nanotubes; and (3) carrying out high-temperature microwave pyrolysis on the biochar sample to prepare the super-long multi-walled carbon nanotube. According to the method, a thin metal (Ni, Mo, Fe, Co and the like) substrate does not need to be used, various hydrocarbons (ethane, methane, acetylene, xylene or a mixture thereof and the like) are replaced by biomass, and the super-long multi-walled carbon nanotube with high graphene crystal content (about 0.97), the length of more than or equal to 1cm and the diameter of 200-400nm is prepared by only adopting microwave heating. The method solves the problems of complex process, high cost, short carbon nanotubes, many defects and the like in the prior art for preparing the super-long multi-walled carbon nanotubes.

Owner:UNIV OF SCI & TECH LIAONING

Production method of high-strength wear-resistant complex-phase poly-crystal engineering plate

The invention discloses a production method of a high-strength wear-resistant complex-phase poly-crystal engineering plate, and relates to the technical field of production of artificial stone materials or part of engineering materials. The method comprises the following steps: mixing calcium-based wastes, auxiliary raw materials and a fluxing clarifying agent, hotly melting, homogenizing and clarifying to form a high-temperature melting body, performing calendering, pouring or water quenching on the high-temperature melting body to prepare a basic amorphous plate or granules, and crystallizing to form the high-strength wear-resistant complex-phase poly-crystal engineering plate. According to the method, the solid wastes are comprehensively utilized; the high-strength wear-resistant complex-phase poly-crystal engineering plate is good in physical and mechanical properties and excellent in processing property, can replace the natural stone materials or the part of engineering materials, is superior to the natural stone materials or the part of engineering materials in physical and mechanical properties and chemical stability, and can be widely applied in the fields of chemical industry, metallurgy, building decorations, petroleum and the like.

Owner:NANTONG MING YU NEW MATERIAL TECH CO LTD +1

Fibre-reinforced anti-crack mortar dry powder

The invention provides a fiber mortar dried powder material for strengthening the anti-crack, which comprises functionality the materials of cement, sand, silicon aluminum hollow spheroid, alkali proof fiber, mineral contraction inhibitor, cement hydration regulation agent, modifier and so on. Wherein, the cement hydration regulation agent comprises cement hydration slow hardening components and molding moisture and negative setup components. The mortar dried powder material for strengthening the anti-crack is able to be used through adding water to solve the problem of inaccurate calculation and material wasting of the traditional method owing to the preparation of the material in the scene. The prepared mortar solves the problem of crack owing to the stress of the ordinary mortar. The invention has the advantages of molding moisture, slow hardening, waterproof and easy construction, which is mainly used as the anti-crack mortar for the construction of heat preservation and heat insulation wall and also other construction walls.

