Preparation method of zinc oxide nanocrystal

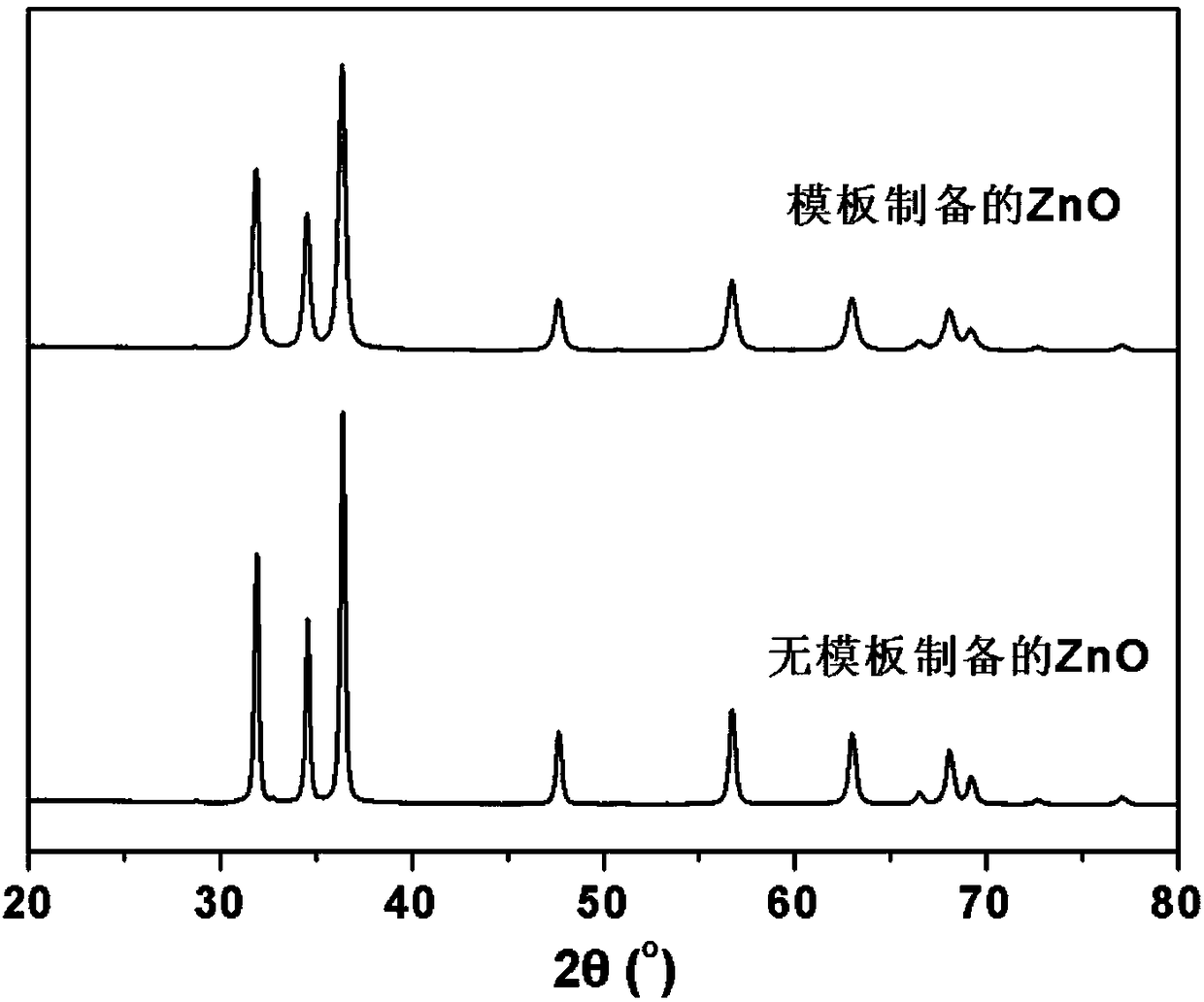

A nano-zinc oxide, zinc oxide technology, applied in the direction of zinc oxide/zinc hydroxide, etc., can solve the problems of affecting the photocatalytic efficiency of ZnO crystal, large grain size, and reduced specific surface area, and achieve high content of wurtzite crystal form. , the preparation process is simple, the specific surface area and pore volume are large

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1, the preparation of TEMPO oxidized cellulose: take by weighing 5g (absolutely dry) bamboo dissolving pulp (α cellulose content ≥ 95%), add deionized water, be mixed with 1.0% suspension, at 25 ℃, mechanical stirring ( 500r / min) to make it evenly dispersed, first add 0.1g TEMPO reagent (TEMPO reagent accounts for 2% of the dissolving pulp quality) in the fiber suspension, adjust the pH of the suspension to be about 10, then add 0.1g sodium bromide reagent, Continue stirring to keep the pH of the suspension at about 10, then add dropwise (1 drop / s) the aqueous sodium hypochlorite solution of 12mmol / g (available chlorine content), when the addition is complete, keep the pH of the suspension at about 10, and keep the temperature at At 25°C, react for 24 hours, then add a small amount of absolute ethanol to terminate the reaction, centrifuge the TEMPO oxidized cellulose suspension (10000r / min) for 30min, and wash it with deionized water for several times until there is no c...

Embodiment 2

[0024]1, the preparation of TEMPO oxidized cellulose: take by weighing 5g (absolutely dry) bamboo dissolving pulp (α cellulose content ≥ 95%), add deionized water, be mixed with 1.0% suspension, at 25 ℃, mechanical stirring ( 500r / min) to make it evenly dispersed, first add 0.1g TEMPO reagent (TEMPO reagent accounts for 2% of the dissolving pulp quality) in the fiber suspension, adjust the pH of the suspension to be about 10, then add 0.1g sodium bromide reagent, Continue stirring to keep the pH of the suspension at about 10, then add dropwise (1 drop / s) the sodium hypochlorite aqueous solution of 6mmol / g (available chlorine content), when the addition is complete, keep the pH of the suspension at about 10, and keep the temperature at At 25°C, react for 24 hours, then add a small amount of absolute ethanol to terminate the reaction, centrifuge the TEMPO oxidized cellulose suspension (10000r / min) for 30min, and wash it with deionized water for several times until there is no chl...

Embodiment 3

[0029] 1, the preparation of TEMPO oxidized cellulose: take by weighing 5g (absolutely dry) bamboo dissolving pulp (α cellulose content ≥ 95%), add deionized water, be mixed with 1.0% suspension, at 25 ℃, mechanical stirring ( 500r / min) to make it evenly dispersed, first add 0.1g TEMPO reagent (TEMPO reagent accounts for 2% of the dissolving pulp quality) in the fiber suspension, adjust the pH of the suspension to be about 10, then add 0.1g sodium bromide reagent, Continue stirring to keep the pH of the suspension at about 10, then add dropwise (1 drop / s) the aqueous sodium hypochlorite solution of 12mmol / g (available chlorine content), when the addition is complete, keep the pH of the suspension at about 10, and keep the temperature at At 25°C, react for 24 hours, then add a small amount of absolute ethanol to terminate the reaction, centrifuge the TEMPO oxidized cellulose suspension (10000r / min) for 30min, and wash it with deionized water for several times until there is no c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com