Cadmium coordination polymer and preparation method and application thereof

A technology of cadmium coordination polymers and ligands, applied in the field of cadmium coordination polymers and its preparation, to achieve the effects of high phase purity, simple process and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

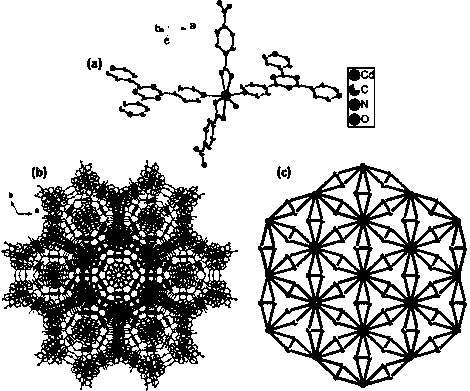

[0020] A preparation method of the cadmium coordination polymer, comprising the following steps:

[0021] 1) Combine 15.5 mg (0.05 mmol) of the organic ligand 2,4,6-tris(4-pyridyl)triazine (tpt), 23.7 mg (0.1 mmol) of terephthalic acid (PTA) and 30.8 mg ( 0.1 mmol) of cadmium nitrate tetrahydrate was added to a mixed solvent consisting of 5 milliliters of N,N-dimethylformamide (DMF), 5 milliliters of ethanol and 5 milliliters of water and mixed uniformly;

[0022] 2) Seal the mixture obtained above at 100 o Under ℃, carry out solvothermal reaction, and reaction time is 72 hours, obtains strip white crystal after natural cooling to room temperature;

[0023] 3) The above white crystals were washed with N,N-dimethylformamide (DMF) and dried to prepare the cadmium coordination polymer.

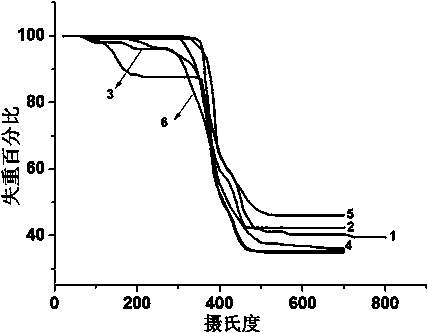

[0024] figure 1 It is the thermal analysis diagram of the cadmium coordination polymer after enclosing the guest, which shows that the decomposition temperature of the coordination framework ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com