Owner:武汉科华高新材料发展有限公司

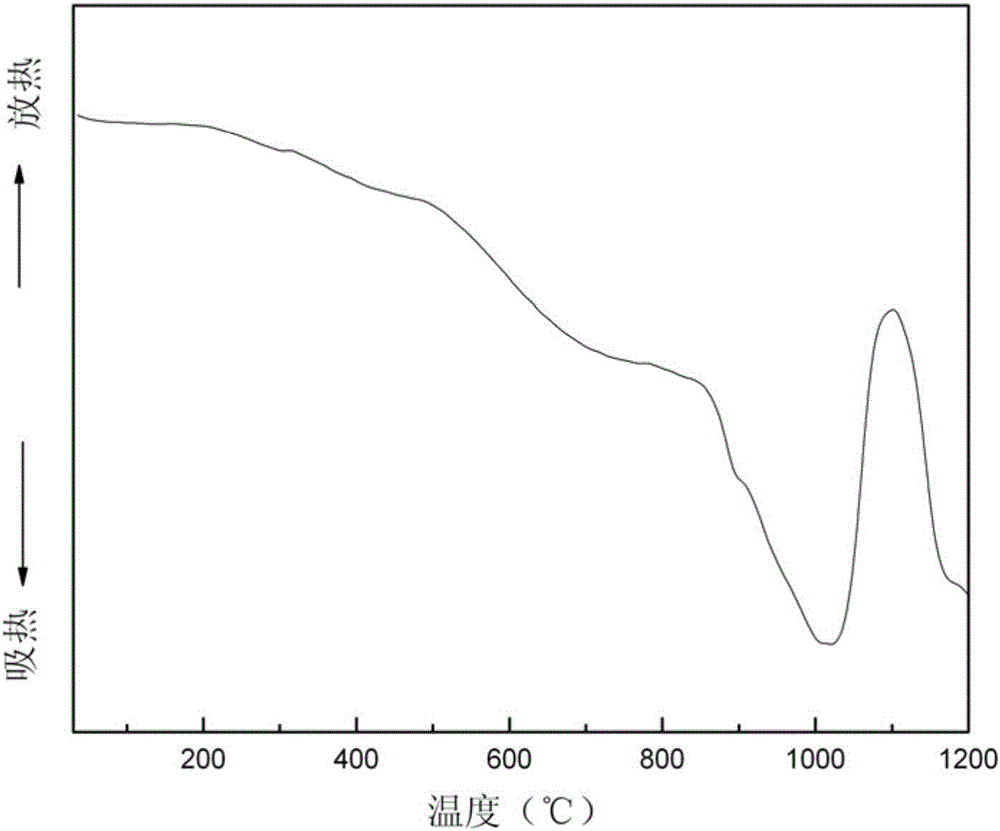

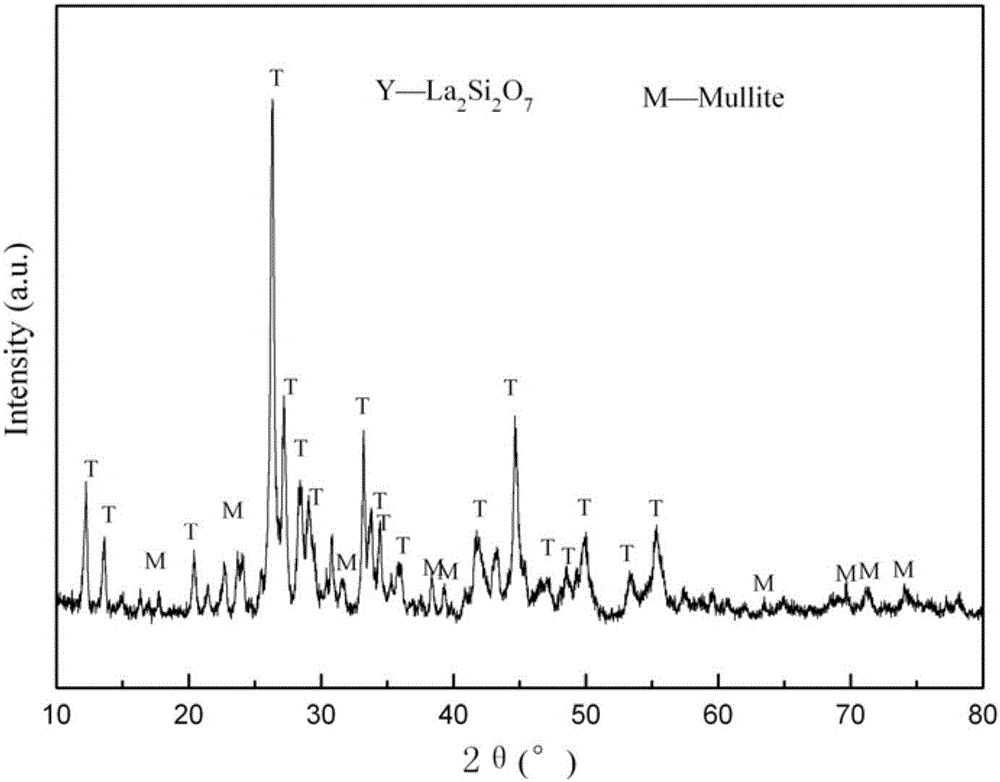

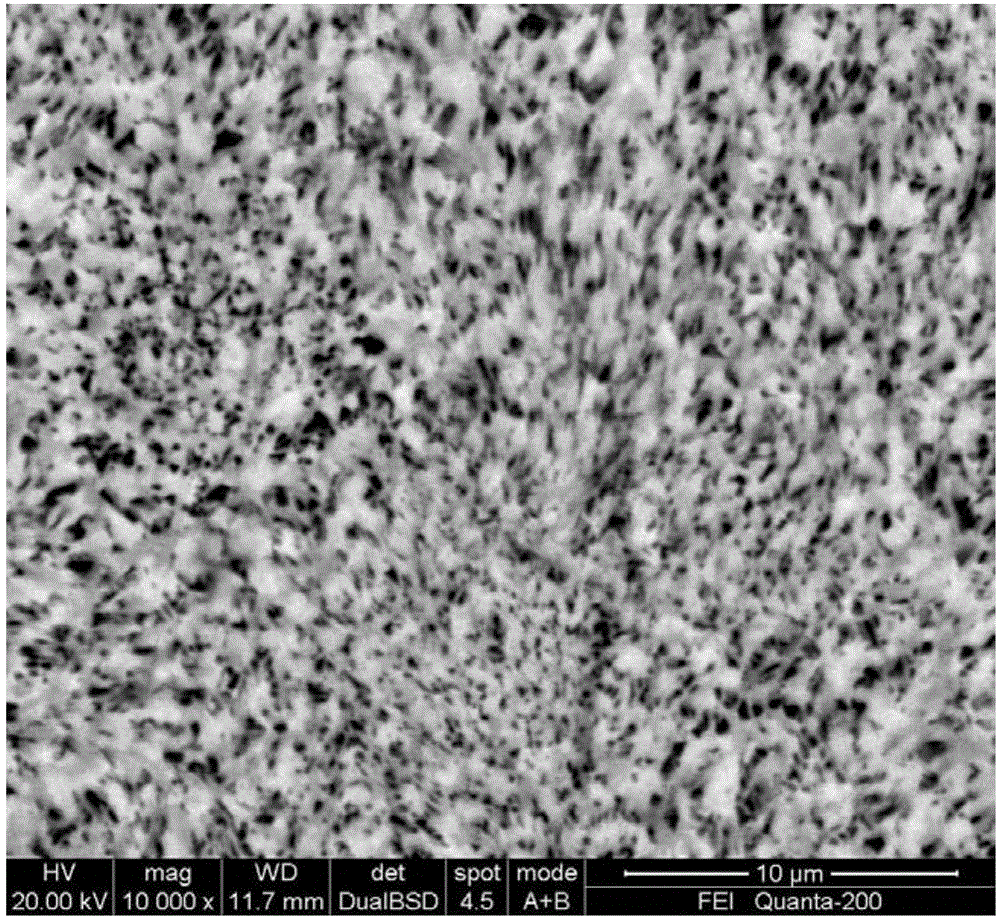

Ceramic glass with lanthanum disilicate as principal crystalline phase, preparation method and application

The invention relates to ceramic glass with lanthanum disilicate as a principal crystalline phase, a preparation method and application. The ceramic glass is obtained by carrying out nucleation and crystallization treatment on base glass. The base glass consists of the following oxides in mole percent: 22-26% of La2O3, 3-5% of MgO, 11-13% of Al2O3 and 58-62% of SiO2. The preparation method comprises the following steps: melting the various raw materials at the temperature of 1,520-1,530 DEG C; pouring melted liquid in a mold and annealing at the temperature of 650-680 DEG C to obtain the base glass; heating the base glass until the temperature of the base glass is higher than glass conversion temperature which is 40-60 DEG C, carrying out nucleation, and continuing heating to the temperature which is equal to devitrification temperature + / - 10 DEG C to obtain a ceramic glass material. The preparation method is simple, energy consumption is low, the ceramic glass is environmentally friendly, the production cost is low, and the obtained material can be used as a thermal barrier coating material, a high-temperature-structure material, an anti-friction and anti-abrasion material and the like.

Owner:CENT SOUTH UNIV

Preparation method for ultrahigh molecular weight polyethylene/biomass nanocrystal composite fibers

ActiveCN102383213BImprove mechanical propertiesHigh strengthMonocomponent polyolefin artificial filamentArtifical filament manufactureFiberWater baths

The invention relates to a preparation method for ultrahigh molecular weight polyethylene / biomass nanocrystal composite fibers. According to the method, fibrous biomass nanocrystals and stearic acid whose end groups have undergone acyl chlorination are prepared at first, wherein, the fibrous biomass nanocrystals are cellulose nanocrystals or chitin nanocrystals, and the stearic acid whose end groups have undergone acyl chlorination is prepared by subjecting stearic acid to stirring-reflux in the solvent of thionyl chloride and removing the solvent through extraction; the fibrous biomass nanocrystals are dispersed in the solvent of dichloromethane through ultrasonic dispersion and added into the stearic acid whose end groups have undergone acyl chlorination, and stirring-reflux is carried out to obtain stearic acid surface grafted biomass nanocrystals; the obtained biomass nanocrystals are blended into a swollen spinning solution of an ultrahigh molecular weight polyethylene resin, gelfibers are obtained by subjecting an obtained mixture to spinning with a metering pump and a spinneret and to fixation in water bath, and the gel fibers are subjected to multistage hot-stretching after extraction and drying so as to obtain a finished product. The method provided in the invention enables mechanical properties of fibers to be improved and high-strength and high-modulus ultrahigh molecular weight polyethylene fibers to be obtained.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

High temperature resistant valve-controlled lead-acid storage battery and manufacturing method of positive plate

PendingCN110190204AIncrease conversion rateExtended service lifeFinal product manufactureSmall-sized cells cases/jacketsFiberInternal pressure

The invention discloses a high temperature resistant valve-controlled lead-acid storage battery. The battery comprises a shell, a positive plate, a negative plate and an electrolyte, wherein the bottom inner surface of the shell is provided with a plurality of mutually parallel bumps, the shell is further externally provided with a metal groove, the positive plate includes a positive plate grid and a positive active substance, and the positive active substance includes the following components in parts by weight: 900-950 parts of lead powder, 50-100 parts of red lead, 0.5-2.0 parts of colloidal graphite, 0.5-1.5 parts of short fibers, 10-20 parts of 4BS crystal seeds, 85-105 parts of 50% dilute sulfuric acid, 0.5-1.2 parts of stannous sulfate, 0.05-0.5 part of three-layer graphene and 100-115 parts of pure water. The invention further discloses a manufacturing method of the positive plate, which comprises the steps of preparation of lead paste, paste coating, solidification and drying,assembly and formation. According to the high temperature resistant valve-controlled lead-acid storage battery and the manufacturing method of the positive plate provided by the invention, the prepared battery has the functions of heat dissipation and strong battery internal pressure resistance, can prevent the expansion and deformation of the battery shell and has long service life.

