Patents

Literature

213results about How to "High phase purity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrothermal synthesis method for lithium ion-cell anode material of ferric phosphate lithium

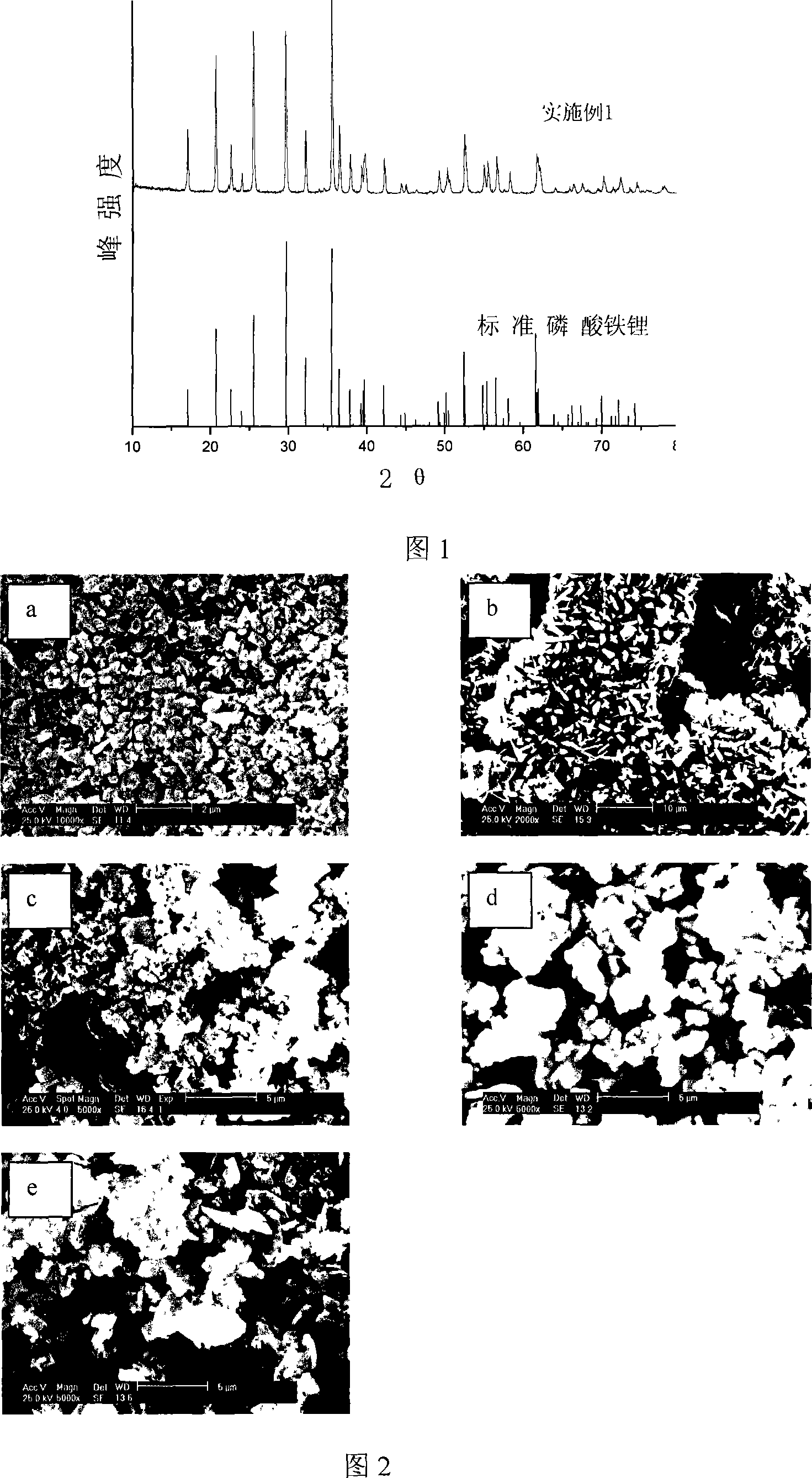

InactiveCN101117216AImprove electrochemical performanceShorten the diffusion pathCell electrodesPhosphorus compoundsExhaust valveDead volume

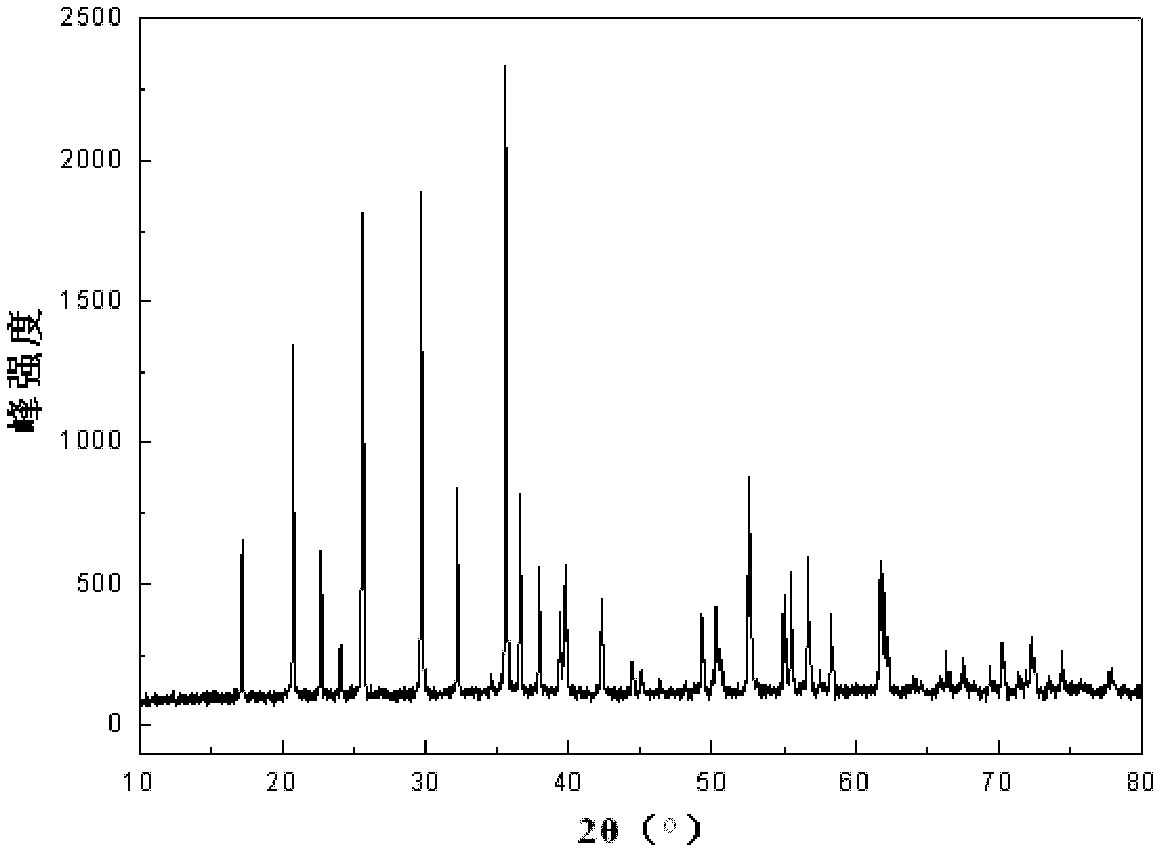

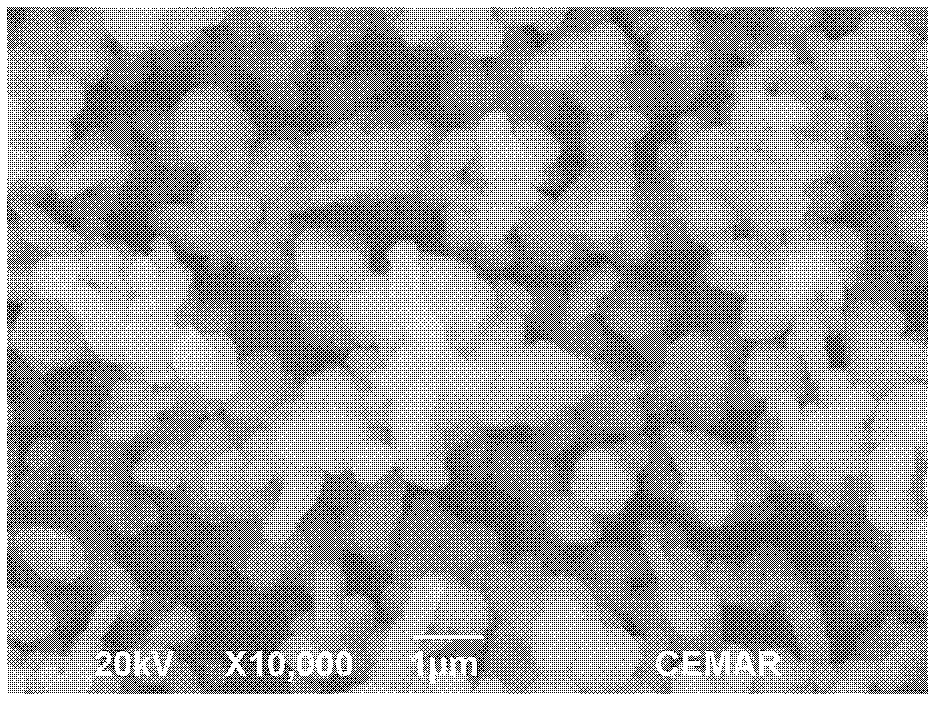

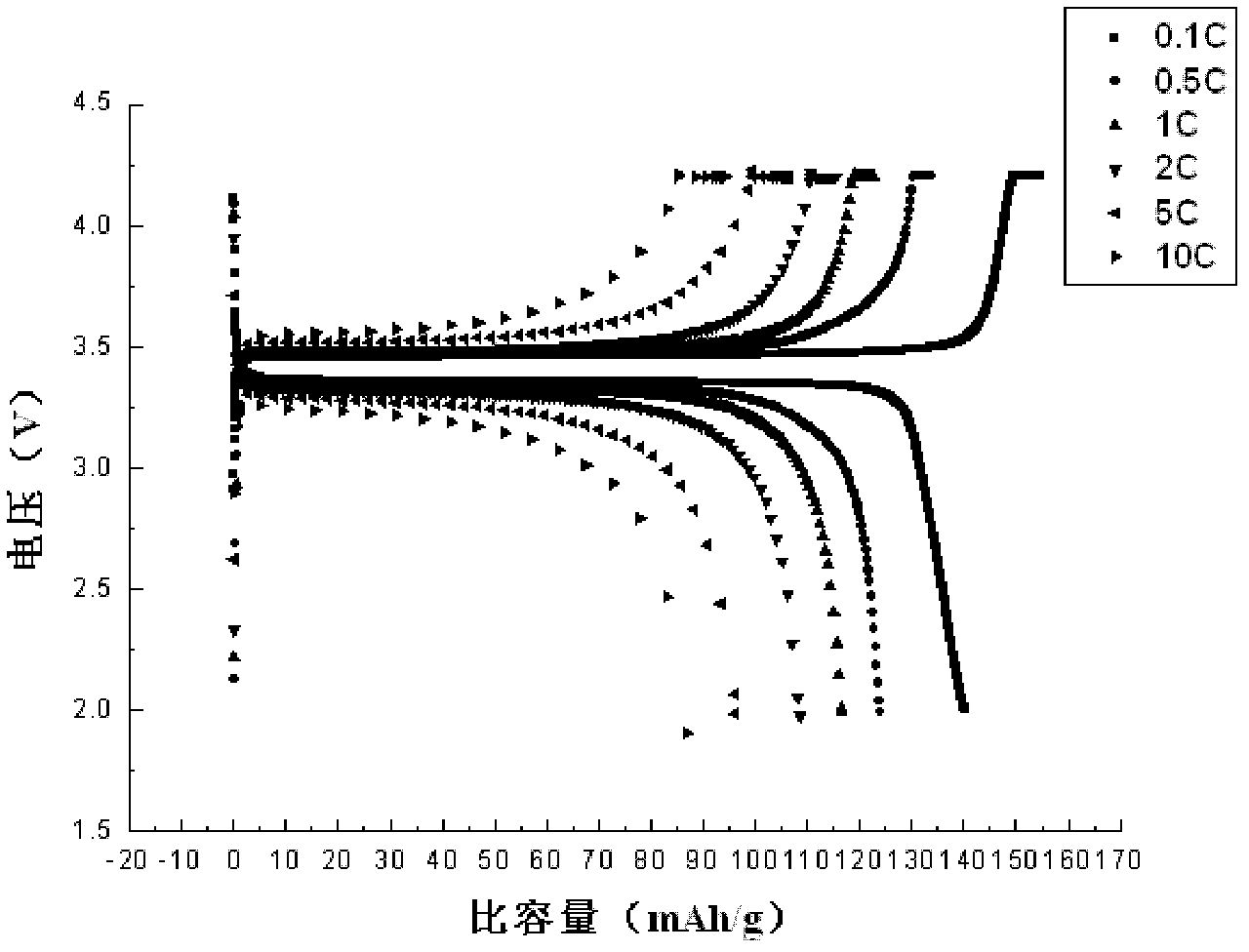

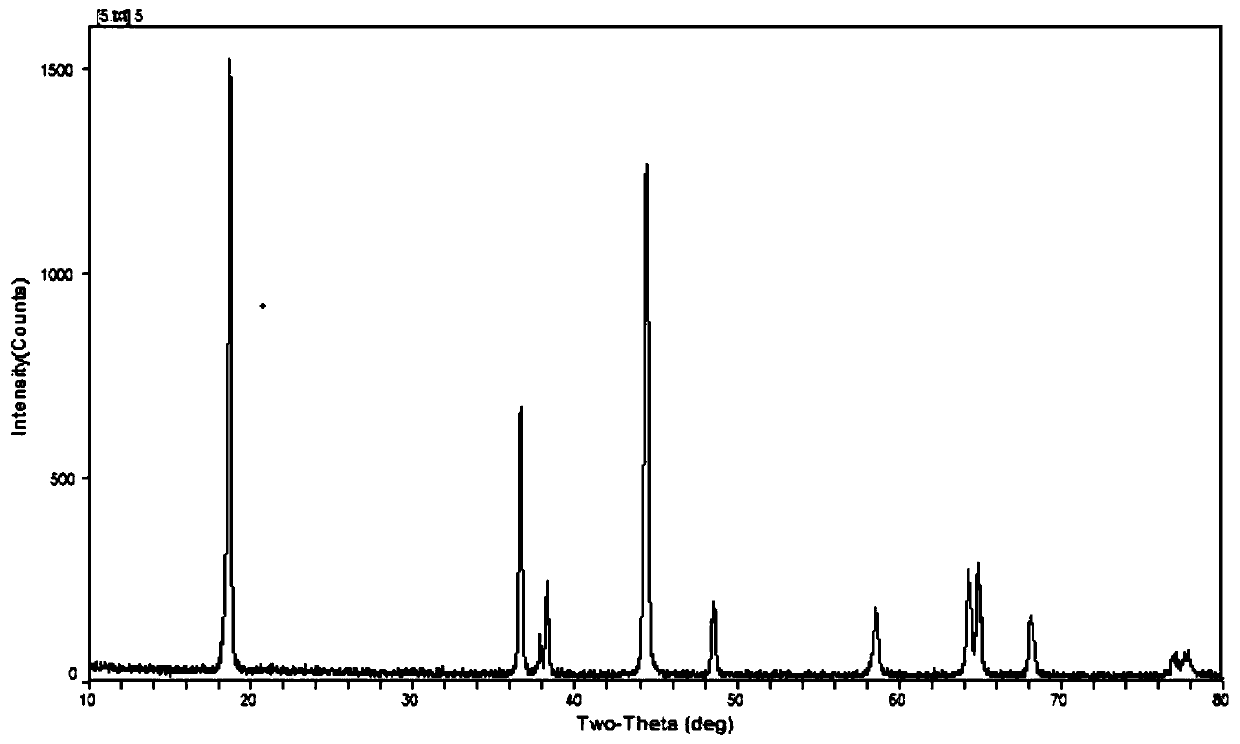

The invention discloses a hydrothermal synthesis method of lithium-ion battery anode material of lithium iron phosphate, relating two kinds of metal phosphate. The steps are as follows: lithium source and phosphorus source are dissolved in water or mixed with water, and added into the reaction autoclave, the quaternary cationic surfactants and the alkylphenols polyoxyethylene ethers nonionic surfactant is also added into the reaction autoclave, the air in the dead volume of the autoclave inside is purged by the inert gas, the autoclave is sealed and heated to 40-50 DEG C with stirring, a feed valve and an exhaust valve are opened, pure ferrous salting liquid is added into the autoclave, and then the autoclave is sealed for the reaction of the material at 140 to 180 DEG C for 30 to 480 minutes; the mixture ratio of the invention is set as follows: the molar ratio of Li, Fe and P is 3.0-3.15:1:1.0-1.15, and then the resultant is filtered, washed, dried and carbon-coated, thus the lithium iron phosphate is obtained. The lithium iron phosphate which is produced by the invention has the advantages that: the electrochemical performance is excellent, the particle size distribution of which the D50 is between 1.5 um to 2 um is even, the phase purity is above 99 percent and the electronic conductivity of the material is improved.

