Sm3+ doped wollastonite glass ceramic and preparation method thereof

A technology of glass-ceramic and wollastonite, applied in the field of materials, can solve the problems of difficulty in heat dissipation, difficulty in distribution, lack of independent intellectual property rights, etc., and achieve the effect of increasing the content of wollastonite crystal phase and overcoming instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Preparation of wollastonite luminescent glass

[0031] Weigh 3.00g of silicon dioxide, 0.90g of calcium oxide, 0.30g of aluminum oxide, 0.58g of sodium carbonate, 0.43g of potassium carbonate, 0.40g of sodium fluoride, and 0.0076g of samarium trioxide. Add an appropriate amount of absolute ethanol to grind to make it fully mixed, then transfer it to a corundum crucible, and place it in a high-temperature furnace at 1400°C (5°C / min) for 2 hours. After the heat preservation is over, quickly take out the glass liquid and pour it into cooling deionized water Glass particles are obtained which, after drying, give wollastonite glass.

Embodiment 2

[0032] Example 2: Two-step sintering method to prepare the crystal structure of wollastonite luminescent glass-ceramics

[0033] Put the wollastonite glass obtained in Example 1 in a muffle furnace, raise the temperature at a rate of 5 °C / min to 850 °C for 2 hours for nucleation, and then increase the rate of temperature at 2 °C / min to 1007 °C for crystallization 2h, to obtain wollastonite glass-ceramics.

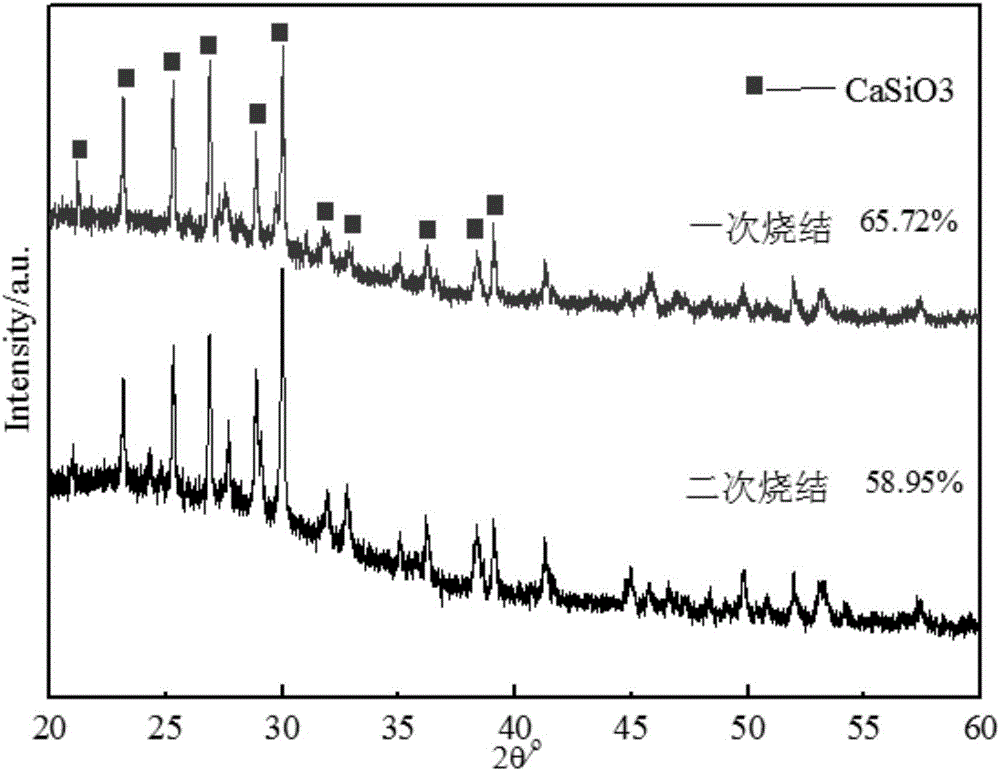

[0034] Depend on figure 1 It can be seen that wollastonite glass-ceramic was prepared by two-step sintering method, and the crystallinity was 58.95%.

Embodiment 3

[0035] Example 3: One-step sintering method to prepare the crystal structure of wollastonite luminescent glass-ceramics

[0036] The wollastonite glass obtained in Example 1 was placed in a muffle furnace, and the temperature was raised to 1050° C. at a rate of 5° C. / min for 1.5 hours to obtain wollastonite glass-ceramics.

[0037] Depend on figure 1 It can be seen that wollastonite glass-ceramic was prepared by one-step sintering method, and the crystallinity was 65.72%. The method crystallinity is 6.77% higher.

