Patents

Literature

47 results about "Salt ceramic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Salt ceramic, also called Victorian salt clay is a traditional salt-based modeling medium.

Soluble salt ceramic tile and production method thereof

The invention discloses a soluble salt ceramic tile and a production method thereof. The method comprises the following steps: (1) preparing ceramic tile powder for later use by a conventional method; (2) preparing a water-soluble soluble salt ink for the soluble salt ceramic tile; (3) preparing surface paste of the soluble salt ceramic tile; (4) preparing a ceramic tile green compact; (5) drying; (6) applying the surface paste; (7) carrying out ink-jet printing; (8) drying and firing; (9) edging; and (10) sorting, packaging and warehousing. The invention solves the following problems in the soluble salt ceramic tile production process in the prior art: the pattern obtained by the soluble salt technique does not have bright and abundant colors; in the subsequent polishing process, the consumption of the grinding material, energy sources and industrial water is high, and abundant polishing waste is generated, thereby influencing and polluting the environment; and the soluble salt ceramic tile has high requirements for the green compact raw materials, thereby causing increase of production cost and great waste of resources. The production method disclosed by the invention is more environment-friendly and economic, and has more abundant decorative effects.

Owner:HANGZHOU NABEL CERAMIC

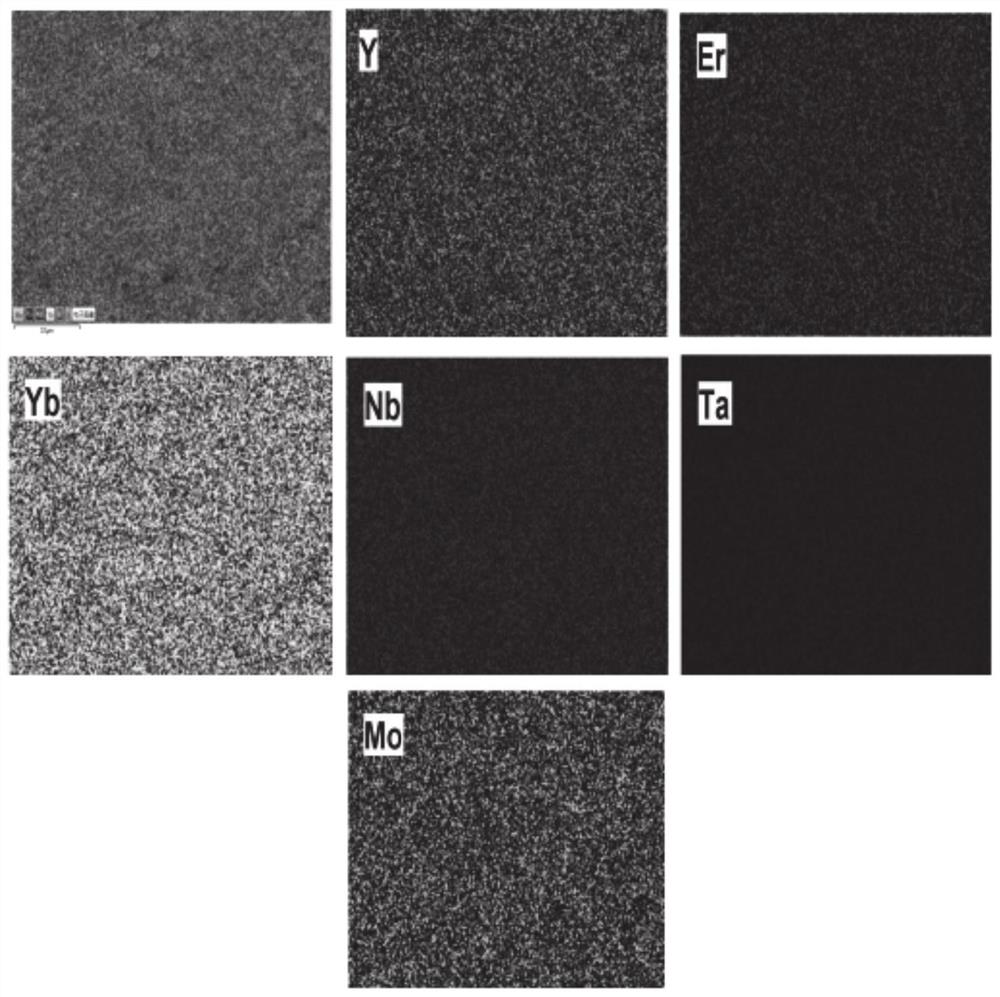

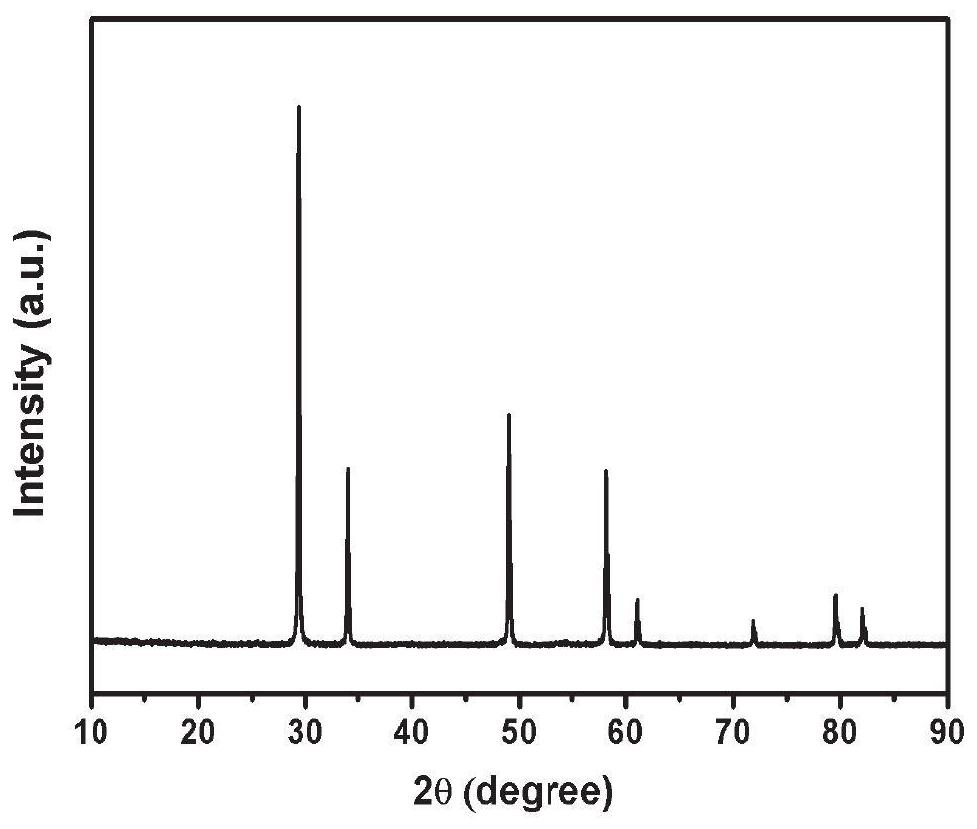

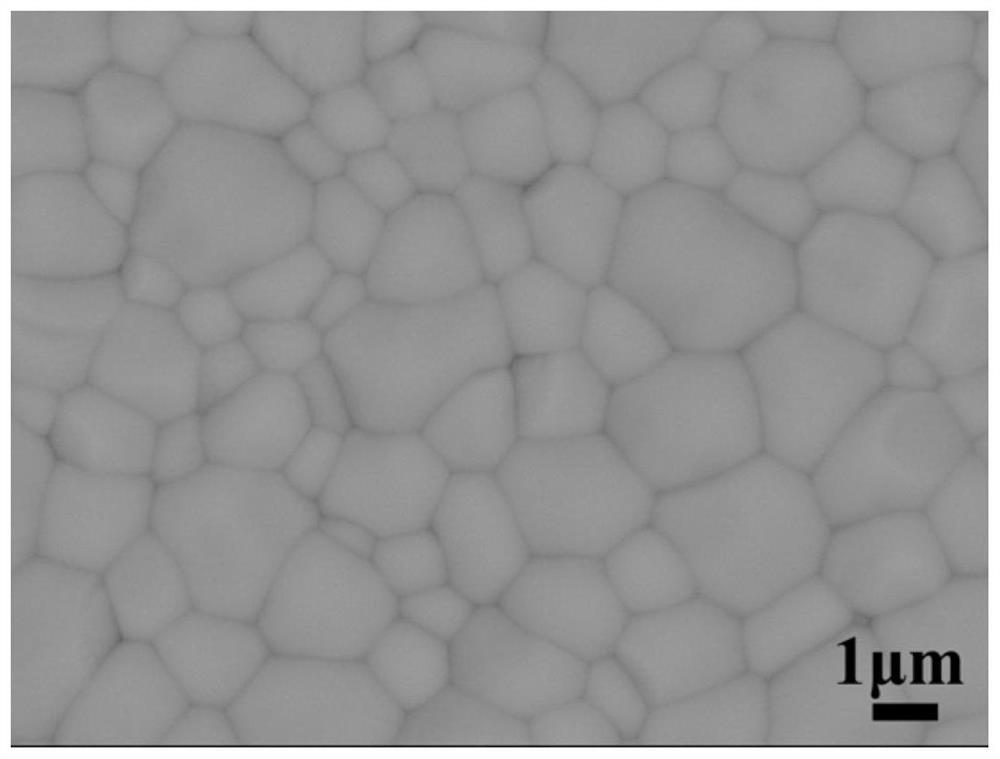

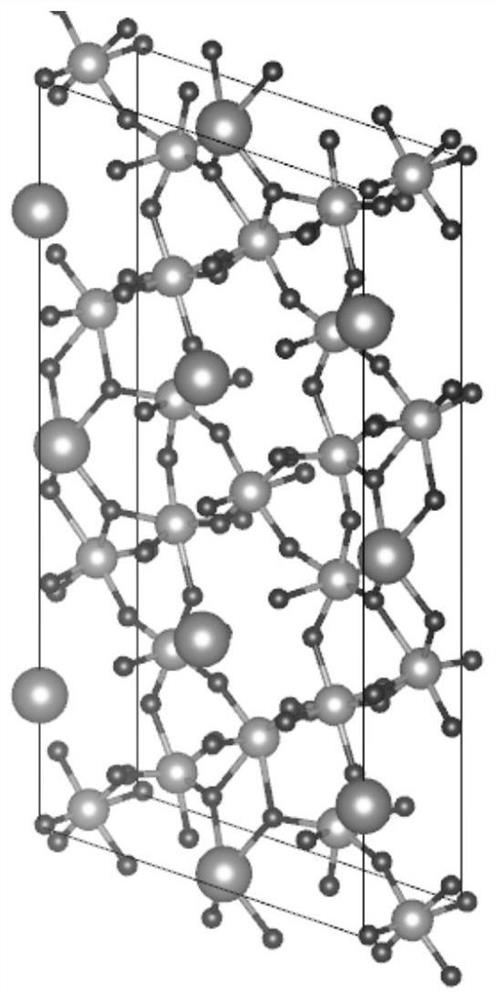

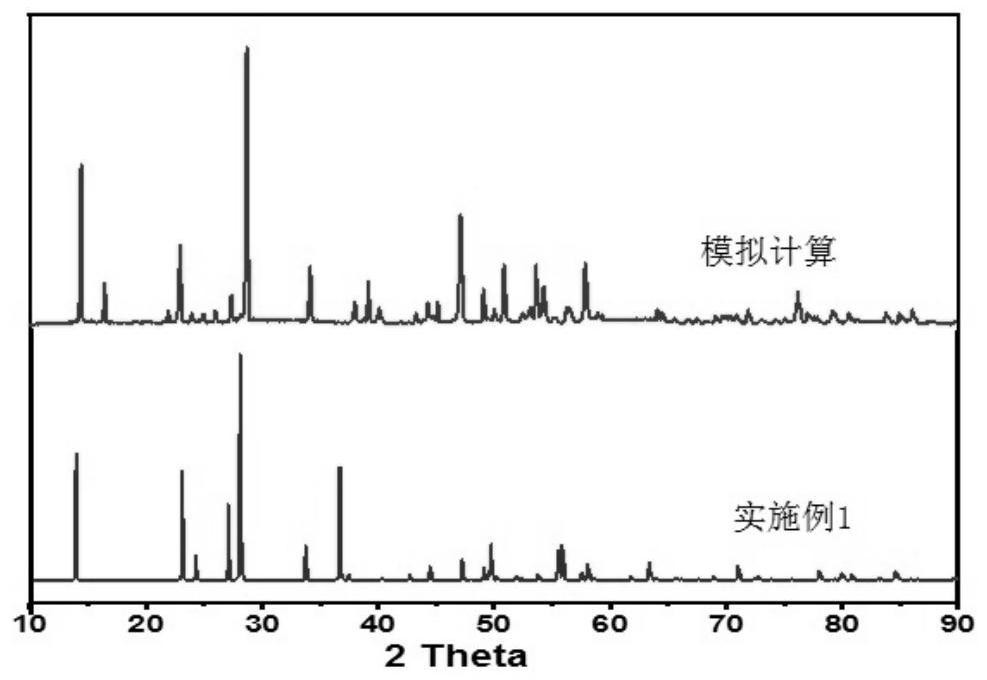

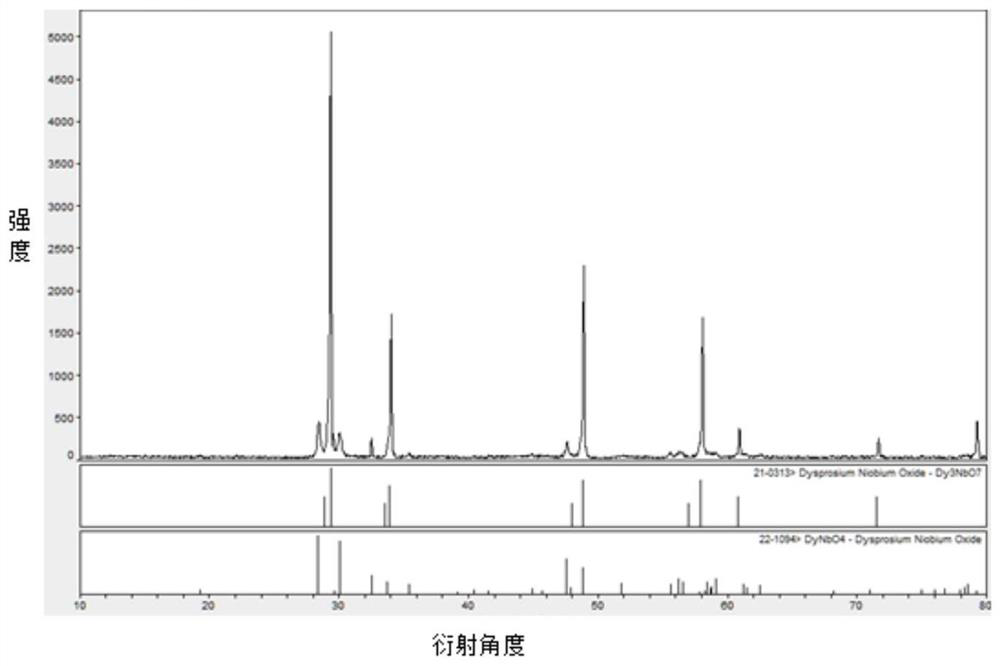

High-entropy rare earth niobium/tantalum/molybdate ceramic and preparation method thereof

The invention relates to the technical field of high-entropy ceramic materials, and particularly provides high-entropy rare earth niobium / tantalum / molybdate ceramic and a preparation method thereof. The chemical formula of the high-entropy rare earth niobium / tantalum / molybdate ceramic is RE3(Nb1 / 3Ta1 / 3Mo1 / 3)O7, RE is any 3-7 different elements of Y, Nd, Sm, Eu, Gd, Dy, Ho, Er, Yb and Lu. The preparation method comprises the following steps of (1) weighing rare earth oxide, niobium pentoxide, tantalum pentoxide, molybdenum trioxide and molybdenum dioxide according to a stoichiometric ratio, (2) adding a solvent and a ball-milling medium, ball-milling and mixing the raw materials by adopting a wet method, and carrying out vacuum drying and sieving to obtain uniformly mixed powder, (3) placing the uniformly mixed powder in a stainless steel mold for hydraulic compaction, and then carrying out cold isostatic pressing to obtain a densified green body, and (4) putting the green body into an alumina crucible, putting the alumina crucible into a high-temperature sintering furnace, and sintering in an air atmosphere. The prepared high-entropy ceramic is low in heat conductivity, the adopted preparation method has the advantages of being simple and rapid in process, low in equipment requirement, low in energy consumption, high in controllability and the like, and large-scale production is easy to achieve.

Owner:SHANDONG UNIV

Basalt fiber-reinforced ceramic bond cubic boron nitride (CBN) grinding wheel and preparation method of basalt fiber-reinforced ceramic bond CBN grinding wheel

InactiveCN103042474AIncrease speedImprove processing efficiencyAbrasion apparatusGrinding devicesCarbide siliconBoron nitride

The invention discloses a basalt fiber-reinforced ceramic bond cubic boron nitride (CBN) grinding wheel and a preparation method of the basalt fiber-reinforced ceramic bond CBN grinding wheel. The grinding wheel comprises by mixing, by weight, CNB grinding material 35-45%, green silicon carbide grinding material 3-8%, borosilicate ceramic bond 30-40%, white sugar 10-15%, basalt fibers 0.3-0.4% and paraffin 2-5%. The preparation method is: fully mixing each component; adding the basalt fibers into mixed powder; putting the mixture in a mold to be compacted, then sintering, and finally performing mechanical processing. The basalt fiber-reinforced ceramic bond CBN grinding wheel can effectively overcome shortcomings of common ceramic bond CBN grinding wheels, improves strength of the grinding wheel, is not prone to be blocked, has abrasive resistance of the grinding wheel, and can improve production processing efficiency of the grinding wheel.