Owner:佛山赛能新能源有限公司

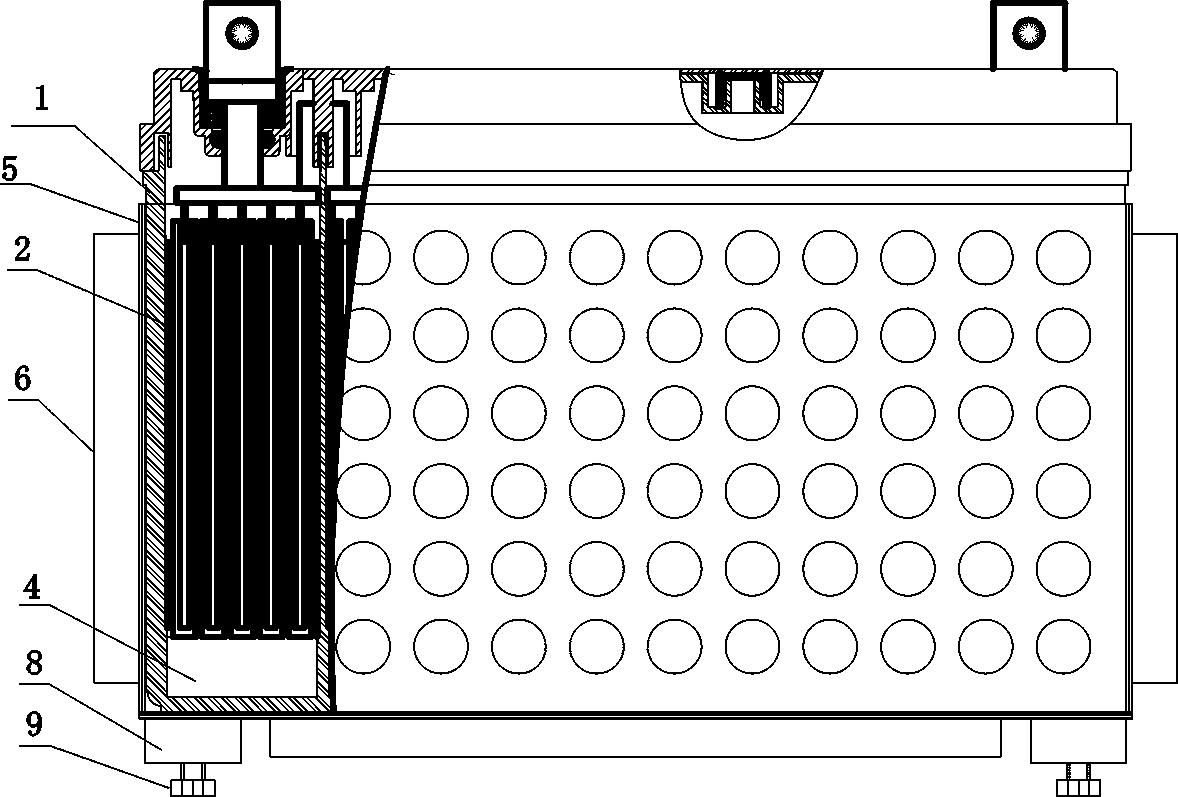

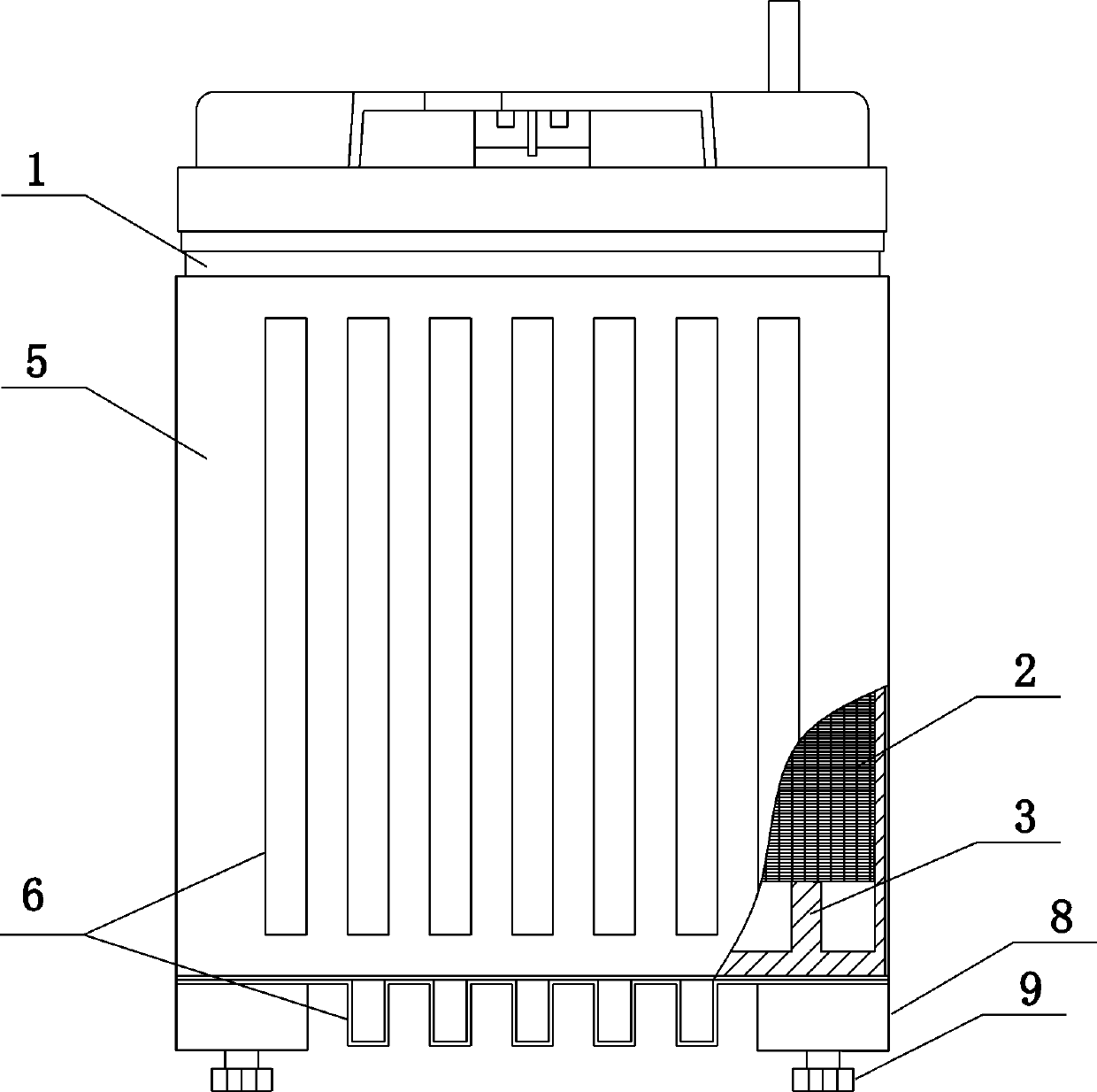

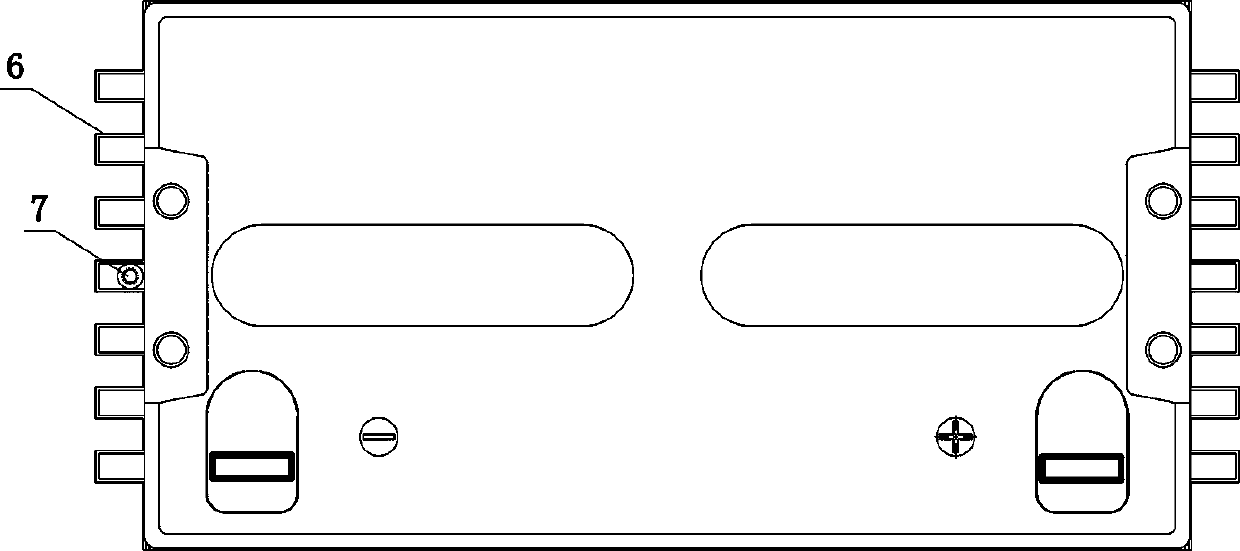

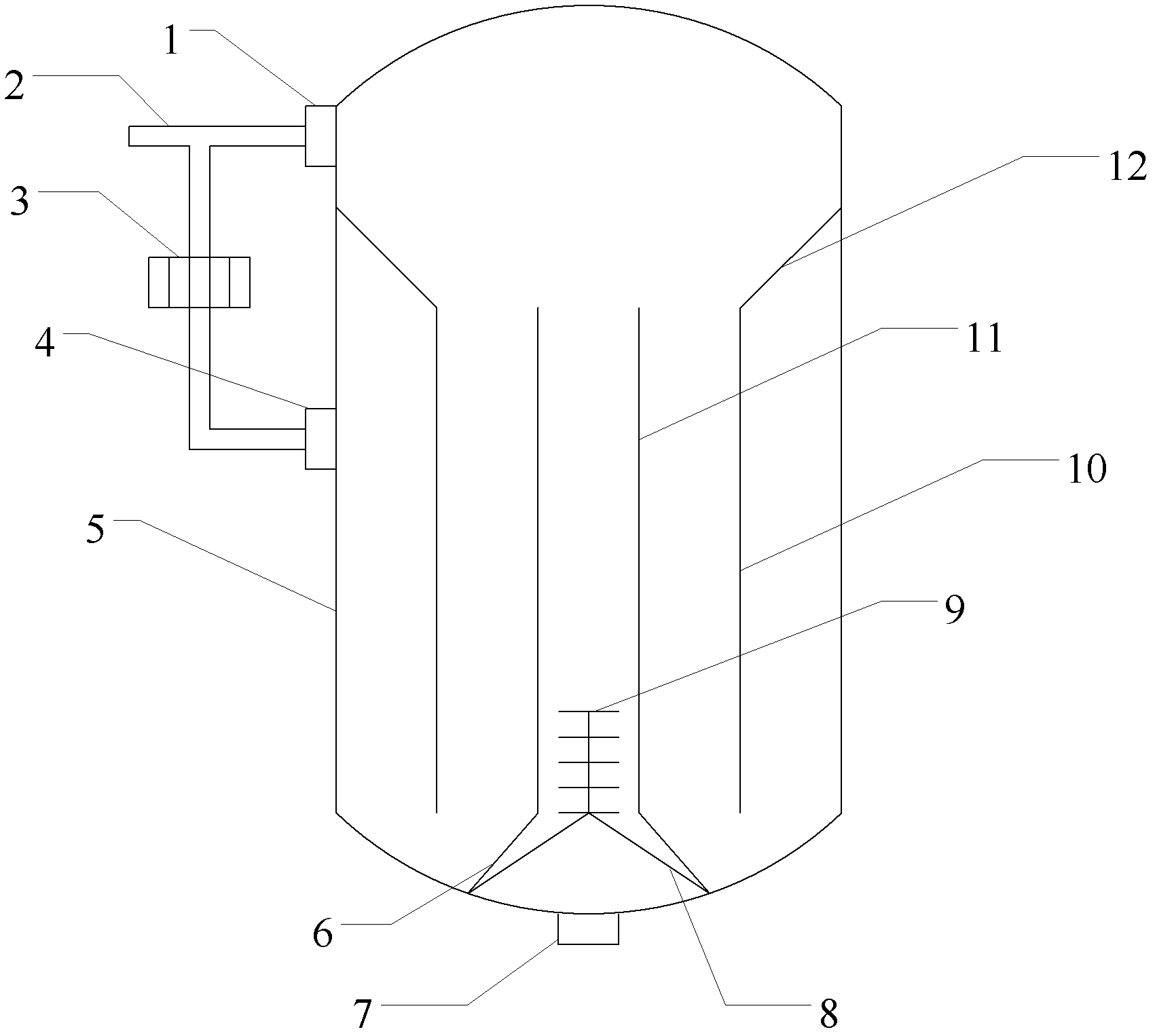

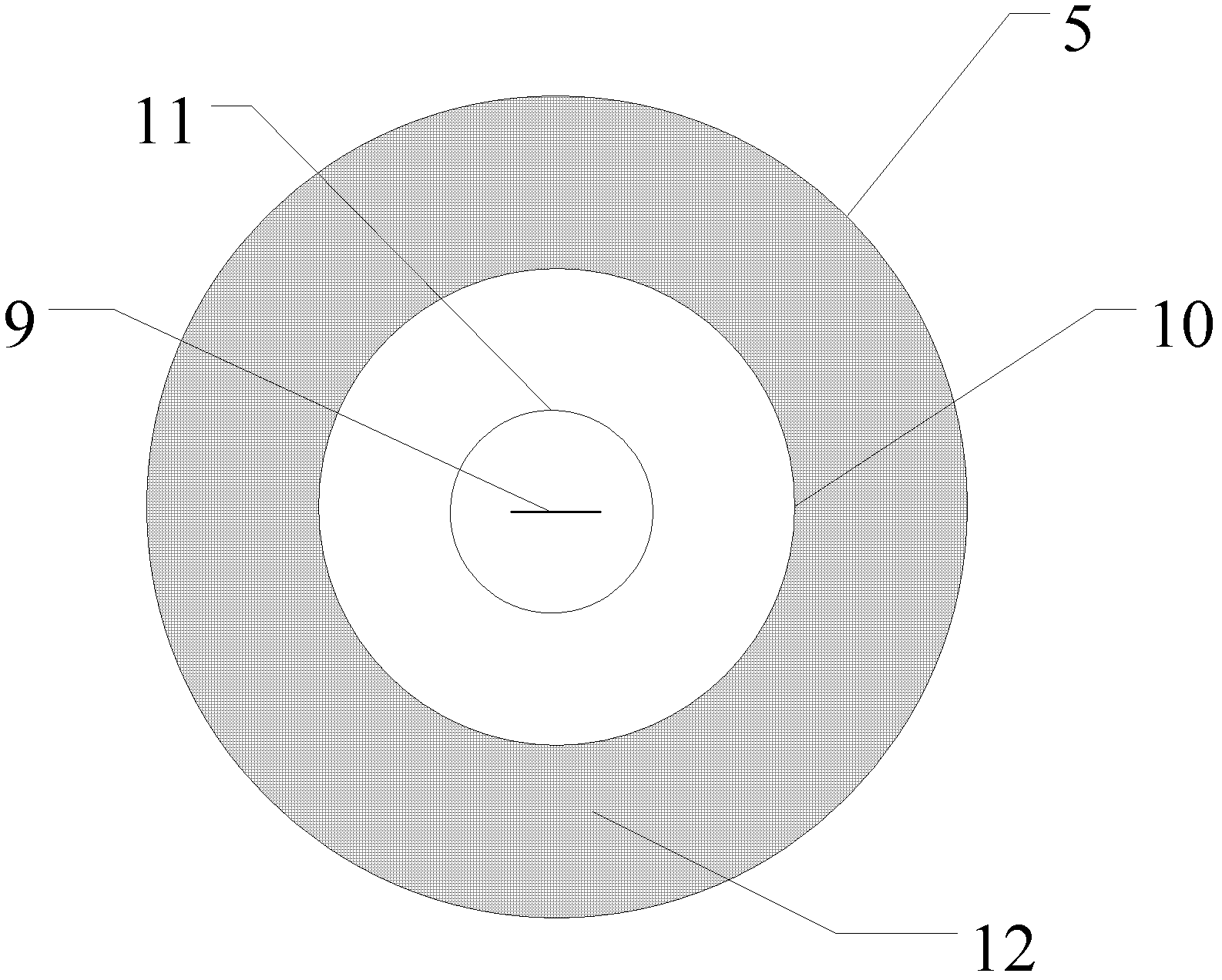

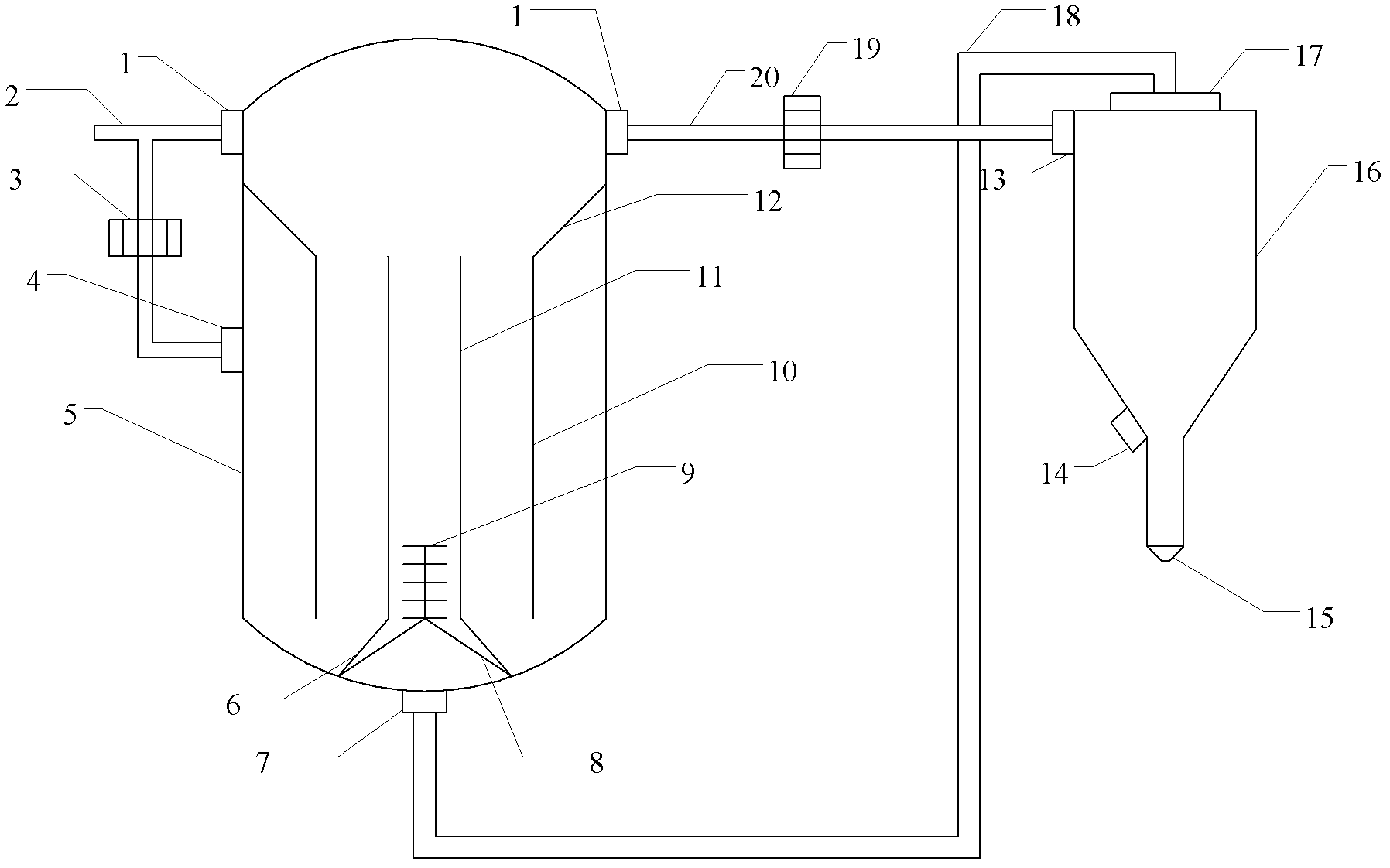

Continuous crystallizing tank and continuous evaporative crystallization process

ActiveCN102614679AReduce consumptionHigh crystal contentEvaporationSolution crystallizationContinuous crystallizationCrystal

The invention relates to the field of chemical production, and discloses a continuous crystallizing tank and a continuous evaporative crystallization process. The continuous crystallizing tank comprises a tank body, a first sleeve which has the lateral surface only and is positioned in the tank body, a second sleeve which has the lateral surface only and is positioned in the first sleeve and a stirrer, wherein side walls of the tank body, the first sleeve and the second sleeve are parallel with each other and do not contact with each other, and the first sleeve and the second sleeve do not contact the bottom of the tank body; the top of the side wall of the first sleeve is connected with the side wall of the tank body by an annular metal plate in a closed mode; the stirrer is positioned in the second sleeve, and the second sleeve and the stirrer are fixed by a support; a first feeding hole and a first discharge hole are formed in the side wall of the tank body, and a first crystal discharge hole is formed in the bottom of the tank body; the first feeding hole is positioned above the annular metal plate; the first discharge hole is positioned between the annular metal plate and the bottom of the side wall of the first sleeve; and the first discharge hole is communicated with the first feeding hole. By the crystallizing tank, continuous evaporative crystallization is realized, crystals are uniform in sizes, and steam consumption is reduced.