Owner:HEBEI LITAO BATTERY MATERIAL

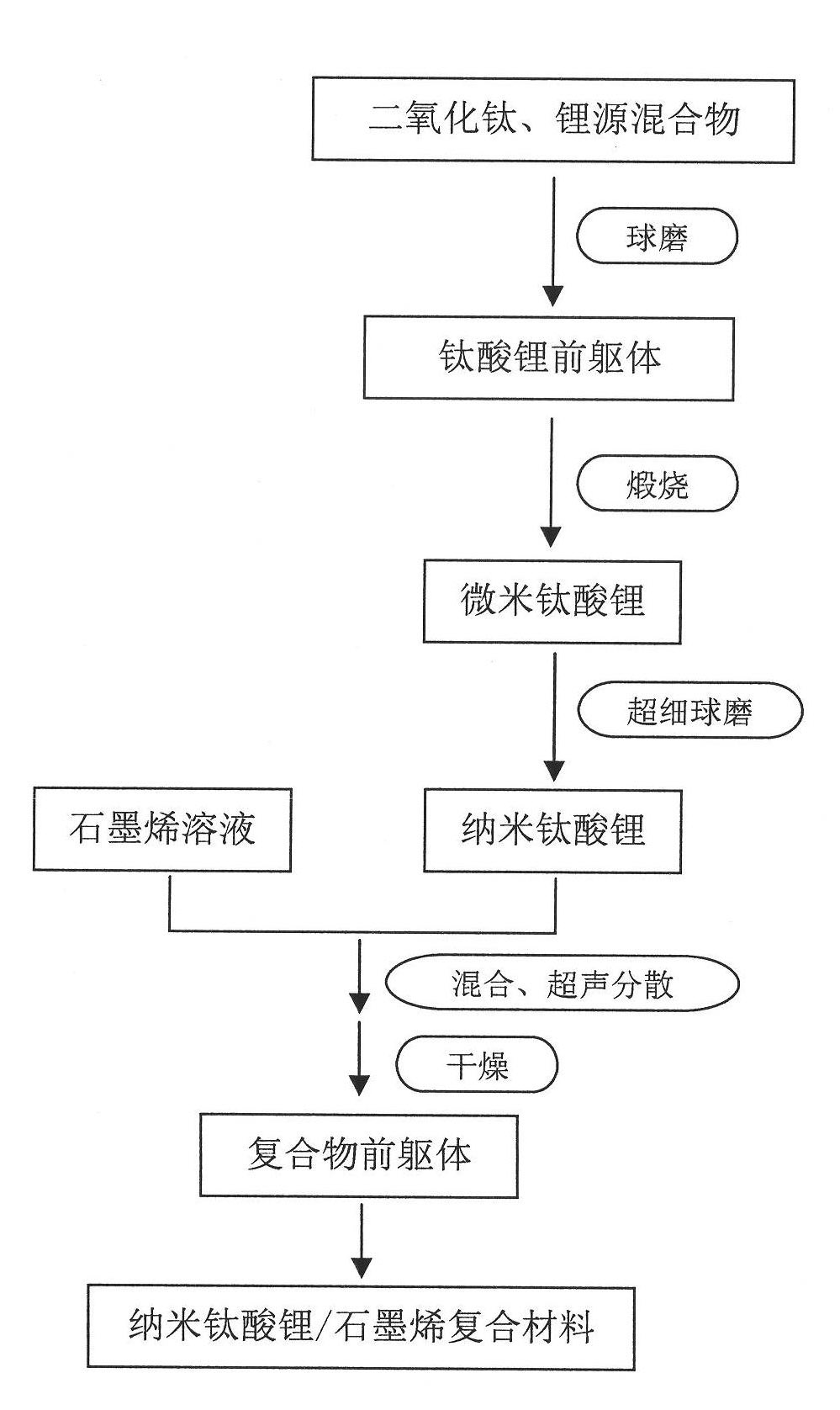

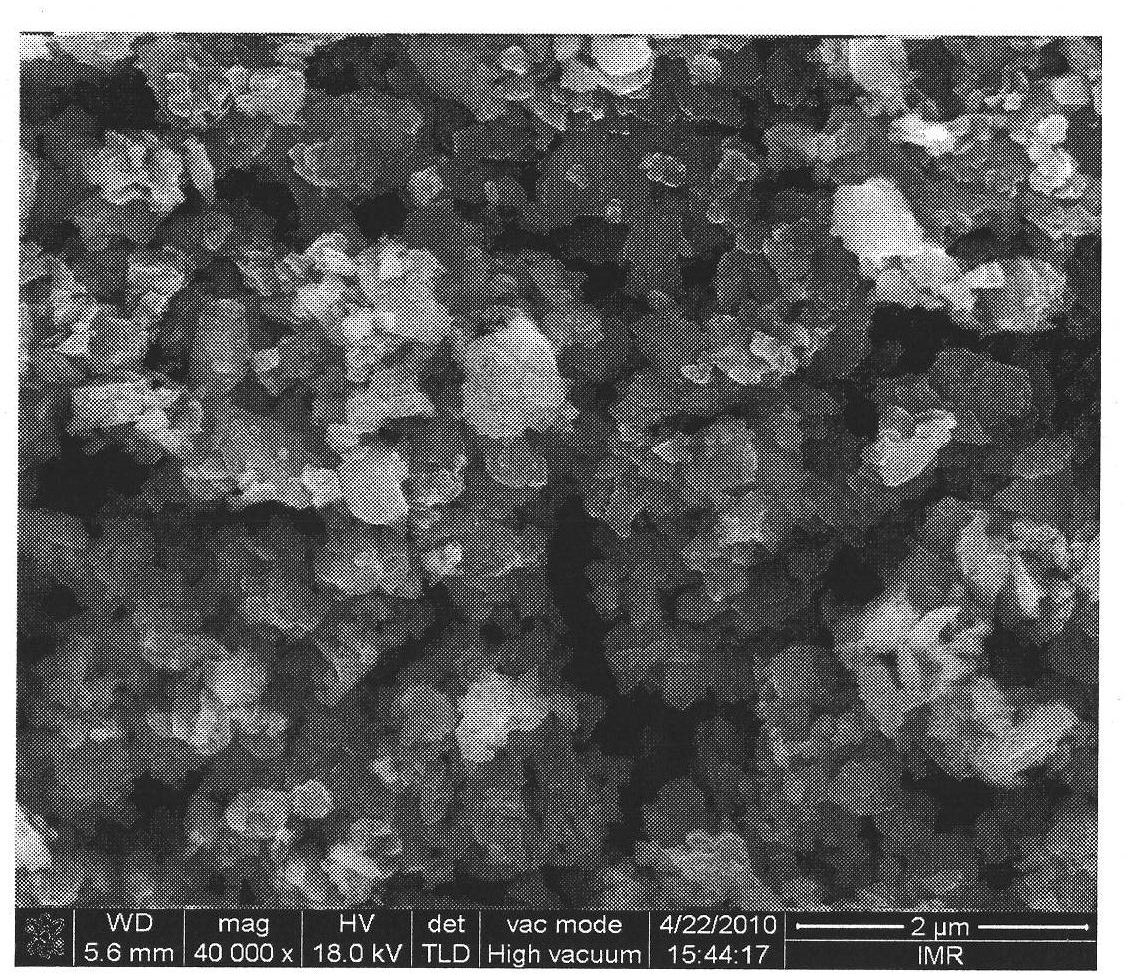

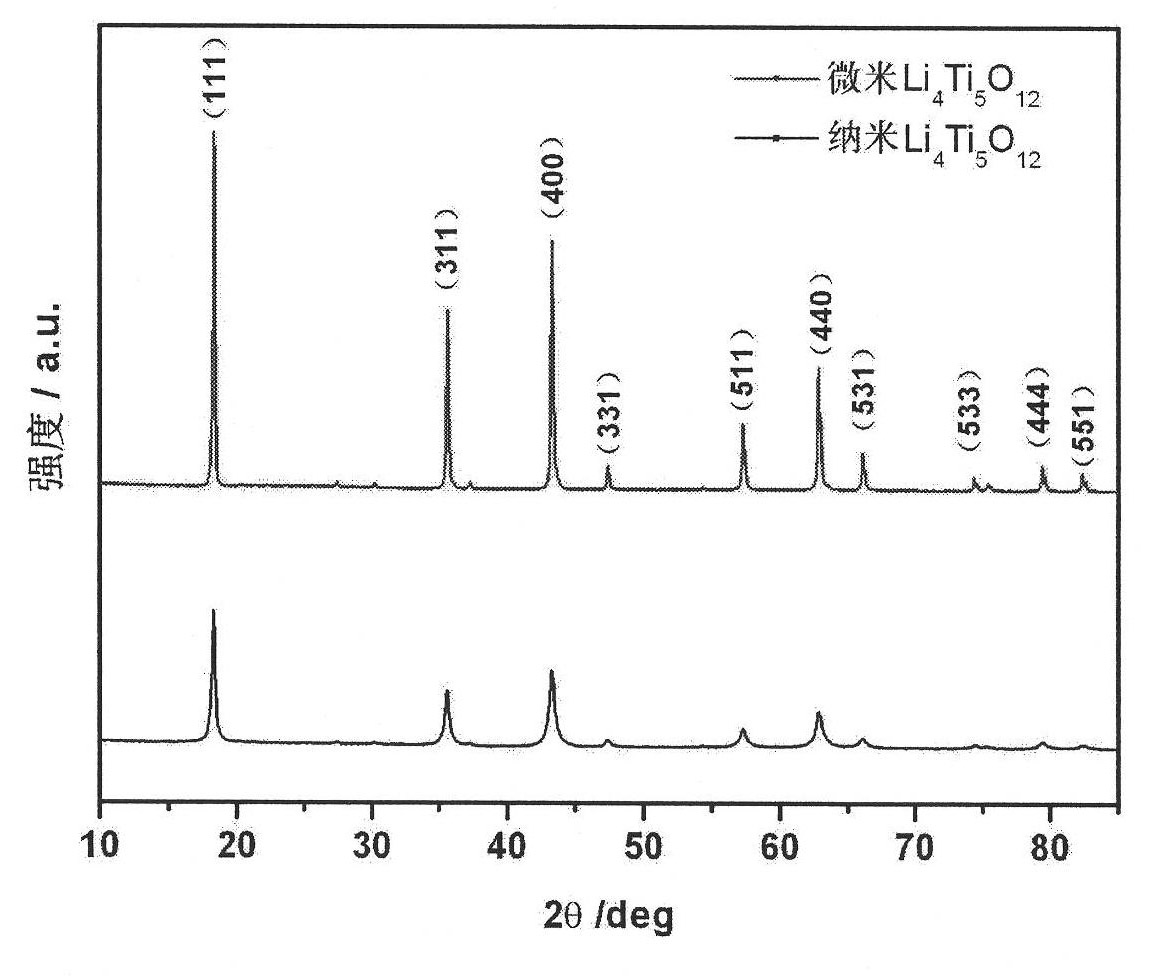

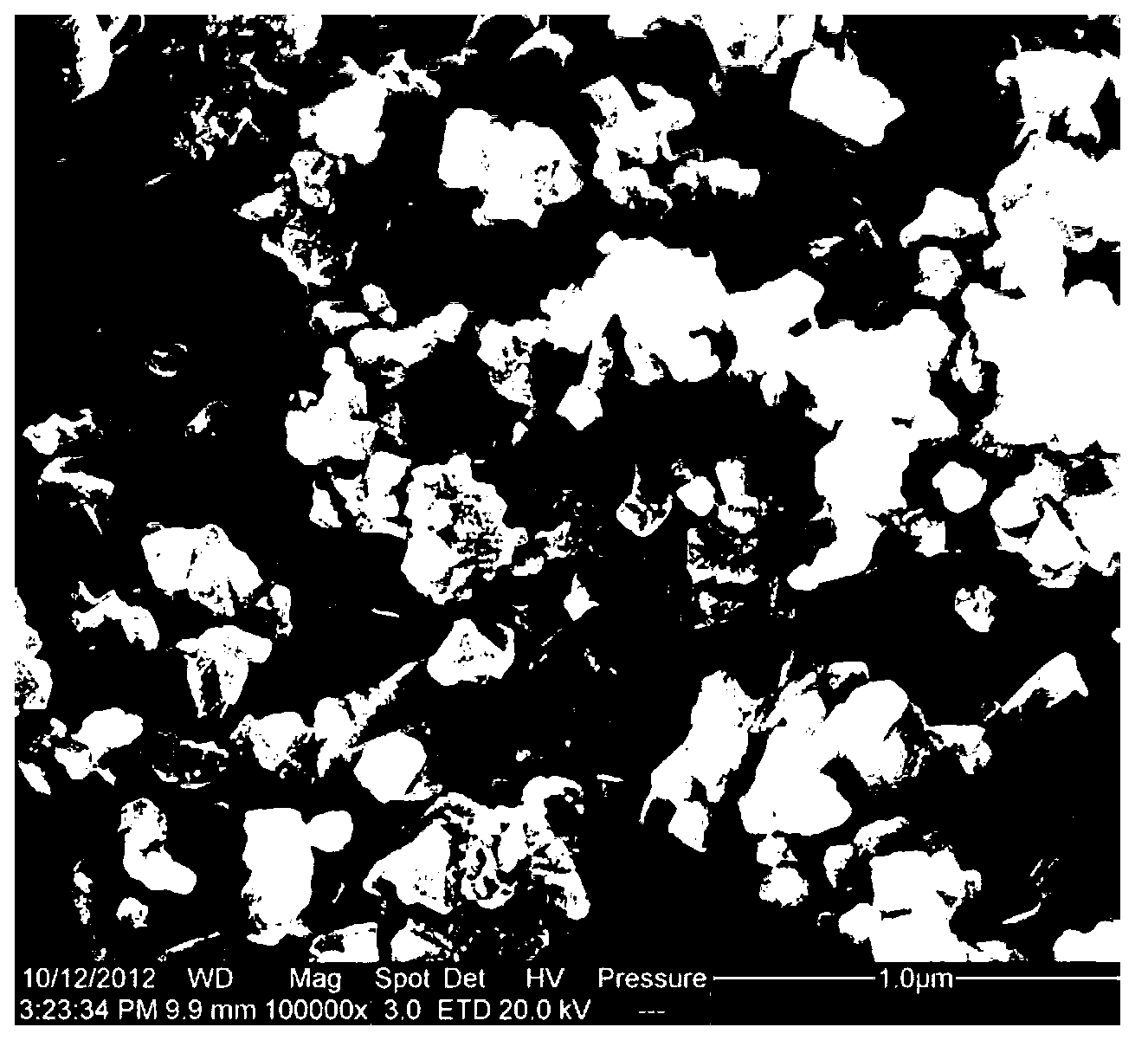

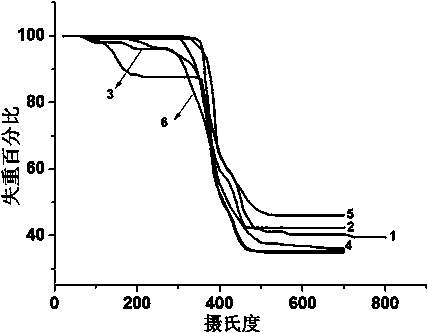

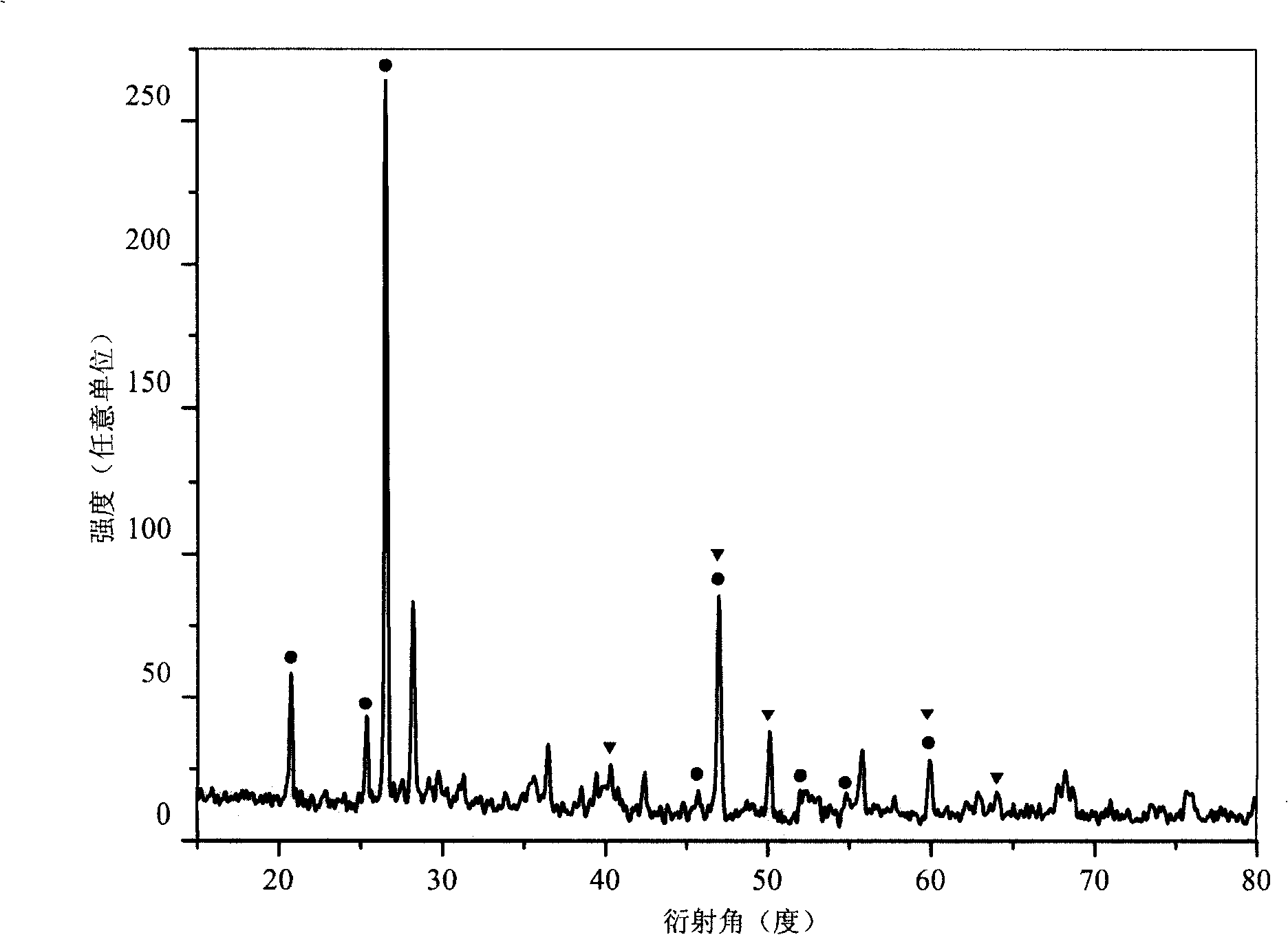

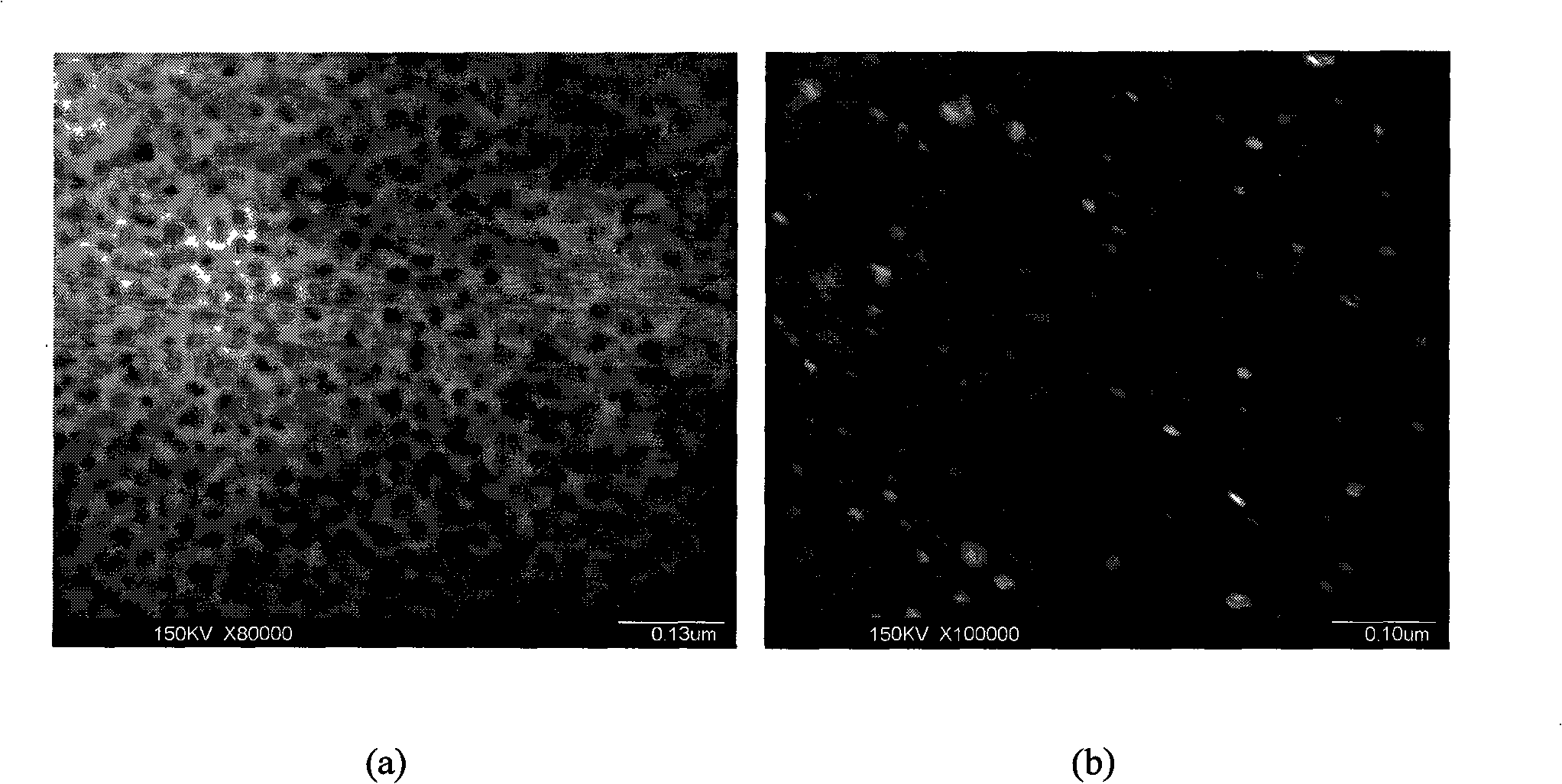

Nanometer lithium titanate/graphene composite negative electrode material and preparation process thereof

InactiveCN102376937AImprove electrochemical performanceAvoid defectsNon-aqueous electrolyte accumulator electrodesGrain treatmentsSodium-ion batteryCvd graphene