Owner:GUANGDONG UNIV OF TECH

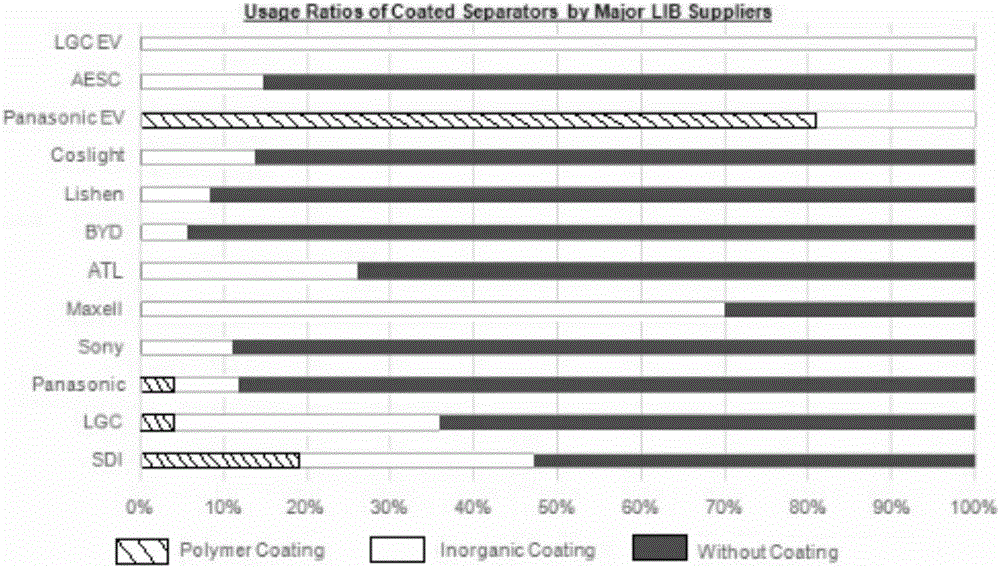

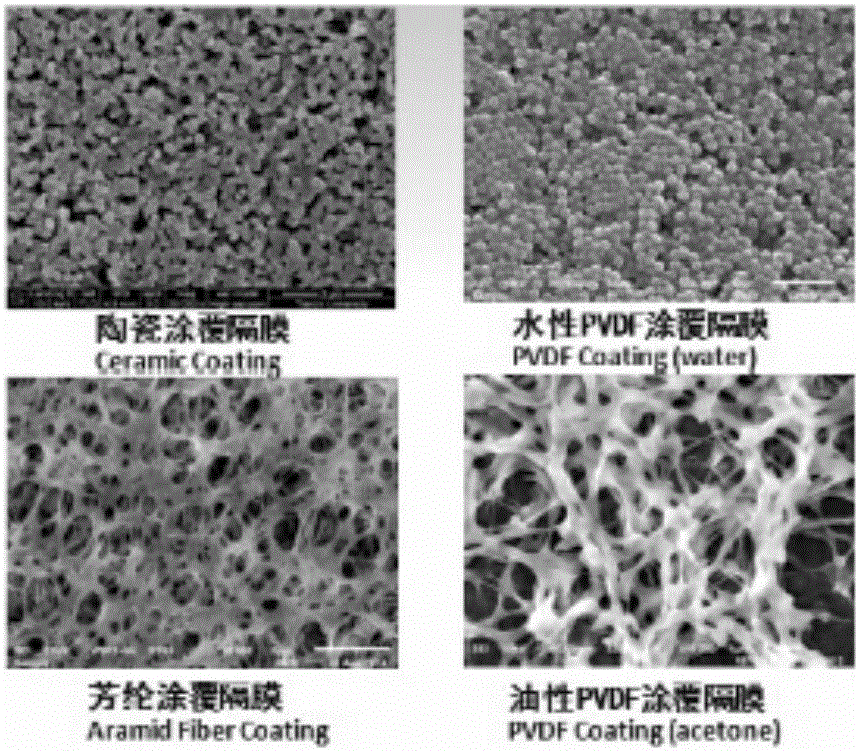

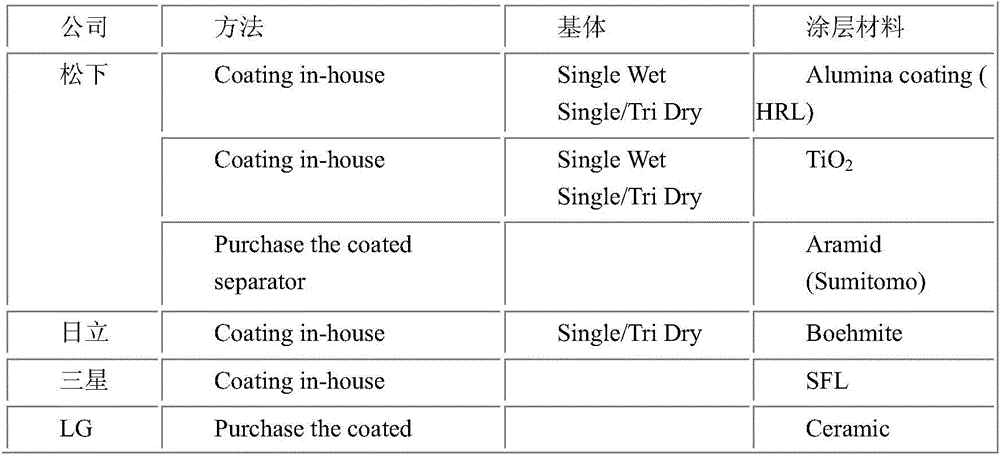

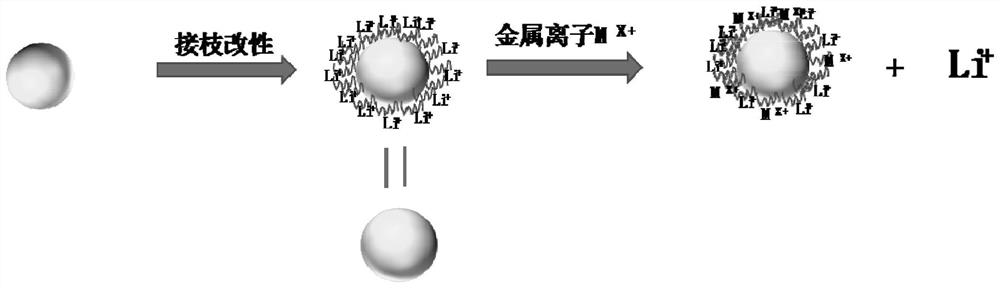

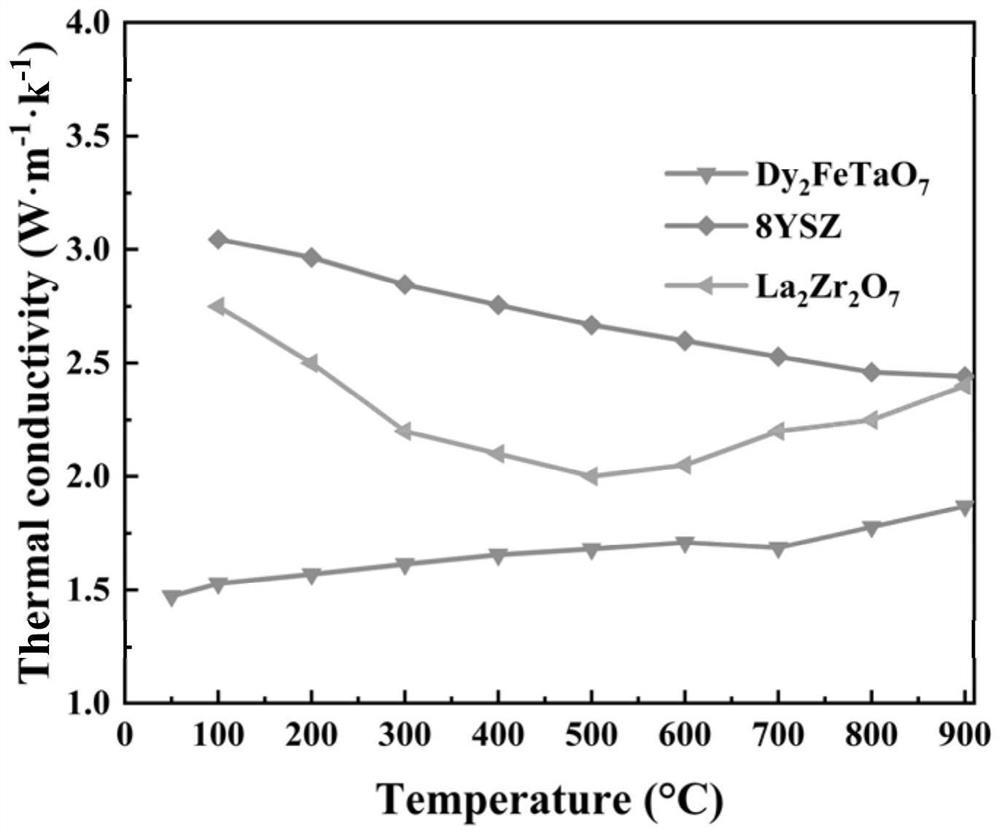

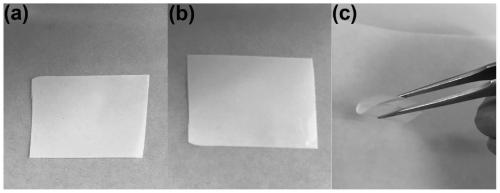

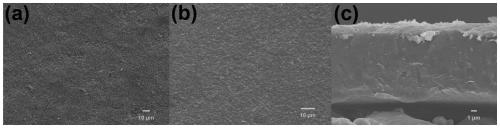

Polyoxometallic acid lithium salt ceramic membrane for lithium-ion battery

InactiveCN105977430AEasy to operateProduction environmental protectionCell component detailsPolyolefinAdhesive

The invention relates to a polyoxometallic acid lithium salt ceramic membrane for a lithium-ion battery and a preparation method, and belongs to the technical field of polymers and polymer composite materials and preparation methods. The targets are achieved as follows: ceramic powder containing a polyoxometallic acid lithium salt coats a base material, so that the safety of the ceramic membrane can be kept due to the presence of the ceramic powder; the lithium ion transmission rate is also improved by the polyoxometallic acid lithium salt; and the double characteristics of the safety and the transmissibility are met. The polyoxometallic acid lithium salt ceramic membrane for the lithium-ion battery contains the ceramic powder and the polyoxometallic acid lithium salt; and the ceramic powder is any one of AlO(OH), SiO2, TiO2, MgO, CaCO3 and BaSO4. The preparation method comprises the following steps of: (1) adding the ceramic powder, the polyoxometallic acid lithium salt and an adhesive to a solvent for stirring evenly and mixing the mixture into slurry; and (2) coating the surface of a polyolefin membrane base material with the slurry prepared in the step (1) and then drying the slurry.

Owner:TSINGHUA UNIV

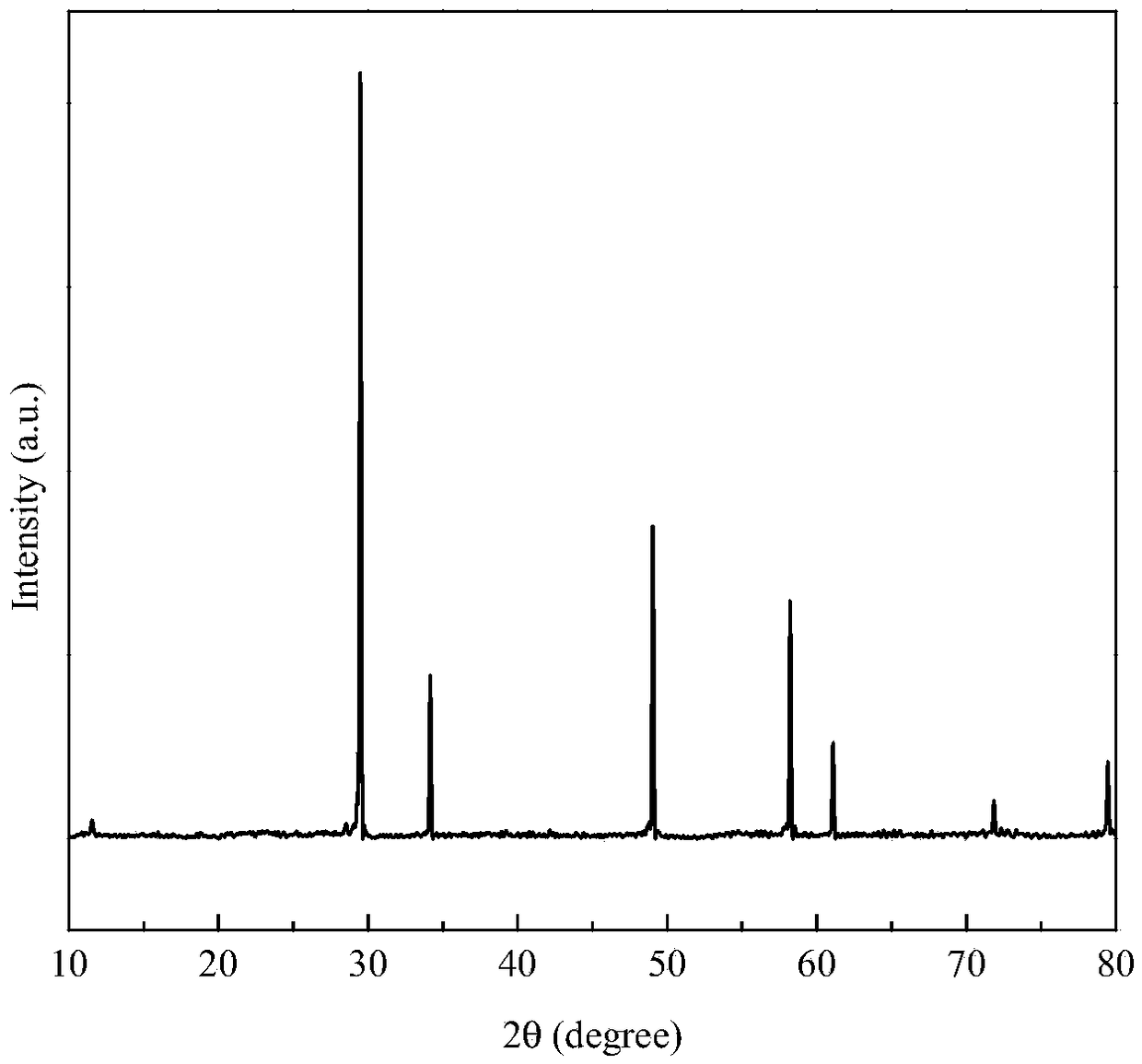

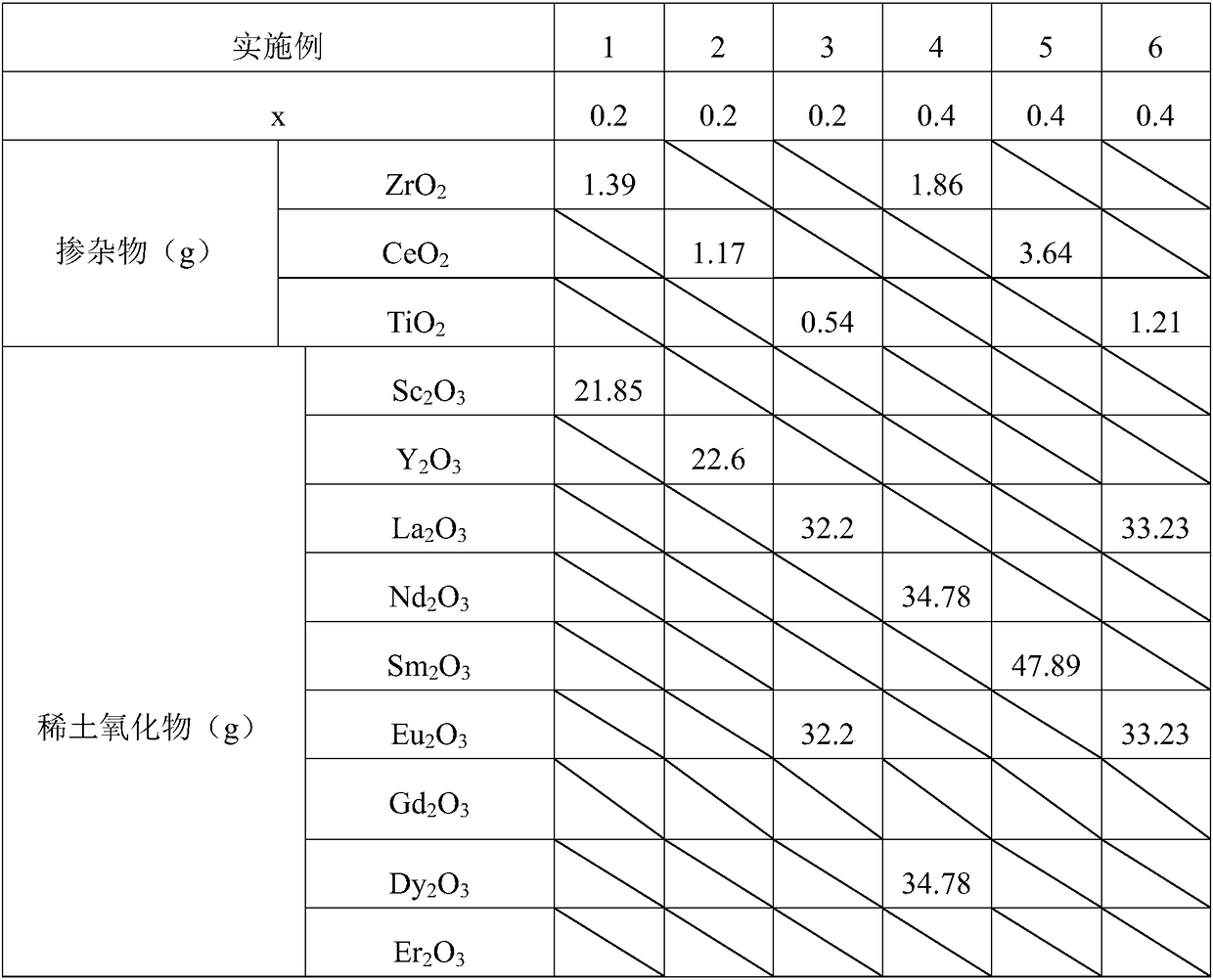

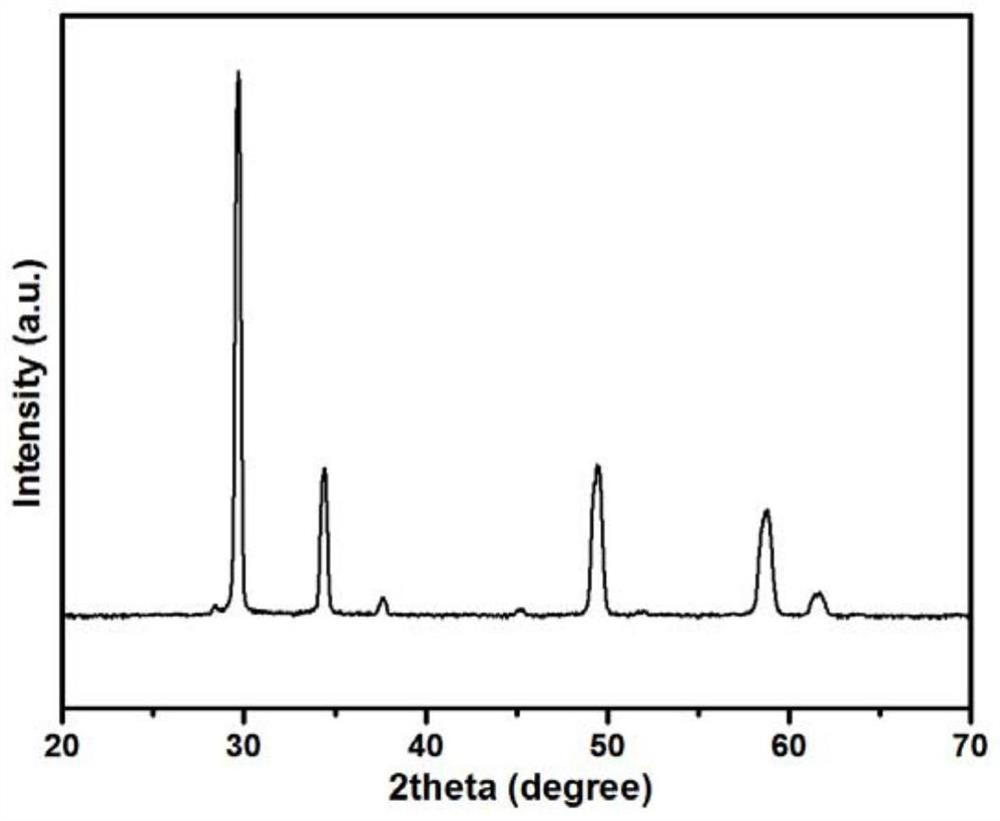

ZrO2/TiO2/CeO2 doped RE3Ta/NbO7 (Rare-Earth Tantalite/Niobate) ceramic powder and preparation method thereof

The invention relates to the technical field of ceramic powder preparation, and specifically discloses ZrO2 / TiO2 / CeO2 doped RE3Ta / NbO7 (Rare-Earth Tantalite / Niobate) ceramic powder. The preparation method comprises the following steps: carrying out ball milling on a dopant (ZrO2 / TiO2 / CeO2), RE2O3 powder, Ta2O5 powder or Nb2O5 powder, and carrying out solid-phase reaction, thus obtaining a target phase; mixing the target phase with an organic adhesive, thus forming slurry; drying by adopting a high-temperature spray pyrolysis method, thus obtaining sphere-like powdery particles; sintering, thusobtaining the ZrO2 / TiO2 / CeO2 doped RE3Ta / NbO7 ceramic powder. A chemical general formula of the ZrO2 / TiO2 / CeO2 doped RE3Ta / NbO7 ceramic powder is RE(3-x)(Ta / Nb)(1-x)(Zr / Ce / Ti)2xO7, wherein x is greater than 0 and is smaller than 1. A crystal structure of the ZrO2 / TiO2 / CeO2 doped RE3Ta / NbO7 ceramic powder is an orthorhombic phase, the space group of a crystal lattice is C2221, the particle diameter is 10 to 50 mum, and the ZrO2 / TiO2 / CeO2 doped RE3Ta / NbO7 ceramic powder is spherical. By adopting the technical scheme disclosed by the invention, the ZrO2 / TiO2 / CeO2 doped RE3Ta / NbO7 ceramic powderwhich can meet APS (Atmospheric Plasma Spraying) technical requirements can be obtained.