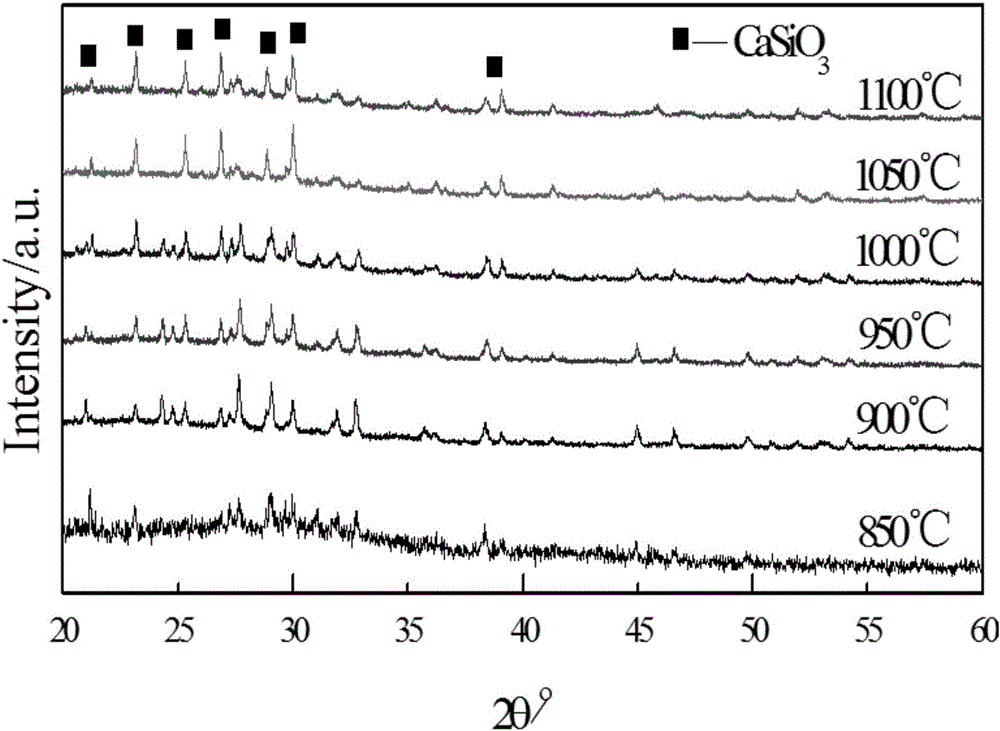

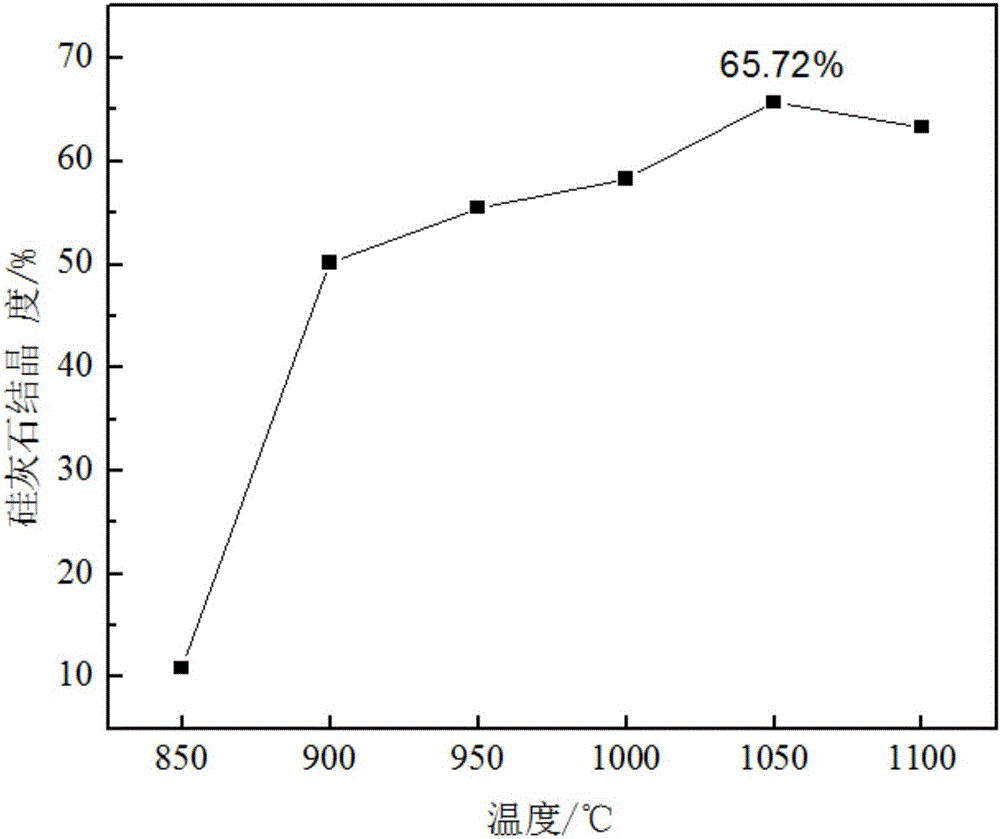

[0038] Example 4: One-step sintering method to prepare wollastonite luminescent glass-ceramics Effect of temperature on crystal structure

[0039] Place the wollastonite glass obtained in Example 1 in a muffle furnace, and raise the temperature to 850°C, 900°C, 950°C, 1000°C, 1050°C, and 1100°C at different heat treatment temperatures at a rate of 5°C / min. Heat preservation for 1.5 hours to obtain wollastonite glass-ceramics at different sintering temperatures. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com