Owner:TONGLIAO MEIHUA BIOLOGICAL SCI TECH CO LTD

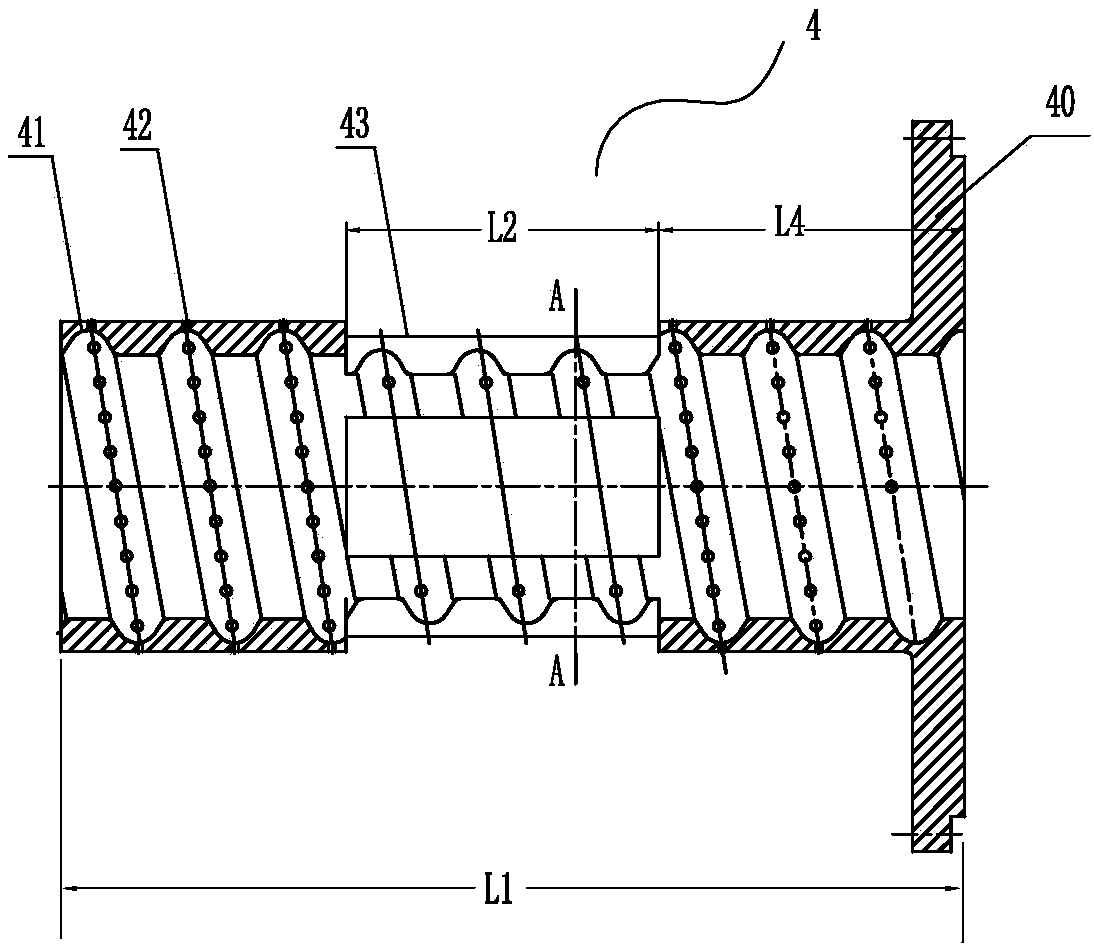

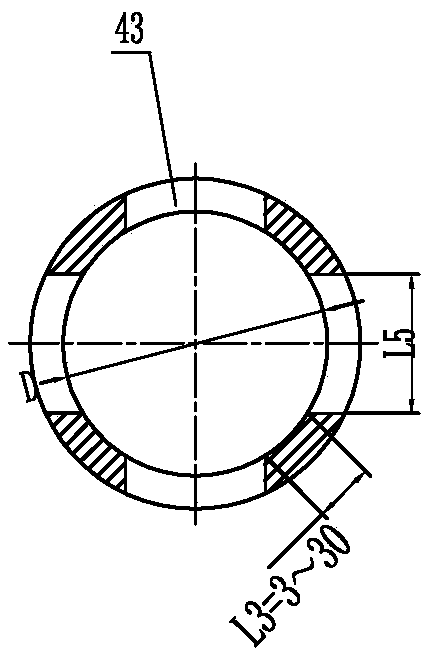

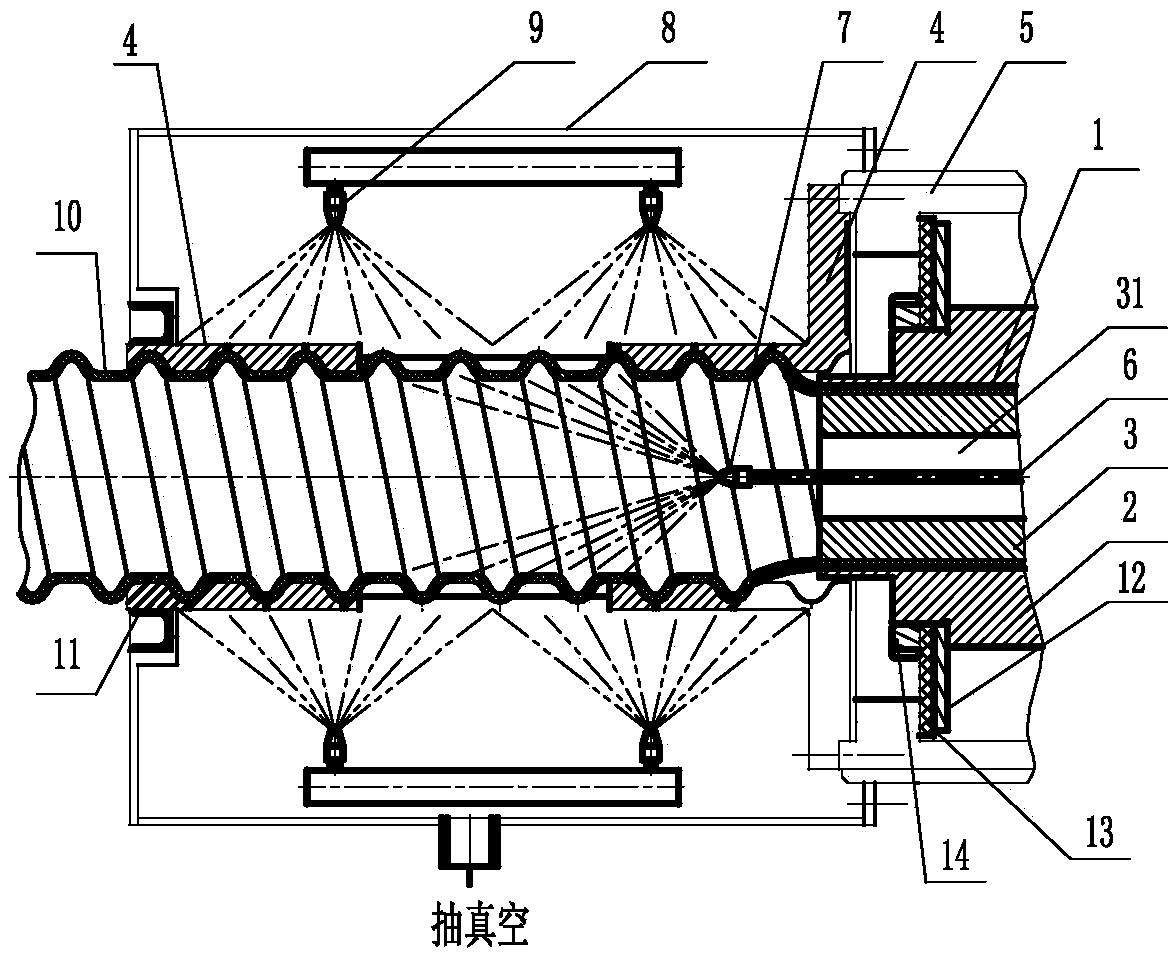

Polypropylene corrugated pipe sizing die and corrugated pipe forming machine head containing the sizing die

The invention relates to a polypropylene corrugated pipe sizing die, wherein N long grooves parallel to a central axis of the corrugated pipe sizing die are sectioned; the length of the long grooves is 50-100mm, the width between two adjacent long grooves is 3-30mm, and the distance between the long grooves and the installation end surface of the corrugated pipe sizing die is equal to the inner diameter of the corrugated pipe sizing die x (0.5-1.5). The corrugated pipe forming machine head containing the sizing die further comprises a machine head die body, a vacuum box, a mouth die, a core die and a cooling device; the corrugated pipe sizing die is arranged in the vacuum box, the mouth die is arranged at the inlet end of the vacuum box, the core die is arranged at the center of the mouthdie; a corrugated pipe blank passage is reserved between the core die and the mouth die; the cooling device comprises an internal water cooling pipe arranged in a core die pipe hole and an external spray head on the inner wall of the vacuum box. The sizing die is scientific in design and simple in structure, the corrugated pipe produced by the corrugated pipe forming machine head containing the sizing die has low cost and high efficiency without pollution; the shaping cooling speed of the corrugated pipe is fast, and the impact toughness and the impact strength are high.

Owner:广西锐嘉弘建筑材料有限公司

Biological medical material with biological responding coating and preparing method

InactiveCN100356991CHigh crystal contentHigh phase purityCoatingsFlagellar basal bodyOsteoblast cell differentiation

Owner:ZHEJIANG UNIV

Chloride crystal and glass composite transparent optical function material as well as preparation method and application thereof

ActiveCN113860747AGood optical clarityHigh luminous intensityLuminescent compositionsComposite materialGlass composites

The invention belongs to the technical field of scintillator materials, and discloses a chloride crystal and glass composite transparent optical function material and a preparation method and application thereof. The transparent optical function material comprises the following components: 50-99 mol% of a chloride crystal phase and 1-50 mol% of a glass phase. The chloride crystal phase is a crystal phase formed by more than one of alkali metal chloride or alkaline earth metal chloride. The glass phase is formed by boron oxide or phosphorus pentoxide. The alkaline earth metal chloride is more than one of CaCl2 and SrCl2. The alkali metal chloride is more than one of LiCl, NaCl, KCl, RbCl and CsCl. The invention also discloses a preparation method of the material. The material provided by the invention has the advantages of high transparency, high crystal content, continuously adjustable crystal content, strong water erosion resistance, and good luminescence property because of doping of luminescent ions. The material provided by the invention is used for preparing a scintillator material and / or a laser material.

