High-entropy rare earth zirconate ceramic capable of simultaneously stabilizing A-site and B-site cations and preparation method of high-entropy rare earth zirconate ceramic

A cation and zirconate technology, applied in the field of materials science and engineering, can solve the problems of the use of nuclear waste storage materials, insufficient oxygen transmission capacity, and insufficient thermal expansion coefficient, etc., to achieve inhibition of grain growth, lower temperature, and high density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

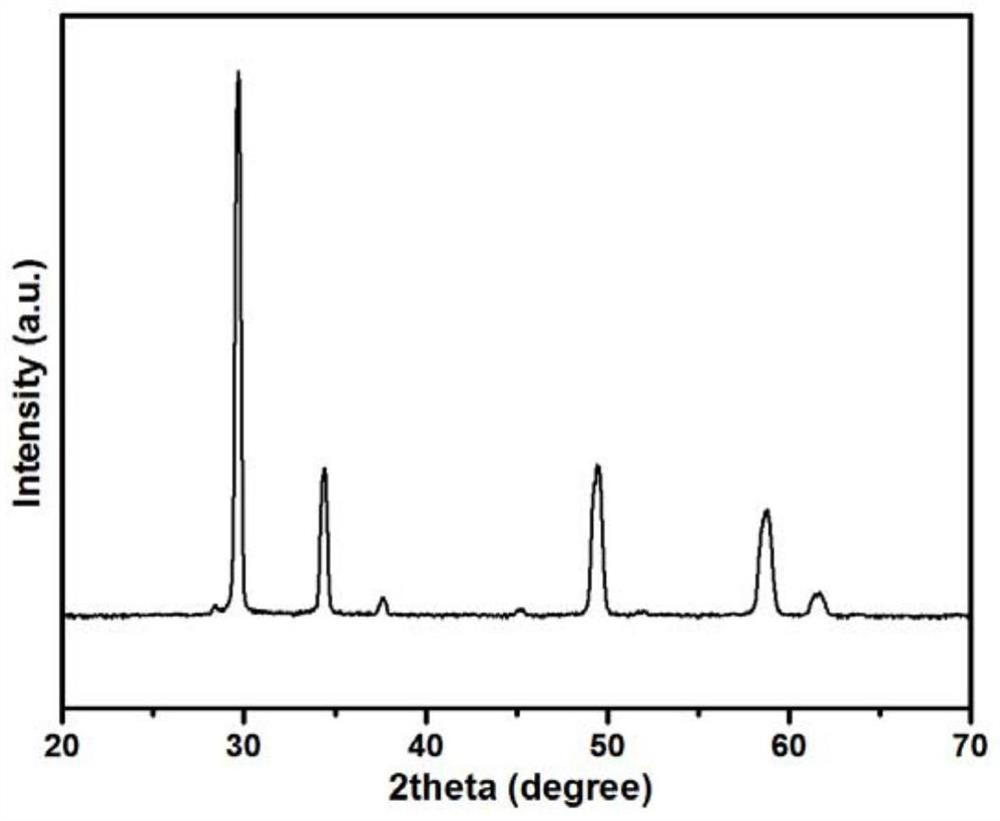

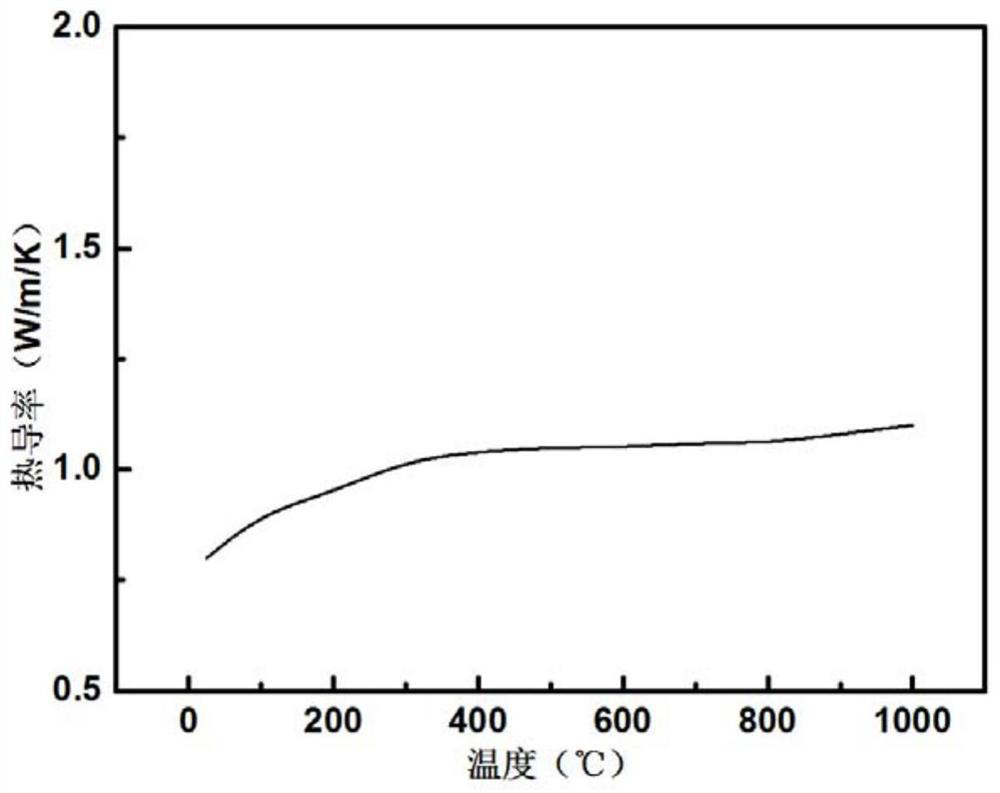

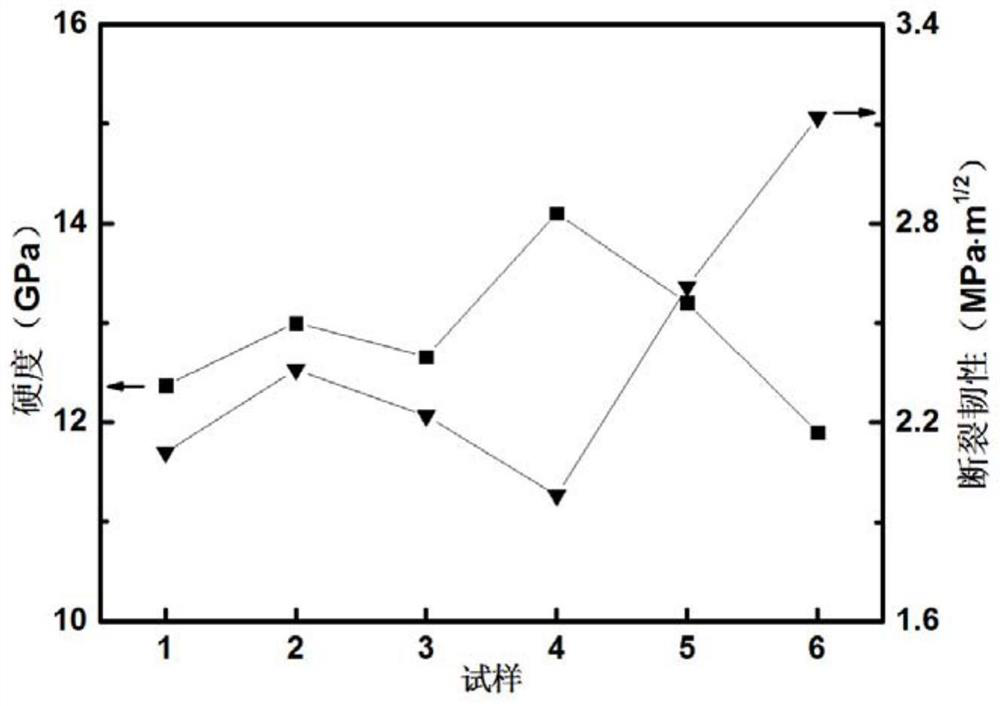

Image

Examples

Embodiment 1

[0026] (1) According to A 2 B 2 o 7 The chemical formula was measured and weighed A 2 o 3 and BO 2 Oxide, wherein A is a mixture of La, Eu, Gd, Dy and Ho with the same molar content, B is a mixture of Ce, Sn, Ti, Zr and Hf with the same molar content, then placed in a high temperature furnace at 900 ℃ for 2 hours to remove organic impurities contained in the powder and reduce the reactivity of the raw material powder, and obtain powder C after cooling down.

[0027] (2) Put powder C, alcohol, and zirconia balls in a ball milling tank at a mass ratio of 1:2:3 for ball milling. The speed of ball milling is 300 revolutions per minute, and the milling time is 12 hours. The powder was dried at 90° C. for 8 hours, and finally sieved to 300 mesh to obtain powder D.

[0028] (3) The powder D is placed in a graphite mold for development and shaping, and then placed in a spark plasma sintering system for high-temperature and high-pressure sintering. The sintering condition is 1400...

Embodiment 2

