Air purifying photocatalyst and preparation method thereof

A photocatalyst and air purification technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, botanical equipment and methods, etc., to achieve the effect of rich raw material sources, small particle size, and controllable particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

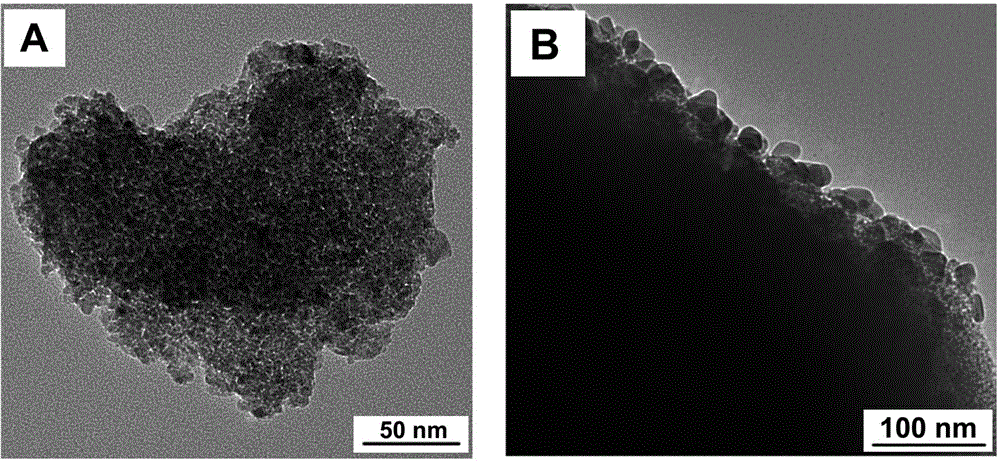

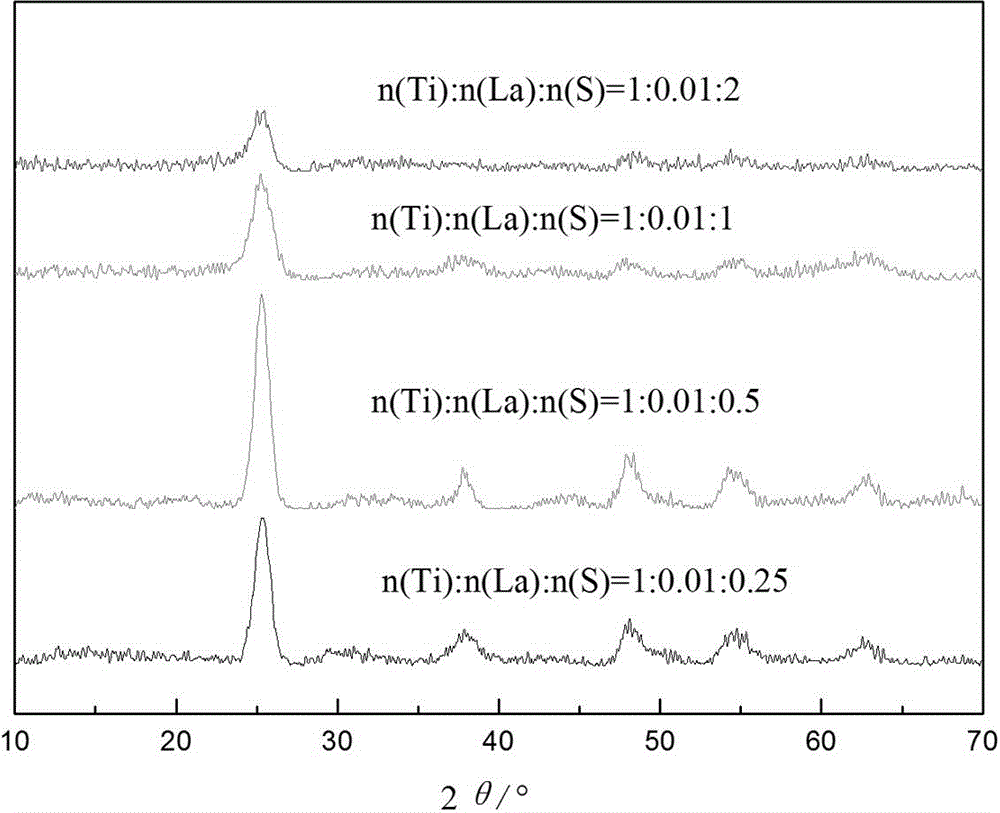

Image

Examples

preparation example Construction

[0027] A method for preparing an air-purifying photocatalyst, comprising the following steps:

[0028] Step 1: Take titanium source, sulfur source and lanthanum source respectively according to the molar ratio of titanium element, sulfur element and lanthanum element in the ratio of 1: (0.1~2): (0.001~0.015), and add the obtained titanium source to the In water ethanol, after that, add dispersant and inhibitor to the obtained mixed solution, wherein, the volume ratio of titanium source, dispersant and inhibitor to absolute ethanol is (17-20): (2.5-3): ( 4-5): 40, after fully mixing, get mixed solution A, set aside;

[0029] The titanium source is any one of tetrabutyl titanate or isopropyl titanate. The sulfur source is any one of thiourea, sodium thiosulfate, ammonium sulfide or thioacetamide. Described lanthanum source is any one in lanthanum sulfate or lanthanum nitrate; Described dispersion agent is Polyethylene Glycol 200, Polyethylene Glycol 300, Polyethylene Glycol 40...

Embodiment 1

[0037] ①Measure 20mL of tetrabutyl titanate, 40mL of absolute ethanol, 3ml of inhibitor triethylamine, and 4ml of dispersant polyethylene glycol 400, and mix them uniformly to prepare solution A;

[0038] ②Measure 40mL of absolute ethanol, 10mL of distilled water (containing 0.2g of lanthanum nitrate as a dopant), and 5ml of glacial acetic acid and mix evenly under stirring to prepare solution B;

[0039] ③Place the prepared solution A in a constant temperature water bath at 60°C for 10 minutes with magnetic stirring;

[0040] ④ Slowly add liquid B dropwise into liquid A under stirring, and the titration time is 30 minutes to obtain a transparent colloid.

[0041] ⑤ The TiO obtained above 2 The sol was poured into a 250 mL beaker, and 4.56 g of thiourea was added under magnetic stirring. At this time, the clear and transparent sol turned into a yellow gel, and at the same time, there was an exothermic phenomenon. After a period of reaction, it was put into a drying oven to d...

Embodiment 2

[0049] ①Measure 17mL of isopropyl titanate, 40mL of absolute ethanol, 2.5ml of inhibitor triethanolamine, and 5ml of dispersant polyethylene glycol 200, and mix uniformly to prepare solution A;

[0050] ②Measure 40mL of absolute ethanol, 10mL of distilled water (including 0.034g of lanthanum sulfate as a dopant), and 10ml of glacial acetic acid and mix them uniformly to prepare solution B;

[0051] ③Place the prepared solution A in a constant temperature water bath at 70°C for 10 minutes with magnetic stirring;

[0052] ④ Slowly add liquid B dropwise into liquid A under stirring, and the titration time is 30 minutes to obtain a transparent colloid.

[0053] ⑤ The TiO obtained above 2 The sol was poured into a 250 mL beaker, and 4.74 g of sodium thiosulfate was added under magnetic stirring. At this time, the clear and transparent sol turned into a yellow gel, and at the same time, there was an exothermic phenomenon. After a period of reaction, it was put into a drying oven t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com