Owner:SOUTH CHINA UNIV OF TECH

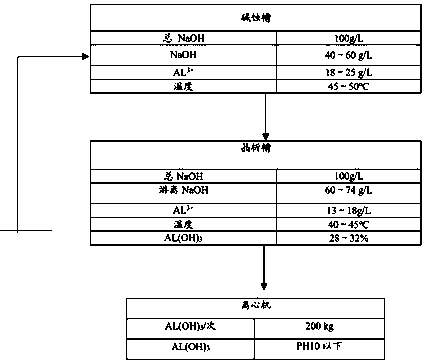

Method for recycling alkali liquor in aluminum alloy section alkali corrosion production procedure

InactiveCN110670073AReduce consumptionEfficient recyclingProcess efficiency improvementAluminum IonAlloy

The invention discloses a method for recycling alkali liquor in an aluminum alloy section alkali corrosion production procedure. The method comprises the following steps of S1, performing alkali corrosion on an aluminum alloy section; S13, after alkali corrosion is performed for 30-54 min, taking out an aluminum alloy section from a bath solution, and therefore completing alkali corrosion of the aluminum alloy section; S2, recycling a NaOH solution, wherein S21, the concentration of Al3+ in the bath solution is detected, when the concentration of Al3+ reaches 28 g / L, a pump is adopted for pumping the bath solution inside an alkali corrosion groove into a crystal separation groove; S23, the pump is adopted for pumping the supernate NaOH solution into a recycling barrel, then, the NaOH solution inside the recycling barrel is poured into the alkali corrosion groove to continue to be used for production, closed loop production is formed, and therefore the NaOH solution is recycled; S3, aluminum ions are recycled. The method has the beneficial effects that the section surface quality stability is improved, consumption of sodium hydroxide is lowered, later sewage treatment difficulty islowered, and economic benefits are improved.

Owner:CHENGDU SUNSHINE ALUMINUM

A kind of silica slag glass-ceramics and preparation method thereof

The invention relates to silicon-slag microcrystalline glass and a preparation method thereof. Silicon smelting waste slag is taken as a major raw material, and silicon dioxide or silica sand (SiO2), fluorite (CaF2), limestone or calcite (CaCO3), industrial sodium carbonate (Na2CO3), zinc oxide (ZnO) and potassium carbonate (K2CO3) are taken as auxiliary raw materials, wherein the dosage of the silicon smelting waste slag in the raw materials of the microcrystalline glass is 26.0-75.0wt%. The preparation method specifically comprises the following steps of: evenly mixing cold-state silicon slag with other auxiliary raw materials in a blender mixer to obtain a basic mixed batch, melting the basic mixed batch into qualified glass liquid in a melting furnace, and then performing calendering, casting or water quenching on the glass liquid to form a basic glass plate or granules; finally, subjecting the basic glass plate to crystallization heat treatment to obtain the microcrystalline glass. The density of the microcrystalline glass is 2.5-2.8 g / cm<3>, the rupture strength of the microcrystalline glass is 30.0-103.5 MPa, the compressive strength of the microcrystalline glass is 70.0-903.0 MPa, the Moh's hardness of the microcrystalline glass is 5-8 and the abrasive resistance of the microcrystalline glass is 0.063-0.15 g / cm<2>; the silicon-slag microcrystalline glass can be widely applied to the fields such as chemical engineering, metallurgy, architectural ornament, petroleum, mine and machinery.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