Owner:KUNMING UNIV OF SCI & TECH

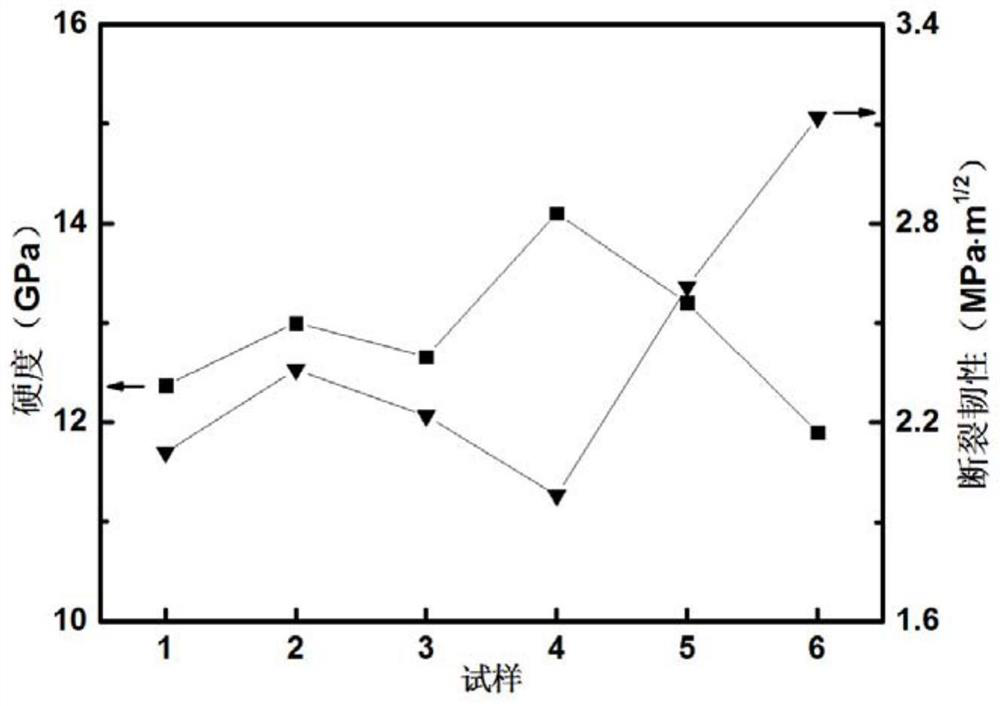

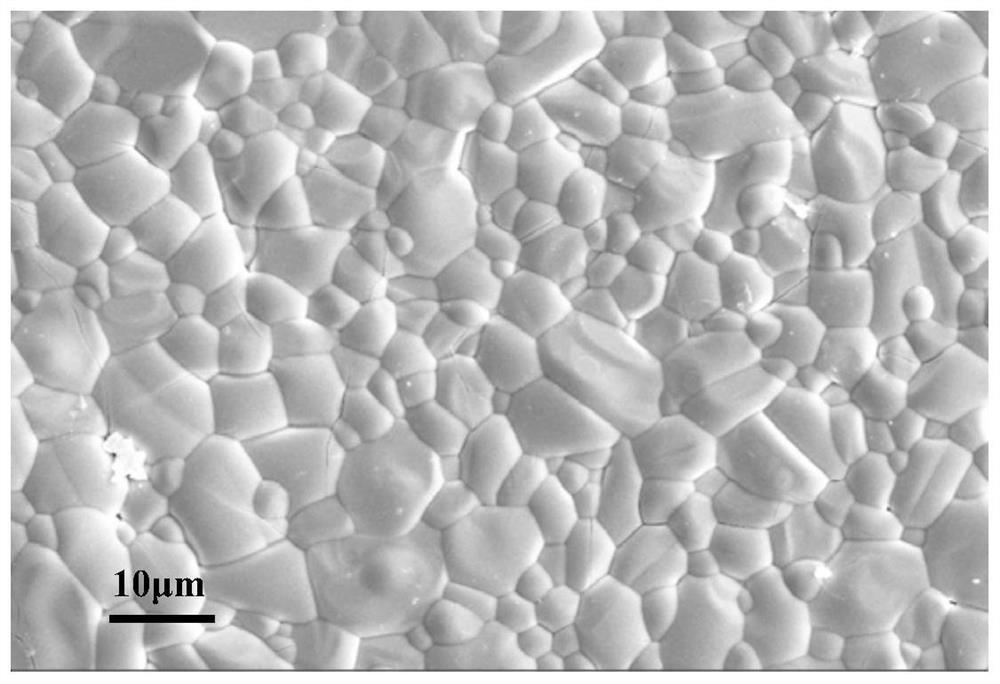

High-entropy rare earth zirconate ceramic capable of simultaneously stabilizing A-site and B-site cations and preparation method of high-entropy rare earth zirconate ceramic

ActiveCN113526954AImprove fracture toughnessLower sintering temperatureHigh densityPhysical chemistry

The invention discloses high-entropy rare earth zirconate ceramic capable of simultaneously stabilizing A-site and B-site cations and a preparation method of the high-entropy rare earth zirconate ceramic. The rare earth zirconate ceramic comprises a substance with a chemical formula of A2B2O7, wherein the A-site cation is a mixture of four or more metal cations of Sc, Y, La, Nd, Sm, Eu, Gd, Dy, Ho, Er, Tm, Yb and Lu, and different metal cations in the A site have the same molar content; the B-site cation is a mixture of three or more metal cations of Ti, Hf, Sn, Th and Ce and Zr ions, and different metal cations in the B site have the same molar content. The rare earth zirconate ceramic prepared by the invention has the characteristics of low thermal conductivity, high hardness, excellent fracture toughness, high phase purity, high density and the like.

Owner:KUNMING UNIV OF SCI & TECH

Soluble salt ceramic tile and production method thereof

Owner:HANGZHOU NABEL CERAMIC

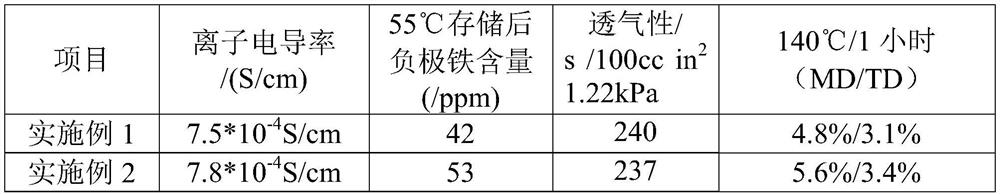

Lithium ion battery diaphragm, preparation method thereof and lithium ion battery

PendingCN112909430AImprove performancePrevent precipitationSecondary cellsCell component detailsCeramic coatingPhysical chemistry

The invention belongs to the technical field of lithium ion battery materials, and particularly relates to a lithium ion battery diaphragm, a preparation method thereof and a lithium ion battery. The lithium ion battery diaphragm comprises a base membrane and a ceramic coating arranged on at least one surface of the base membrane, the ceramic coating comprises a first type of particles and a second type of particles, the first type of particles comprise ceramic particles and polymer lithium salt, and the ceramic particles and the polymer lithium salt are connected through chemical groups. According to the ceramic coating on the surface of the lithium ion battery diaphragm, the first type of particles modified by the polymer lithium salt and the second type of particles which are not modified are matched for use, so that the diaphragm has low impedance and has the effect of adsorbing metal ions dissolved out of a positive electrode, the metal ions of the positive electrode are prevented from being separated out at a negative electrode, and the battery performance is improved.

Owner:EVERGRANDE NEW ENERGY TECH SHENZHEN CO LTD

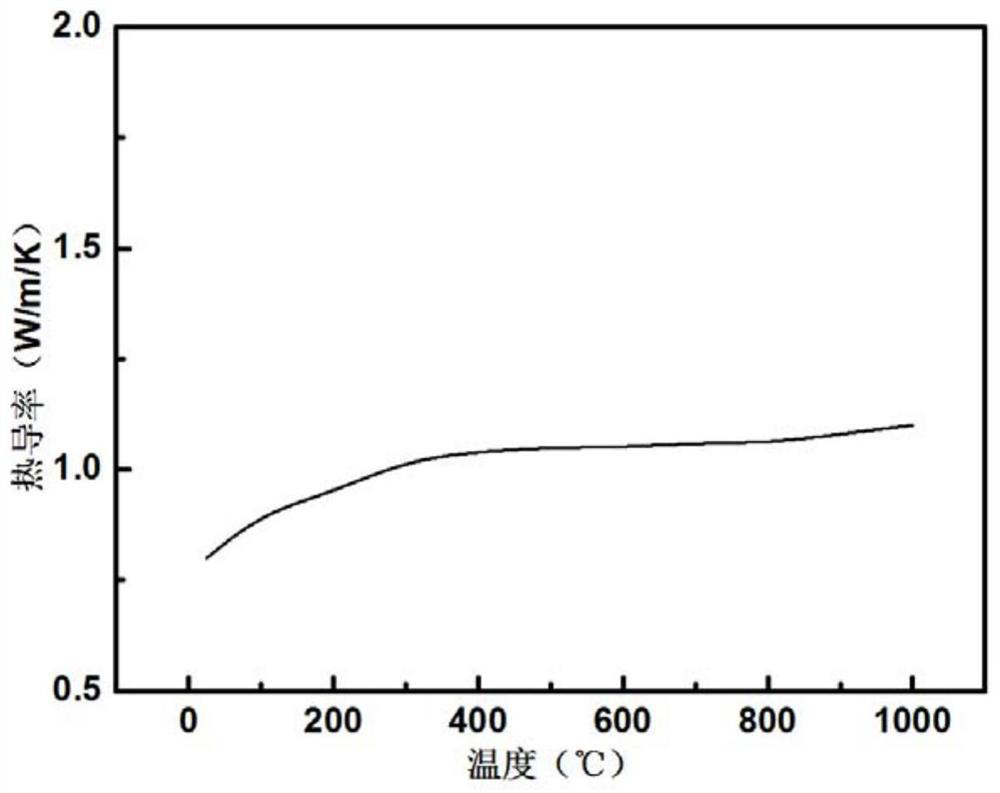

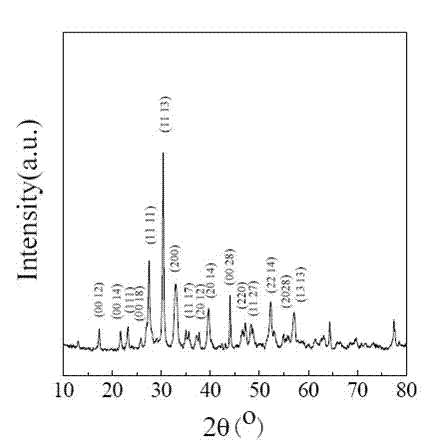

A2B2O7 type rare earth tantalate ceramic and preparation method thereof

ActiveCN111925211ALow thermal conductivityMeet the need for low thermal conductivityWater bathsGraphite

The invention relates to the technical field of thermal barrier coatings, and particularly discloses an A2B2O7 type rare earth tantalate ceramic and a preparation method thereof. The preparation method comprises the following steps: respectively dissolving RE2O3 and M2O3 into concentrated nitric acid according to the structural formula of RE2MTaO7 to react and adjusting the pH value to be not lessthan 1.5, dropwise adding a TaOCl3 solution, continuously stirring, adding ammonia water to stabilize the pH value of the system at 9-10, continuously stirring in a water bath environment, washing the precipitate with deionized water until the pH value is 7, drying the obtained filter cake in a drying oven, and screening for later use; and placing the powder in a graphite grinding tool, performing spark plasma sintering in a sintering furnace, then performing annealing and carbon removal on a sintered sample to obtain a compact RE2MTaO7 block. The material has the characteristics of low heatconductivity, high hardness, fracture toughness and the like.