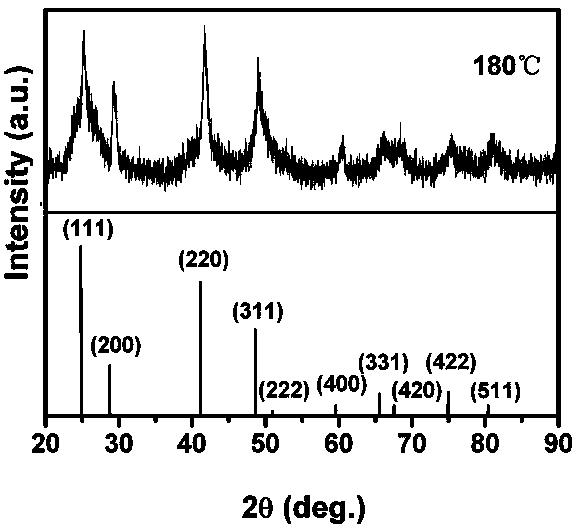

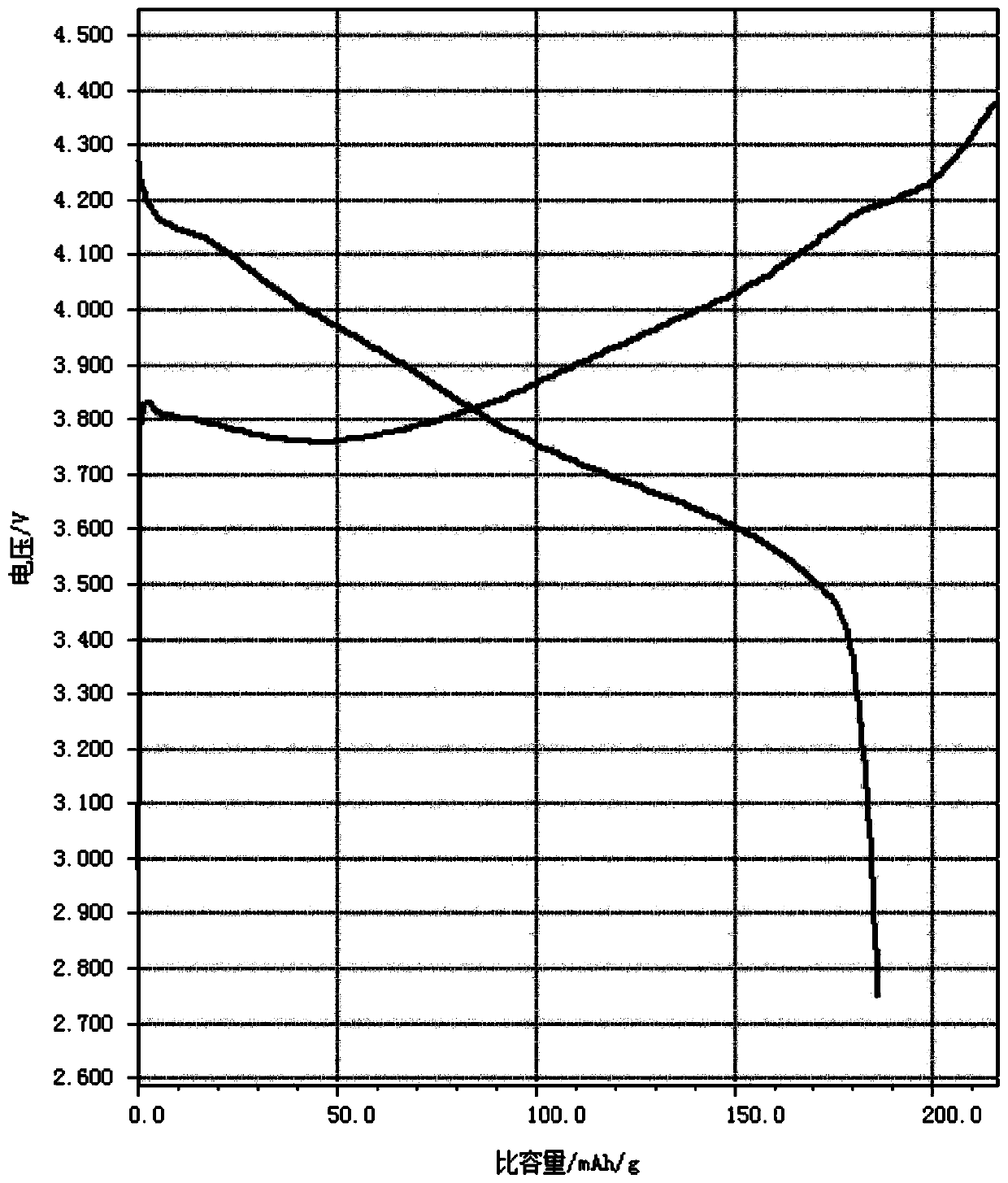

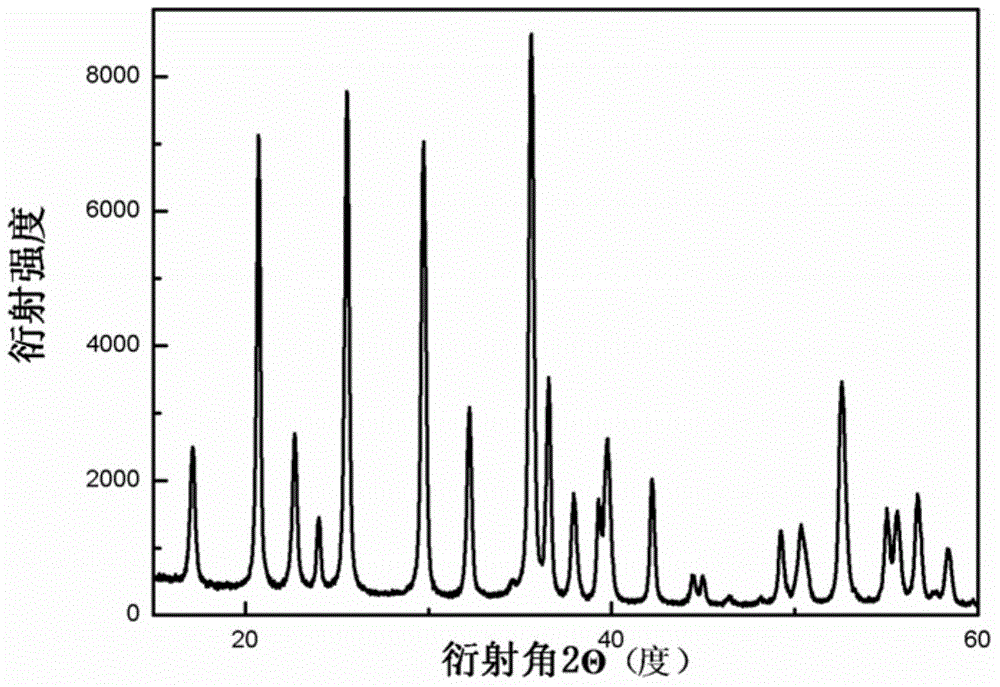

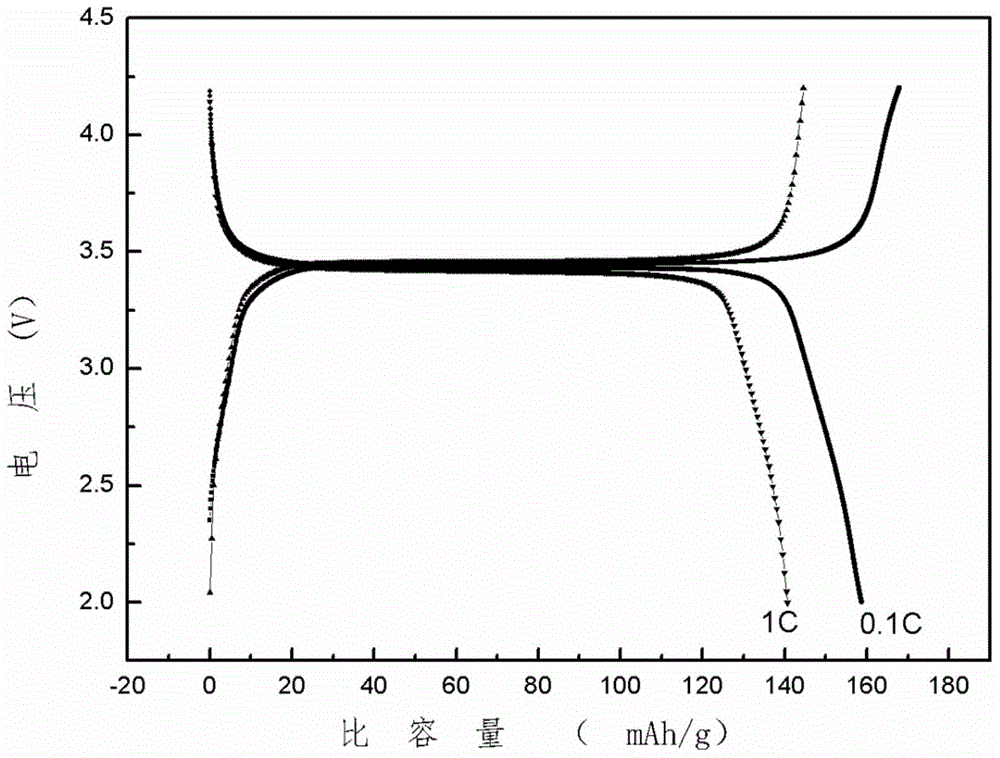

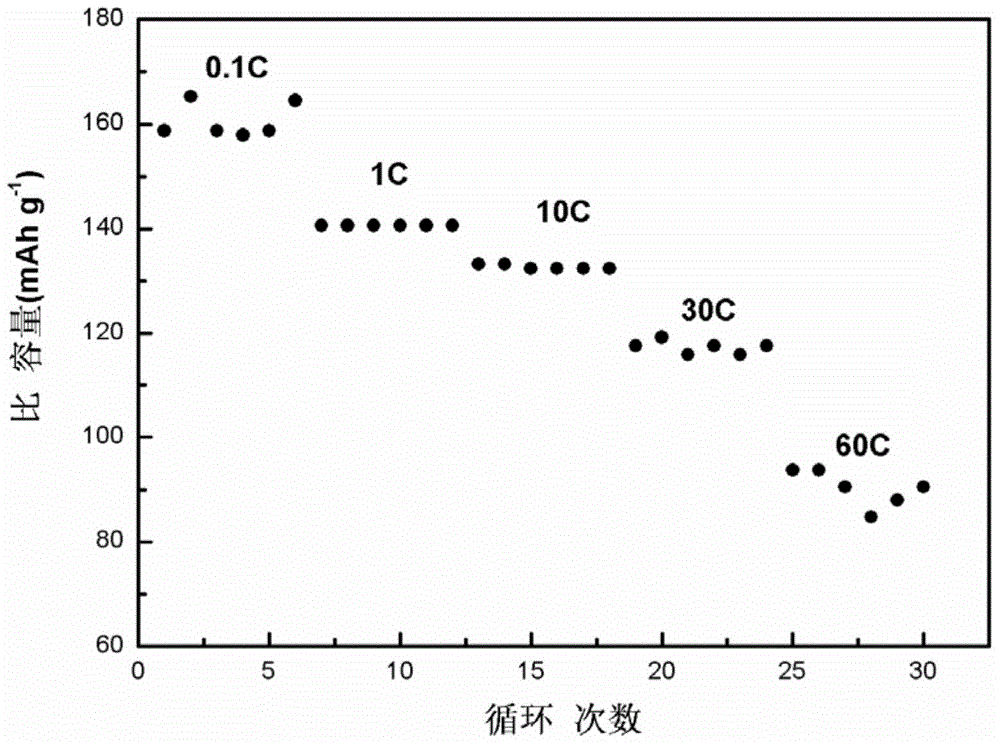

The invention relates to the field of negative electrode materials of lithium ion batteries, and specifically to a nanometer lithium titanate / graphene composite negative electrode material and a preparation process thereof. According to the invention, micron-sized lithium titanate prepared by the solid phase method is subjected to ultrafine ball milling to obtain nanometer powder, and the nanometer lithium titanate powder and graphene are uniformly compounded and subjected to heat treatment so as to obtain a high performance lithium ion battery negative electrode material; the invention is characterized in that uniform distribution of graphene in the nanometer lithium titanate powder is realized through in situ compounding; the weight of graphene in the composite negative electrode material accounts for 0.5 to 20%, and the weight of lithium titanate accounts for 80 to 99.5%. The lithium ion battery negative electrode material has good electrochemical performance, 1C capacity greater than 165 mAh / g, 30C capacity greater than 120 mAh / g and 50C capacity greater than 90 mAh / g. Nanometer lithium titanate in the lithium ion battery negative electrode material prepared in the invention has high phase purity; the preparation process of the material is simple and is easy for industrial production.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

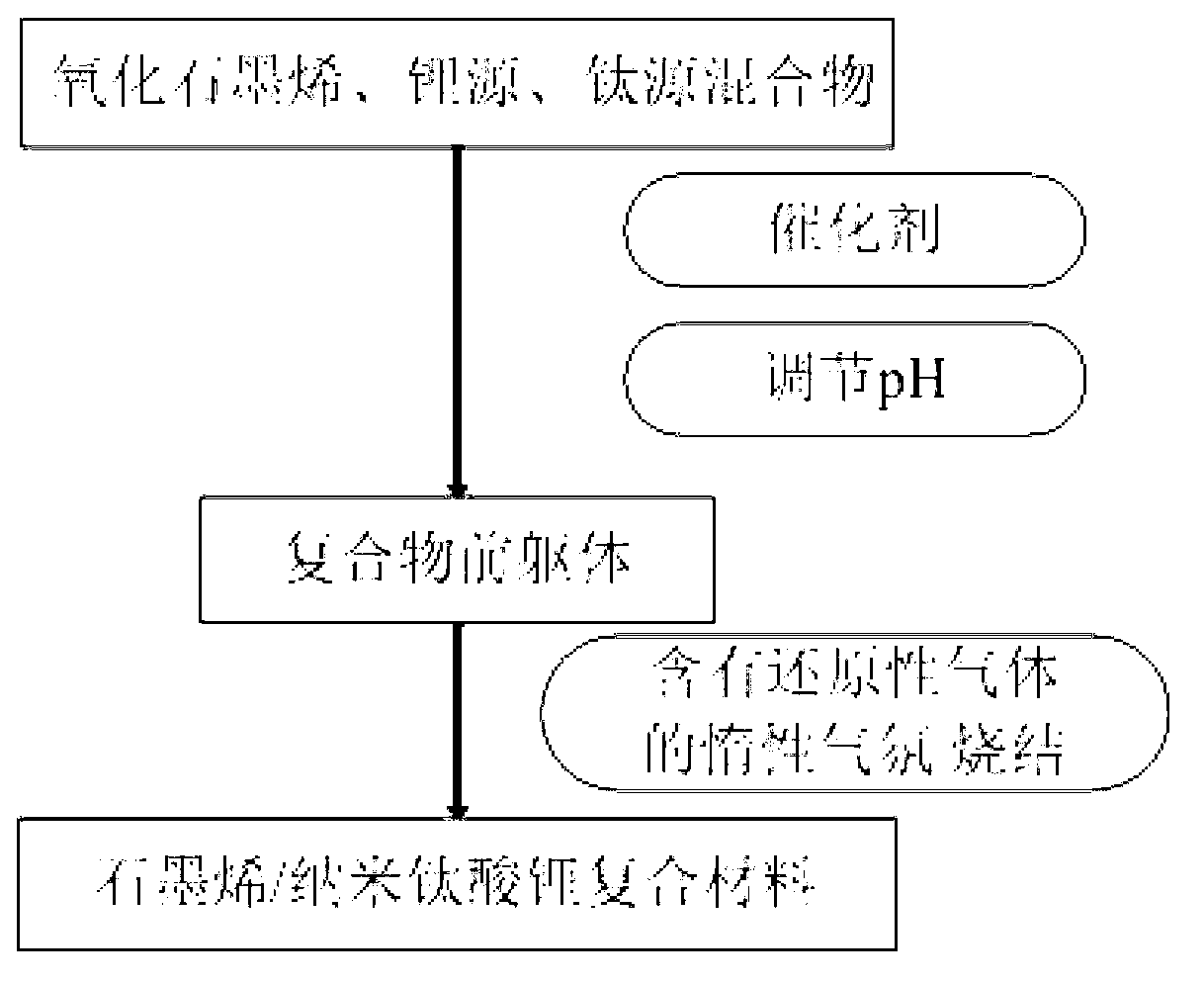

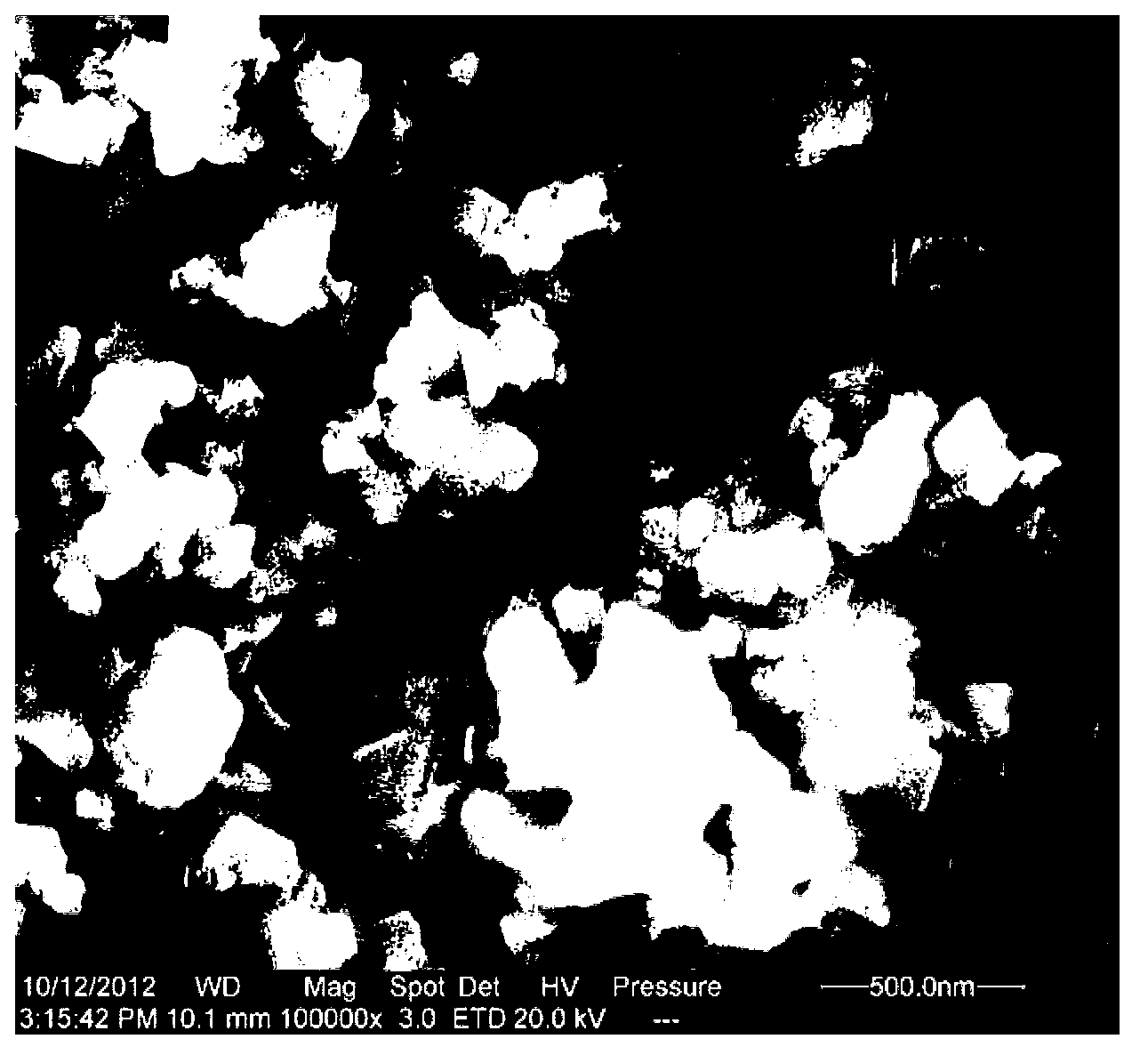

Preparation method of graphene/lithium titanate composite anode material

ActiveCN103022459AImprove electrochemical performanceGood magnificationCell electrodesHybrid/EDL manufactureActivated carbonSupercapacitor

The invention discloses a preparation method of a graphene / lithium titanate composite anode material, which comprises the following steps: compounding compounds serving as a lithium source and a titanium source and graphene oxide through a liquid-phase method and reducing graphene oxide of the compound in inert gas mixed with reducing gas into graphene so as to obtain the graphene / lithium titanate composite anode material. The method has the characteristic of realizing uniform distribution of graphene in lithium titanate through an in-situ compounding technique. Under the same conditions, the discharge time of a hybrid capacitor which respectively takes the graphene / lithium titanate composite anode material and activated carbon as the anode and cathode is obviously greater than that of an electric double-layer capacitor which takes activated carbon as an electrode and that of a hybrid capacitor which respectively takes lithium titanate and activated carbon as the anode and cathode. The lithium titanate phase purity of a hybrid supercapacitor and lithium ion battery composite anode materials prepared by the method disclosed by the invention is higher. Furthermore, the preparation method further has the characteristic of easily realizing the large-scale industrial production.

Owner:ZHANGJIAGANG IND TECH RES INST CO LTD DALIAN INST OF CHEM PHYSICS CHINESE ACADEMY OF SCI +1

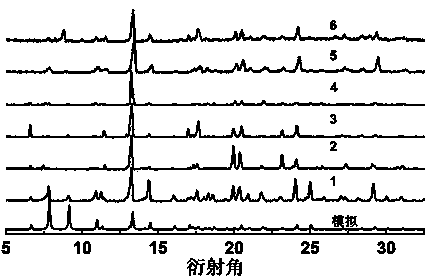

Cadmium coordination polymer and preparation method and application thereof

ActiveCN103588799AImprove thermal stabilityImprove water stabilityLuminescent compositionsCadmium organic compoundsAlcoholTriazine

The invention discloses a cadmium coordination polymer. The chemical formula of the cadmium coordination polymer is C60H36Cd3N12O17, 2,4,6-three(4-pyridyl) triazine serves as the main ligand of the cadmium coordination polymer, terephthalic acid serves as the auxiliary ligand of the cadmium coordination polymer, mixed liquor of N, N-dimethylformamide, ethyl alcohol and water serves as the solution, and accordingly a triple-interpenetrating three-dimensional 'tfz' topology network structure with an inner sealed hole is formed. The cadmium coordination polymer is prepared through the solvothermal method. The cadmium coordination polymer has the advantages that the coordination frame is high in thermal stability and water stability, and the light emitting performance of the cadmium coordination polymer can be controlled by packaging guest molecules with different functions. The manufacturing method of the cadmium coordination polymer has the advantages that the technology is simple in process and easy to apply, the crystal yield and purity are high, and the cadmium coordination polymer has good application prospect in the field of material science as an energy converter and a solid light-emitting material.

Owner:NANKAI UNIV

Medical fluorinated calcium phosphate coating material and its prepn process

InactiveCN1486751AHigh phase purityIncrease profitMetallic material coating processesCalcium phosphate coatingPhosphoric acid

The present invention relates to one kind of medical material used for hard tissue. It consists of medical base body and surface fluorinated calcium phosphate coating, which is fluorinated hydroxyapatite, fluorinated calciprivic hydroxyapatite, fluorinated tricalcium phosphate or carbonate radical substituted hydroxyapatite. During the preparation, alcohol solution of the mixture of alcohol soluble calcium salt and phosphate or partially esterified phosphoric acid is used as precursor and surface coating is formed on alumina ceramic or medical metal base body via conventional sol-gel soaking pulling process, rotary painting process, combined soaking pulling and centrifuging process or hot solution spraying process. The coating has high crystalline phase content, no impurity phase and high phase purity. The preparation process of th present invention can obtain coating with thickness adjustable from several hundred nanometers to several decade microns.