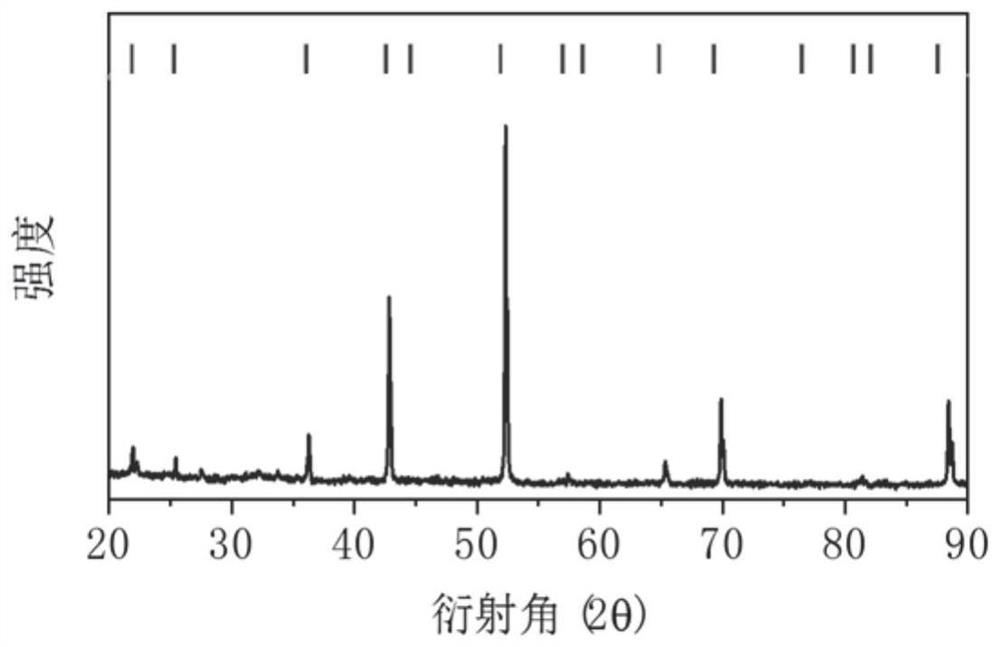

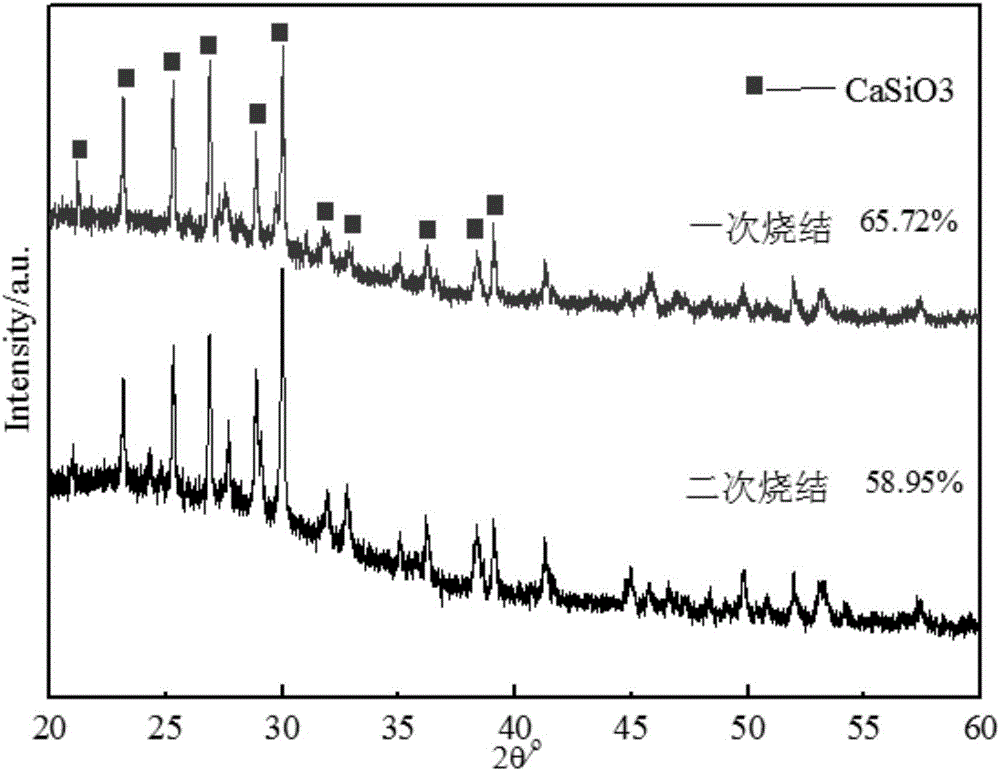

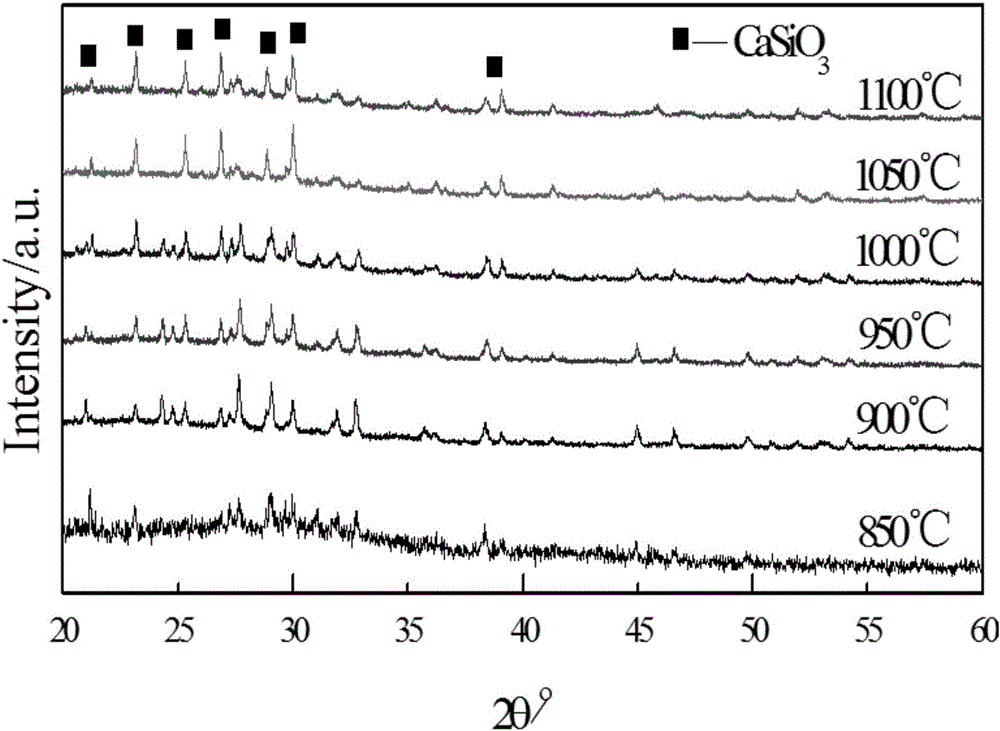

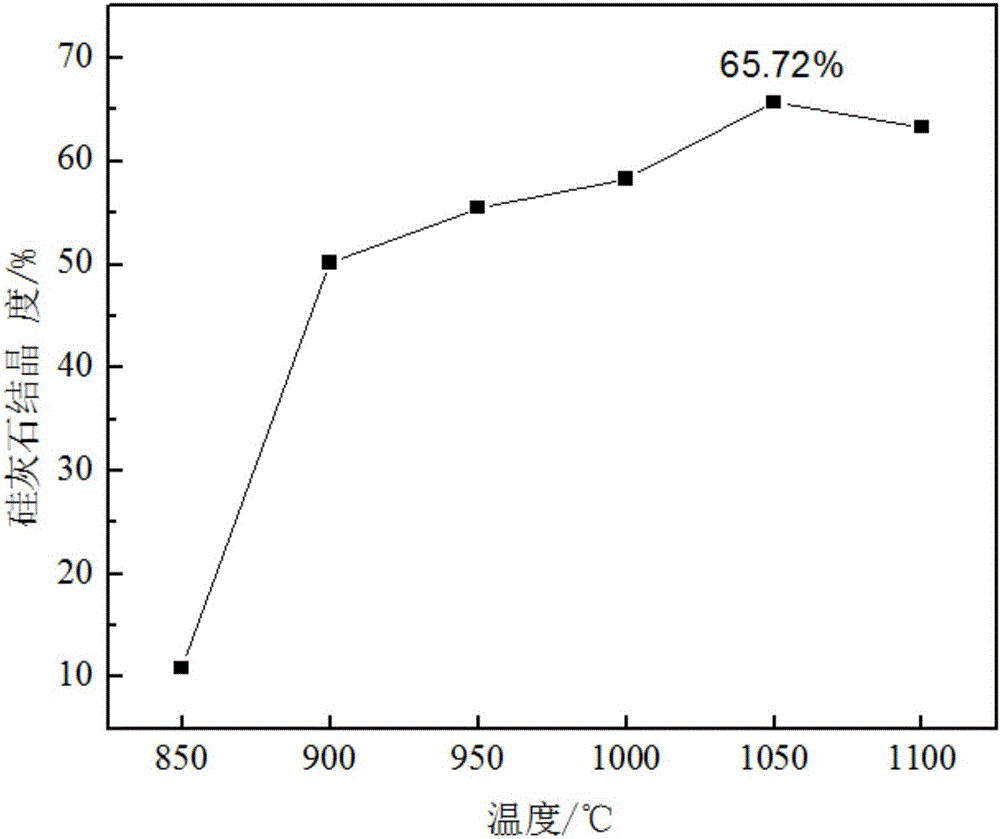

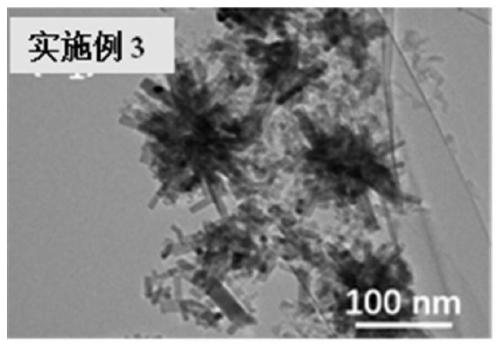

Sm3+ doped wollastonite glass ceramic and preparation method thereof

The invention discloses Sm3+ doped wollastonite glass ceramic and a preparation method thereof. Sm3+ activated luminescent glass ceramic using wollastonite (CaSiO3) as a main crystal phase is prepared by means of sintering; the wollastonite glass ceramic is SiO2-CaO-Al2O3 glass ceramic, the ratio of SiO2, CaO and Al2O3 is 57.4:18.4:3.3, Sm3+ accounts for 0.01-0.09% by mol of total mass of the SiO2-Cao-Al2O3 glass ceramic according to percentage by weight, such system can be excited under near-ultraviolet wavelength of 413 nm to emit orange red light of 590 nm, crystallization degree under thermal treatment temperature of 1050 DEG C is up to 65.72%, fluorescent strength under such temperature preparation condition is highest, and concentration quenching occurs if Sm3+ doping exceeds 0.05%. The results show that the Sm3+ doped diopside glass ceramic can be excited by blue ultraviolet to produce stable red light, and stable red light supplementary material can be provided for white LEDs.

Owner:SHANGLUO UNIV +1

Compression-resistance compound additive applied to ceramic and preparation method thereof

The invention discloses a compression-resistance compound additive applied to ceramic and a preparation method thereof and relates to the technical field of ceramic additives. The compound additive disclosed by the invention is prepared from the following raw materials in parts by weight: 20 to 40 parts of rutile type titanium dioxide, 15 to 30 parts of albite, 10 to 20 parts of calcite, 5 to 12 parts of shell powder, 3 to 8 parts of silicon nitride, 1 to 6 parts of waterborne polyurethane, 2 to 5 parts of ferric oxide, 1 to 3 parts of white carbon black, 0.2 to 0.6 part of vanadium pentoxide,0.1 to 0.5 part of dispersing agent and 0.02 to 0.08 part of grinding agent. The preparation method comprises the steps of mixing the materials, sintering at high temperature and superfinely grinding. The compound additive disclosed by the invention reduces a sintering temperature of a ceramic green body and improves compactness, crush resistance, seismic resistance and a mullite crystal phase content of ceramic at the same time; furthermore, the compound additive has the advantages of high efficiency and small use quantity; cost is saved.