Owner:KUNMING UNIV OF SCI & TECH +1

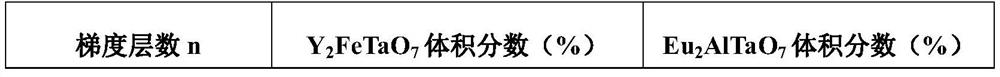

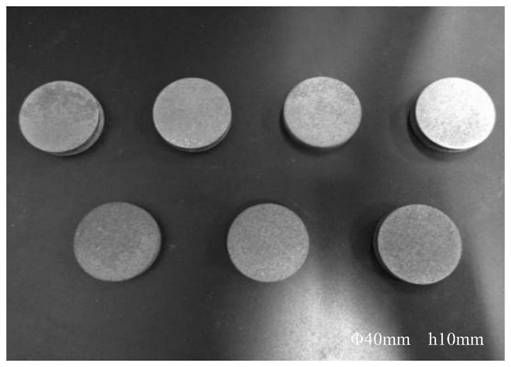

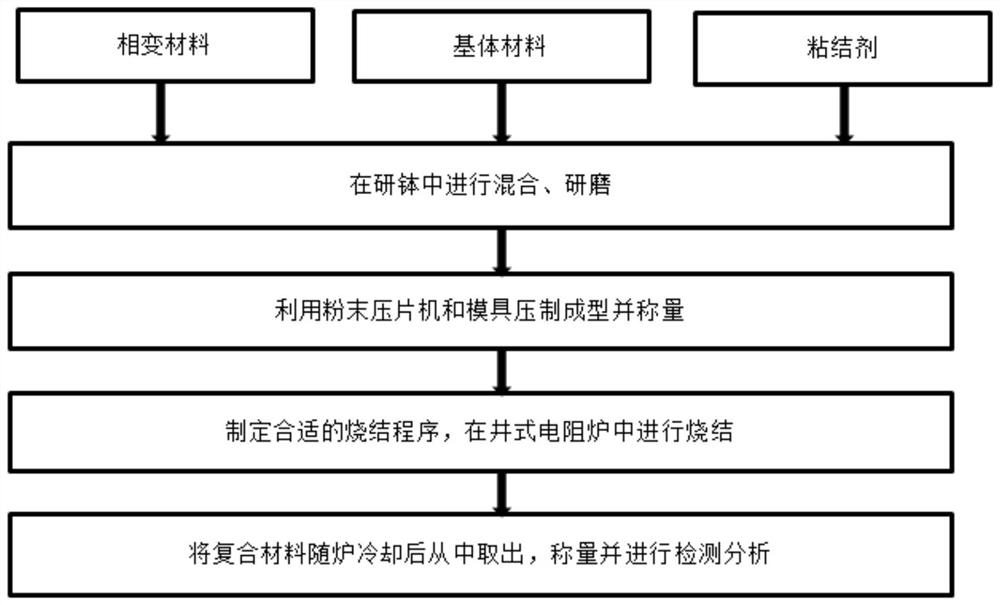

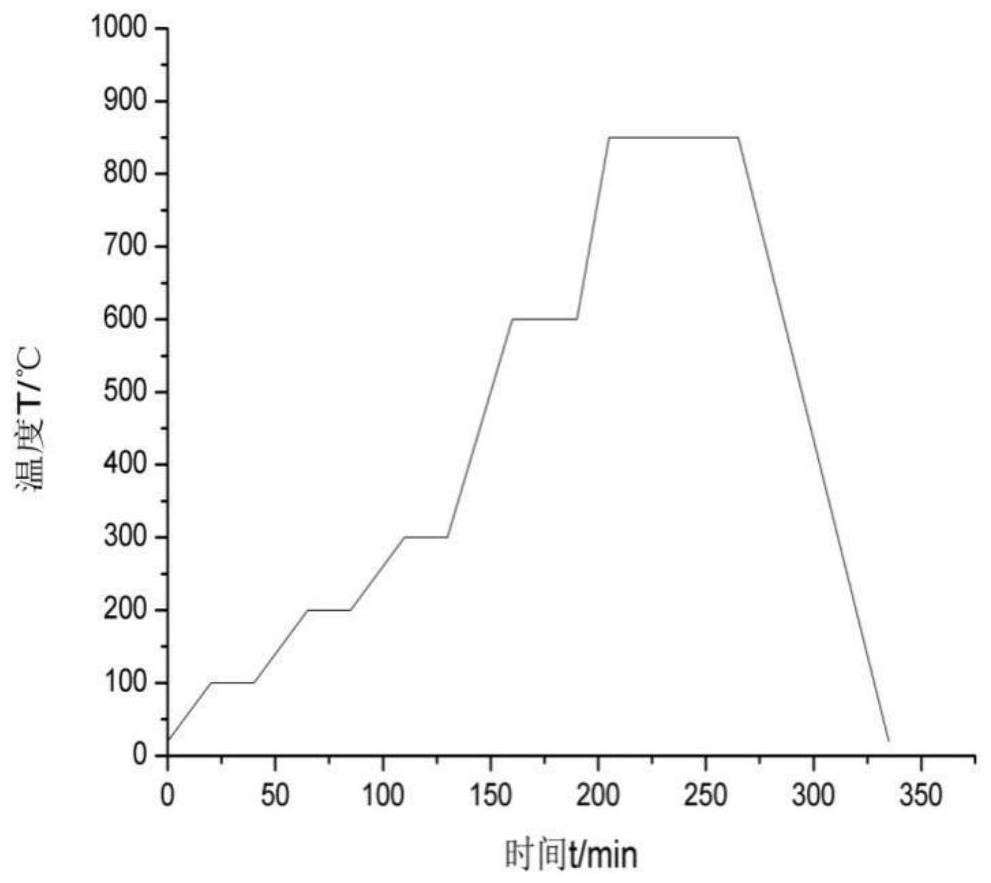

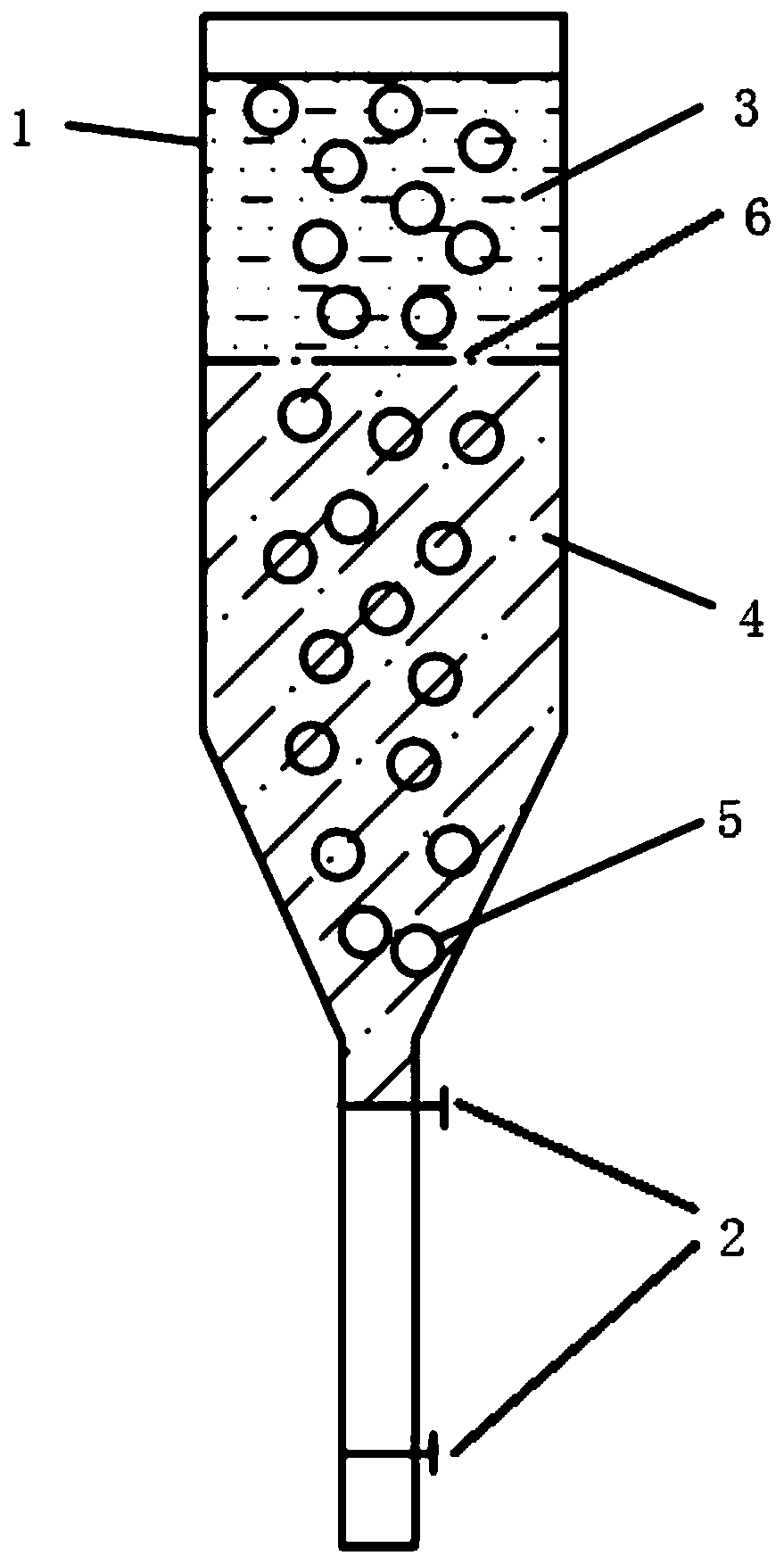

Preparation method of inorganic salt-ceramic high-temperature phase change composite heat storage material

InactiveCN113174239ALow costHigh phase transition temperatureHeat-exchange elementsInorganic saltsCompression molding

The invention discloses a preparation method of an inorganic salt-ceramic high-temperature phase change composite heat storage material. The preparation method is specifically implemented according to the following steps: pouring 25-30% of a phase change material NaCl and 69-74% of a ceramic matrix material SiC into a mortar, fully mixing and grinding to fully and uniformly mix the materials, and adding 0.5-1% of aluminum dihydrogen phosphate as a binder in the grinding process to obtain a mixture; pouring the ground mixture into a grinding tool, pressurizing by using a powder tablet press in a one-way pressurizing manner, and then pressing to obtain a cylindrical blank; and putting the blank obtained after compression molding into a pit type resistance furnace, sintering, and carrying out furnace cooling to obtain the NaCl-SiC composite phase change heat storage material. According to the preparation method of the inorganic salt-ceramic high-temperature phase-change composite heat storage material, the problems of serious loss, high material cost and poor heat-conducting property of a phase-change material in the preparation process in the prior art are solved.

Owner:NORTHWEST BRANCH OF CHINA DATANG CORP SCI & TECH RES INST

Method for preparing low-thermal-conductivity high-temperature thermal barrier ceramic CaWTa2O9 by solid-phase method

ActiveCN112250440ALow thermal conductivityFulfil requirementsEfficient propulsion technologiesThermal dilatationCompression molding

The invention relates to the technical field of high-temperature ceramic coatings, and particularly discloses a method for preparing low-thermal-conductivity high-temperature thermal barrier ceramic CaWTa2O9 by a solid-phase method, which comprises the following steps: proportioning Ta2O5 and CaWO4 according to a molar ratio of 1: 1, mixing with a ball milling medium, carrying out ball milling, drying, and screening to obtain powder; carrying out compression molding on the powder in a mold, and carrying out pressure-maintaining sintering at 1400-1600 DEG C for 5-10 hours to obtain the thermalbarrier ceramic CaWTa2O9. The thermal conductivity of the thermal barrier ceramic CaWTa2O9 prepared by the method at 800 DEG C reaches 1.25 W.m<-1>.K<-1> at minimum, the thermal expansion coefficientreaches 8.6 K<-1> at 1100 DEG C, the requirements of a high-temperature thermal barrier coating on low thermal conductivity and high thermal expansion coefficient of a ceramic material are met, and the thermal conductivity of the obtained pure CaWTa2O9 ceramic is far lower than that of the existing rare earth tantalate ceramic.

Owner:陕西天璇涂层科技有限公司

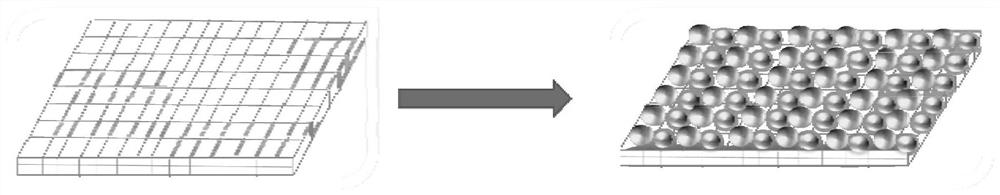

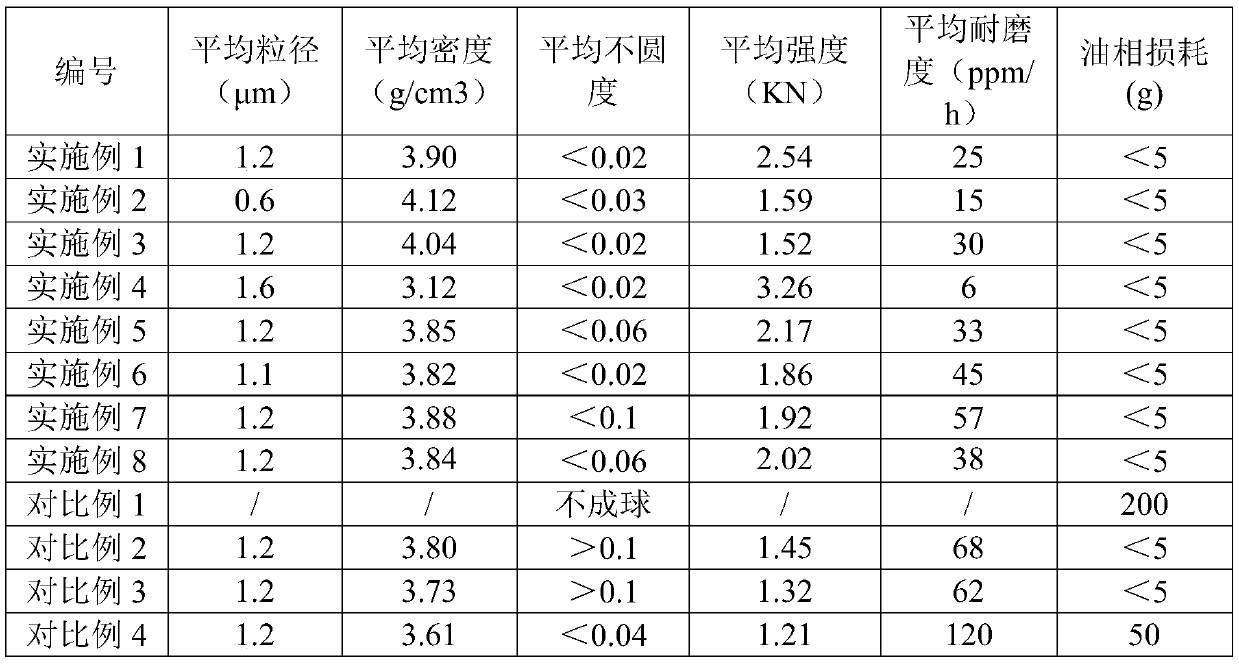

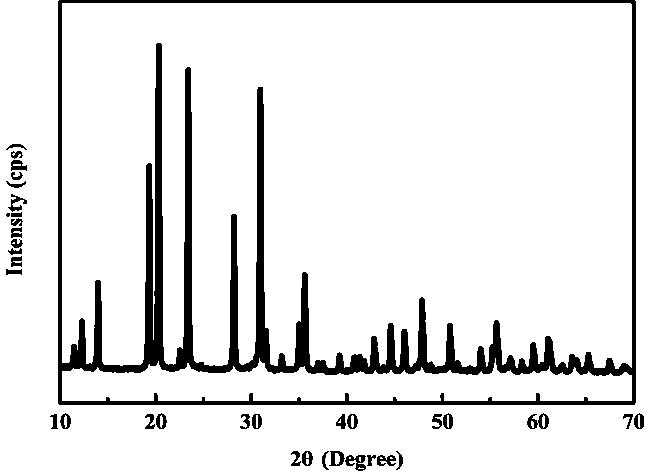

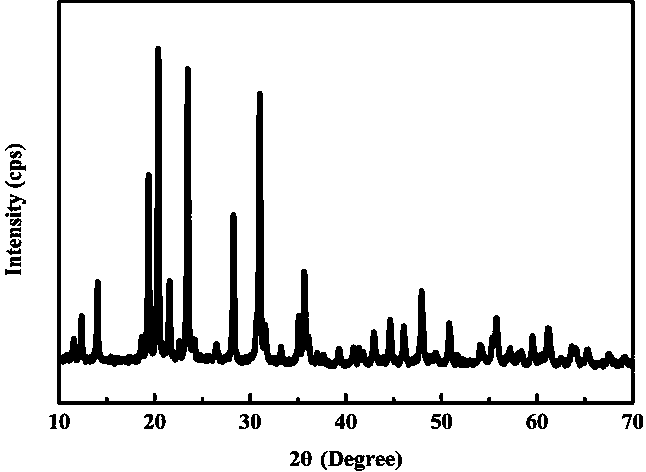

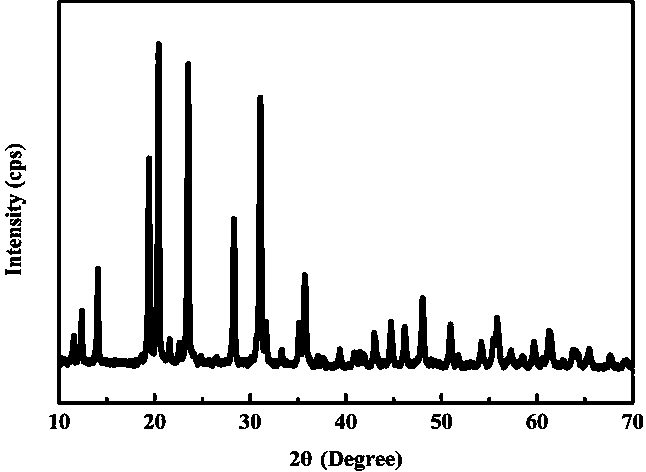

Method for preparing ceramic microbeads, ceramic microbeads and application thereof

The invention relates to the field of ceramics, and discloses a method for preparing ceramic microbeads. The method comprises the following steps: slurry containing an organic monomer, a cross-linkingagent, water-soluble alginate, ceramic powder, a sintering aid, an initiator and a dispersing agent is prepared, and the organic monomer, the cross-linking agent, the water-soluble alginate, the initiator and the dispersing agent are dissolved in the slurry, wherein the number-average molecular weight of the water-soluble alginate is not lower than 4000; the slurry prepared in the step (1) is fedinto an oil phase containing a catalyst in the form of liquid drops, and primary gel casting is carried out to obtain cured microspheres; the cured microbeads obtained in the step (2) are fed into anaqueous solution of a calcium source, and secondary gel casting is carried out to obtain hardened microbeads; and the hardened microbeads obtained in the step (3) are sintered. The ceramic microbeadprepared by the method has the advantages of high density, high strength, high wear resistance, low surface roughness, low out-of-roundness and low oil phase loss.

Owner:LUOYANG ZHONGCHAO NEW MATERIAL SHARES CO LTD

Low-expansion phosphate ceramic material and preparation method thereof

InactiveCN108358624ARaise the sintering temperatureImprove high temperature resistancePhosphateAdditive ingredient

The invention relates to a low-expansion NZP family ceramic material capable of resisting high temperature and a preparation method thereof, and belongs to the field of low-expansion ceramics. The ceramic material disclosed by the invention is the NZP family solid solution Ca0.5Sr0.5Zr4-xTixP6O24 (CSZTP for short) phosphate ceramic material which can resist high temperature and thermal shock and has a low coefficient of thermal expansion, wherein the average coefficient of thermal expansion of the ceramic material is 2.5-3.2*10<-6> / DEG C when x is greater than 0 and less than or equal to 0.2.An inverted sequence co-precipitation method is adopted to prepare the CSZTP ceramic material; according to the method, the disadvantages of overhigh calcination temperature, long calcination time, difficulty in second phase elimination and uneven ingredient distribution of a solid phase synthesis method are overcome, and meanwhile, the defects of long synthesis period and low yield of a hydrothermal method and a sol-gel method are overcome. The powder body prepared with the method has the advantages of pure phase composition, even powder body granularity, short synthesis time, simple production technology and the like and is convenient in popularization and application. The phosphate ceramic material prepared with the method keeps a low thermal expansion coefficient, also has the advantages of good compactness (relative density is 90% or above), high sintering temperature, good high-temperature performance, good thermal shock resistance and the like, and can be applied to various important high-temperature fields.

Owner:UNIV OF JINAN

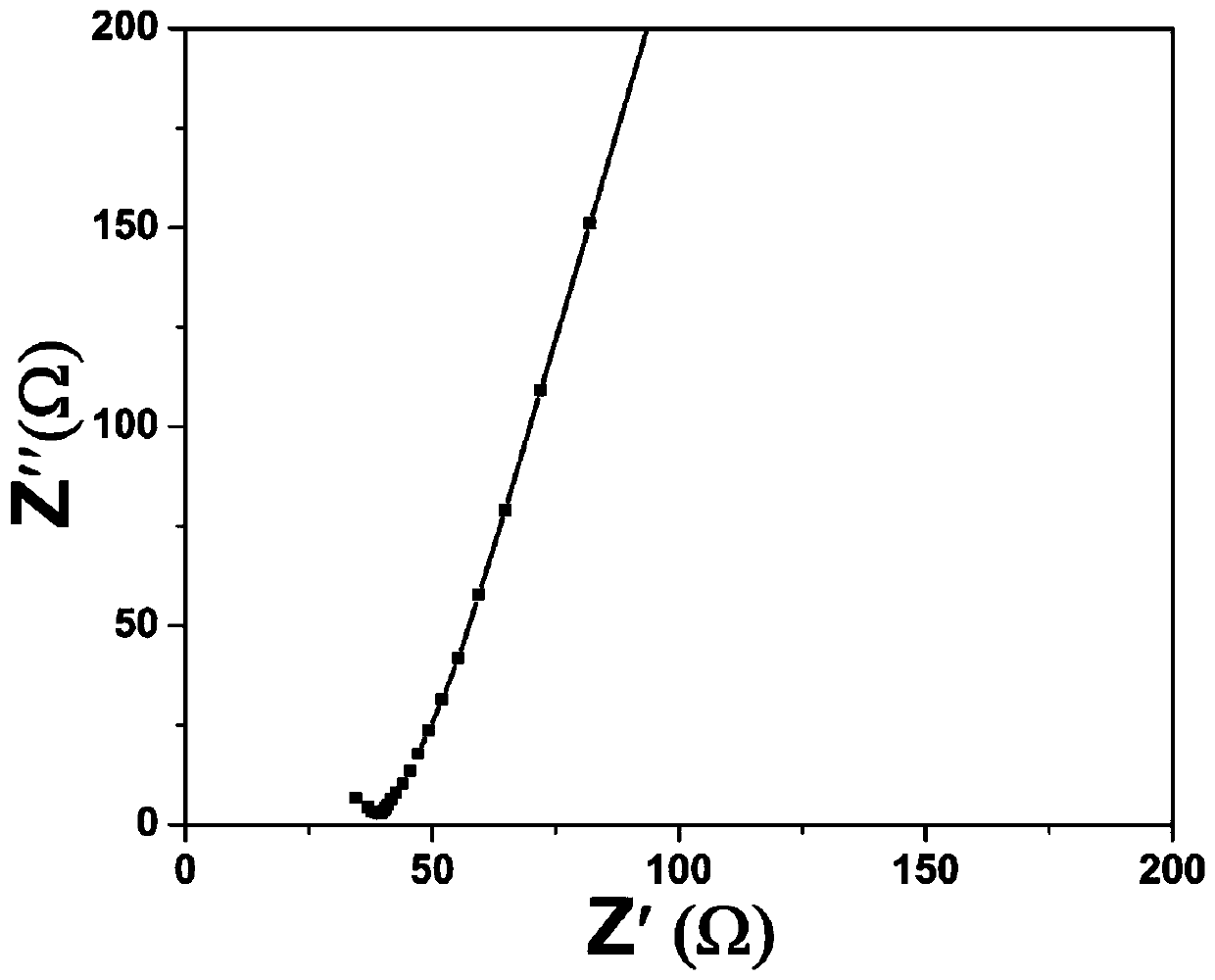

Composite solid electrolyte with wide electrochemical window and and preparation method of composite solid electrolyte

ActiveCN111370760AGreat application potentialSimple preparation processFinal product manufactureElectrolyte accumulators manufactureComposite electrolyteElectrical battery

The invention relates to the field of electrochemical energy storage, in particular to a composite solid electrolyte with a wide electrochemical window and a preparation method of the composite solidelectrolyte. The composite solid electrolyte comprises polyacrylonitrile, a lithium salt, a ceramic filler and a protective layer material. The preparation method comprises the following steps: firstly, preparing precursor slurry of the composite electrolyte through ball milling or heating and stirring; then coating a clean glass plate with the slurry by adopting a tape casting method, and dryingto obtain a PAN-based composite solid electrolyte; and finally, preparing protective layer slurry, uniformly coating one surface of the obtained PAN-based composite solid electrolyte with the protective layer slurry through a spin-coating method or a tape casting method, and drying to obtain the composite solid electrolyte with the wide electrochemical window. The composite solid electrolyte disclosed by the invention has the advantages of wide electrochemical window (0-4.5 Vvs.Li / Li < + >), small thickness (5-300 microns), good flexibility, simple preparation method and the like, and is suitable for the fields of lithium ion batteries, flow batteries and the like.