[0031] (1) According to A 2 B 2 o 7 The chemical formula was measured and weighed A 2 o 3 and BO 2 Oxide, where A is a mixture of Eu, Gd, Dy and Ho with the same molar content, B is a mixture of Ce, Sn, Ti, Zr and Hf with the same molar content, then placed in a high temperature furnace at 600 °C 10 hours to remove the organic impurities contained in the powder and reduce the reactivity of the raw material powder, and obtain powder C after cooling down.

[0032] (2) Put powder C, alcohol, and zirconia balls in a ball milling tank at a mass ratio of 1:2:3 for ball milling. The speed of ball milling is 500 revolutions per minute, and the milling time is 6 hours. The powder was dried at 100° C. for 4 hours, and finally sieved with 200 mesh to obtain powder D.

[0033] (3) The powder D is placed in a graphite mold for development and shaping, and then placed in a spark plasma sintering system for high-temperature and high-pressure sintering. The sintering condition is 1200°C...

Embodiment 3

[0036] (1) According to A 2 B 2 o 7 The chemical formula was measured and weighed A 2 o 3 and BO 2 Oxide, wherein A is a mixture of La, Sm, Eu, Gd, Dy and Ho with the same molar content, B is a mixture of Sn, Ti, Zr and Hf with the same molar content, then placed in a high temperature furnace at 1200 ℃ for 2 hours to remove organic impurities contained in the powder and reduce the reactivity of the raw material powder, and obtain powder C after cooling down.

[0037] (2) Put powder C, alcohol and zirconia grinding balls in a ball milling jar according to the mass ratio of 1:2:3 for ball milling and mixing. The powder was dried at 70° C. for 10 hours, and finally sieved with 500 mesh to obtain powder D.

[0038] (3) The powder D is placed in a graphite mold for development and shaping, and then placed in a spark plasma sintering system for high-temperature and high-pressure sintering. The sintering condition is 1600°C-100MPa-5min to obtain a sintered bulk ceramic.

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fracture toughness | aaaaa | aaaaa |

| fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com