Owner:ZHEJIANG UNIV

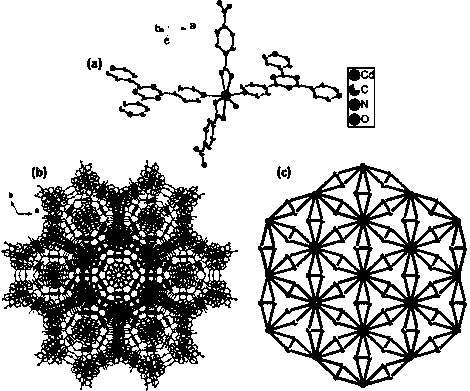

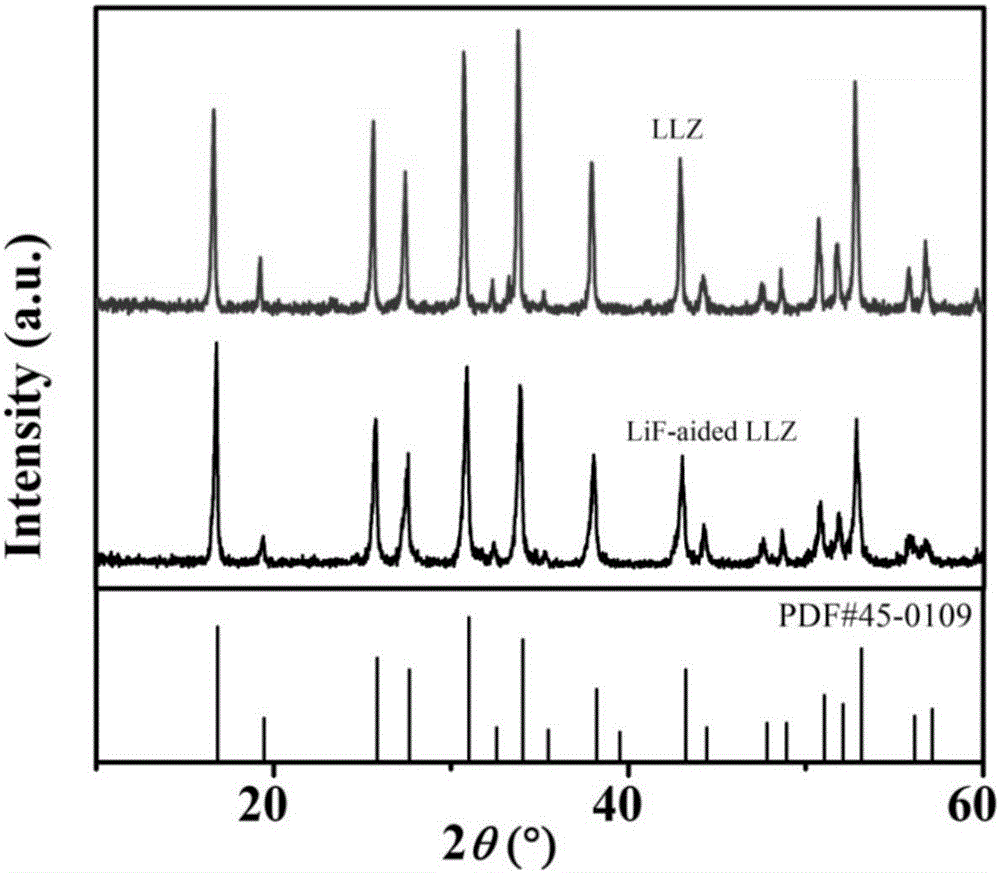

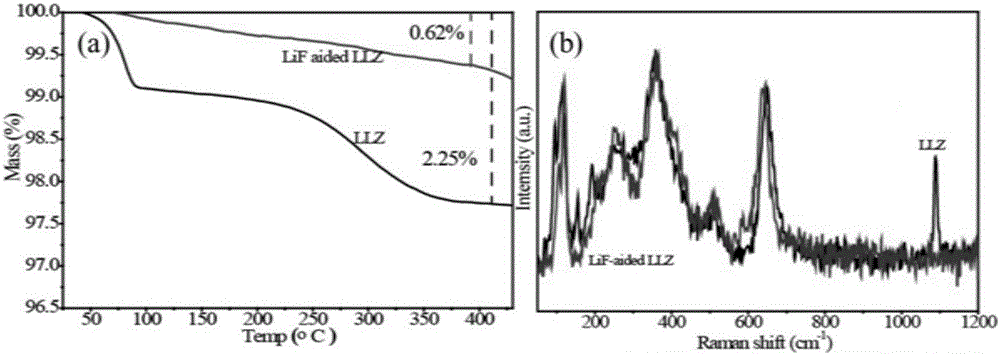

Solid electrolyte capable of lowering interface resistance on metal lithium electrode, and preparation method for solid electrolyte

ActiveCN106129466AReduce lossReduce time lossSecondary cellsElectrolyte immobilisation/gelificationSolid state electrolyteState of art

The invention relates to a solid electrolyte capable of lowering interface resistance on a metal lithium electrode, and a preparation method for the solid electrolyte. The preparation method comprises the steps of mixing lithium carbonate, lanthanum oxide and zirconium oxide, and uniformly grinding the mixture by a dry grinding method; then sintering the mixture in a muffle furnace, and grinding to obtain mother powder, and tabletting the mother powder; putting the tablet-shaped material into a crucible with a cover; then performing mother powder filling and sintering in the muffle furnace to obtain the compact ceramic sheet; and polishing the ceramic sheet until the surface of the ceramic sheet is smooth to obtain the solid electrolyte. Compared with the prior art, the electrolyte prepared by the method has the advantages of absence of impure phase on the surface, high relative density, low interface resistance on the metal lithium electrode, and the like.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of Si3N4-SiC-C fire-resistant material powder

The invention relates to a preparation method of Si3N4-SiC-C fire-resistant material powder, belonging to the technical field of fire-resistant material preparation. The preparation method is characterized by comprising the following steps of: reducing nitrided natural quartz by coke dust and graphite or carbon black in a carbothermal way in a proper high-temperature environment and a nitrogen atmosphere to prepare an Si3N4-SiC-C high-temperature resistant material; and preparing the Si3N4-SiC-C fire-resistant material powder which can be used for fire-resistant products, i.e. side wall bricks of an aluminium cell and the like, through processes, i.e. crushing, grinding, levigating, and the like. The Si3N4-SiC-C fire-resistant material mainly comprises the following components: alpha-Si3N4, beta-Si3N4, alpha-SiC, beta-SiC, a small amount of C and Si2N2O, and the like. The novel preparation method of the Si3N4-SiC-C fire-resistant material powder has the outstanding advantages of simple equipment, low cost, little energy consumption of the preparation process, convenient large-scaled production, and the like, and also provides a new technological approach for the efficient appreciation utilization of the natural quartz.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Battery grade sheet hydrated iron phosphate and preparation method thereof

InactiveCN103022482AShape is easy to controlControl shapeCell electrodesLithium iron phosphateSurface-active agents

The invention relates to a lithium ion battery anode material precursor and a preparation method thereof. The precursor is sheet hydrated iron phosphate, and the preparation method comprises the following steps of: dissolving a surface active agent, an iron source compound and a phosphorus source compound in water to form a uniform and stable solution A, wherein the added quantity of the surface active agent is 2 to 10 g / L, the concentration of iron is 0.08 to 0.32 mol / L, the mole ratio of the iron to phosphorus is 1:X, and X is more than or equal to 3.0 and less than or equal to 5.0; adding oxydol into the solution A, and stirring to obtain a solution B; performing high-temperature reaction on the solution B to obtain a solution C; and filtering the solution C to obtain the hydrated iron phosphate. By the method, the sheet hydrated iron phosphate with a controllable shape can be prepared, thus the electrochemical performance of a lithium ion battery anode material namely lithium iron phosphate is improved; and the filtrate obtained in the preparation process can be recycled to improve the utilization ratio of raw materials.

Owner:PULEAD TECH IND

Air purifying photocatalyst and preparation method thereof

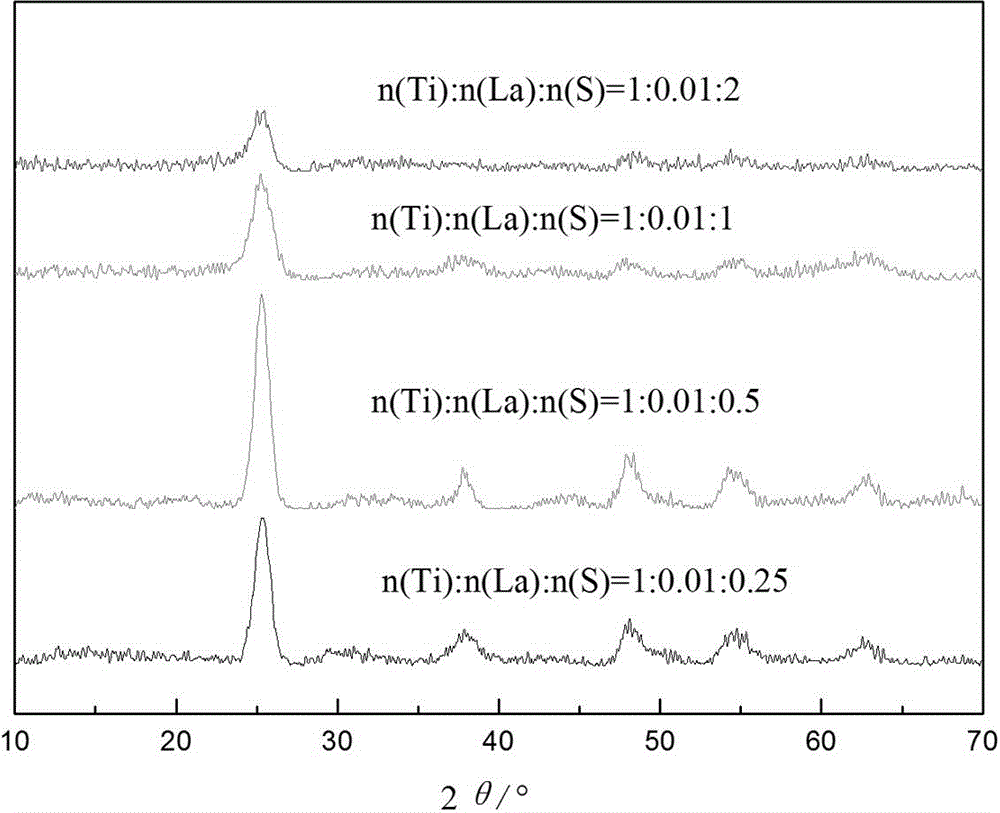

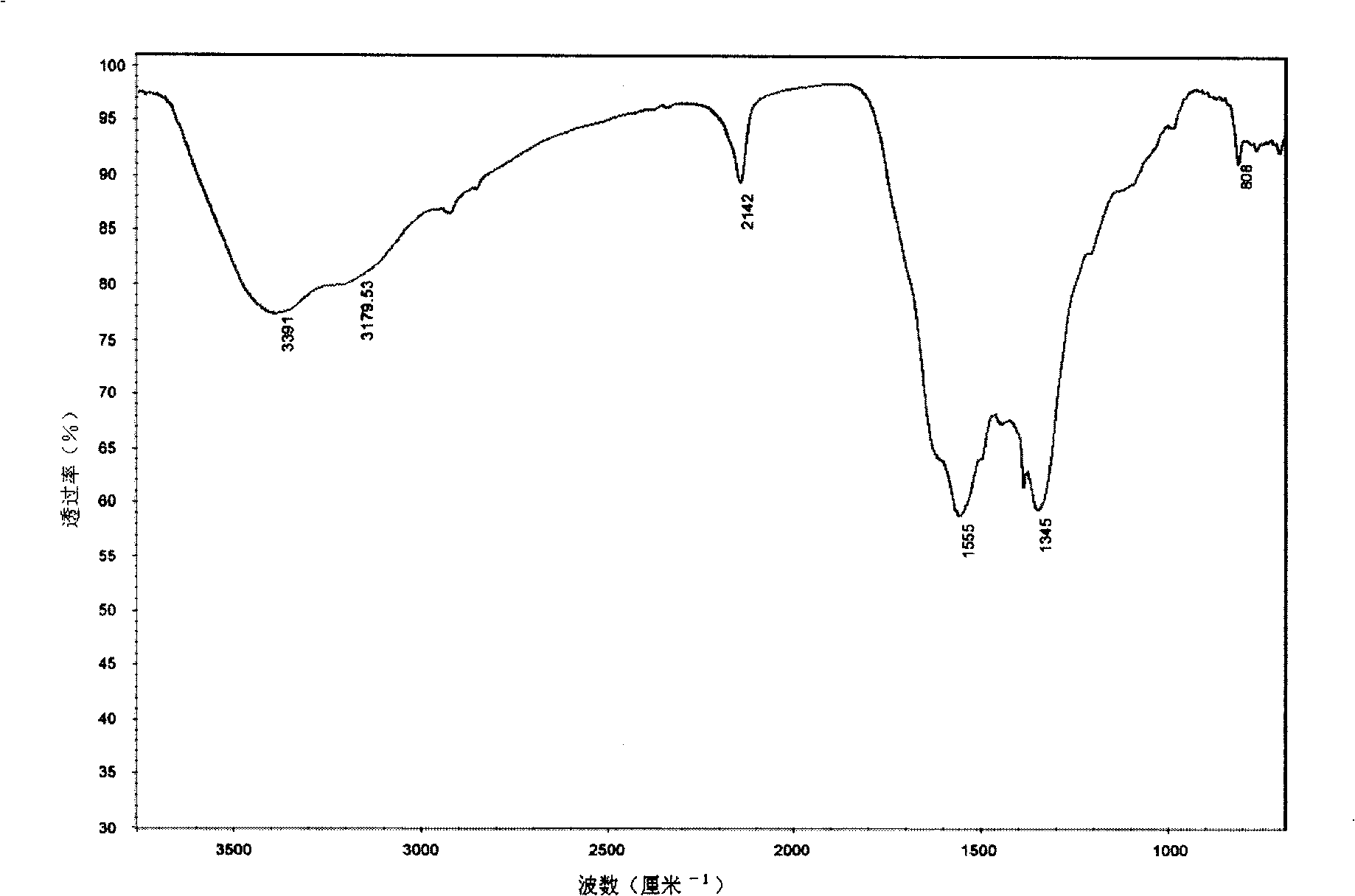

ActiveCN104624208ARich sourcesLarge specific surface areaBiocidePhysical/chemical process catalystsPtru catalystAir decontamination

The invention discloses an air purifying photocatalyst. Anatase type titanium dioxide acts as a base body of the catalyst, and sulfur and lanthanum act as doped components, wherein the mole ratio of sulfur to lanthanum to titanium dioxide is (0.1-2) to (0.001-0.015) to 1, and the catalyst exists in a form of powder. The preparation process of the catalyst comprises the following steps of feeding the titanium source, the sulfur source and the lanthanum source according to a certain ratio, adding a dispersing agent and an inhibitor, hydrolyzing at the temperature of 10-80 DEG C with the pH of 2-7 so as to generate gel, drying at constant temperature in a drying oven, putting into a muffle furnace, firing and the like. The prepared anatase type sulfur and lanthanum codoped nano titanium dioxide powder is uniform in particle size, is controllable in particle size, is good in dispersibility, has a good catalytic degradation and purification effect on harmful gases, such as formaldehyde in an air environment, and meanwhile has a good antibacterial property.

Owner:LUOYANG INST OF SCI & TECH

Solvent thermal constant-pressure synthesis method for controlling phase of carbon nitride material

InactiveCN101254905AAchieve selective synthesisHigh phase purityNitrogen purification/separationNitrogen and non-metal compoundsSynthesis methodsSolvent

A method for controlling the phase of carbon nitride material by solvent heating constant pressure synthesis belongs to fields of chemical production and new material. The method includes preparing carbon source solution and nitrogen source solution; feeding into a reaction kettle; applying constant pressure of 40-2,000MPa before heating; heating up to 220-1,000 DEG C at a heating rate of 0.01-60 DEG C / min; cooling after the reaction is completed; and post-treating the product. When the boron carbon nitride is synthesized by the method, temperature and pressure of the reaction system can be independently controlled, so that the reaction can be carried out under the constant pressure, and the pressure of the reaction system can be varied according to the requirement so as to control the speed and the direction of the reaction for synthesizing boron carbon nitride. The method is capable of preparing high-particle size carbon nitride crystal.

Owner:SHANDONG UNIV

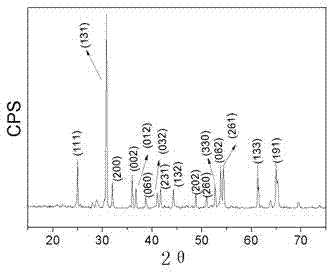

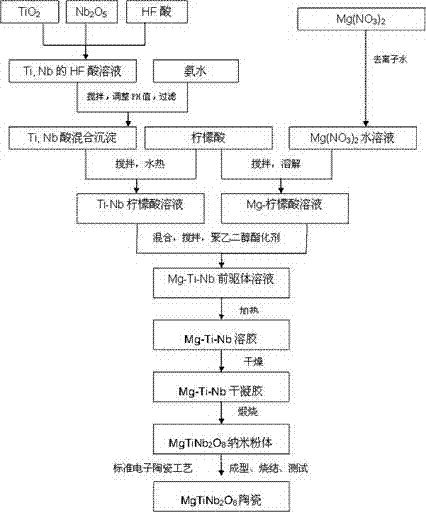

New method for finely preparing ixiolite structure MgTiNb2O8 microwave dielectric ceramic by using chemical process

Owner:UNIV OF JINAN

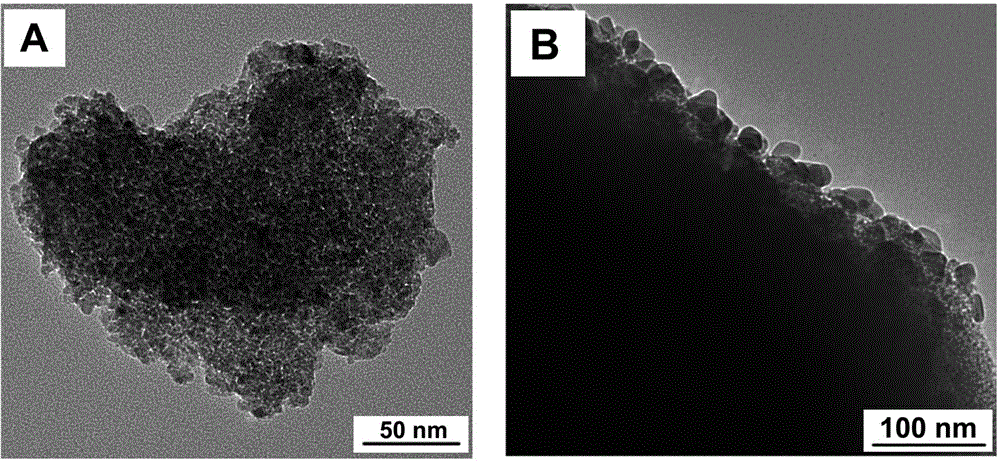

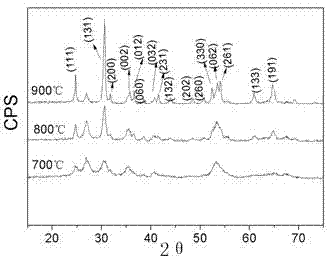

Preparation method of CuInSe2 with a chalcopyrite structure and CuIn1-xGazSe2 nano particles