Owner:THE HONG KONG UNIV OF SCI & TECH

Multiferroic titanium-iron-cobalt-nickel acid bismuth salt ceramic material having six-layer structure and preparation method thereof

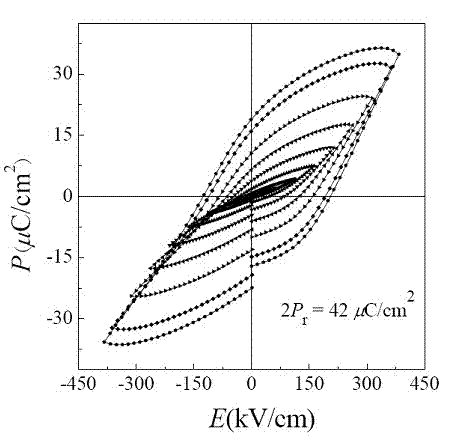

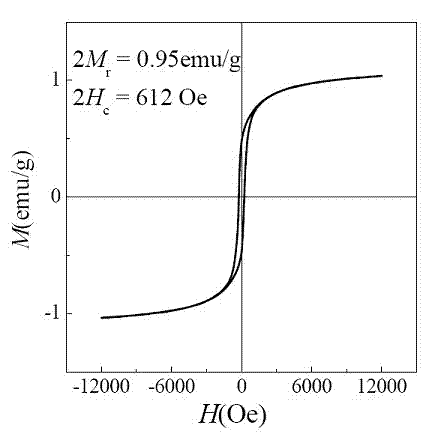

InactiveCN102515749AImprove ferromagnetic propertiesImprove ferroelectric propertiesMagnetizationMultiferroics

The invention discloses a multiferroic titanium-iron-cobalt-nickel acid bismuth salt ceramic material having a six-layer structure and a preparation method thereof. The multiferroic titanium-iron-cobalt-nickel acid bismuth salt ceramic material having a six-layer structure has a chemical formula of Bi7FeCoNiTi3O21. The preparation method comprises that raw materials of Bi2O3, Fe2O3, Co2O3, Ni2O3 and TiO2 are subjected to ball milling, drying, pre-synthesis, further ball milling, drying, molding, binder removal and sintering to form Bi7FeCoNiTi3O21, wherein a mole ratio of Bi2O3, Fe2O3, Co2O3, Ni2O3 to TiO2 is (6 to 6.6): 1: 1: 1: 6. The preparation method provided by the invention adopts a conventional solid phase sintering method, has simple processes and good environmental harmony. Bi7FeCoNiTi3O21 has ferroelectric and ferromagnetic properties at a room temperature, wherein Bi7FeCoNiTi3O21 has remanent polarization (2Pr) of 43 muC / cm<2> when a measure electric field is 390kV / cm and remanent magnetization of 0.95 emu / g.

Owner:YANGZHOU UNIV

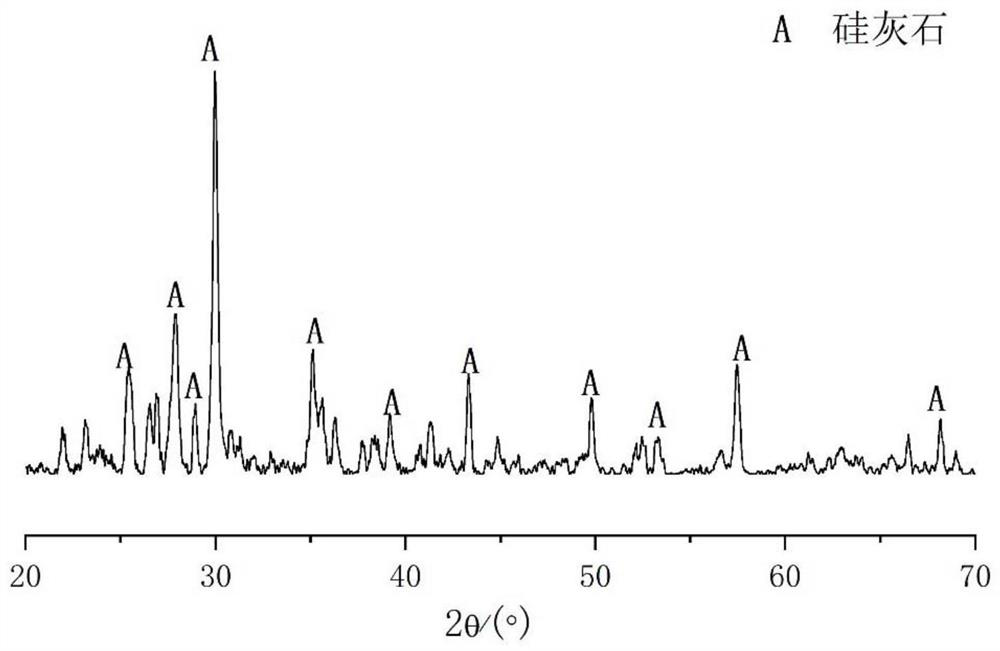

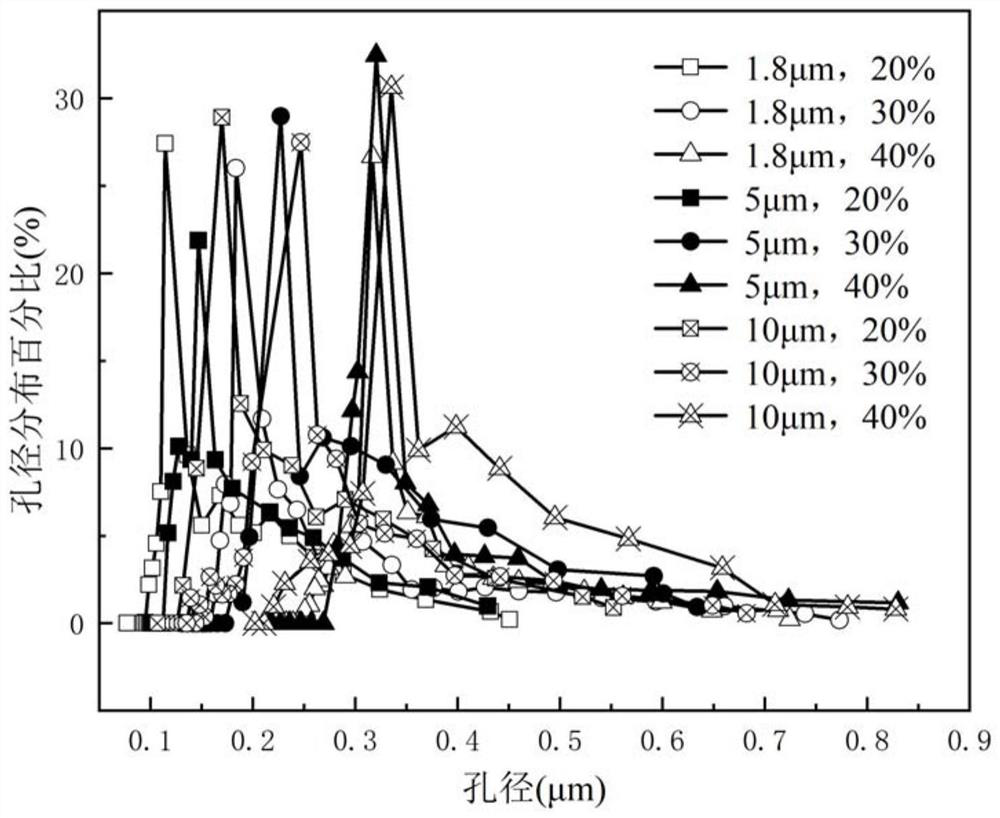

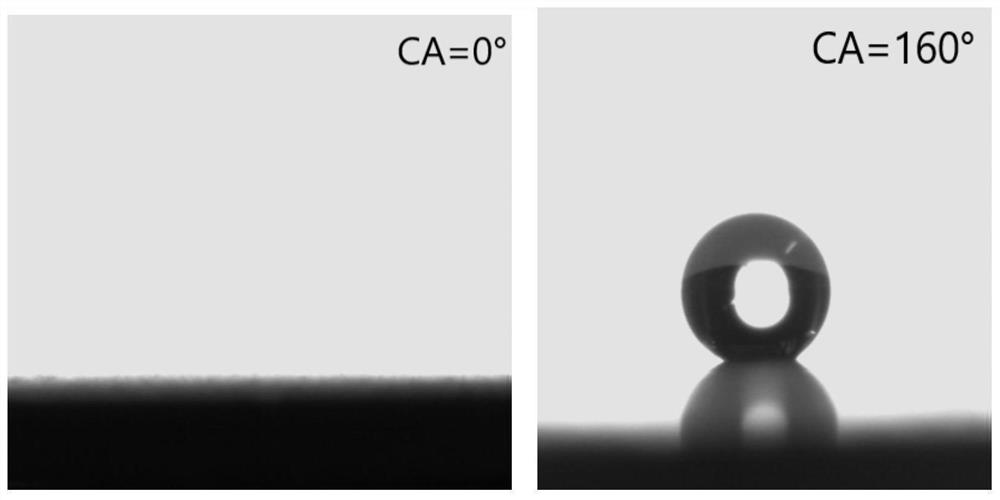

Method for preparing porous wollastonite ceramic membrane for membrane distillation desalination through dry pressing by taking blast furnace slag as main raw material

InactiveCN113019158ALow raw material costReduce occupancyMembranesSolid waste disposalSlagPolymethyl methacrylate

The invention discloses a method for preparing a porous wollastonite ceramic membrane for membrane distillation desalination through dry pressing by taking blast furnace slag as a main raw material, and belongs to the technical field of desalination. Blast furnace slag is taken as a main raw material, polymethyl methacrylate is taken as a pore-forming agent, the porous wollastonite ceramic membrane is prepared at low cost through dry-pressing solid-phase reaction, polymethylhydrosiloxane is taken as a modifier, hydrophobization treatment is performed on the porous wollastonite ceramic membrane by adopting a pyrolysis method, and the hydrophobic porous wollastonite ceramic membrane can be used for membrane distillation desalination. The method comprises the following steps: uniformly mixing the blast furnace slag with calcium oxide and silicon dioxide, adding a certain amount of polymethyl methacrylate, carrying out ball milling, drying and sieving to obtain a ceramic raw material, tabletting the ceramic raw material into a ceramic membrane blank, and calcining to obtain the wollastonite ceramic membrane with a good porous structure. The wollastonite porous ceramic membrane subjected to hydrophobization treatment can be used for membrane distillation desalination. The ceramic membrane has high water flux, and the desalination rate is close to 100%.

Owner:BEIJING UNIV OF TECH

Nanometer rare earth zirconate electrolyte for fuel cell and preparation method

InactiveCN108288723AIncreased diffusion rateSolve the problem of severe reunionMaterial nanotechnologyFuel cellsCeramic sinteringZirconate

The invention provides a preparation method of a nanometer rare earth zirconate electrolyte for a fuel cell. The method comprises the steps that rare earth oxide is dissolved a dilute nitric acid andzirconyl chloride solution and evenly mixed, the solution is mixed with excessive ammonium hydroxide, a gel material aqueous solution is obtained through coprecipitation and ageing, and after the solution is filtered, filter residues are soaked in alcohol, dispersed and ground; then, pre-burning at low temperature is conducted, and residual ammonium ions are desorbed; finally, sintering at high temperature is conducted, heat preservation is conducted for 4 h at 1,500 DEG C or above, and after cooling, nanometer-phase rare earth zirconate ceramic powder is obtained. According to the preparationmethod, the problems are solved that for a traditional pyrochlore structure, the ceramic is difficultly sintered, ordering phase change is easily caused during medium-temperature processing, and theagglomeration degree of the powder is high in the preparation process; the prepared film material can be evenly formed into film, the mechanical property and toughness of the film are high, and accordingly the service life of the electrolyte is prolonged.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

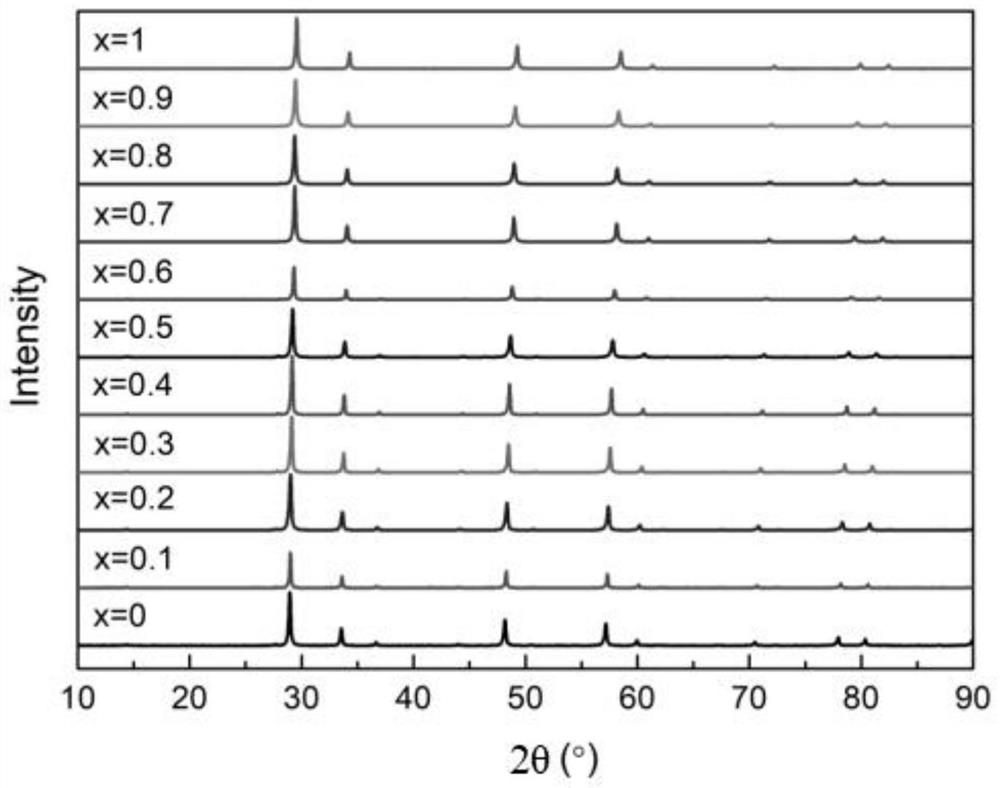

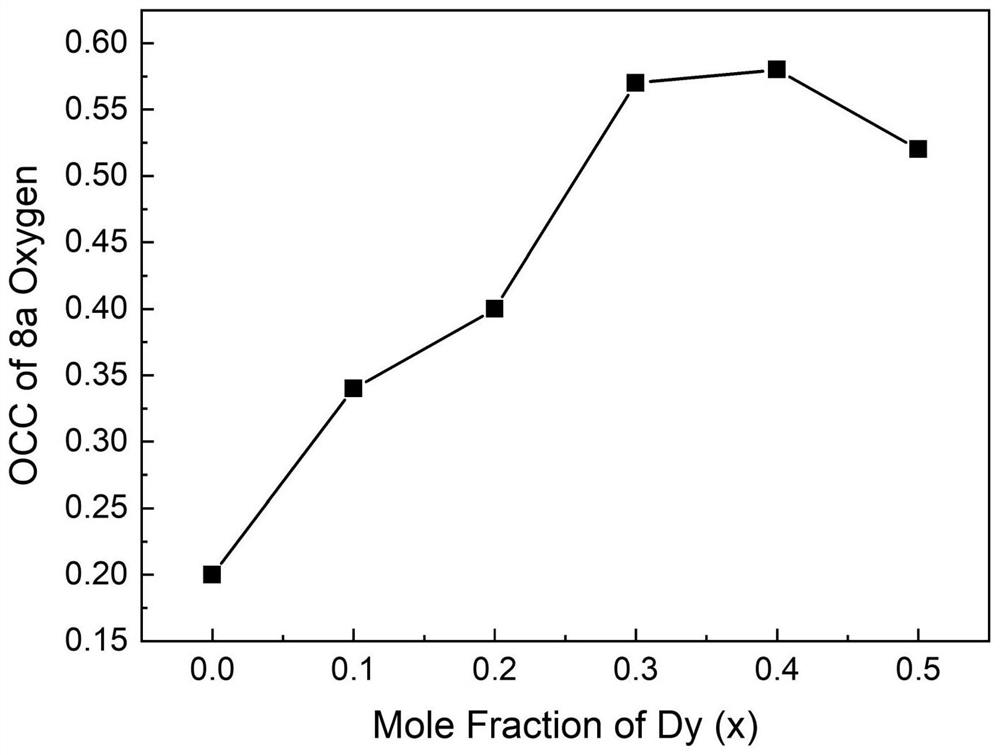

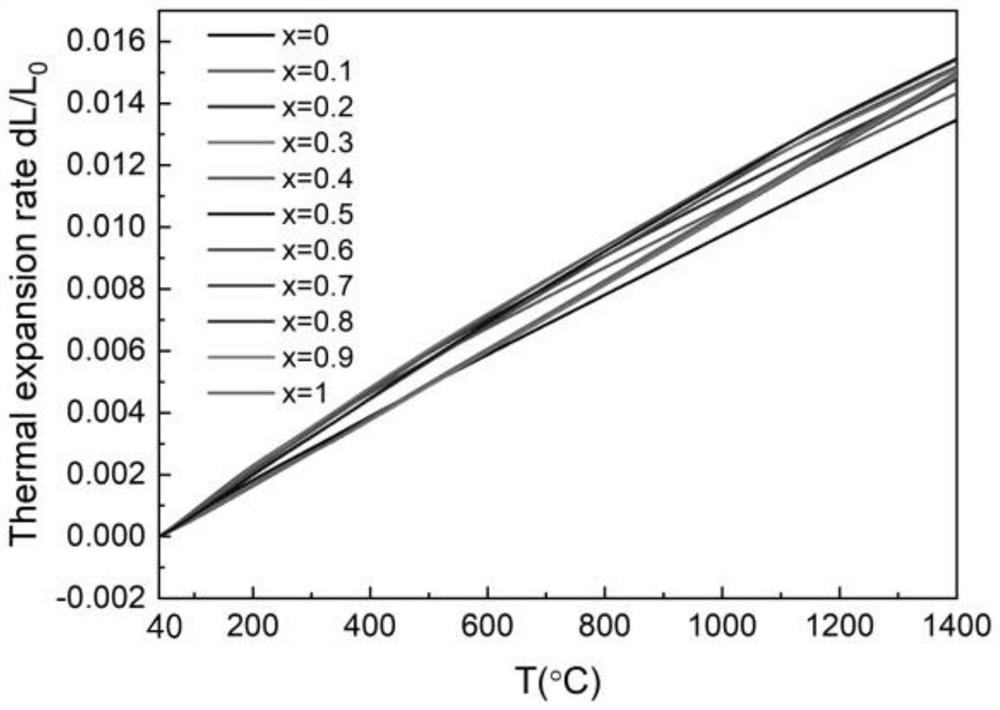

Double-rare-earth zirconate thermal barrier coating material and preparation method thereof

ActiveCN114560697ASimple processReduce manufacturing costEfficient propulsion technologiesRare earth ionsZirconate

The invention belongs to the technical field of thermal barrier coating materials, and discloses a double-rare-earth zirconate thermal barrier coating material, which is prepared by the following steps: uniformly mixing three original powders of Nd2O3, Dy2O3 and ZrO2 through ball milling, calcining, and synthesizing a compact pure pyrochlore phase or pure fluorite phase double-rare-earth zirconate ceramic material in situ. According to the invention, small-radius rare earth ions are doped at the rare earth position of pyrochlore phase rare earth zirconate, an ordered and disordered transformation process is constructed, and lattice disordering is utilized to improve the high-temperature thermal expansion coefficient of the rare earth zirconate. The invention further provides a preparation method of the double-rare-earth zirconate thermal barrier coating material, the process is simple, the product preparation cost is low, the purity is high, the impurity content is low, and the double-rare-earth zirconate thermal barrier coating material is suitable for popularization and application and has important significance for developing the rare-earth zirconate thermal barrier coating material with high temperature and high thermal expansion coefficient.

