Method for preparing ferrous silicate lithium/carbon composite positive pole material with micropore spherical structure

A technology of lithium ferrous silicate and positive electrode materials, which is applied in the direction of structural parts, battery electrodes, electrical components, etc., can solve the problems of low electronic conductivity and poor diffusion performance, and achieve uniform grain distribution, high rate performance, good The effect of cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] 1) Preparation of gel: Switching citric acid and lithium hydroxide to add water and stir dissolved; add iron oxalic acid metal iron, adjust the solution pH to 7-8, 80-95 ° C, the oil bath is insulated for 24-72hSoluble; add nano -silica, ultrasonic 20-60min, stir at room temperature for 1 to 3h to make gel.Among them, lithium hydroxide, iron and nano -nano -sanxia silicon Murbi is measured by li: Fe: Si = 2: 1: 1; the proportion of citric acid and iron oxalic acid metal acid is: 0.9 ~ 1.7.

[0021] 2) Dry: Step 1) The gel is sprayed to dry at 100-120 ° C to get a siliconic metal iron / carbon composite front drive body.

[0022] 3) High -temperature cracking: Step 2) The lithium silicate lithium Iron / carbon composite front -drive body is heat -treated in the atmosphere of the atmosphere to the reaction to complete.Among them, the thermal treatment was baked for 8-12 hours at 600 to 800 ° C.