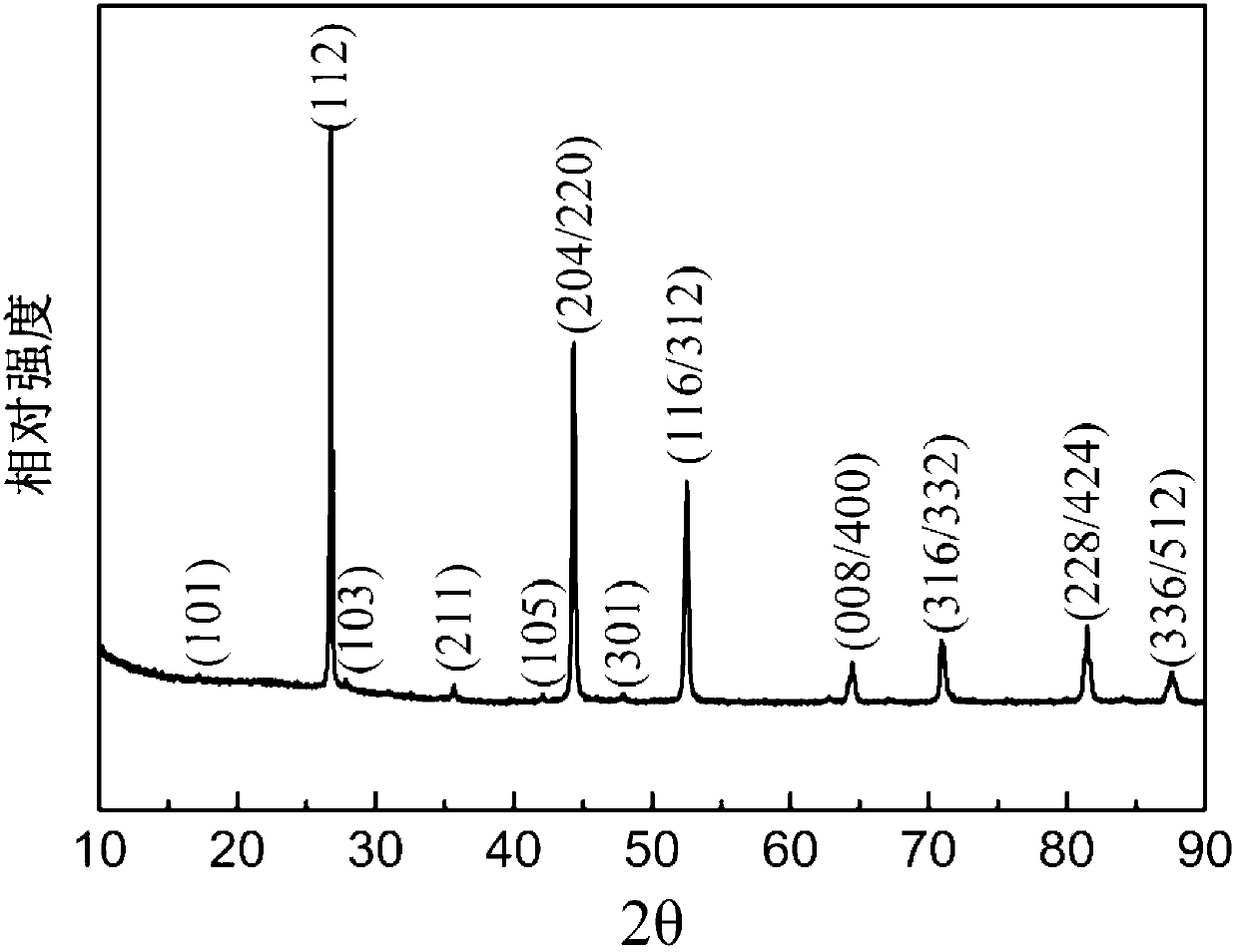

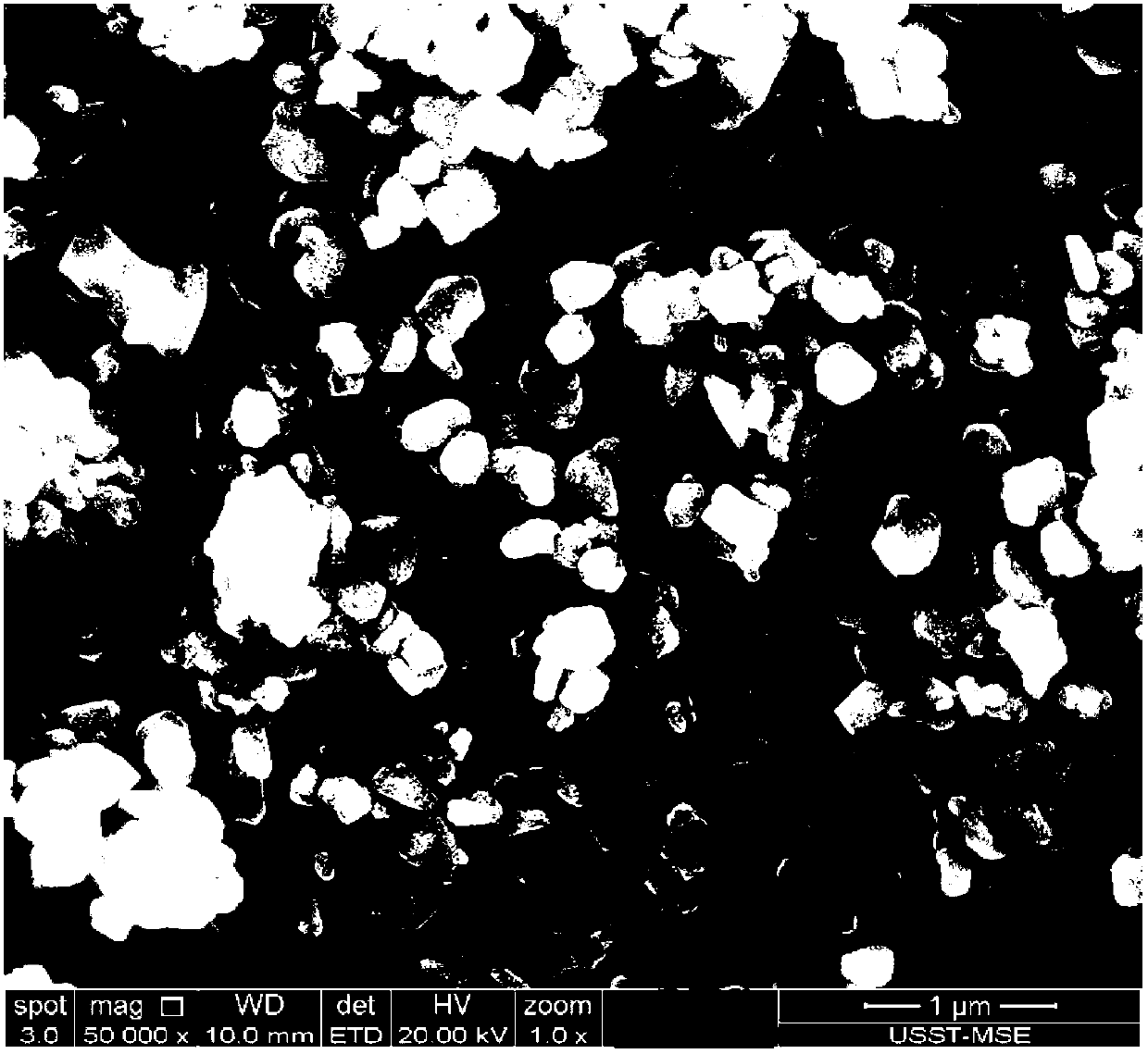

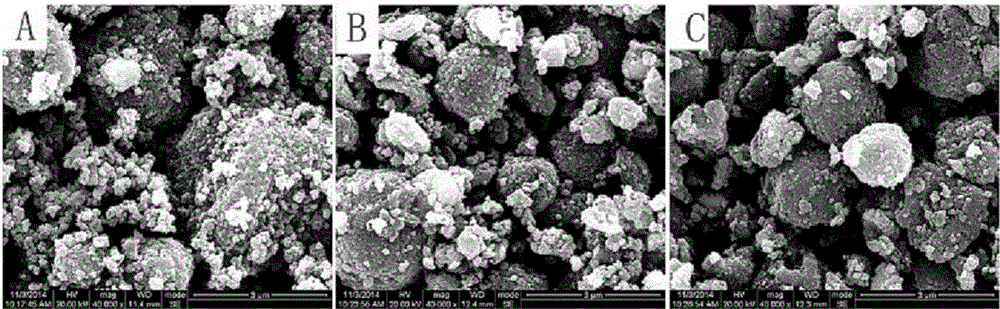

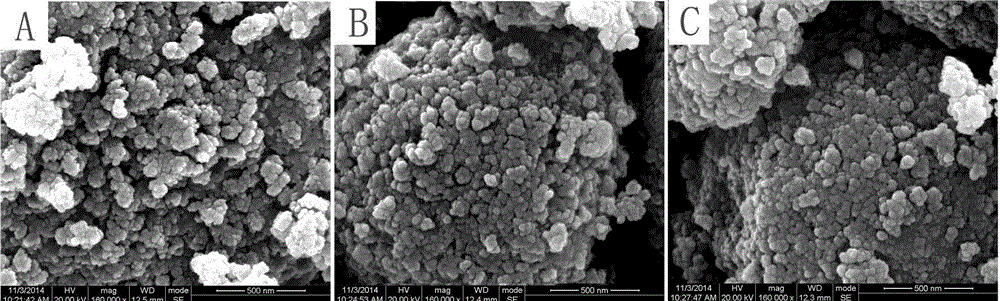

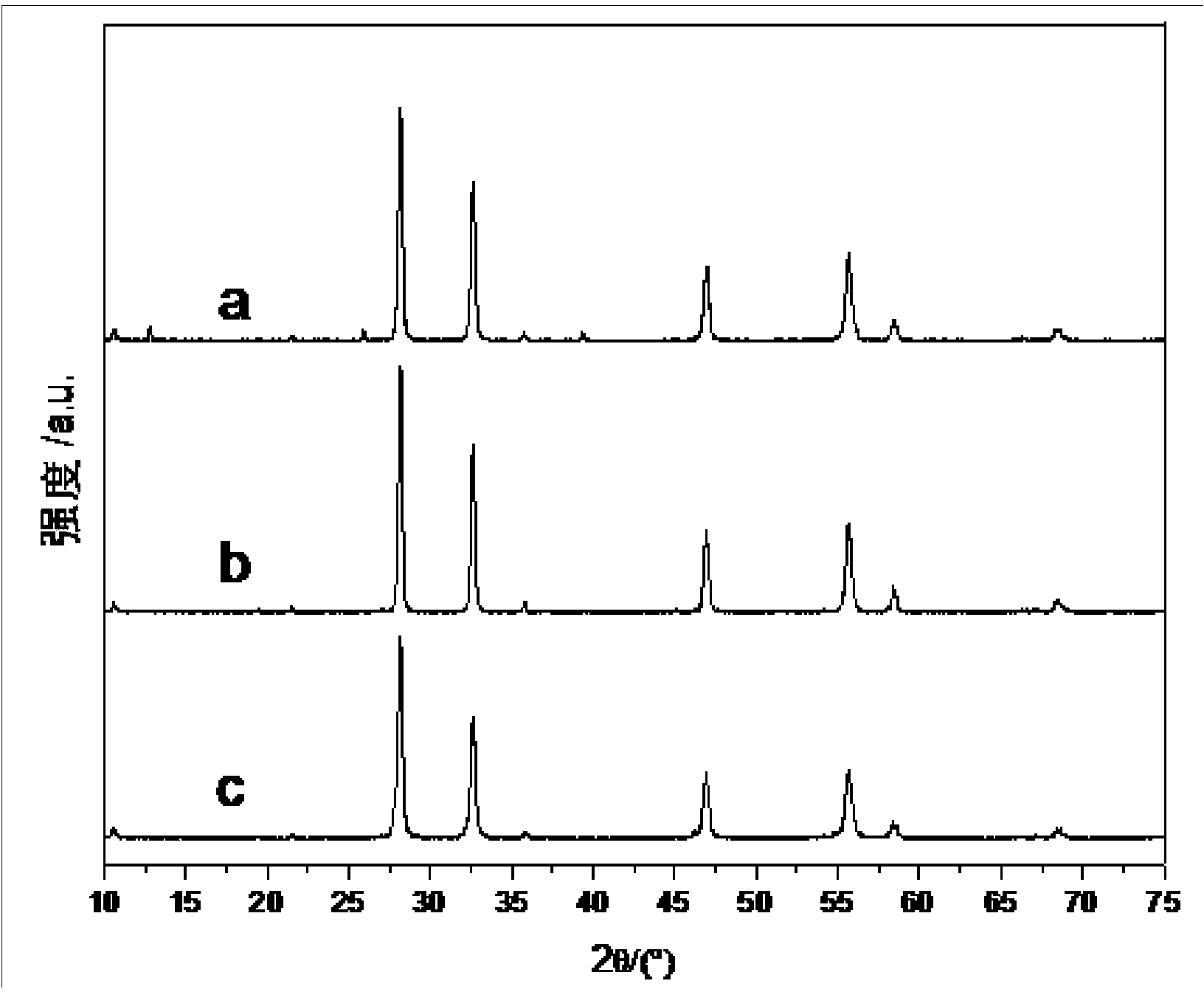

InactiveCN103213956AGood dispersionHigh phase purityMaterial nanotechnologySelenium/tellurium compundsChalcopyriteCentrifugation

The invention relates to a preparation method of CuInSe2 with a chalcopyrite structure and CuIn1-xGazSe2 nano particles. Firstly, a metal precursor solution containing Cu+ or Cu2+, In3 or Ga3+ cation and a Se powder precursor solution are respectively prepared, and then the metal precursor solution and the Se powder precursor solution are mixed and uniformly stirred, and the solution is heated to 200-285 DEG C. with high purity nitrogen protection and reacted for 0.5-2 hours, and then the CuInSe2 or CuIn1-xGazSe2 nano particle solution is obtained, after high speed centrifugation, cleaning and drying steps, the CuInSe2 or CuIn1-xGazSe2 nano particles are obtained. The CuInSe2 or CuIn1-xGazSe2 nano particle has the advantages of chalcopyrite crystal structure, good dispersibility and high phase purity, and the element ingredient approaches to the stoichiometric ratio, thereby laying a foundation for preparing a high conversion efficiency film solar energy battery. The invention employs cheap metal salt and selenium powder as precursors, and employs a simple one-pot synthetic method, and has the advantages of simple operation, short synthesis period, strong repeatability without injection, and is suitable for mass production.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Biological medical material with biological responding coating and preparing method

InactiveCN1743014AHigh crystal contentHigh phase purityCoatingsFlagellar basal bodyBiomedical engineering

The present invention discloses a biological medical material with biological resposibility coating layer and its preparation method. It is formed from medical basal body and metal-iron-doped fluorine-contained hydroxy apatite nano coating layer coated on the surface of medical basal body. Said biological medical material can stimulate osteoblast differentiation and proliferation in early stage of implatation, can promote growth of bone and can accelerate cure process. Said invention also provides the concrete steps of its preparation method.

Owner:ZHEJIANG UNIV

Preparation method of amorphous BaF2

InactiveCN104211100ASmall grain sizeUniform shapeCalcium/strontium/barium fluoridesCrystalliteLarge applications

The invention belongs to the technical field of material preparation and relates to a preparation method of amorphous BaF2. The preparation method comprises the following steps of preparing cubic fluorite-structure BaF2 nano-crystal grains as initial raw materials having crystal grain sizes of about 14nm by a solvothermal synthesis method, applying pressure to the material by a diamond opposite-pressing anvil press until the highest pressure is 30GPa so that the cubic fluorite structure of the sample is transformed into an amorphous structure, and releasing the pressure in the diamond opposite-pressing anvil press until the pressure is equal to ordinary pressure so that the amorphous structure of the BaF2 sample is still retained under the ordinary pressure. The initial raw materials have the advantages of simple processes, small crystal grain size, uniform morphology and narrow particle size distribution. The product obtained by high-pressure synthesis has a stable amorphous structure under the ordinary pressure and has high phase purity. The BaF2 material has good optical performances. The novel synthetic material has large application potential in fields of optics and biology.

Owner:JILIN NORMAL UNIV

Method for preparing lithium iron phosphate cathode material of lithium ion battery by supercritical hydrothermal process

InactiveCN102569800AImprove discharge capacityImprove cycle lifeCell electrodesCarbon coatingFiltration

The invention relates to a method for preparing a lithium iron phosphate cathode material of a lithium ion battery by a supercritical hydrothermal process and belongs to the technical field of a novel material. The method comprises the following steps: (1) hydrothermal synthesis reaction, i.e. dissolving an iron source, a phosphorus source, a lithium source and a template agent in water, placing mixes solution into a reaction kettle, pumping out the air in the kettle by adopting a vacuum pump, heating the reaction kettle to the temperature of 380 DEG C to 500 DEG C, regulating the pressure in the kettle into 23MPa to 40MPa by a water injection pump, performing a reaction for 10s to 100min, and controlling the proportion of the added materials into a molar ratio of Li to Fe to P of (3.0 to 3.15):1:(1.0 to 1.15); (2) filtration, washing and drying of a product, i.e. after the reaction is completed, carrying out water-cooling temperature reduction on the reaction kettle and finally, filtering, washing and drying the generated product to obtain gray white LiFePO4 powder; (3) calcining and carbon coating treatment, i.e. calcining the obtained product for 1 to 8 hours at the temperature of 500 DEG C to 800 DEG C in the protective atmosphere to obtain carbon-coated lithium iron phosphate. The product obtained by the method of the invention has excellent electrochemical performance and uniform particle size distribution. The sizes of the particles of the product are in the range of 300nm to 800nm. The phase purity of the product can reach over 99%. The electron conductivity of the material and the diffusion performance of lithium ions are improved.

Owner:DALIAN UNIV OF TECH

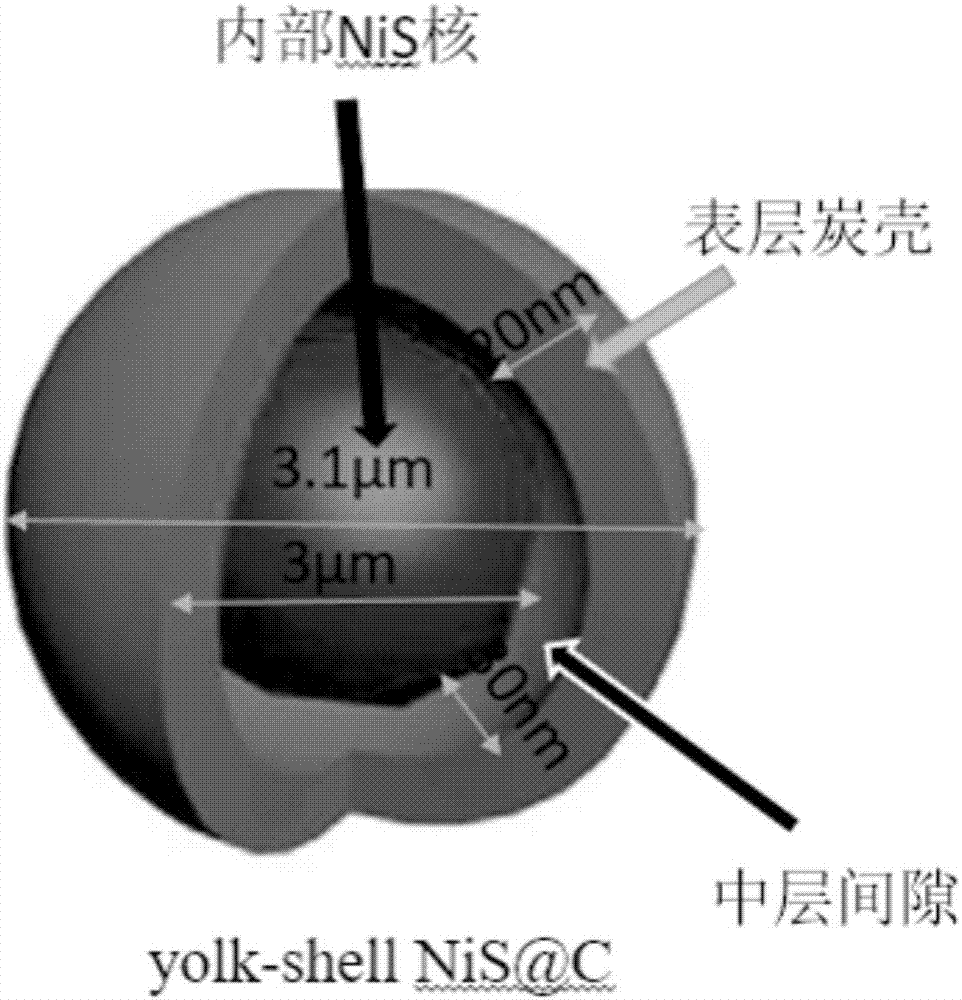

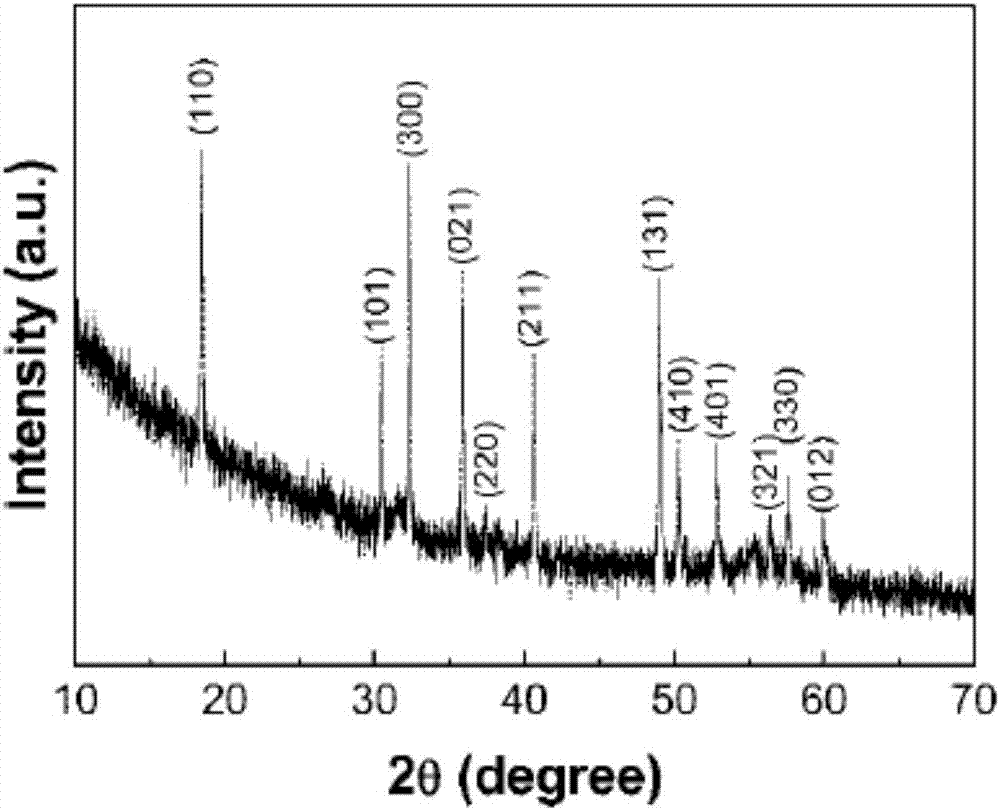

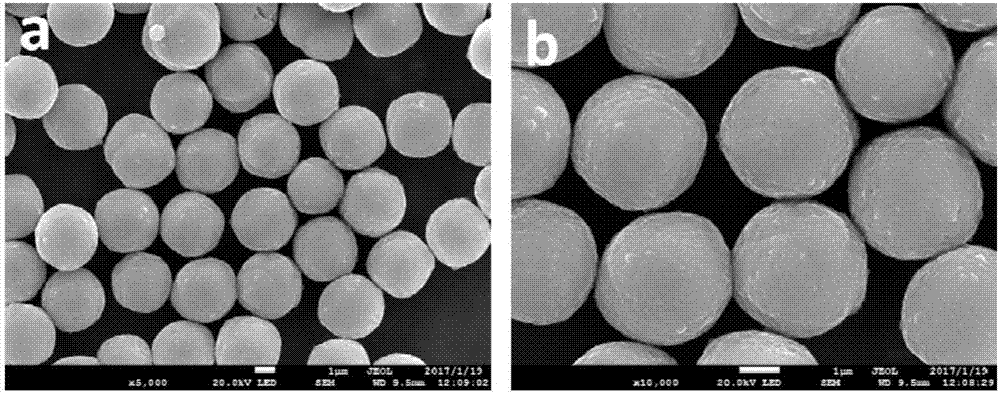

Carbon shell coated NiS classification microsphere and preparation method and application thereof

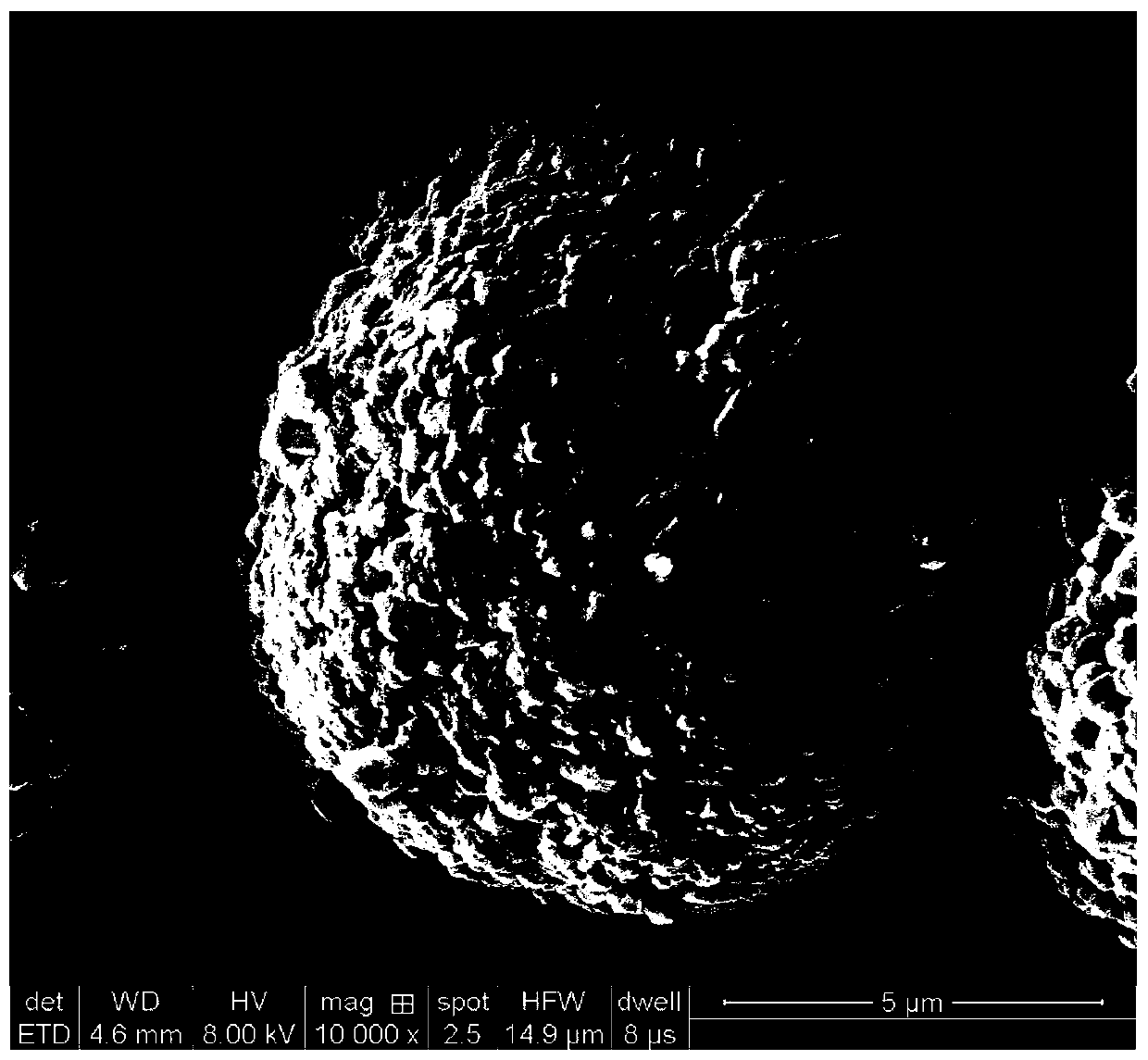

ActiveCN106876676AReduce manufacturing costSimple preparation processCell electrodesSecondary cellsMicrosphereMicrometer

The invention provides a carbon shell coated NiS classification microsphere and a preparation method and application thereof. A diameter of the carbon shell coated NiS classification microsphere is 3-4 micrometers. The NiS classification microsphere comprises a NiS microsphere core and a carbon shell coating the outer layer of the NiS microsphere. A clearance exists between the inner surface of the carbon shell and the outer surface of the NiS microsphere. The diameter of the NiS microsphere is 2-3 micrometers. According to the carbon shell coated NiS classification microsphere, the preparation method and the application, a carbon shell coated NiS classification microsphere electrode material is prepared through adoption of a solvothermal reaction-coating-calcining-etching four-step method. According to the carbon shell coated NiS classification microsphere, the preparation method and the application, on the basis that expansion coefficients of different dielectric materials are different, materials with different strain capacities are combined; when the carbon shell coated NiS classification microsphere is used as a sodium-ion battery anode material, the relatively high reversible capacity and excellent cycling stability are shown; the carbon shell coated NiS classification microsphere is a potential application material of a high-capacity and long-service-life sodium-ion battery; the cost of raw materials is low; a synthesis technology is simple; a condition is mild; a green chemical demand satisfied; and industrial application and popularization are facilitated.