Owner:TSINGHUA UNIV +1

A kind of lanthanum cerium composite zirconate titanate ceramic material and preparation method thereof

ActiveCN103435343BHarm reductionPiezoelectric/electrostrictive/magnetostrictive devicesComposite ceramicCerium

The invention discloses a composite rare earth zirconate titanate ceramic material. The chemical formula of the material is: LaxCe1-xZr0.5Ti0.5O3, where 1>x>0. The invention also discloses a preparation method of composite rare earth zirconate titanate ceramic material. When x=0.5 and the external electric field is 20V, the Ps of La0.5Ce0.5Zr0.5Ti0.5O3 ≈ 100 μC / cm2; Pr ≈60μC / cm2; Er≈700V / cm. The invention prepares a LaxCe1-xZr0.5Ti0.5O3 composite rare earth zirconate titanate ceramic material in which Pb is replaced by a composite of La and Ce, which reduces the harm of Pb to the environment and can be used in the manufacture of new piezoelectric materials.

Owner:浙江枫翎新材料科技有限公司

Modified carbon nanotube far-infrared heating slurry and preparation method thereof

InactiveCN107216770APrevent curing crackingImprove high temperature adhesionEpoxy resin coatingsEpoxyModified carbon

The invention provides modified carbon nanotube far-infrared heating slurry and a preparation method thereof. The slurry comprises the following components in parts by mass: 15-20 parts of modified carbon nanotubes, 5-10 parts of nano bamboo carbon powder, 10-15 parts of a ceramic emitting agent, 20-25 parts of epoxy resin paint, 25-30 parts of an epoxy resin paint solvent, 2-4 parts of a curing agent, 5-10 parts of silicon micro powder, 1-2 parts of a dispersing agent and 1-2 parts of a coupling agent. Due to introduction of the modified carbon nanotubes, the nano bamboo carbon powder, a polycarboxylic acid ammonia salt ceramic dispersing agent and the silicon micro powder, the conductivity and high-temperature cohesiveness of the heating slurry are improved.

Owner:WUHU SAUNAKING ELECTRONICS TECH CO LTD

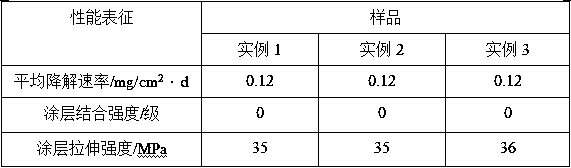

Preparation method of high-strength biological zinc-magnesium alloy composite material

InactiveCN108823439AImprove bindingMatch mechanical propertiesElectrolytic inorganic material coatingPharmaceutical delivery mechanismAlloy substrateSlurry

The invention relates to a preparation method of a high-strength biological zinc-magnesium alloy composite material, and belongs to the technical field of medical materials. The method is characterized in that an in-situ hydrothermal synthesis technology is adopted to coat the surface of an alloy substrate with a molecular sieve structure film having an excellent structure, and a large amount of afilm forming solution penetrates into the surface of the material through capillary slurry suction and crystallizes to form molecular sieve particles, the formed molecular sieve particles have a porous structure, and a crystal enters the pores of the molecular sieve and covers the surface of the molecular sieve to form a mechanical interlocking interface structure between the coating outer layerand an oxide layer, so the bonding property between the coating and the substrate is improved; and the performances of the plating coating layer are between those of a medical metal and a calcium phosphate salt ceramic, so the composite coating and the substrate have matched mechanical properties, and the corrosion resistance of the composite system is improved, thereby the overall biological activity and the compatibility are improved.

Owner:FOSHAN GAOMING DISTRICT ZHUAHE NEW MATERIAL TECH CO LTD

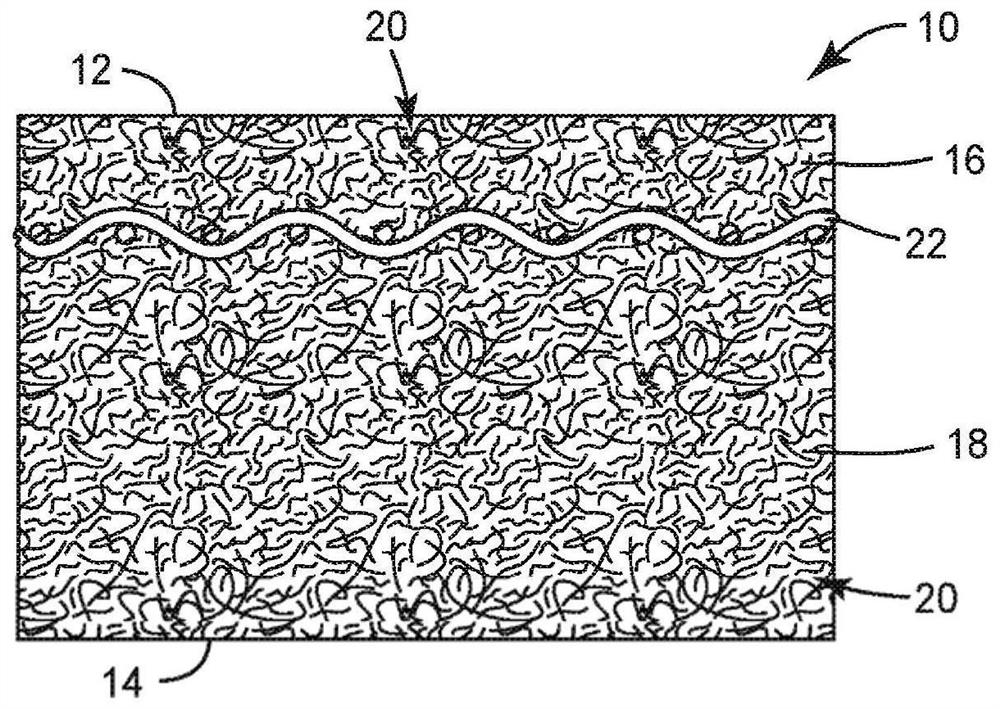

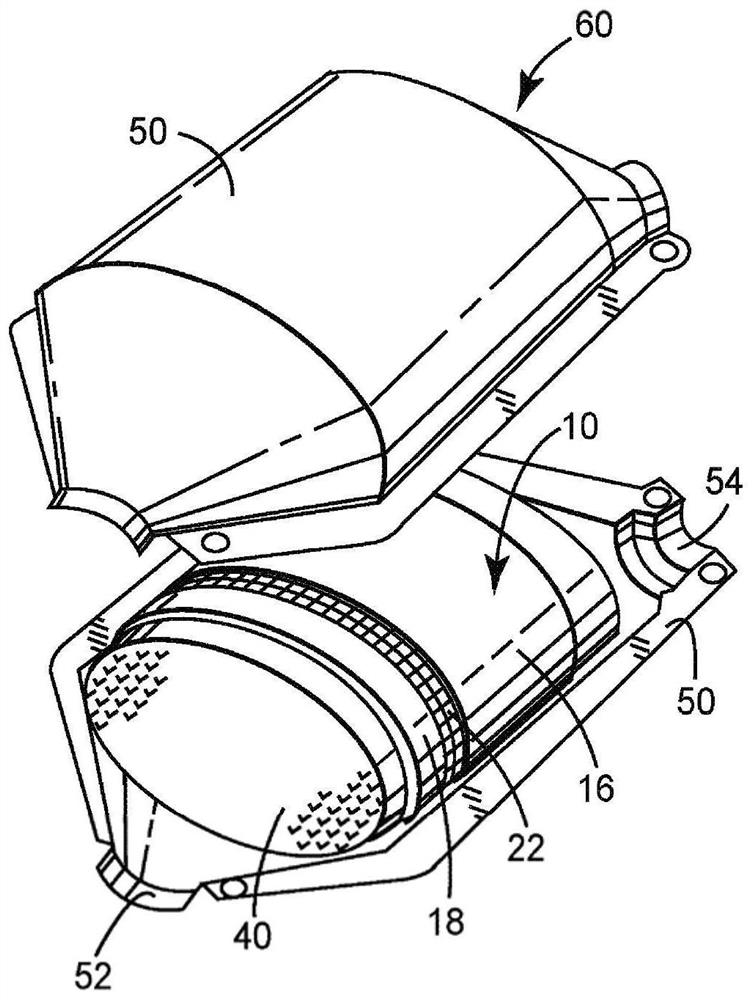

Polycrystalline, aluminosilicate ceramic filaments, fibers, and nonwoven mats, and methods of making and using the same

InactiveCN112118909AImprove thermal conductivityImproved thermomechanical propertiesPhysical/chemical process catalystsExhaust apparatusSalt ceramicSilk fiber

Provided is a nonwoven article comprising a two-dimensional nonwoven structure having a longest major surface dimension and a shortest major surface dimension. The two-dimensional nonwoven structure comprises a plurality of discontinuous polycrystalline, with aluminosilicate ceramic fibers having a length equal to the longest or shortest major surface dimension of the two-dimensional nonwoven structure or a length in between those dimensions.

Owner:3M INNOVATIVE PROPERTIES CO

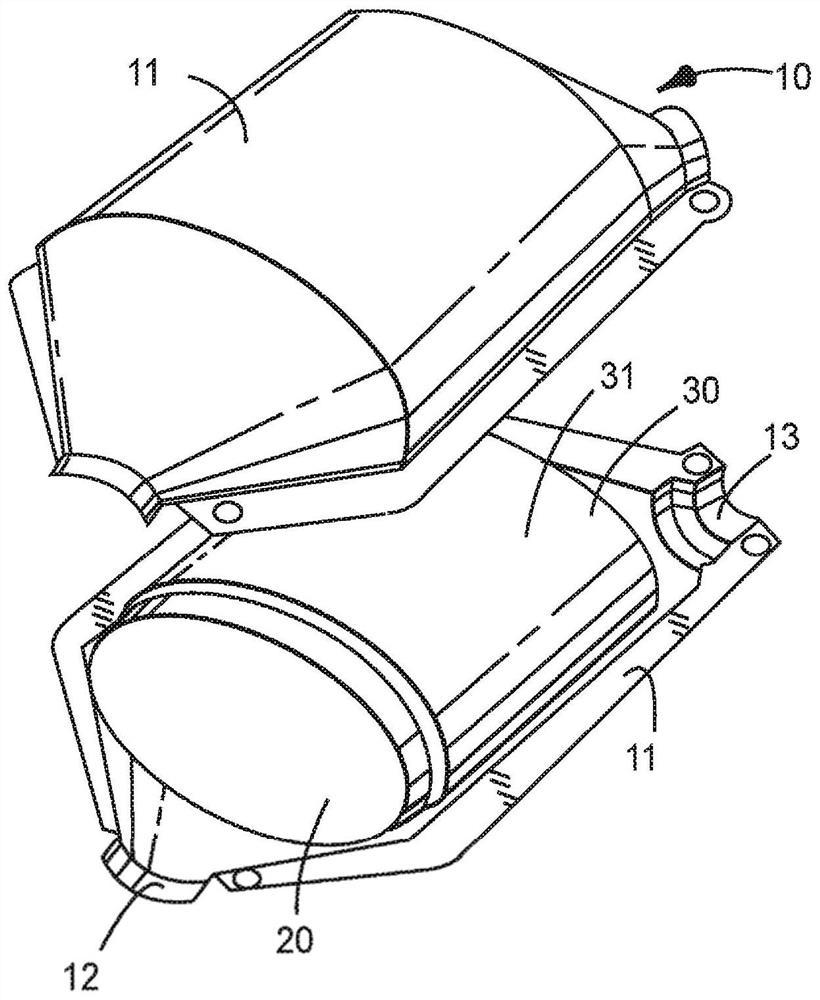

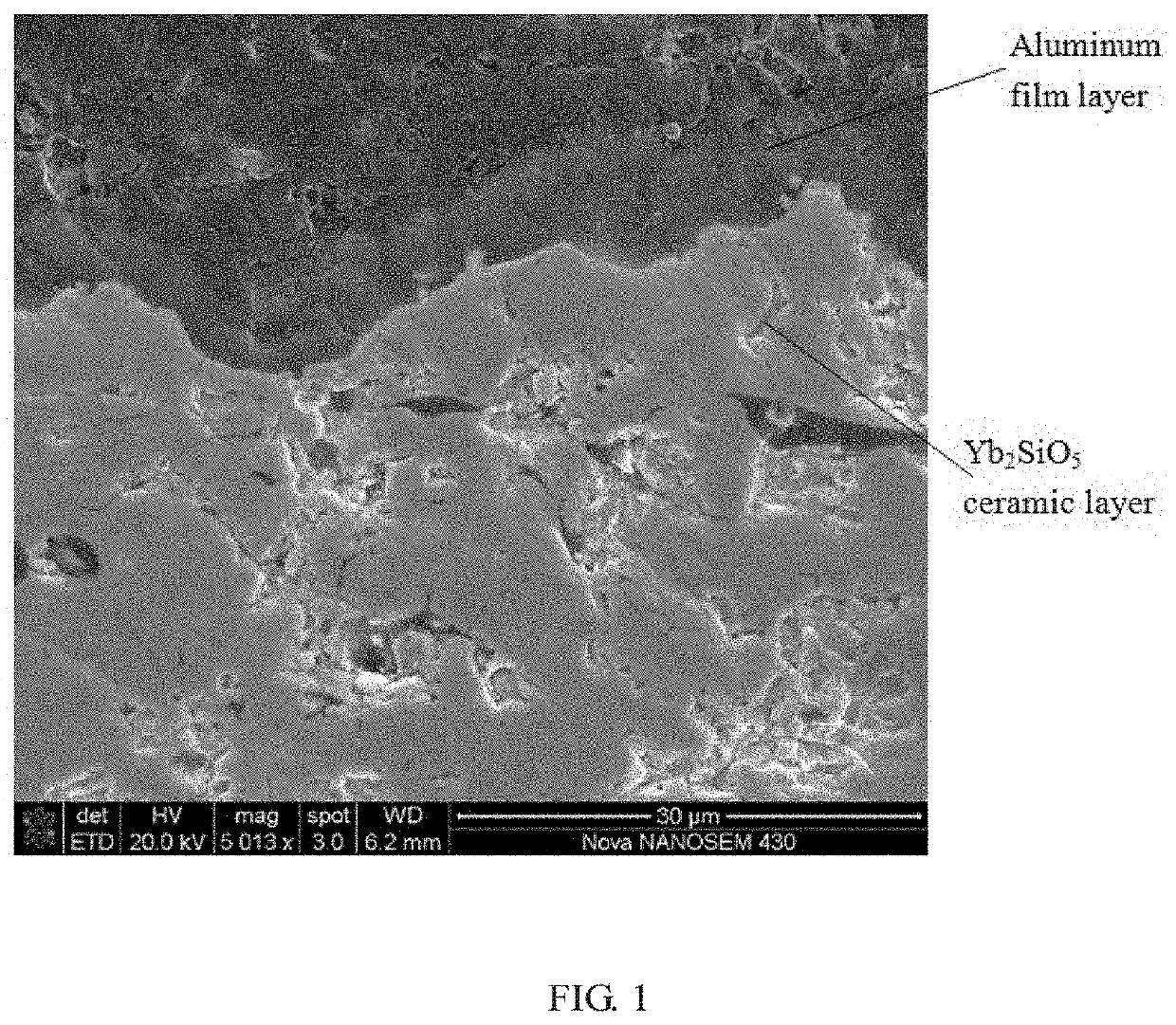

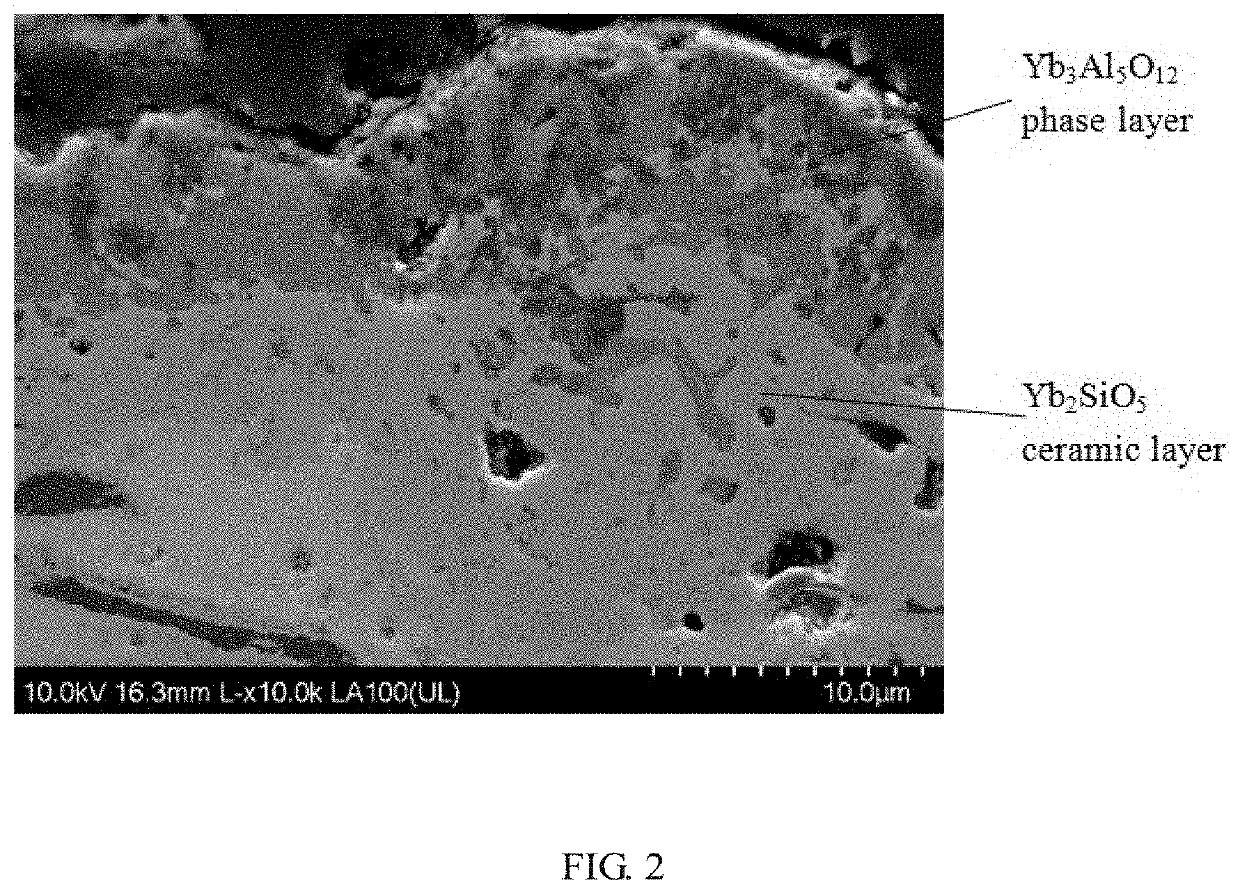

Method for coating thermal/environmental barrier coating

InactiveUS20210047722A1Improve service performanceExtend service hoursMolten spray coatingVacuum evaporation coatingAluminateSalt ceramic

The present disclosure discloses a method for coating an environmental barrier coating, comprising: coating an aluminum film layer on a surface of a rare earth silicate ceramic layer, and heat treating the aluminum film layer to form a rare earth aluminate phase at least in pores of a side of the rare earth silicate ceramic layer facing the aluminum film layer. An environmental barrier coating prepared by the above method is also disclosed.

