High rate LiFePO4/C positive electrode material and preparation method thereof

A cathode material, high-rate technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of poor material consistency, difficult state control, high energy consumption, etc., to shorten the preparation cycle, expand the source, and the conductivity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The present invention provides a high rate LiFePO 4 / C The preparation method of the positive electrode material, wherein, the method comprises: mixing the phosphorus source aqueous solution, the lithium source aqueous solution, the divalent iron source aqueous solution with the dispersant and / or the surfactant uniformly; performing a hydrothermal reaction on the uniformly mixed solution, The temperature of the hydrothermal reaction is 120°C-250°C; the precipitate is separated from the material after the hydrothermal reaction, and the precipitate is washed and then subjected to the first drying; Second drying, and then sintering, the sintered solid is cooled.

[0026] In the present invention, the washing method can be carried out according to the conventional methods in the art, generally using deionized water, absolute ethanol and acetone to wash several times at a time, which is well known to those skilled in the art and will not be described in detail here.

[0027...

Embodiment 1

[0047] The concentration of 5mL is the phosphoric acid solution of 1M (unit M represents mol / L, this is well known to those skilled in the art), the concentration of 15mL is the lithium hydroxide solution of 1M and the concentration of 10mL is the ferrous sulfate solution of 0.5M, press Sequentially added to 120 mL of tetraethylene glycol, and stirred uniformly under a protective atmosphere. The mixture was transferred to a hydrothermal reactor, and kept at 140 °C for 24 hours under hydrothermal conditions; after naturally cooling to room temperature, the hydrothermally obtained product was centrifuged to obtain a lithium iron phosphate precipitate; and the product was used for Ionized water, absolute ethanol and acetone were washed several times; then the cleaned product was dried in a vacuum drying oven at 60 ° C for 12 h to obtain a lithium iron phosphate sample; 15% by weight of ascorbic acid ( That is, the weight ratio of ascorbic acid to lithium iron phosphate sample is ...