Owner:WUHAN UNIV OF TECH

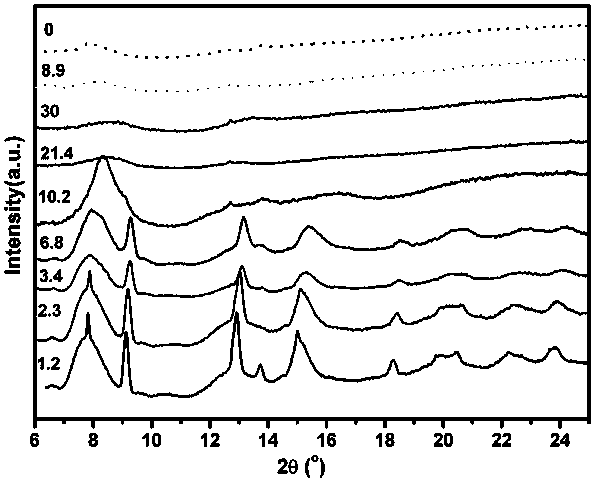

Method for synthesizing GME zeolite molecular sieve

ActiveCN104445264ALow costEnvironmental protectionCrystalline aluminosilicate zeolitesMolecular sievePolyethylene glycol

Owner:CHINA PETROLEUM & CHEM CORP +1

Doped high-nickel high-voltage NCM positive electrode material and preparation method thereof

PendingCN110797529AReduce consumptionIncrease profitCell electrodesSecondary cellsHigh energyManganese

The invention discloses a doped high-nickel high-voltage NCM positive electrode material and a preparation method thereof, and belongs to the field of lithium ion batteries. The preparation method comprises the following steps: simultaneously doping manganese and cobalt to obtain an NCM precursor; and adding a dopant M into the precursor, and sintering the precursor in a high-pressure oxygen atmosphere to obtain a lithium ion battery positive electrode material. The positive electrode material has very high specific discharge capacity and excellent cycling stability, can meet the high-rate charging and discharging requirement, and can achieve long-life safe cycling under high voltage. The positive electrode material is prepared by combining four-solution parallel-flow co-precipitation witha high-pressure solid-phase synthesis method, and the prepared product has the advantages of high purity, high crystallization quality, high particle density, uniform distribution of particles, excellent electrochemical performance and low manufacturing cost, is an ideal positive electrode material with high energy density, and has a wide application prospect.

Owner:SICHUAN FUHUA NEW ENERGY HIGH TECH CO LTD

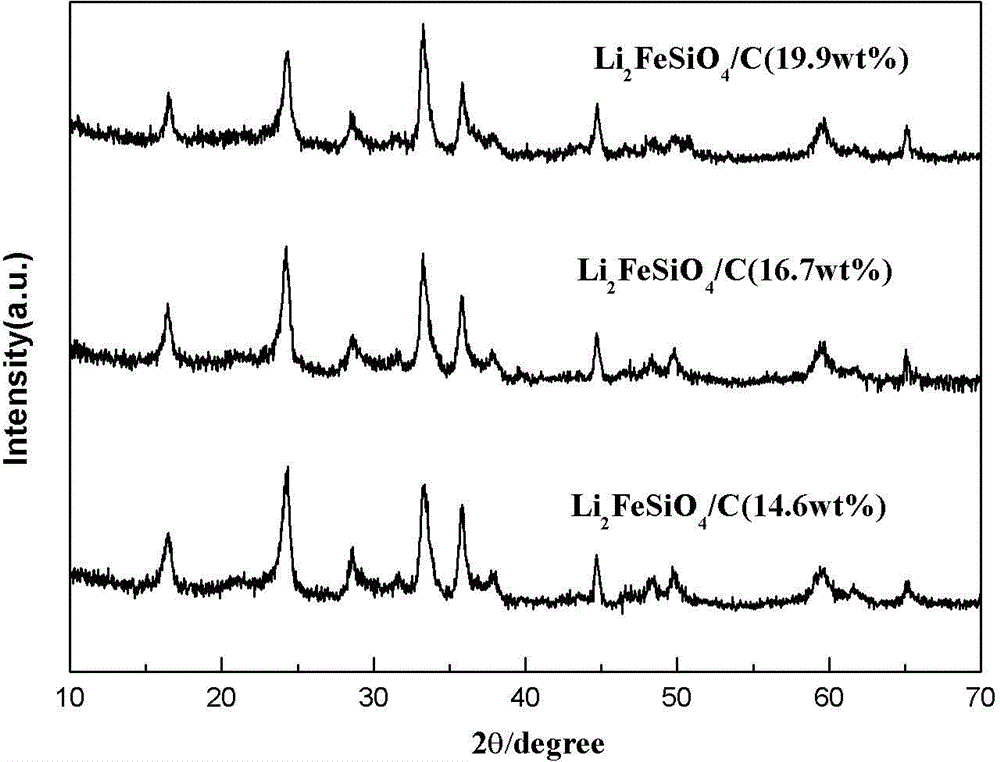

High rate LiFePO4/C positive electrode material and preparation method thereof

InactiveCN104638261AWide variety of sourcesLow process temperatureCell electrodesHigh rateLithium iron phosphate

The invention provides a high rate LiFePO4 / C positive electrode material and a preparation method thereof. The method comprises the following steps: uniformly mixing an aqueous solution of a phosphorus source, an aqueous solution of a lithium source and an aqueous solution of a divalent iron source with a dispersant and / or a surfactant; carrying out a hydrothermal reaction on the above obtained uniformly mixed solution at 120-250DEG C; separating out a precipitate from a material obtained after the hydrothermal reaction, washing the precipitate, and carrying out first stage drying on the precipitate; and uniformly mixing the obtained first stage dried solid with a carbon source, carrying out second stage drying, sintering the obtained solid, and cooling the sintered solid. The particle size of lithium iron phosphate (LiFePO4) synthesized through the method along b direction (the lithium ion diffusion direction) is 20-200nm, and the LiFePO4 / C positive electrode material has the advantages of small particle size and uniform distribution of particles, high phase purity, improvement of the diffusion performance and the electrochemical performances of lithium ions in the lithium iron phosphate material, high conductivity, large specific capacity and good cycle life.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

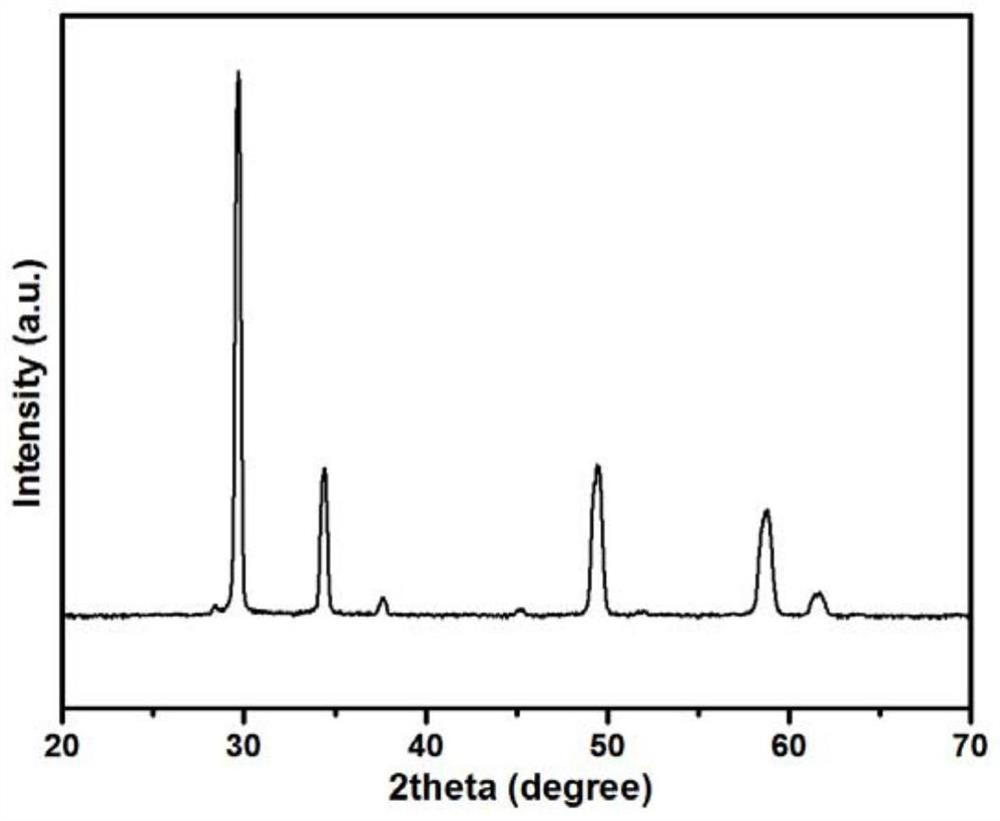

Ceramic nanometer composite material for heat barrier coating and preparation method of ceramic nanometer composite material

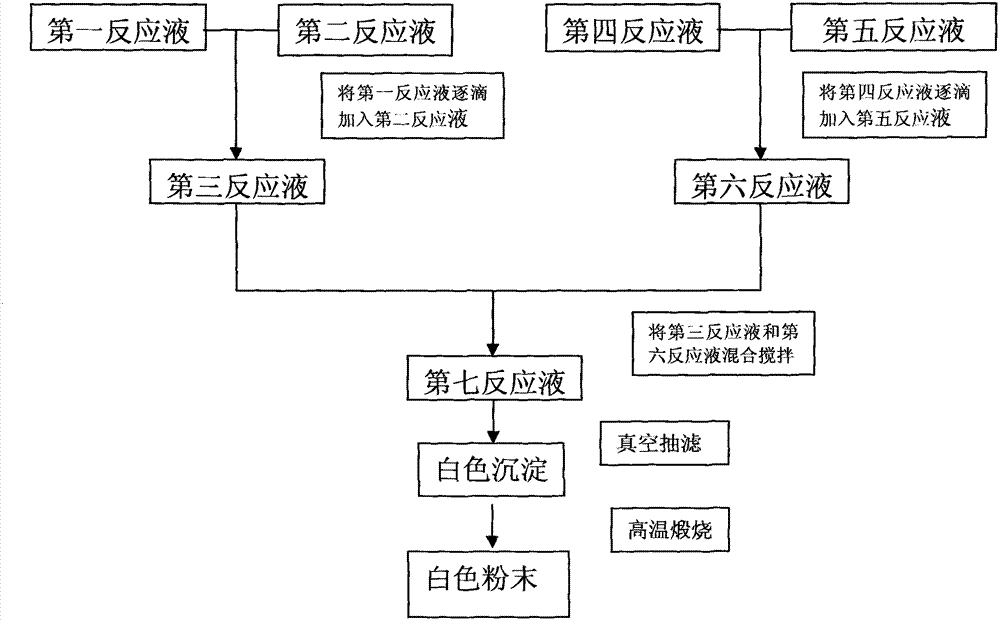

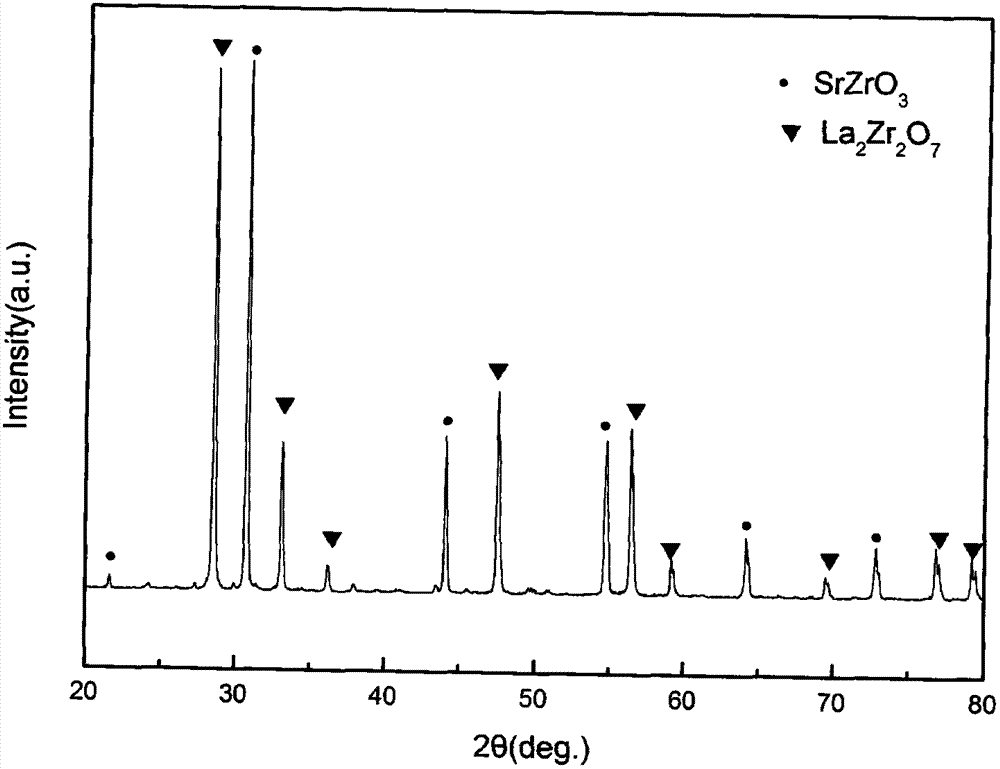

The invention belongs to the technical field of a ceramic nanometer composite material, and provides a ceramic nanometer composite material for a heat barrier coating and a preparation method of the ceramic nanometer composite material. Cheap Ln(NO3)3.6H2O, Sr(NO3)2 and Zr(NO3)4.5H2O are used as raw materials and are subjected to solution preparation, sedimentation, suction filtration, drying and calcination to obtain the required ceramic nanometer composite material. The size of crystal grains of each phase in the prepared ceramic nanometer composite material is less than 70 nm; each phase is uniform in distribution; the ceramic nanometer composite material has good high-temperature chemical stability, scouring resistance and heat insulation; growth of the crystal grains under a high temperature condition is favorably suppressed; the mechanical property, particularly toughness, of the ceramic nanometer composite material is improved; and the ceramic nanometer composite material is used as a superior candidate material for the heat barrier coating. The ceramic nanometer composite material has the advantages of simple preparation method, relatively low synthesis temperature, short time, high phase purity, energy saving, suitability for large-scale synthesis and high promotion and application values.

Owner:INNER MONGOLIA UNIV OF TECH

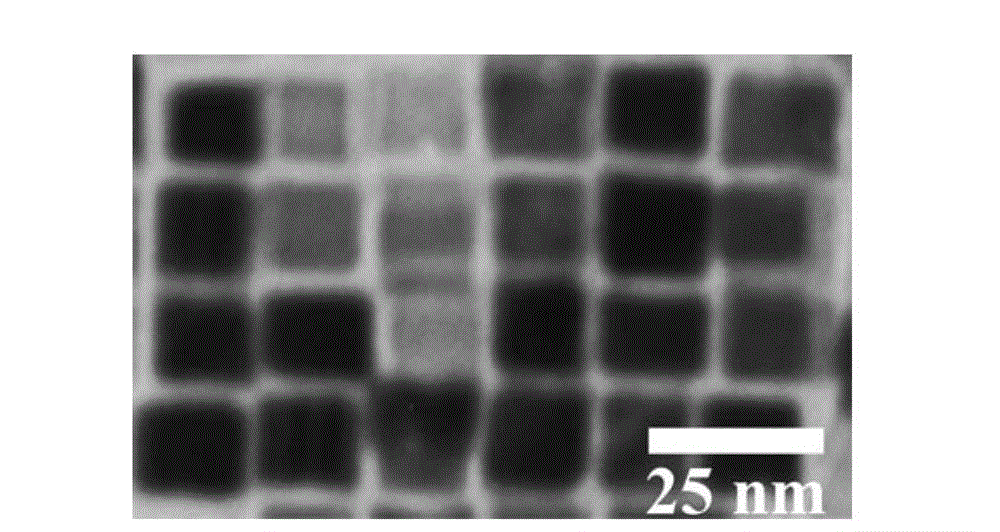

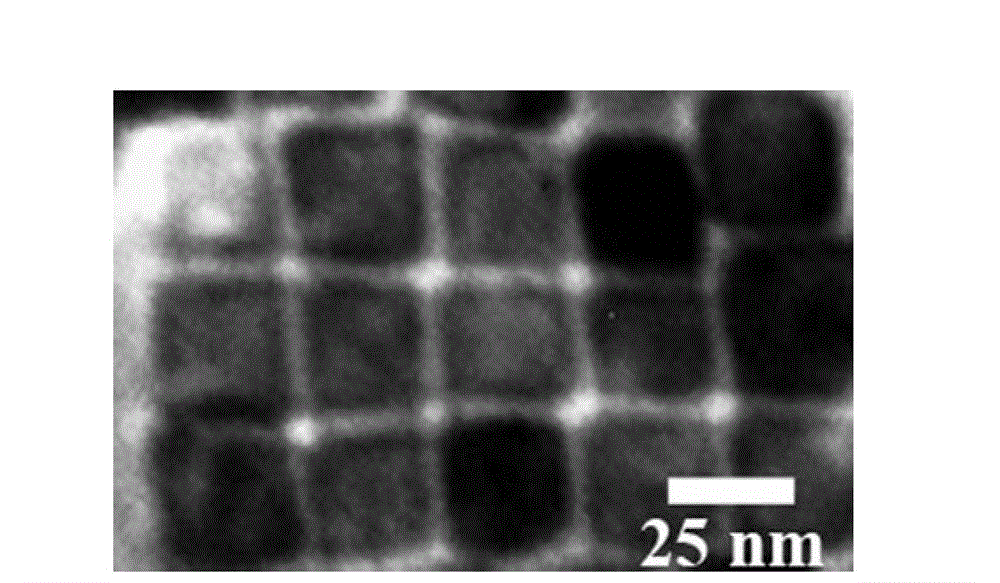

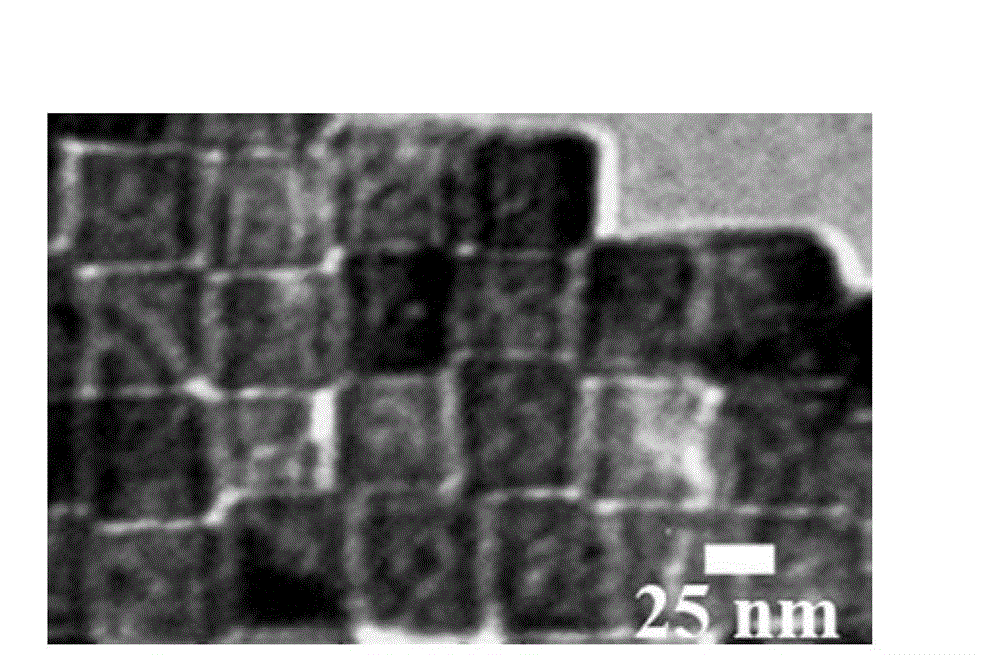

Synthesis method for rock salt mine MnS nano-cuboid superlattice

InactiveCN102942224AStabilized Rock Salt Mine StructureStable structureMaterial nanotechnologyManganese compoundsSynthesis methodsCrystallinity

A synthesis method for a rock salt mine MnS nano-cuboid superlattice, which is disclosed by the invention, belongs to the technical field of nano-material preparation. Anhydrous manganese chloride and thioacetamide as materials and oleylamine and oleic acid as ligands are mixed, agitated and heated until uniform orange solution is obtained; the solution is then heated to 240 DEG C to 260 DEG C, and reacts for 0.5 to 2 hours, so that rock salt mine MnS nano-crystals are formed; and finally, the solution is naturally cooled to room temperature, so that the rock salt mine MnS nano-cuboid superlattice is obtained. The synthesis method has the advantages of common used materials, simple process, short synthesis time, high repeatability, safety and the like, and the nano-crystal size of the product is controllable; and the prepared rock salt mine MnS nano-cuboid superlattice has the advantages of stable structure, high phase purity, good crystallinity, uniform grain size distribution and good optical and magnetic properties.