Owner:GUANGDONG INST OF NEW MATERIALS

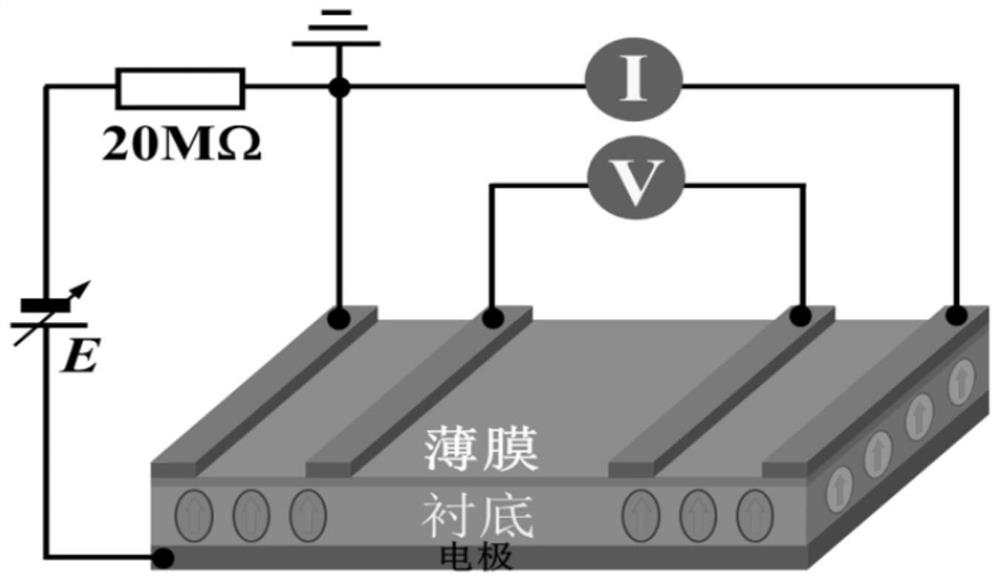

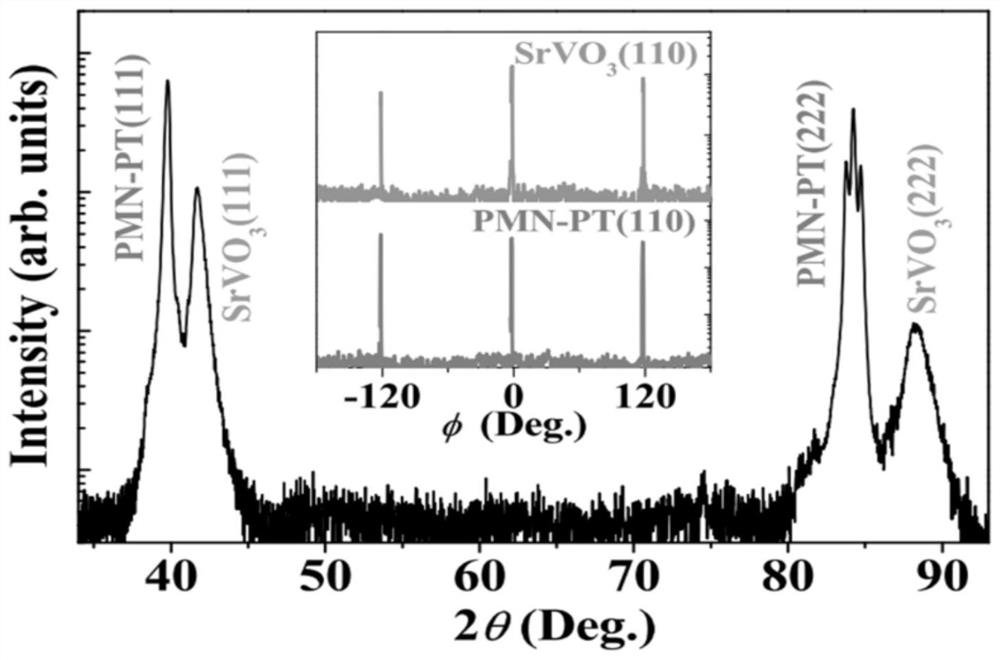

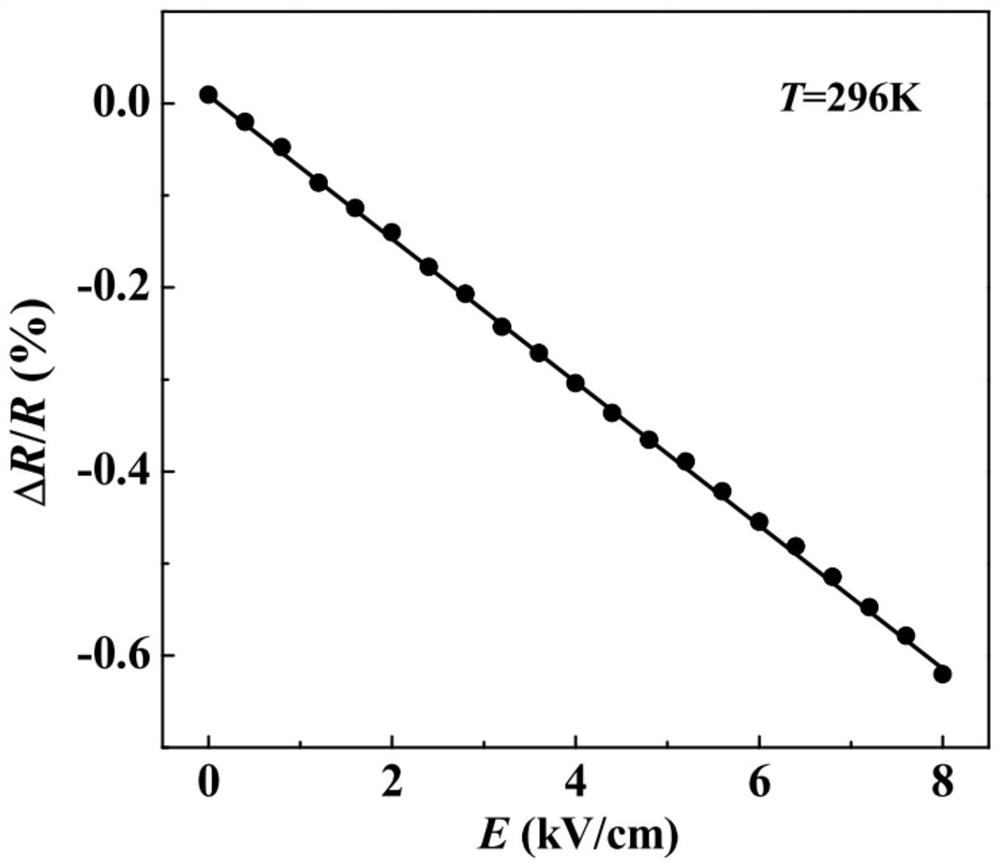

Perovskite type alkaline earth vanadate film ferroelectric heterostructure and preparation method thereof

PendingCN114551717ARealize regulationResistance regulationMagnetic-field-controlled resistorsFrom chemically reactive gasesHeterojunctionFilm resistance

The invention discloses a perovskite type alkaline earth vanadate film ferroelectric heterostructure and a preparation method thereof. The heterostructure comprises a ferroelectric single crystal substrate and a perovskite type alkaline earth vanadate film epitaxially growing on the substrate. The preparation method comprises the following steps: step 1, selecting a perovskite type alkaline earth vanadate ceramic block as a target material; and 2, depositing a layer of epitaxial perovskite type alkaline earth vanadate film on the ferroelectric single crystal substrate by adopting a pulse laser deposition technology. According to the invention, the alkaline earth vanadate film is epitaxially grown on the ferroelectric single crystal substrate, the ferroelectric single crystal substrate generates an inverse piezoelectric effect and introduces in-plane compressive strain by controlling the intensity of a longitudinally applied direct-current electric field, so that the resistance of the alkaline earth vanadate film is regulated and controlled, an electro-resistance effect is presented, and the performance of the device is improved. The method has important guiding significance for application of related metal materials in new-generation electric field adjustable low-power-consumption nonvolatile electronic devices.

Owner:CHINA UNIV OF MINING & TECH

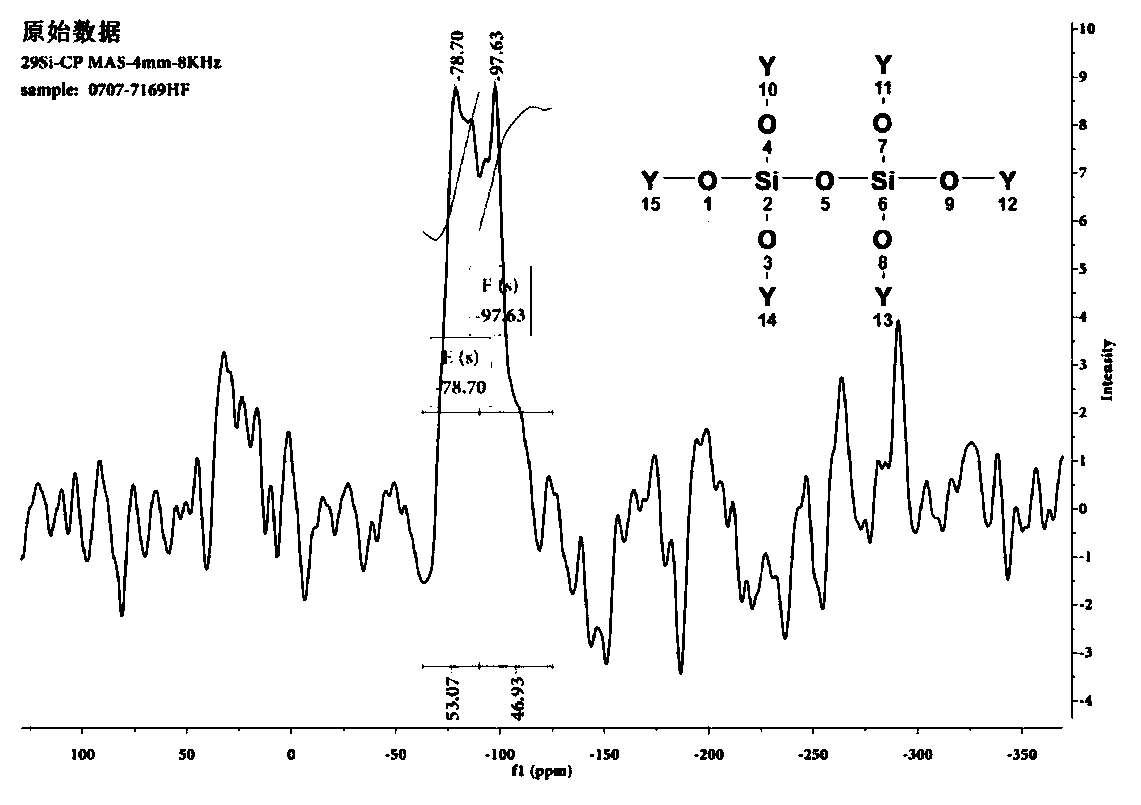

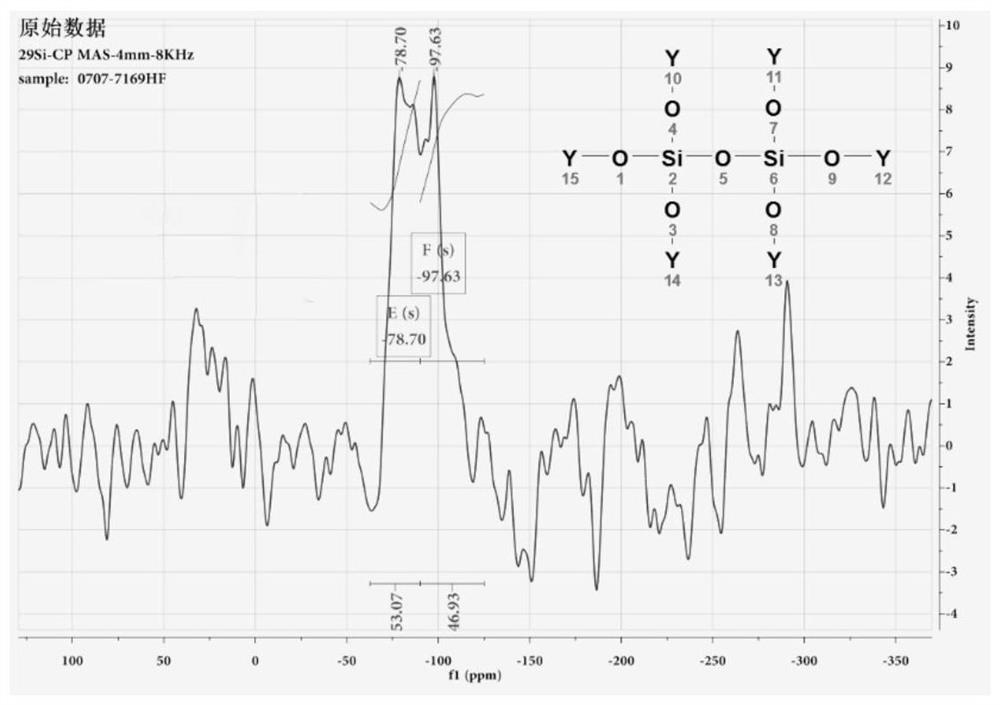

Method for preparing rare earth silicate ceramics by chemical vapor deposition of oxygen-containing precursor

The invention relates to a method for preparing rare earth silicate ceramics by chemical vapor deposition of an oxygen-containing precursor. A rare earth oxide is used as a reactant, CH3SiCl3 is usedas a precursor, CO2 is used as an oxygen source, hydrogen is used as a carrier gas and a dilution gas, argon is used as a protective gas, and the rare earth silicate ceramics are obtained by chemicalvapor deposition. The method can be used for preparing rare earth silicate ceramic powder, and can also be used for preparing rare earth silicate ceramic coatings, rare earth silicate ceramic modifiedstructural ceramics and ceramic matrix composite materials. The preparation temperature of the rare earth silicate ceramics is low, the problem that the preparation temperature of the rare earth silicate ceramic is too high is solved, the preparation process is simple to operate, the repeatability is strong, the shape of the material is not affected, industrial production can be realized, and a new method is provided for preparing the rare earth silicate ceramics and the rare earth silicate modified ceramic matrix composite materials by chemical vapor deposition.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

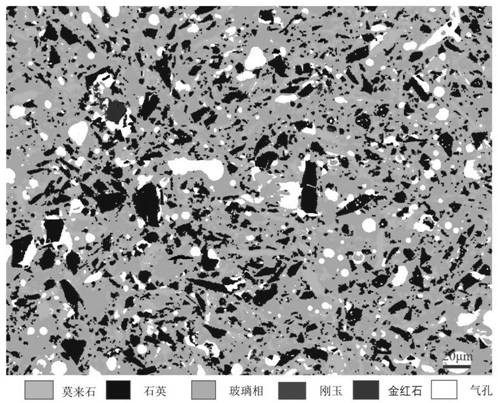

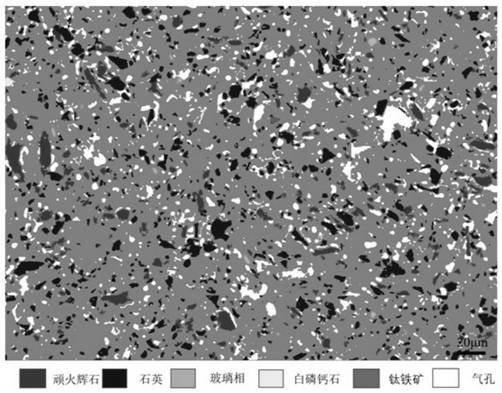

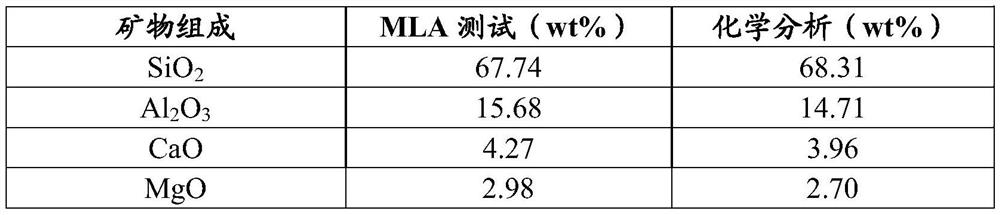

Silicate ceramic composition detection method

PendingCN114047362AImprovement of ceramic processing technologyAccurate measurementMaterial analysis using wave/particle radiationScanning probe techniquesEpoxyResin embedding

The invention belongs to the technical field of analysis and detection, and particularly discloses a silicate ceramic composition detection method. The method comprises the following steps: firstly, cutting a silicate ceramic sample into blocks, then carrying out epoxy resin embedding treatment on the block-shaped sample, and curing to obtain an epoxy resin polished section; carrying out polishing and carbon spraying on the epoxy resin polished section, and then carrying out measurement by adopting an MLA system to obtain a newly built X-ray energy spectrum list; and arranging and naming a newly-built X-ray energy spectrum list, then carrying out phase classification on measurement data, and then calculating to obtain the mass percent contents of crystalline phase minerals, amorphous phases and pores in the silicate ceramic sample. According to the method disclosed by the invention, the performance of the silicate ceramic can be evaluated by measuring the composition of the silicate ceramic, and a theoretical basis and support are provided for optimizing a ceramic processing technology.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