Embodiment 1

[0023] Example 1 li 2 Feesio 4 / C compound positive material preparation

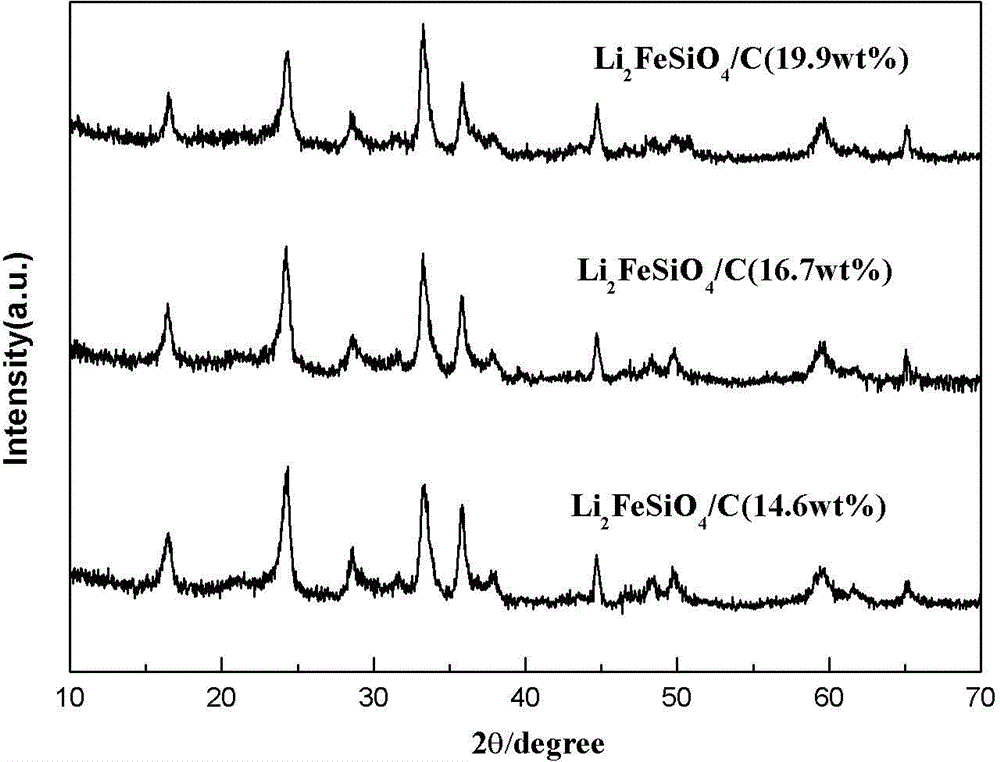

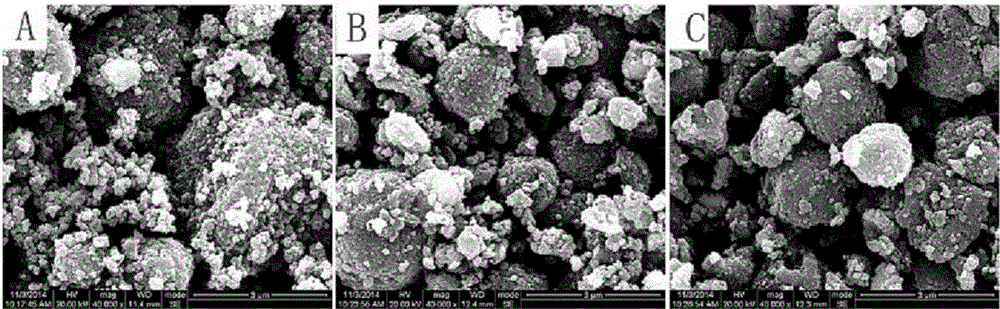

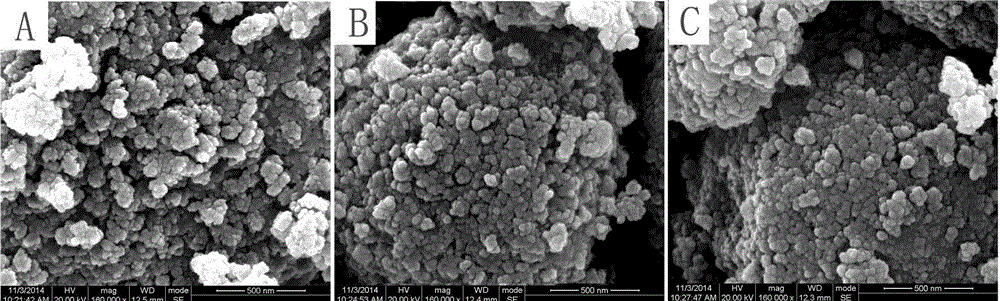

[0024] Illects 0.052mol citric acid and 0.08mol lithium hydroxide add 500ml of water, and the magnetic force is dissolved; add 0.04 mol oxalic acid sub -iron, regulate the pH of the solution to 7-8, and the oil bath is formed by the oil bath at 90 ° C to form a dark green solution; add0.04mol nano -nano -sanxide, ultrasonic 20min, stirred 1h at 25 ° C to make gel; spray the gel at 108 ° C to get a lithium silicon / carbon composite front drive;The composite front -wheel drive is treated at 700 ° C for 10h in the atmosphere.Through element analysis and testing, LI 2 Feesio 4 The content of carbon in the composite positive material is about 14.6%.See figure 1 , Scan the electronic microscope map, see figure 2 As well as image 3 Essence

Embodiment 2

[0025] Example 2 li 2 Feesio 4 / C compound positive material preparation

[0026]Talking about 0.06mol citric acid and 0.08mol lithium hydroxide add 500ml of water, and the magnetic mixing is dissolved; add 0.04 mol oxalic acid sub -iron, regulate the pH of the solution to 7-8, and the oil bath is formed after 36h at 90 ° C; add the dark green solution; add0.04mol nano -nano -sanxide, ultrasonic 20min, stirred 1h at 25 ° C to make gel; spray the gel at 108 ° C to get a lithium silicon / carbon composite front drive;The composite front -wheel drive is treated at 700 ° C for 10h in the atmosphere.Through element analysis and testing, LI obtained 2 Feesio 4 The content of carbon in the composite positive material is about 16.7%.See figure 1 , Scan the electronic microscope map, see figure 2 As well as image 3 Essence

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com