Owner:JILIN UNIV

Method for preparing ferrous silicate lithium/carbon composite positive pole material with micropore spherical structure

ActiveCN104362318AImprove electronic conductivityImprove conductivityCell electrodesCarbon compositesOxalate

The invention discloses a method for preparing a ferrous silicate lithium / carbon composite positive pole material with a micropore spherical structure. The method particularly comprises the following steps of (1) adding citric acid and lithium hydroxide into water, and stirring for dissolution; adding ferrous oxalate, regulating the pH of a solution to 6-8, carrying out oil bath at 80-95 DEG C, and keeping temperature for 24-72 hours to form a deep green solution; adding nanometer silicon dioxide, carrying out ultrasonography for 20-60 minutes, and stirring at room temperature for 1-3 hours to prepare gel; (2) spray-drying the gel at 100-120 DEG C to obtain a ferrous silicate lithium / carbon composite precursor; (3) calcining the ferrous silicate lithium / carbon composite precursor in argon at 600-800 DEG C for 8-12 hours to obtain the ferrous silicate lithium / carbon composite positive pole material with the micropore spherical structure. The method disclosed by the invention is simple and safe in process and low in cost. The obtained ferrous silicate lithium / carbon composite positive pole material has the advantages of fine granules, uniformity in distribution, excellent microstructure and preferable electrochemical property.

Owner:HUNAN UNIV OF ARTS & SCI

Nanometer bismuth tungstate with hollow square ball structure and preparation method thereof

InactiveCN103950985ANoveltySimple preparation processMaterial nanotechnologyTungsten compoundsTungstatePollution

The invention discloses nanometer bismuth tungstate with a hollow square ball structure and a preparation method thereof. The preparation method is characterized in that a hollow square ball formed by stacked bismuth tungstate nanosheets is prepared by using bismuth nitrate pentahydrate as a bismuth source, sodium tungstate dihydrate as a tungsten source and an STAB (Sodium triacetoxyborohydride)-containing alcohol-water solution as a dispersing agent and utilizing ammonia water and sodium hydroxide under a hydrothermal condition, and the thicknesses of the nanosheets are about 30nm; and the inner diameter of the square ball is about 1.5 micrometers, and the outer diameter of the square ball is about 2 micrometers. The preparation method has the advantages of simplicity, easiness in operation, strong repeatability, environment protection, no toxicity and harmlessness in a preparation process, novel product morphology, high phase purity and the like and has a high application value in terms of pollution treatment, ray absorption and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

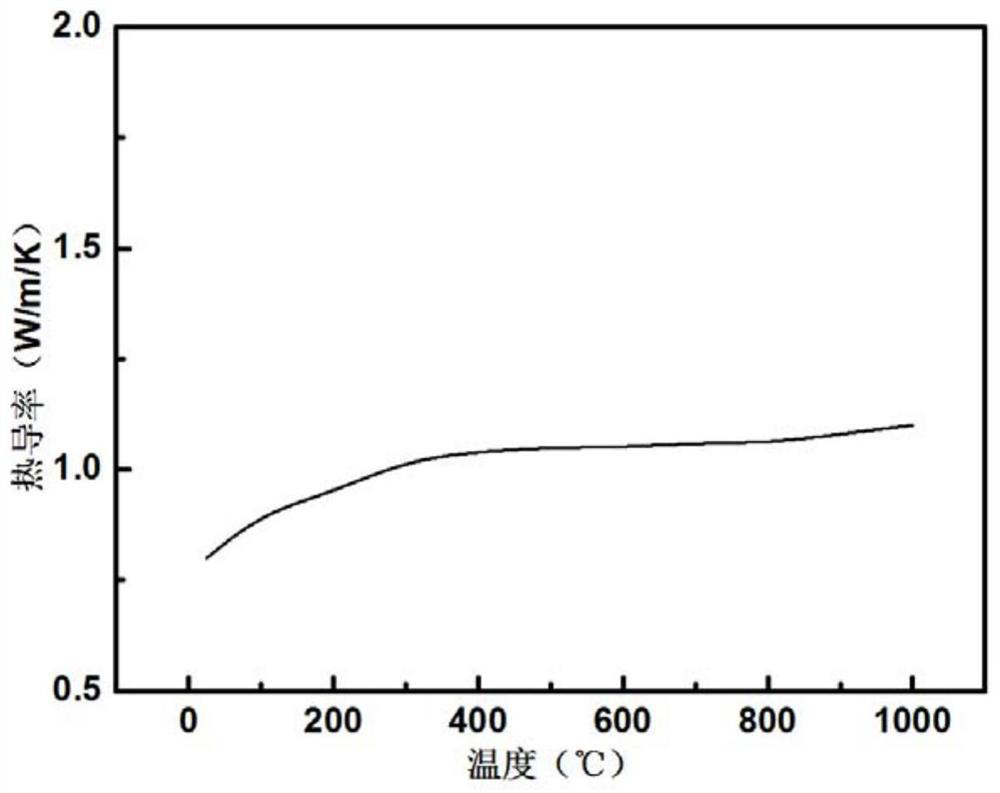

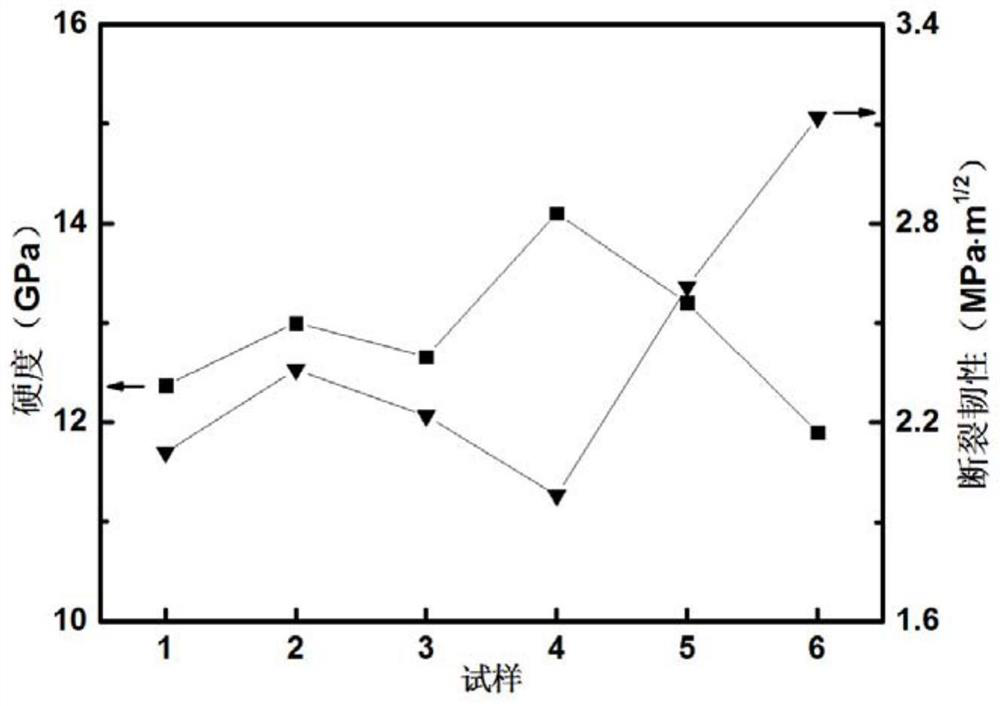

High-entropy rare earth zirconate ceramic capable of simultaneously stabilizing A-site and B-site cations and preparation method of high-entropy rare earth zirconate ceramic

ActiveCN113526954AImprove fracture toughnessLower sintering temperatureHigh densityPhysical chemistry

The invention discloses high-entropy rare earth zirconate ceramic capable of simultaneously stabilizing A-site and B-site cations and a preparation method of the high-entropy rare earth zirconate ceramic. The rare earth zirconate ceramic comprises a substance with a chemical formula of A2B2O7, wherein the A-site cation is a mixture of four or more metal cations of Sc, Y, La, Nd, Sm, Eu, Gd, Dy, Ho, Er, Tm, Yb and Lu, and different metal cations in the A site have the same molar content; the B-site cation is a mixture of three or more metal cations of Ti, Hf, Sn, Th and Ce and Zr ions, and different metal cations in the B site have the same molar content. The rare earth zirconate ceramic prepared by the invention has the characteristics of low thermal conductivity, high hardness, excellent fracture toughness, high phase purity, high density and the like.

Owner:KUNMING UNIV OF SCI & TECH

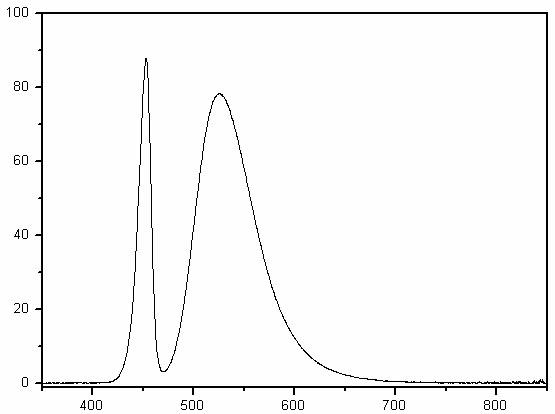

Fluorescent powder for white light-emitting diodes (LEDs) and backlight LEDs

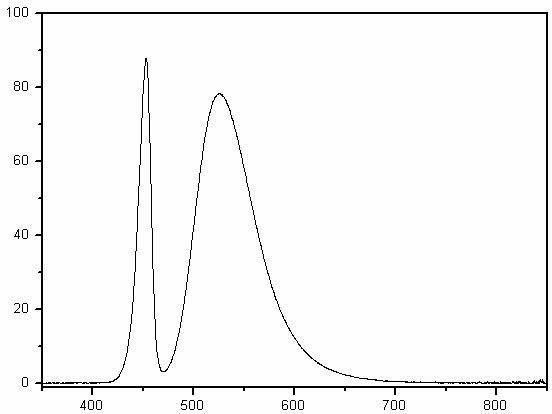

InactiveCN102352248AUniform distribution of luminescent ionsIncrease brightnessEnergy efficient lightingLuminescent compositionsRare-earth elementAlkaline earth metal

The invention belongs to the technical field of light-emitting diode (LED) light source and in particular relates to fluorescent powder for white LEDs and backlight LEDs. The chemical structural formula of the fluorescent powder is RE1xCexM2AlO5, wherein M is one or more of alkaline-earth metals; RE is one or more of La, Ce, Pr, Nd, Sm, Gd, Tb, Dy, Ho, Er, Tm and Lu in rare-earth elements; and x is more than or equal to 0.001 and less than 1. During preparation, nitrates of various elements serve as original reactants; NH4X, BaX2, SrX2, boric acid or borate serves as a cosolvent; a liquid phase method is adopted; the materials are burned at high temperature in air and then are reduced in reducing atmosphere; the prepared fluorescent powder has higher brightness and stability and a more complete crystal form. During preparation, oxalate and ammonia water serve as precipitating agents, so that the elements RE, Ce, Al and M in the structural formula are precipitated completely, and the phase purity of the fluorescent powder can be improved. The fluorescent powder can be used for preparing the white LEDs and the backlight LEDs.

Owner:上海穗杉实业股份有限公司

Method of preparing Bi3TiNbO9 micro-nano piezoelectricity ferro-electricity powder

This invention relates to a method for low temperature preparation of Bi3TiNb09 nanometer power. The preparation procedures are: (1) niobium pentoxide is dissolved in hydrofluoric acid under 80-90deg.C, then ammonia water is dropped into the solution, regulating the pH value to 8.5-9.5, to obtain precipitate of niobium hydroxide, which, after filtration and washing, is then dissolved in citric acid solution to produce Nb-citric acid solution; (2), tetrabutyl titanate, pentahydrate bismuth nitrate, EDTA and ammonium nitrate are added successively into aboved-mentioned solution, together with heating and agitation to obtain pre-product-gelatin; (3), said gelatin is then sintered to obtain this inventive product. This invention utilizes oxidation-reduction method having advantages of simple process, low reaction temperature, short reaction time, small particle size and even distribution and high-pureness.

Owner:SHANDONG UNIV

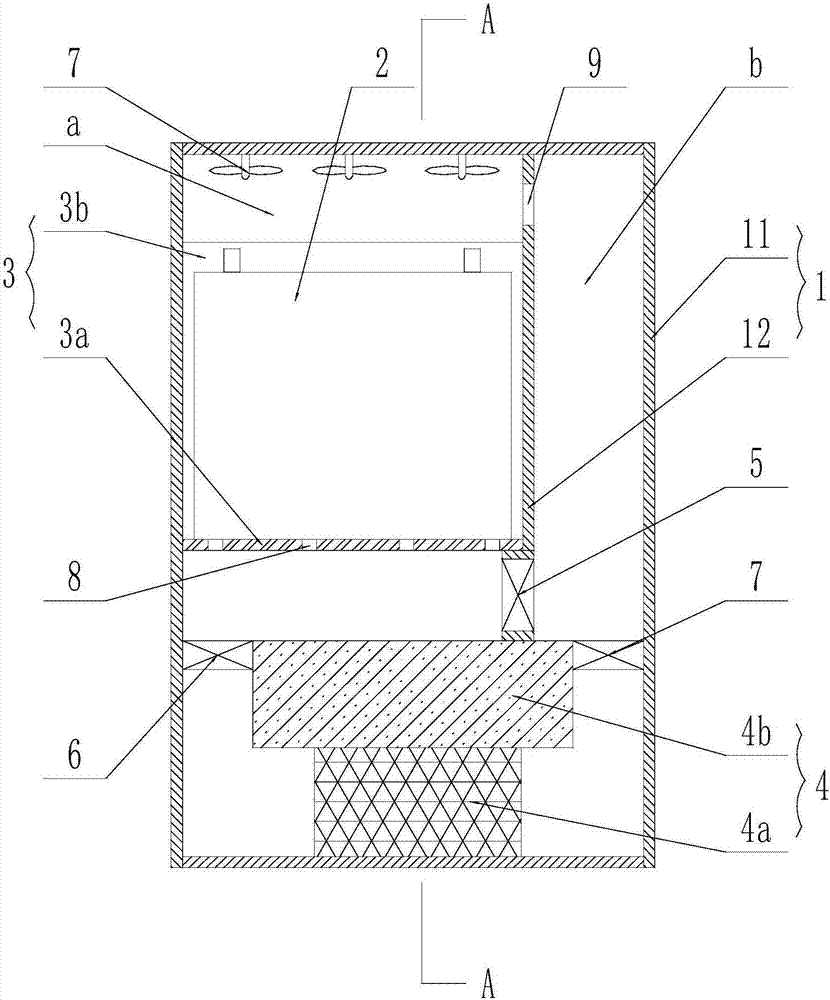

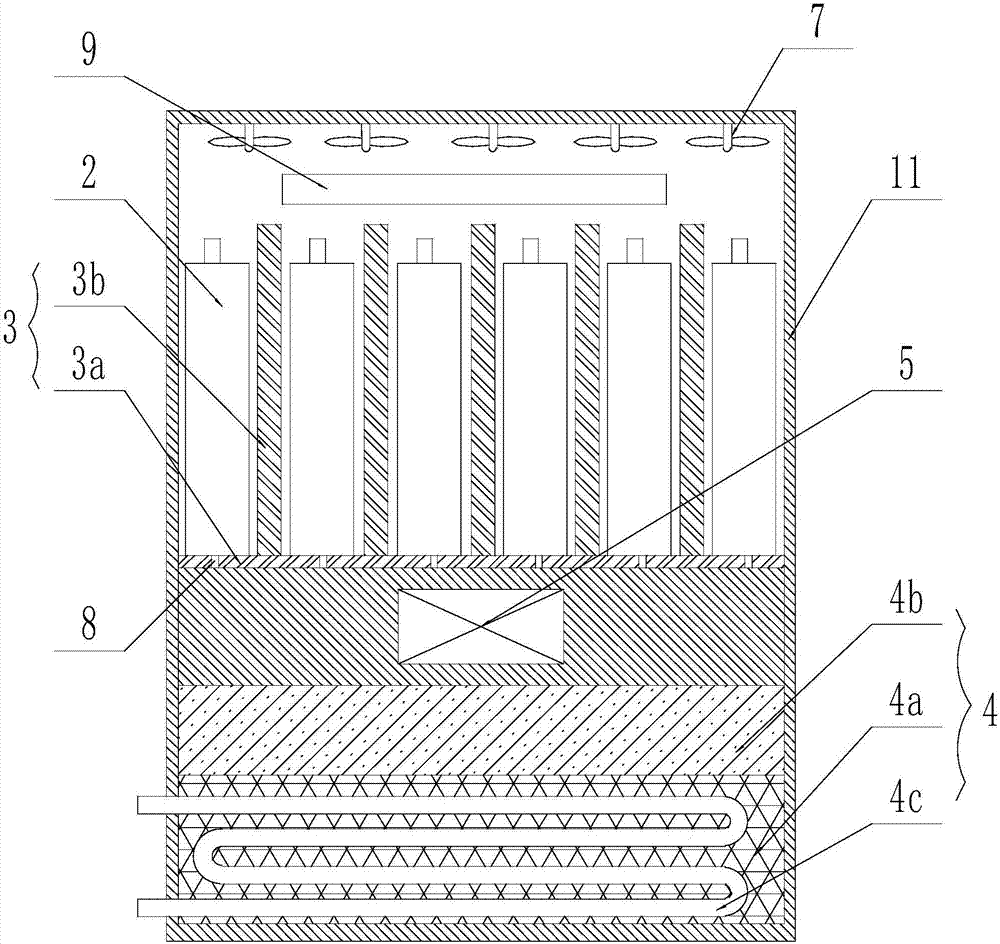

Vehicle-mounted new energy battery pack

InactiveCN107230751ARealize the heat dissipation functionImprove high rate discharge performanceCell electrodesSecondary cellsHigh rateElectrical battery

The invention discloses a vehicle-mounted new energy battery pack. The vehicle-mounted new energy battery pack comprises a battery box and multiple battery bodies arranged in the battery box; the battery box comprises a sealed type box body; a space partition plate is vertically arranged in the sealed type box body; the battery box is divided by the space partition plate into a battery placement region and a heat dissipation region; a fan is arranged on the battery box top plate above the battery placement region; a temperature detector is arranged in the battery placement region; multiple ventilating holes are formed in a battery fixation frame in the battery placement region; the ventilating holes are connected with the heat dissipation region to from an air circulation channel; and an air cooling apparatus is arranged in the air circulation channel. Compared with the prior art, the battery pack is arranged in the sealed box body according to the structure of the vehicle-mounted new energy battery pack, so that effects of thermal insulation and waterproofness are realized; by virtue of divisional setting, the temperature field distribution in the battery box can be improved; and by virtue of the battery bodies, the high-rate discharging performance of the lithium battery is improved, and excellent electronic conductivity and ionic conductivity and high high-rate charging-discharging performance are represented.