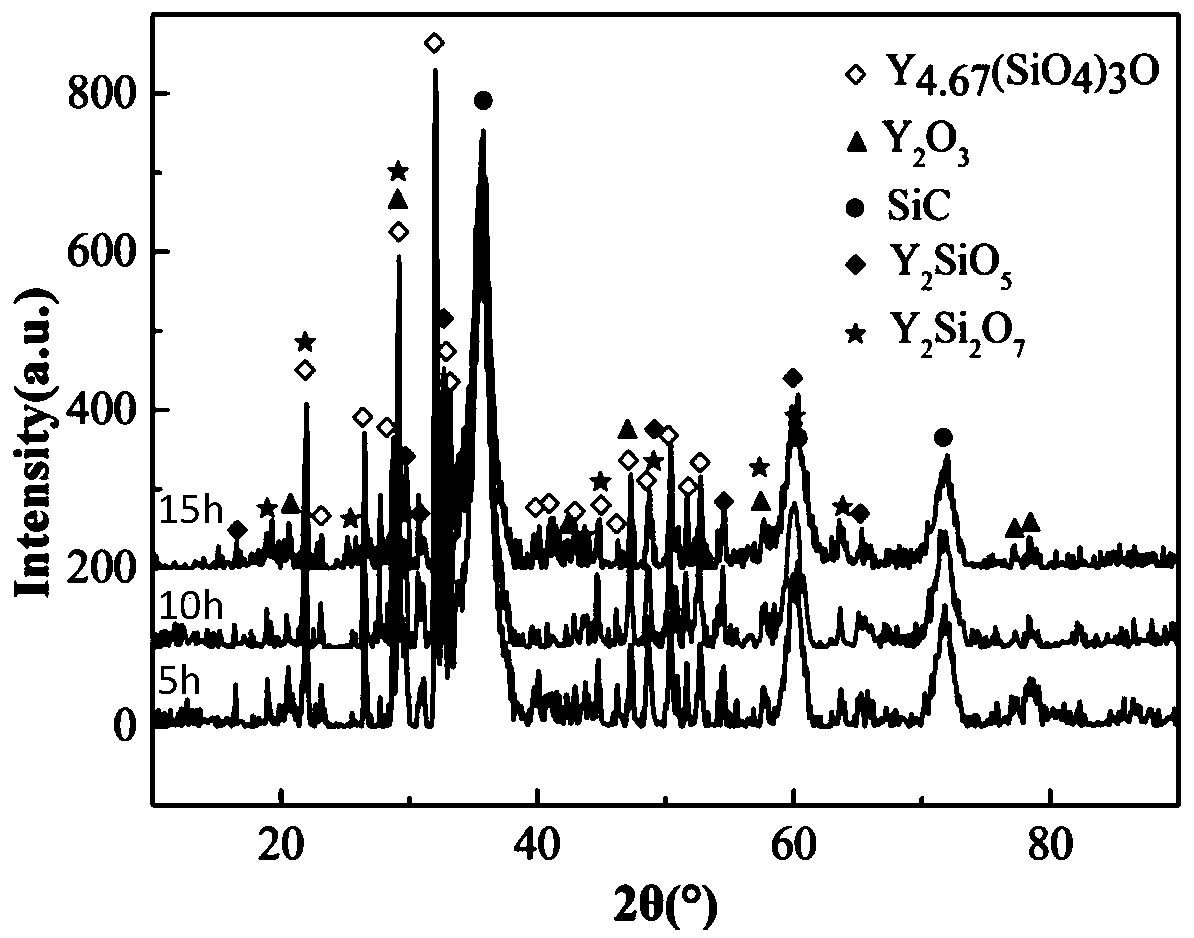

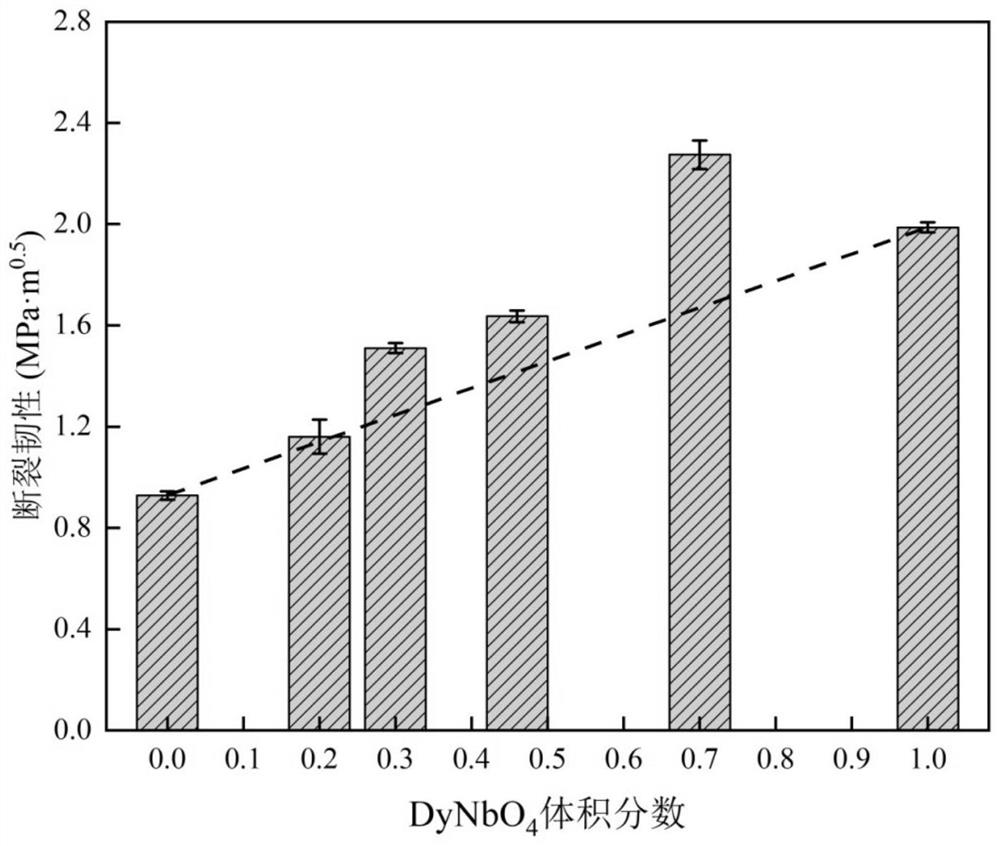

A kind of in-situ synthesis of pseudo-binary complex-phase rare earth niobate ceramics and its preparation method

The invention discloses in-situ-synthesized fake binary complex-phase rare earth niobate ceramic and a preparation method thereof. The preparation method comprises the following steps: 1), calcinatingrare earth oxide RE2O3, then mixing with niobium oxide (Nb2O5) by a wet ball milling method, performing rotary evaporative drying, sintering and sieving to obtain presintered powder, grinding the pre-sintered powder by the wet ball milling method, performing rotary evaporation and sieving to obtain fine powder; 2), placing the fine powder in a mould, hydraulically compacting, performing cold isostatic compacting and then secondarily sintering to obtain the fake binary complex-phase rare earth niobate ceramic. By the preparation method, a technology is simple, a product is low in preparation cost and high in purity and is suitable for batch production, and the prepared fake binary complex-phase rare earth niobate ceramic has relatively good thermal properties.

Owner:TSINGHUA UNIV

Method for preparing rare earth silicate ceramics by chemical vapor deposition of oxygen-containing precursor

ActiveCN110407583BUniform and dense preparationEffective protectionCeramic coatingPhysical chemistry

The invention relates to a method for preparing rare earth silicate ceramics by chemical vapor deposition of an oxygen-containing precursor. Rare earth oxides are used as reactants, and CH 3 SiCl 3 As a precursor, CO 2 As an oxygen source, hydrogen as a carrier gas and dilution gas, and argon as a protective gas, rare earth silicate ceramics are obtained through chemical vapor deposition. It can be used to prepare rare earth silicate ceramic powder, and can also be used to prepare rare earth silicate ceramic coating, and rare earth silicate ceramic modified structural ceramics and ceramic matrix composite materials. The preparation temperature of the rare earth silicate ceramics of the present invention is low, which solves the problem that the preparation temperature of the rare earth silicate ceramics is too high. Vapor deposition provides a new method for preparing rare earth silicate ceramics and rare earth silicate modified ceramic matrix composites.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

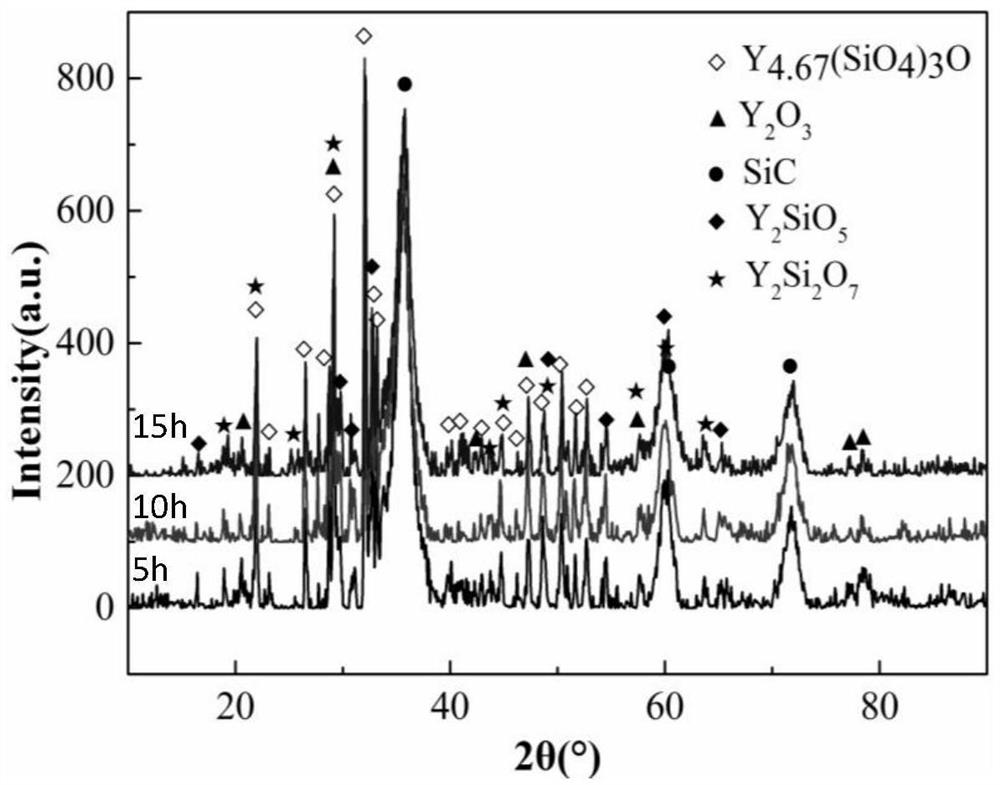

High-temperature-resistant CMAS-corrosion-resistant rare earth silicate ceramic and preparation method thereof

ActiveCN114853473APrevent infiltrationImproving the corrosion resistance of high temperature CMASEfficient propulsion technologiesComposite ceramicPhysical chemistry

The invention relates to high-temperature-resistant CMAS-corrosion-resistant rare earth silicate ceramic and a preparation method thereof. The ceramic is of a composite ceramic structure compounded by high-entropy rare earth monosilicate and high-entropy rare earth disilicate. The preparation method comprises the following steps: respectively synthesizing RE2O3 and SiO2 into single-phase (xRE1 / x) 2SiO5 powder and single-phase (xRE1 / x) 2Si2O7 powder through a solid-phase reaction method, then compounding the single-phase (xRE1 / x) 2SiO5 powder and the single-phase (xRE1 / x) 2Si2O7 powder according to a certain proportion to form (xRE1 / x) 2SiO5 / (xRE1 / x) 2Si2O7 complex-phase powder, tabletting the powder, and carrying out pressureless sintering to form (xRE1 / x) 2SiO5 / (xRE1 / x) 2Si2O7 complex-phase ceramic blocks; the high-entropy rare earth silicate ceramic with the structure has excellent performances such as good high-temperature CMAS corrosion resistance and the like.

Owner:SHENYANG POLYTECHNIC UNIV +1

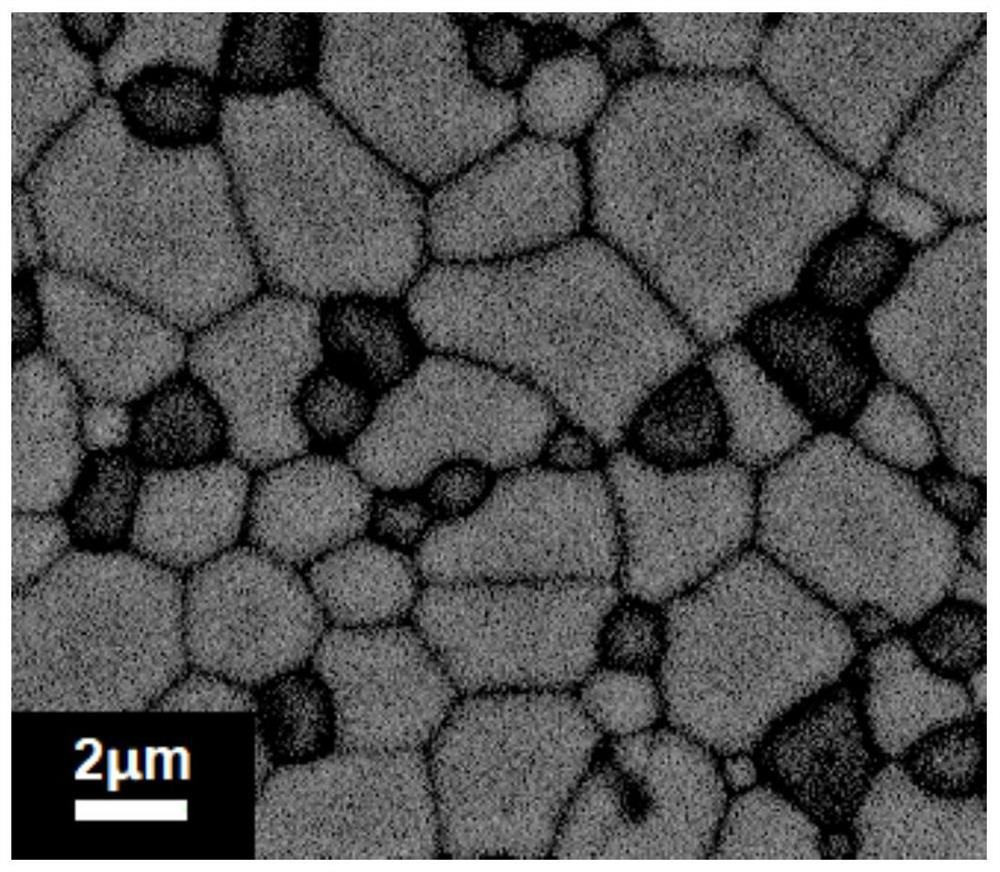

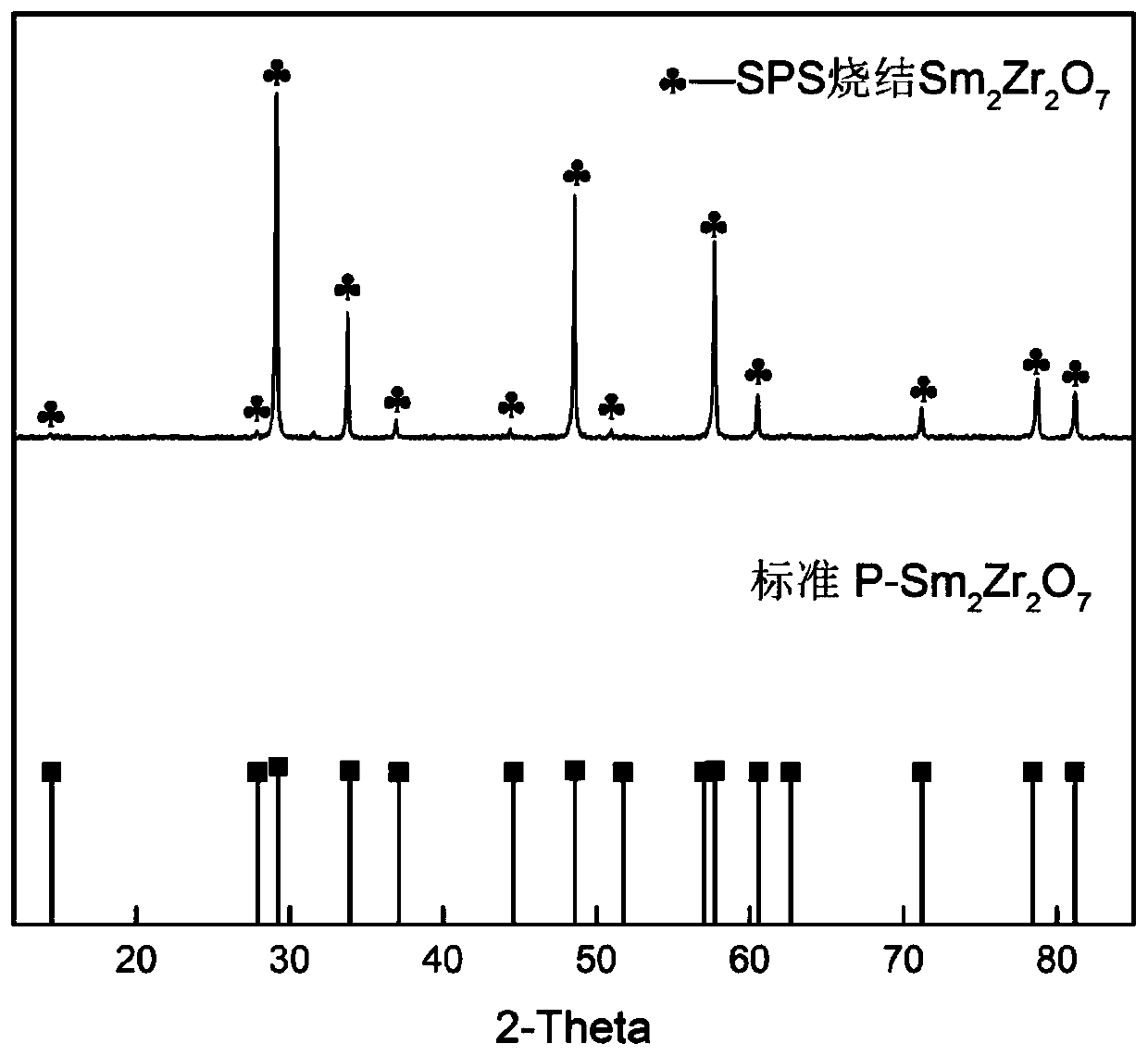

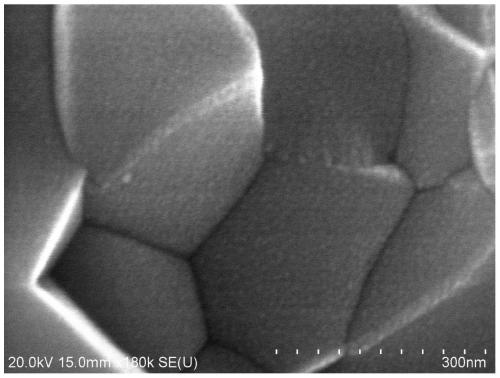

A preparation method of a submicron rare earth zirconate ceramic bulk material

ActiveCN107032788BSolve the problem of violent grain growthInhibit growthRare-earth elementZirconate

The invention relates to a method for preparing a submicron order rare-earth zirconate ceramic bulk material and belongs to the technical field of inorganic nonmetallic materials. The method comprises the following steps: carrying out a chemical coprecipitation reaction between a nitric acid solution of rare-earth oxides and an aqueous solution of zirconium oxychloride in excessive ammonia water so as to obtain precursor powder; and performing precalcination on the obtained precursor powder, and sintering by utilizing a spark plasma sintering technology, thereby obtaining the rare-earth zirconate ceramic bulk material. According to the method disclosed by the invention, grain growth is inhibited by utilizing the advantages that the spark plasma sintering technology is low in sintering temperature and short in heating time, and the density reaches 92% or higher; and moreover, the method is simple in process and short in preparation cycle, sintering aids are not added, and the high-purity phase ceramic material can be obtained.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com