Embodiment 2

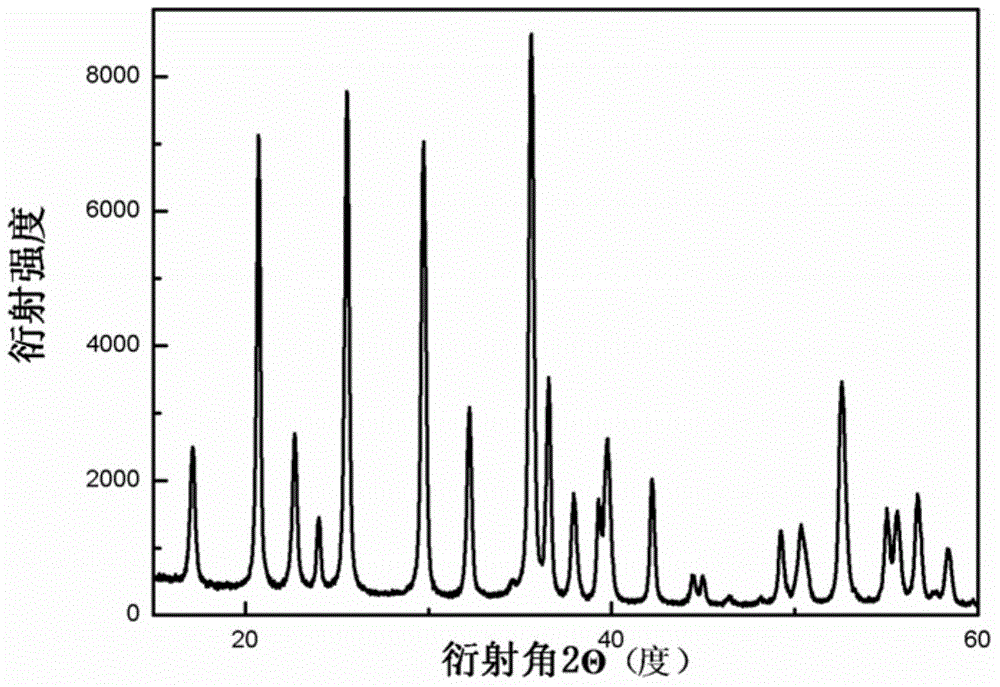

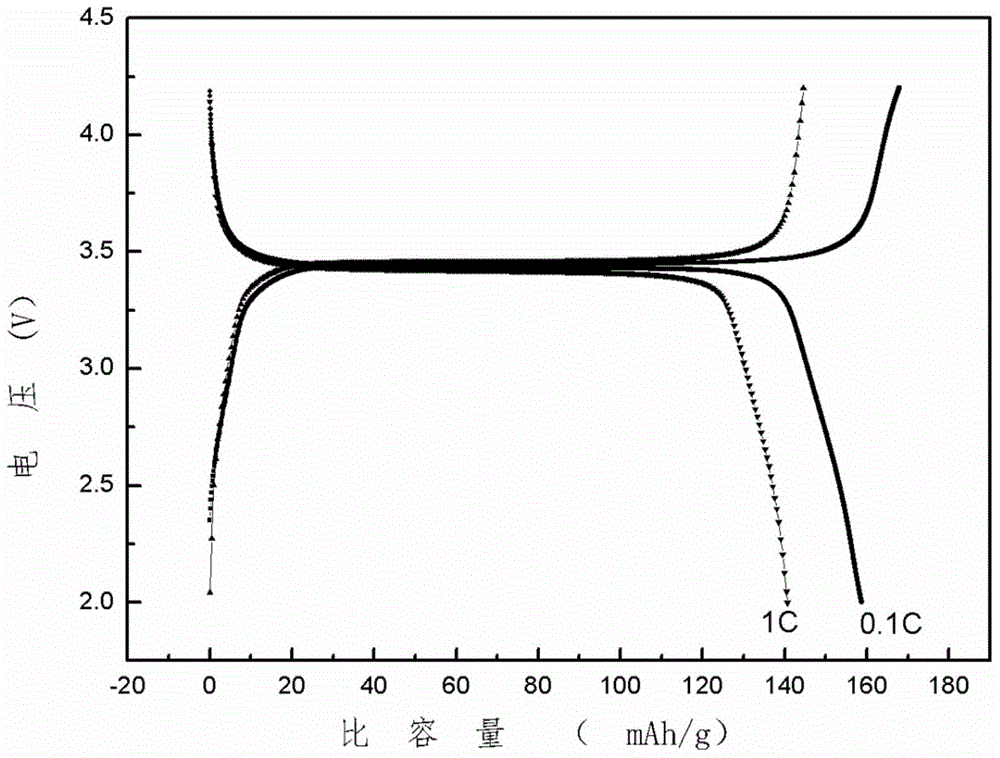

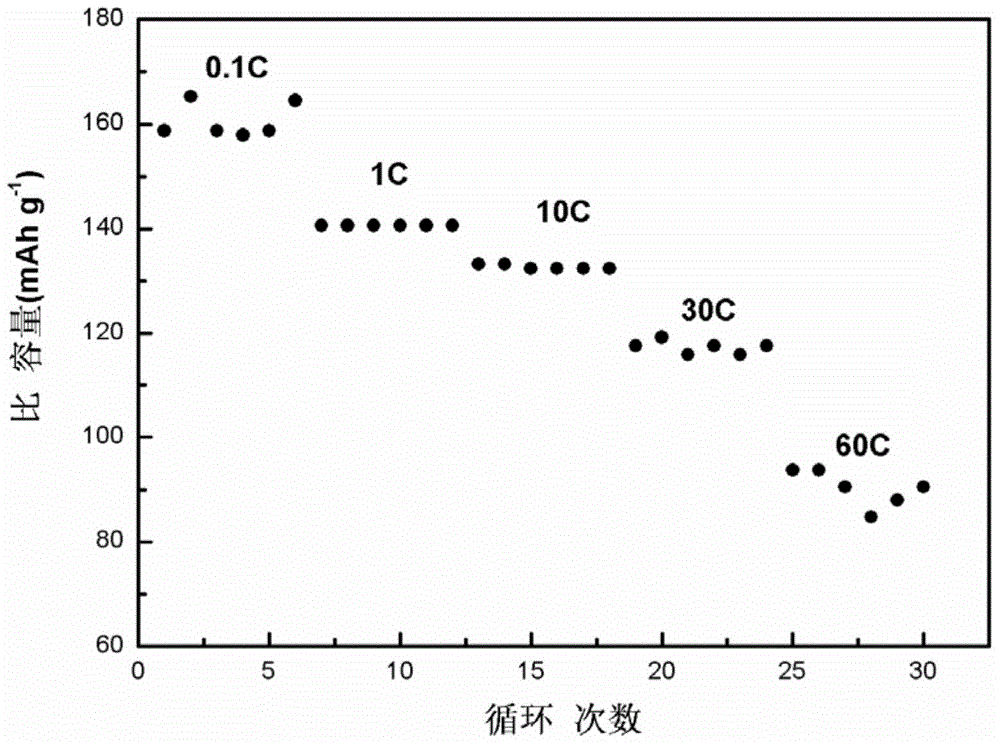

[0049] Prepare LiFePO according to the method of Example 1 4 / C positive electrode material, the difference is that the carbon source is glucose, and its addition amount is 20% by weight (that is, the weight ratio of glucose to lithium iron phosphate sample is 20:100), and the other conditions are the same to obtain carbon-coated Lithium iron phosphate (LiFePO) cathode material for lithium ion batteries 4 ) nanorods (X-ray powder diffraction analysis showed that the product was pure lithium iron phosphate (LiFePO 4 ); using the product as the positive electrode material, an experimental button-type lithium-ion battery was assembled in an argon-protected glove box, and the charge-discharge cycle was performed between 2.0-4.2V at different rates, and the discharge capacity at 0.1C was 155mAh / g, 1C The discharge capacity is 140 mAh / g, showing excellent electrochemical performance).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com