Owner:江苏昊科汽车空调有限公司

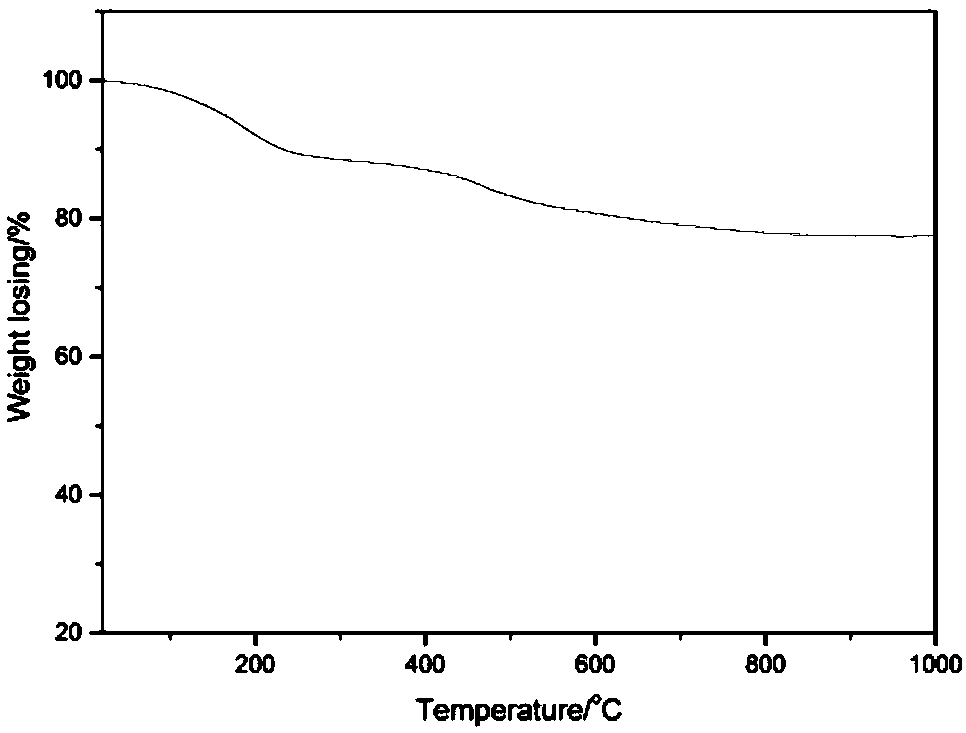

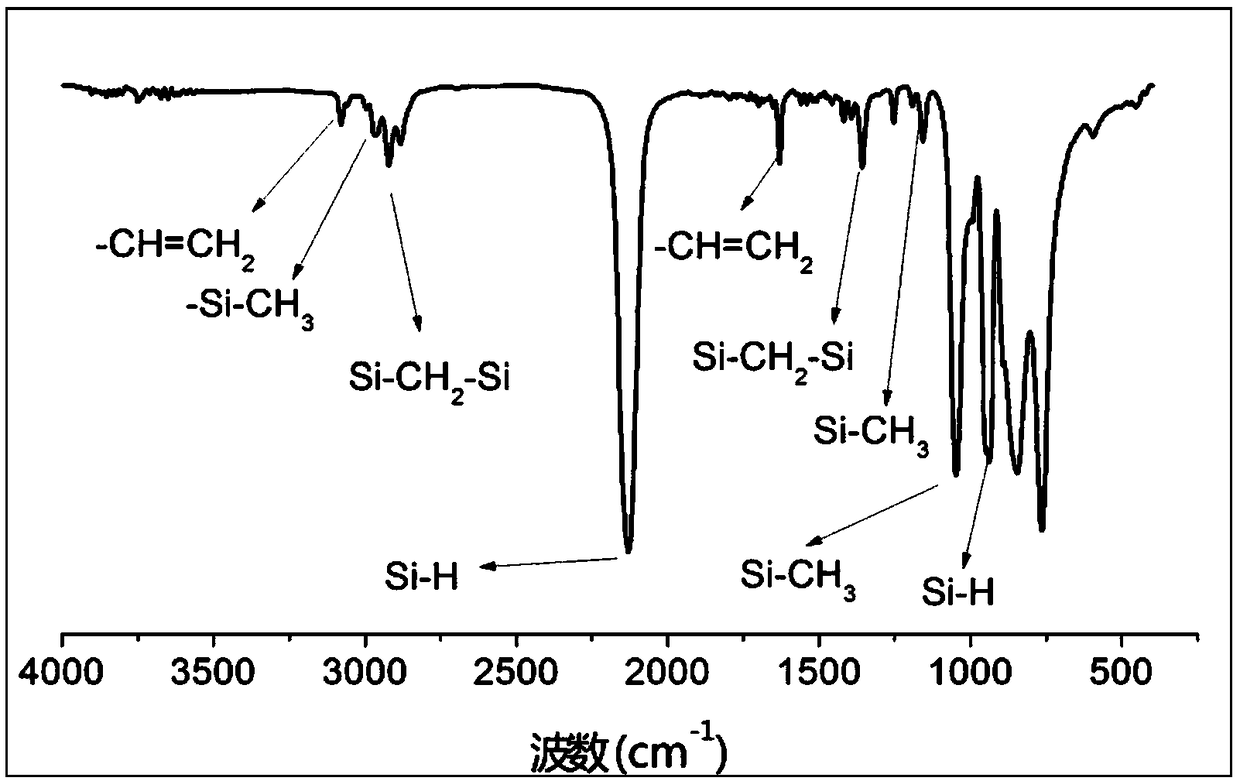

Preparation method of liquid-state polycarbosilane

The invention relates to a preparation method of liquid-state polycarbosilane. The preparation method includes: subjecting hexamethyl disilazane and chloromethyl trichlorosilane to partial ammonolysis, being in format coupling reaction with unsaturated chloroalkane and chloromethyl chlorosilane, adding a certain amount of NaBH4 (sodium borohydride) reductant for reduction after reaction is completed, adding petroleum ether, deionized water and concentrated hydrochloric acid into an obtained material for acid pickling and extraction, adopting NaOH to dry an obtained petroleum ether solution, filtering, and adopting a method of reduced pressure distillation to evaporate the petroleum ether out to obtain flavescent thick liquid which is liquid-state polycarbosilane. Liquid-state polycarbosilane prepared by the method is high in fluidity and processability and can be directly in thermal polymerization, and ceramic yield is higher than 70%. Content of free carbon in ceramic is low, SiC ceramic phase is high in purity, and liquid-state polycarbosilane is suitable for serving as a high-performance SiC ceramic precursor, can be used for ultrahigh-temperature ceramic based composite material soaking substrates and can also be used for preparing high-performance materials like SiC ceramic coatings and fiber.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

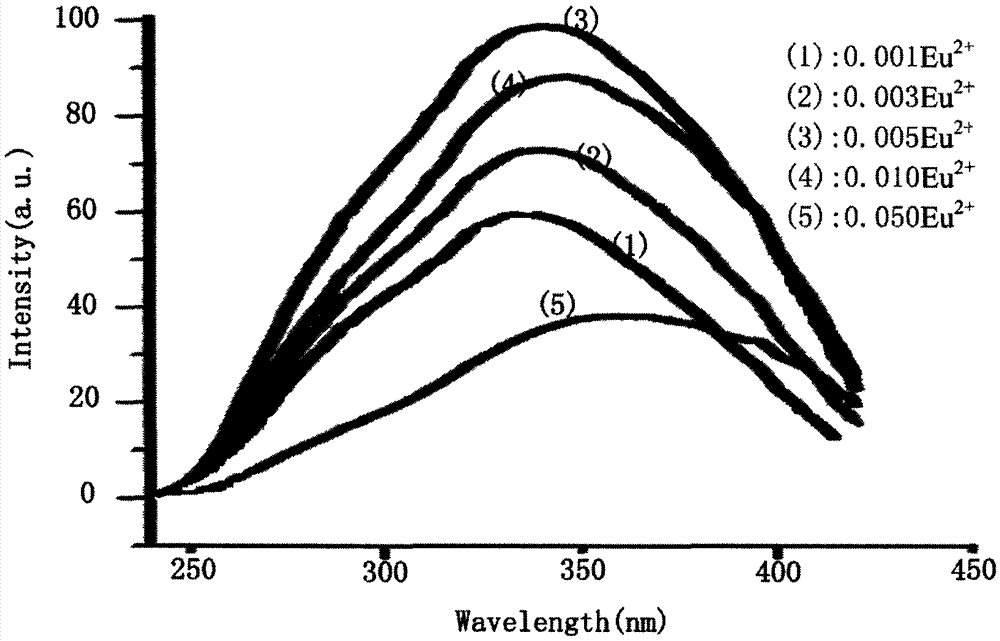

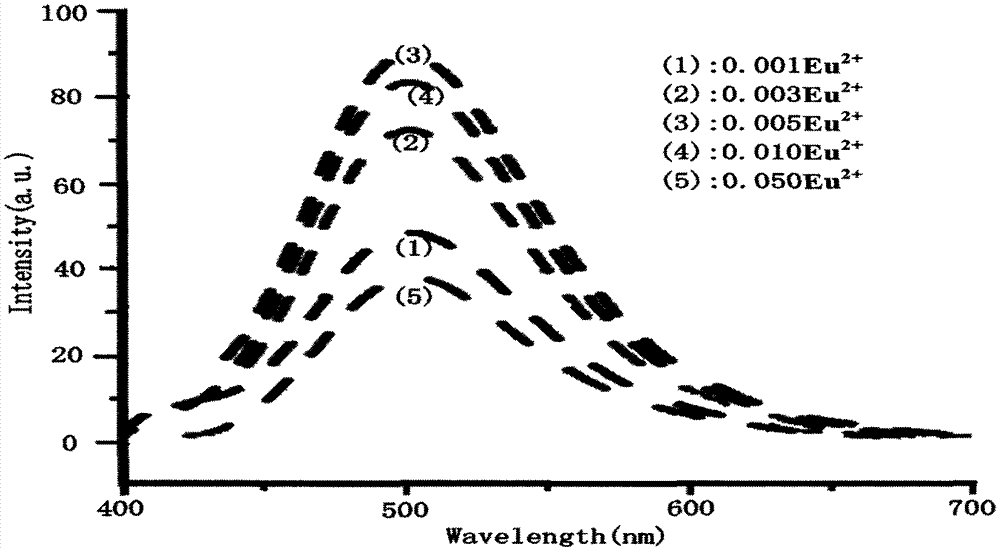

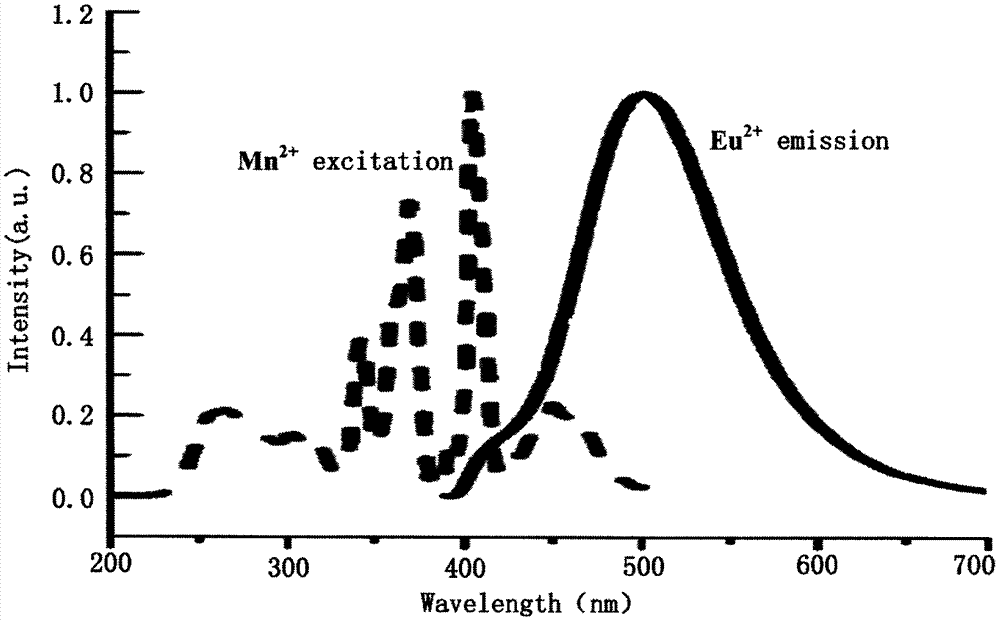

Emission peak-adjustable phosphate fluorescent powder for white-light LED (Light-Emitting Diode) and preparation method thereof

InactiveCN103773372AImprove luminosityHigh color rendering indexLuminescent compositionsPhosphateRare earth

The invention belongs to the technical field of rare-earth light-emitting materials, relates to emission peak-adjustable phosphate fluorescent powder for a white-light LED (Light-Emitting Diode) and a preparation method thereof. Fluorescent powder for the white-light LED, which is stable in chemical property, high in light-emitting performance, high in physical phase purity and adjustable in the emission peak from green light to red light when being excited by near ultraviolet light, purple light and blue light and can be applied to the white-light LED excited by using a blue-light LED chip. The chemical components of the fluorescent powder can be shown as a chemical formula, namely, Ca9(1-x-y)-La(PO4)7:xEu<2+>,yMn<2+>, wherein x is more than or equal to 0.002 and less than or equal to 0.2, and y is more than or equal 0.002 and less than or equal to 0.2. The fluorescent powder can be used for exciting white light together with blue fluorescent powder BaMgAl10O17:xEu<2+>. An encapsulated device can reach a white-light area with low color temperature, warm tone (CCT is less than or equal 5,000K), high color rendering index (CRI, RA is more than or equal to 90) and a color coordinate being up to CIE1931. The preparation method is simple and easy to operate, contributes to saving energy and time, and has extremely good application prospect in the field of solid illumination.

Owner:CHINA JILIANG UNIV

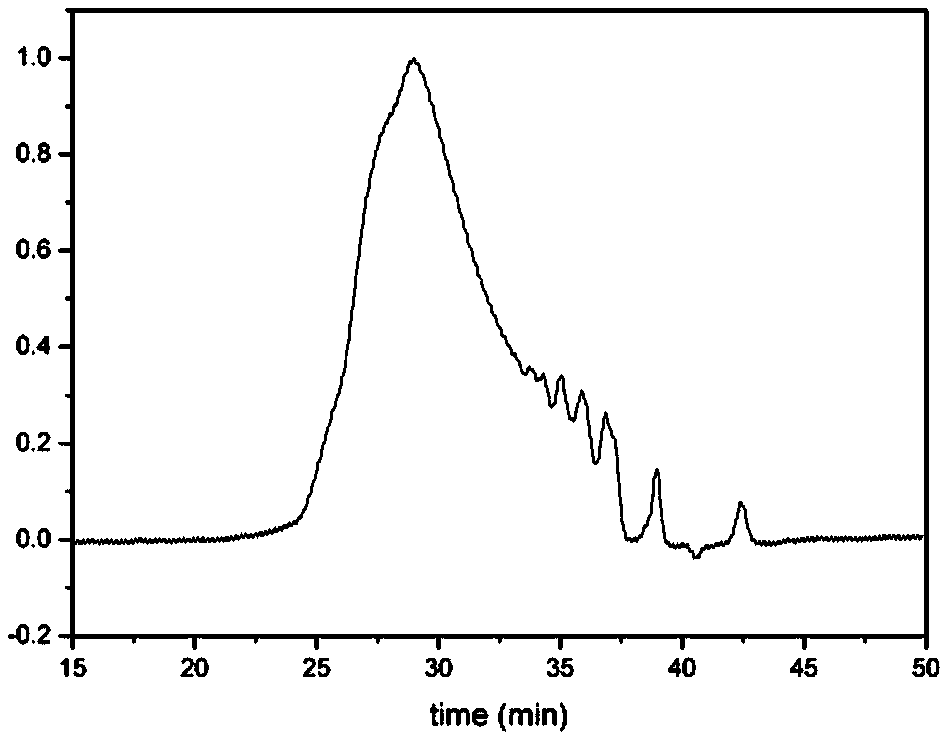

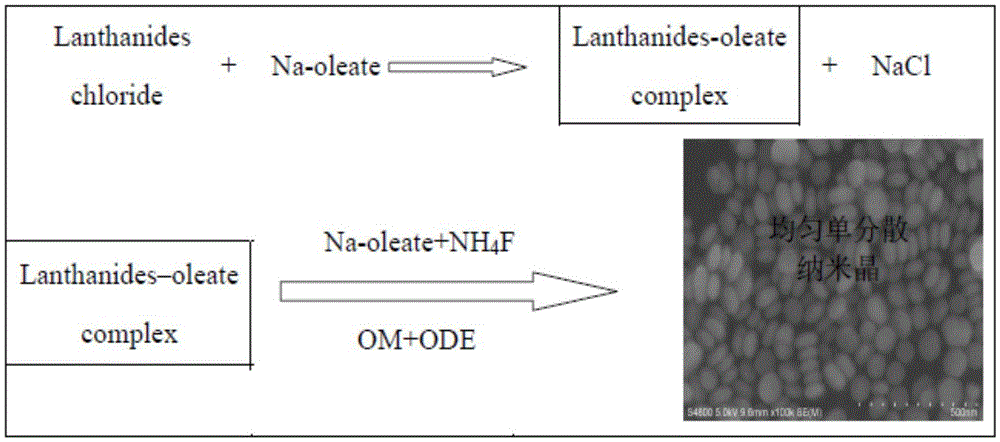

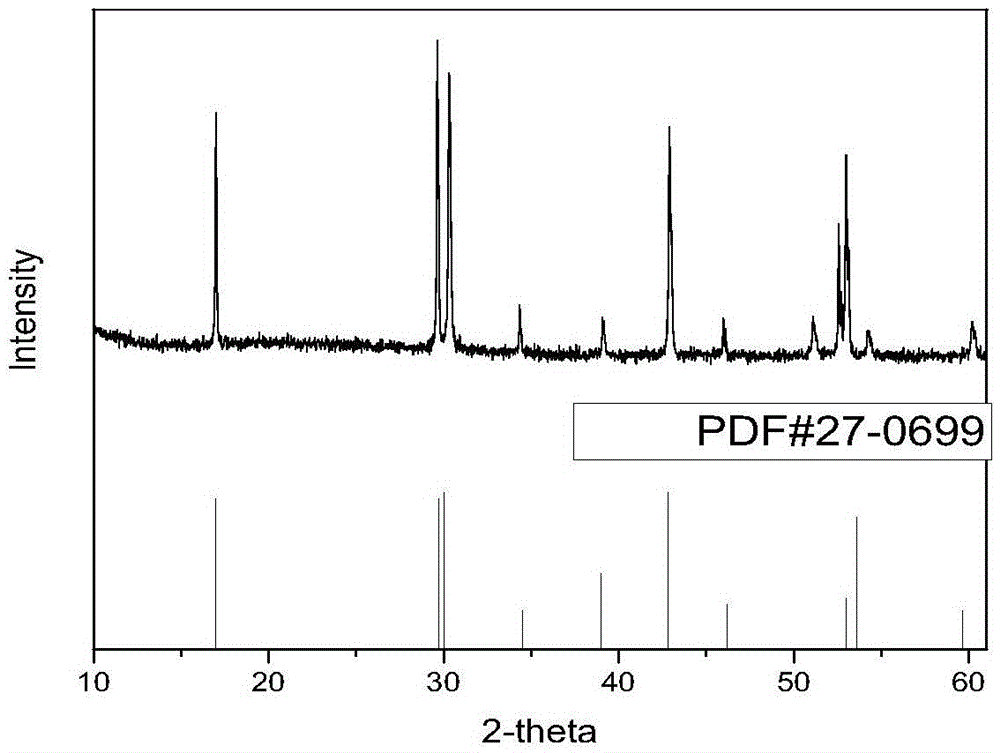

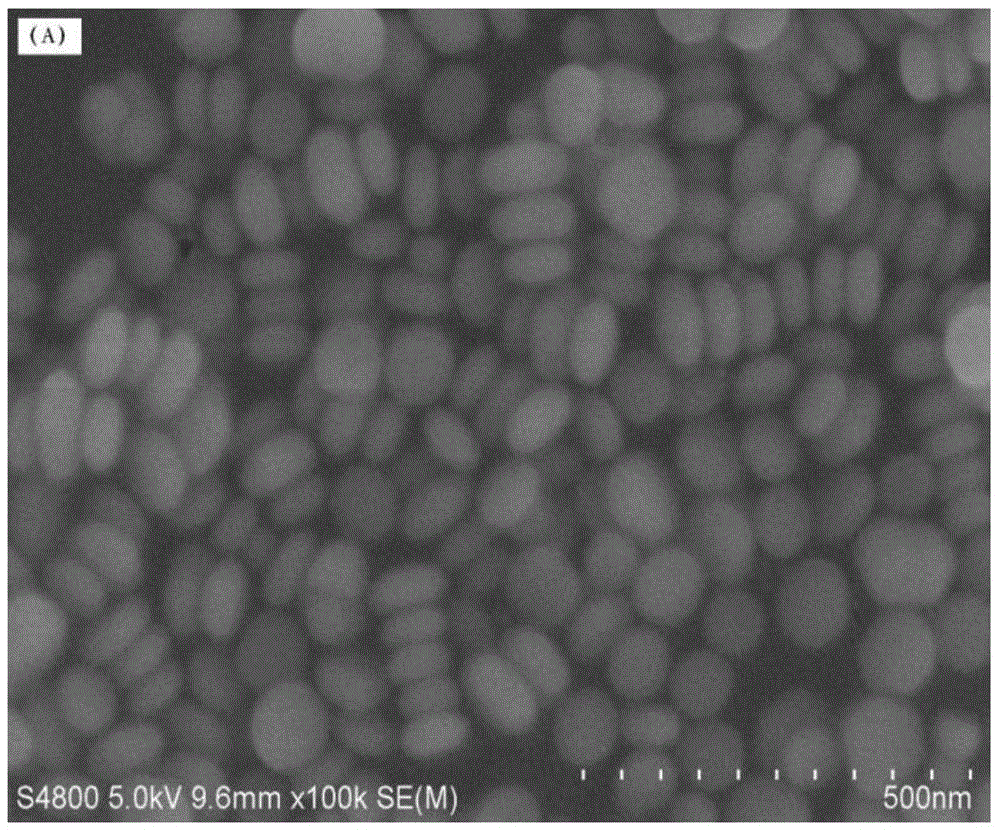

Rare earth-doped NaGdF4 upconversion nanocrystalline and preparation method thereof

The invention belongs to the technical field of luminescent materials, and particularly relates to a rare earth-doped NaGdF4 upconversion nanocrystalline and a preparation method thereof. The chemical expression formula of the rare earth-doped NaGdF4 upconversion nanocrystalline is beta-NaGd(100-X-Y)F4:X%Yb<3+>, Y%Er<3+> or beta-NaGd(100-X-Y)F4:X%Yb<3+>, Y%Tm<3+>, the value range of X is 10-90, and the value range of Y is 0.5-3. According to the rare earth-doped NaGdF4 upconversion nanocrystalline and the preparation method thereof, the Yb<3+> and Er<3+>-doped or Yb<3+> and Tm<3+>-doped beta-NaGdF4 upconversion nanocrystalline material is prepared through a high-temperature thermal cracking method and a solvothermal method, the preparation technology is simple and easy to operate, and the preparation cost of a multicolor luminescent material is greatly lowered; in addition, the preparation process is green and environmentally friendly, and the potential application value in the fields of solid lasers, solar cells, infrared radiation detection, biomedical imaging and the like is achieved.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com