Owner:ANHUI QINGHUAFANG FINE BONE PORCELAIN

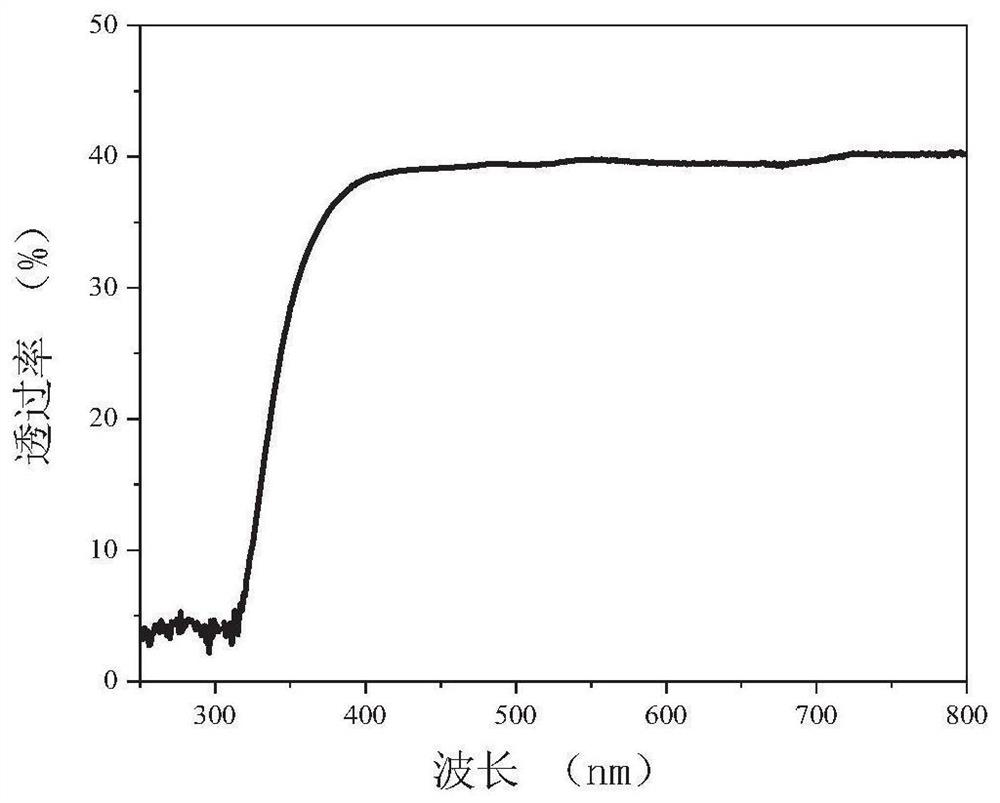

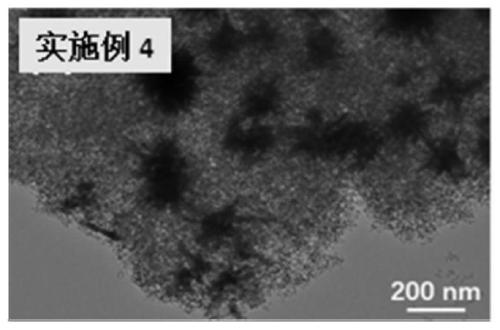

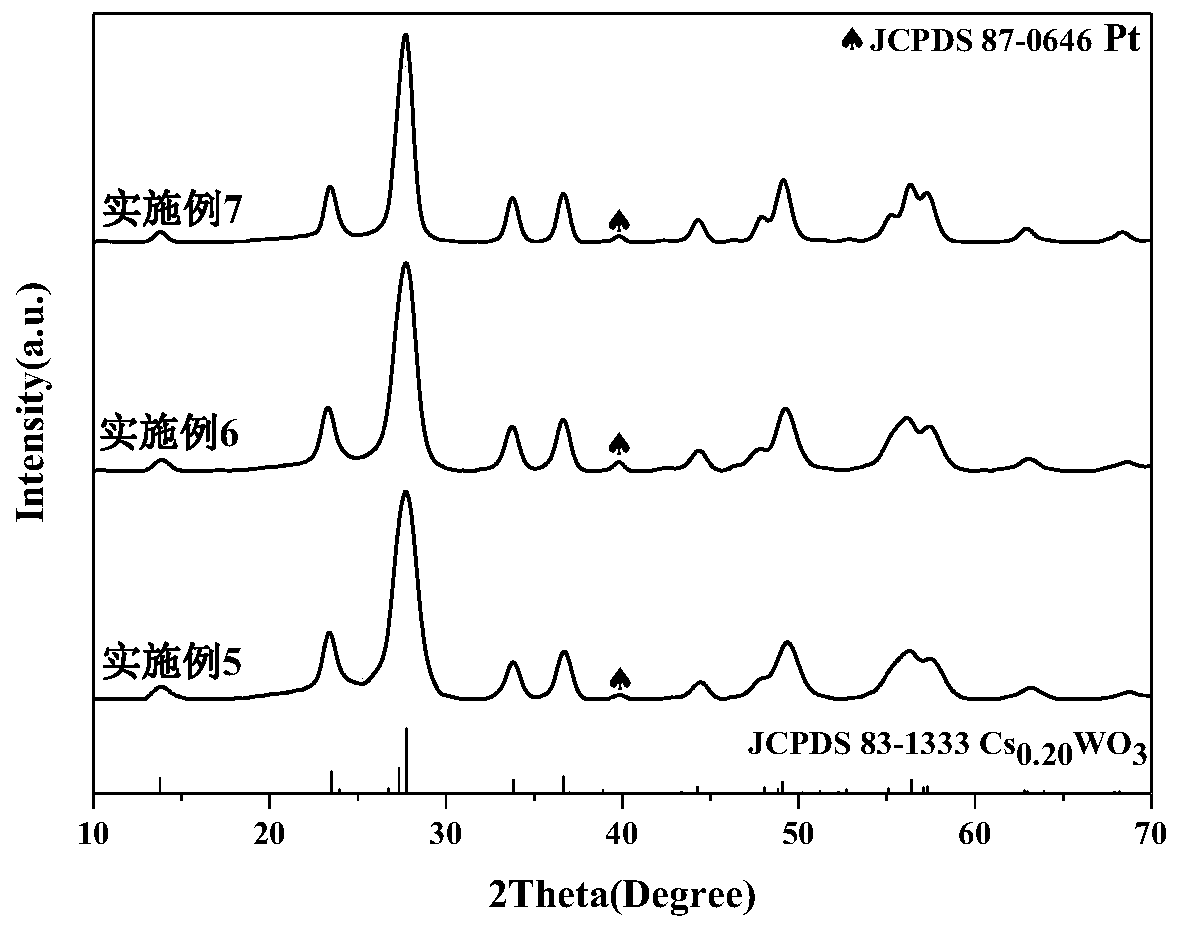

Ptn-MxWO3/SiO2 composite aerogel and preparation method of Ptn-MxWO3/SiO2 composite aerogel

ActiveCN111589382AExcellent adsorption/heat insulation performanceGood heat insulationAerogel preparationColloidal chemistry detailsPhotocatalytic degradationPhoto catalysis

The invention relates to Ptn-MxWO3 / SiO2 composite aerogel and a preparation method thereof, and belongs to the technical field of new materials and energy conservation and environmental protection. According to the Ptn-MxWO3 / SiO2 composite aerogel, the whole Ptn-MxWO3 / SiO2 composite aerogel is of a porous network structure, the specific surface area of the composite aerogel is 100-300 m<2> / g, thepore volume is 0.4-2.0 cm <3> / g, and the pore diameter is 5-25 nm; and Ptn-MxWO3 nanorod-shaped crystal grains are embedded into the composite aerogel porous network structure, and have a hexagonal tungsten bronze MyWO3 crystal structure, M in MyWO3 is Li, Na, K, Rb, Cs or NH4, y is equal to 0.2-0.7, and n is equal to 0.001-0.1. The Ptn-MxWO3 / SiO2 composite aerogel provided by the invention has visible light transmission, near-infrared shielding performance, heat insulation and pollutant adsorption / photocatalytic degradation performance at the same time.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Medical fluorinated calcium phosphate coating material and its prepn process

InactiveCN1228097CHigh phase purityIncrease profitMetallic material coating processesCalcium phosphate coatingPhosphoric acid

The present invention relates to one kind of medical material used for hard tissue. It consists of medical base body and surface fluorinated calcium phosphate coating, which is fluorinated hydroxyapatite, fluorinated calciprivic hydroxyapatite, fluorinated tricalcium phosphate or carbonate radical substituted hydroxyapatite. During the preparation, alcohol solution of the mixture of alcohol soluble calcium salt and phosphate or partially esterified phosphoric acid is used as precursor and surface coating is formed on alumina ceramic or medical metal base body via conventional sol-gel soaking pulling process, rotary painting process, combined soaking pulling and centrifuging process or hot solution spraying process. The coating has high crystalline phase content, no impurity phase and high phase purity. The preparation process of th present invention can obtain coating with thickness adjustable from several hundred nanometers to several decade microns.

Owner:ZHEJIANG UNIV

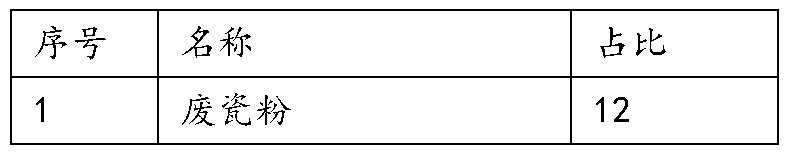

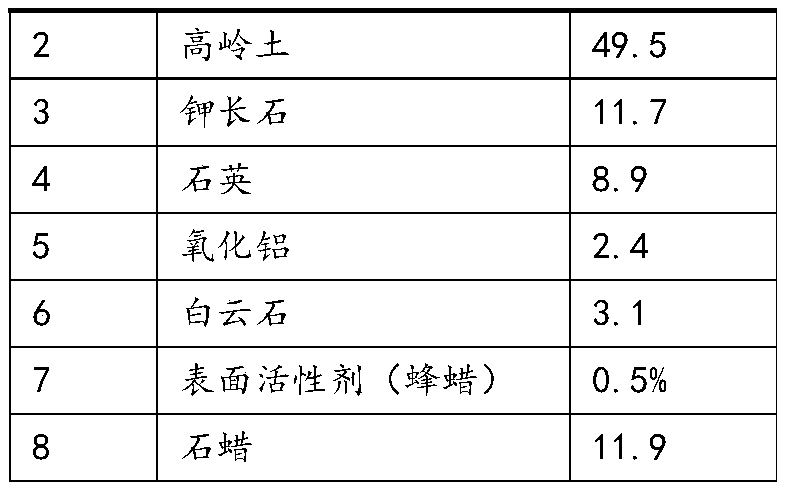

Ceramic floor drain and preparation method thereof

PendingCN109776066ALow costPromote environmental protectionSewerage structuresCeramic materials productionPotassium feldsparDolomite

The invention discloses a ceramic floor drain and a preparation method thereof. The ceramic floor drain is prepared from, by mass, 8.0-12.0% of waste porcelain powder, 9.0-11.0% of potassium feldspar,7.0-9.0% of quartz, 1.5-2.5% of alumina, 2.6-3.2% of dolomite, 0.1-1.0% of a surfactant, 10.0-12.0% of paraffin and the balance kaolin. The ceramic floor drain has the advantages of low cost, high strength, high precision, great deformation resistance and the like.

Owner:JOMOO KITCHEN & BATHROOM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com